Later-compression-stroke carbon filling type carbon powder engine

A compression stroke and engine technology, applied in the direction of powdered engine fuel, engine components, combustion engines, etc., can solve the problems of high piston temperature, consumption of lubricating oil, concentration reduction, etc., to achieve strong output power, low exhaustion speed, and short production cycle short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation mode of the present invention is illustrated below by way of example.

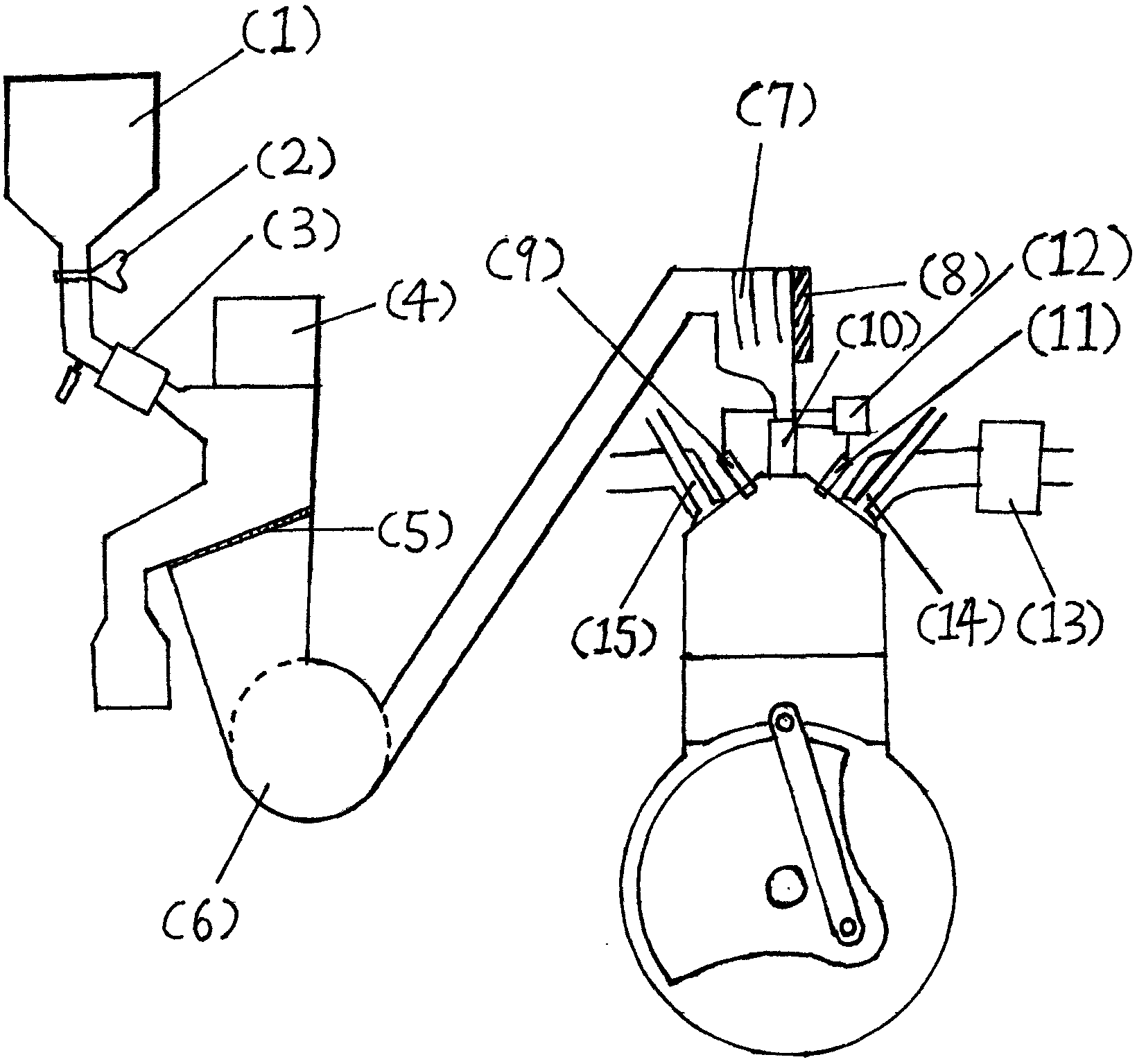

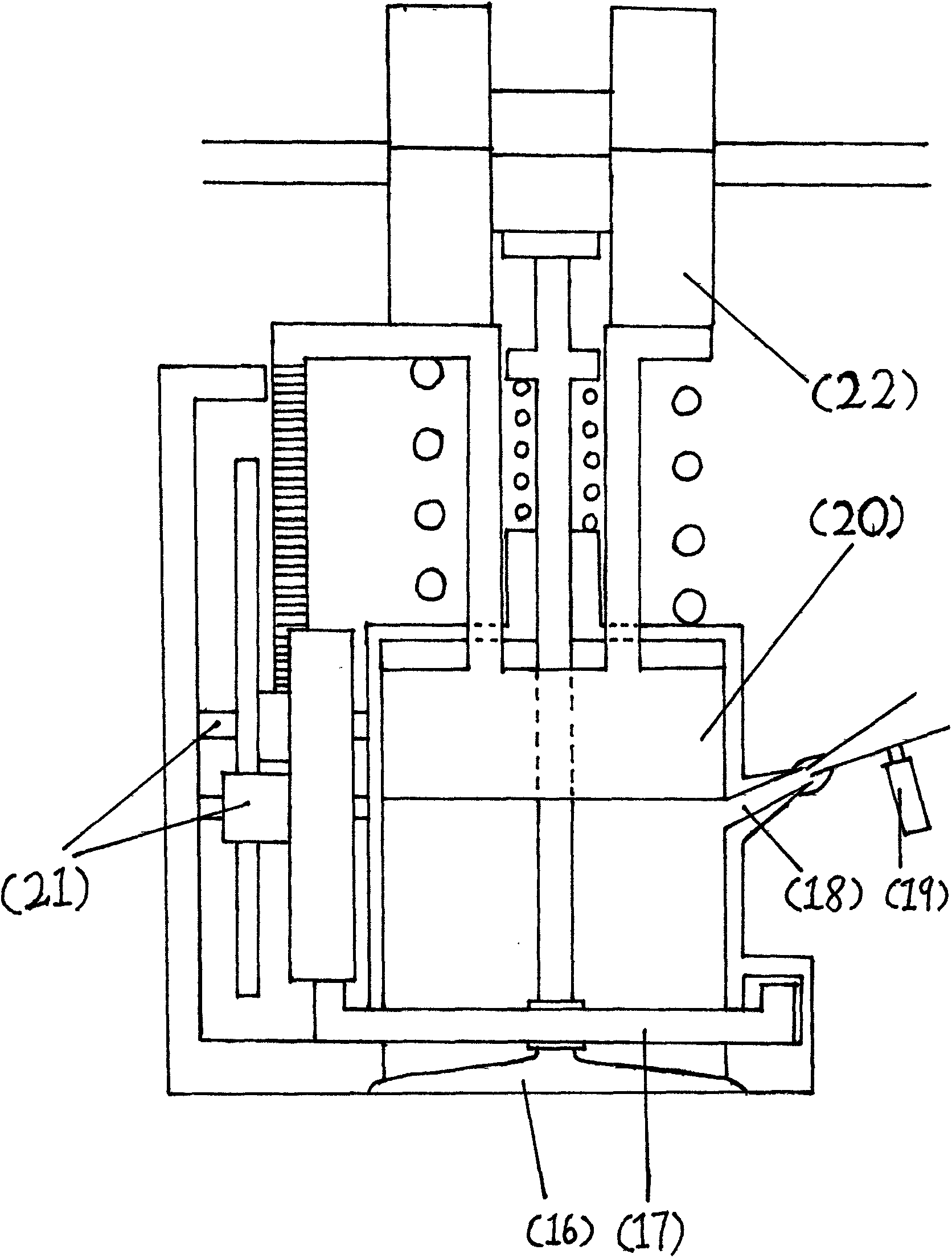

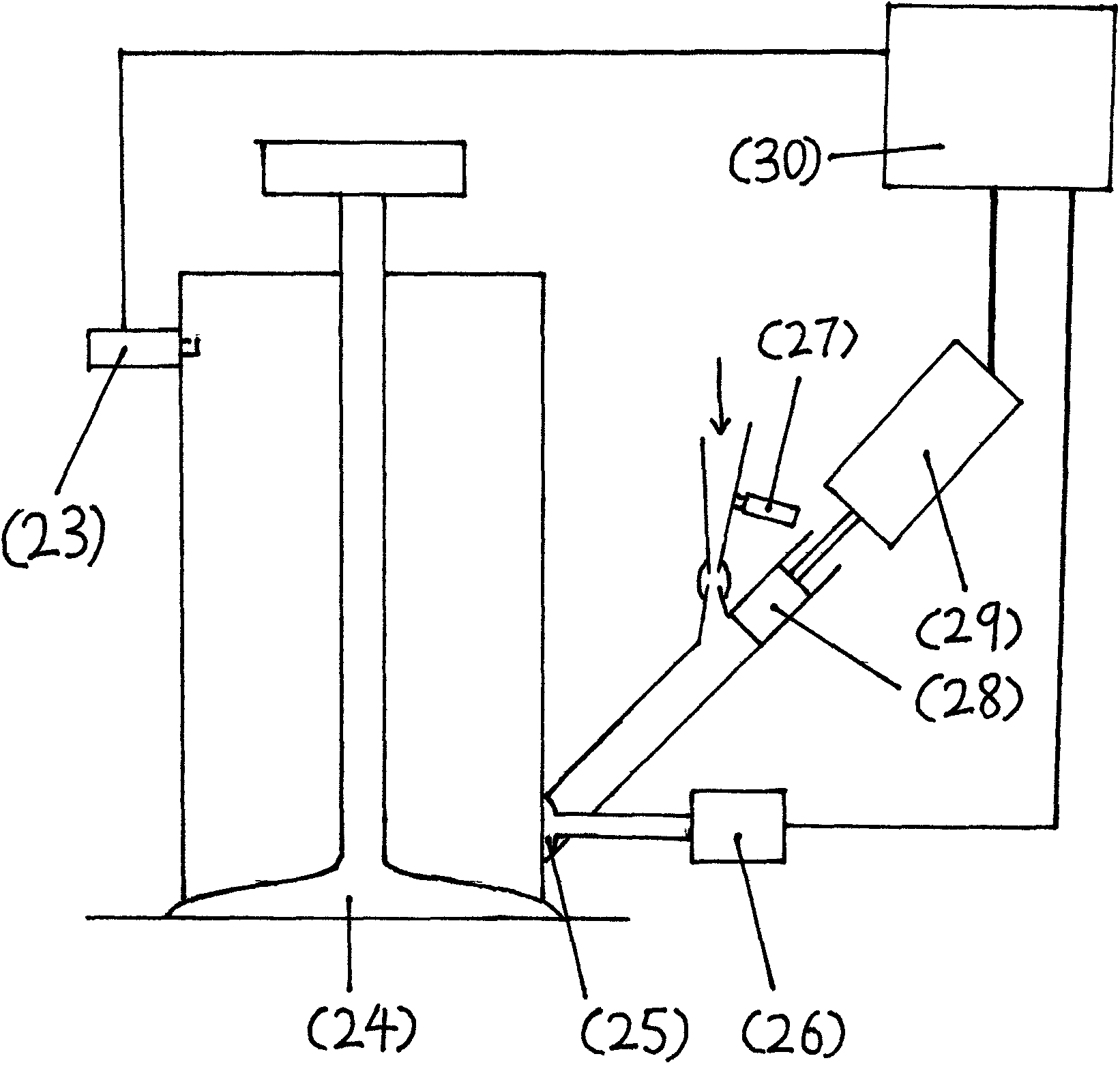

[0031] The first is an ignition-type compression stroke late carbon-charged toner engine. The toner leaks from the powder storage tank (1) to the electric dryer (3), and then falls to the filter screen (5), where (4) is an exhaust fan + air filter, responsible for sucking in air to assist the toner filter. Powder extractor (6) extracts the carbon powder to the top of the engine main body. Then the carbon powder enters the carbon charging device.

[0032] The engine is a four-stroke engine. When the compression stroke ends and the piston moves to the top dead center, the carbon filling device is filled with carbon powder, and then ignited by the spark plug, the carbon-air mixture burns violently, and the high-pressure expansion pushes the piston to do work. Among them, there is a ring of high temperature and high pressure resistant lubricating oil material at the top de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com