Novel low-viscosity bio-based epoxy resin composition and carbon fiber composite material

A technology based on epoxy resin and composite material, which is applied in the field of new low-viscosity bio-based epoxy resin composition and carbon fiber composite material, and can solve the problems of reduced strength, carbon fiber damage, and insufficient practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] A method for preparing a low-viscosity bio-based epoxy resin composition of the present invention, comprising:

[0040] Step 1: Mix the raw materials; the mixing can be directly mixed according to the type of curing agent, or when the curing agent is an amine curing agent, the amine curing agent and the bio-based epoxy resin can be heated separately and then mixed ; The heating temperature is preferably 60-90 ° C;

[0041] Step 2: Curing the fully mixed raw materials at 60-90°C for 2-6 hours, then curing at 91-120°C for 2-6 hours, and then curing at 121-150°C for 3-5 hours to obtain the low-viscosity bio-based epoxy resin composition.

[0042] The present invention also provides a carbon fiber composite material, which comprises:

[0043]

[0044] Described bio-based epoxy resin, it has the structure shown in formula (1):

[0045]

[0046] The curing agent is an acid anhydride curing agent or an amine curing agent. The acid anhydride curing agent is preferably m...

Embodiment 1

[0063] The preparation of embodiment 1 bio-based epoxy resin

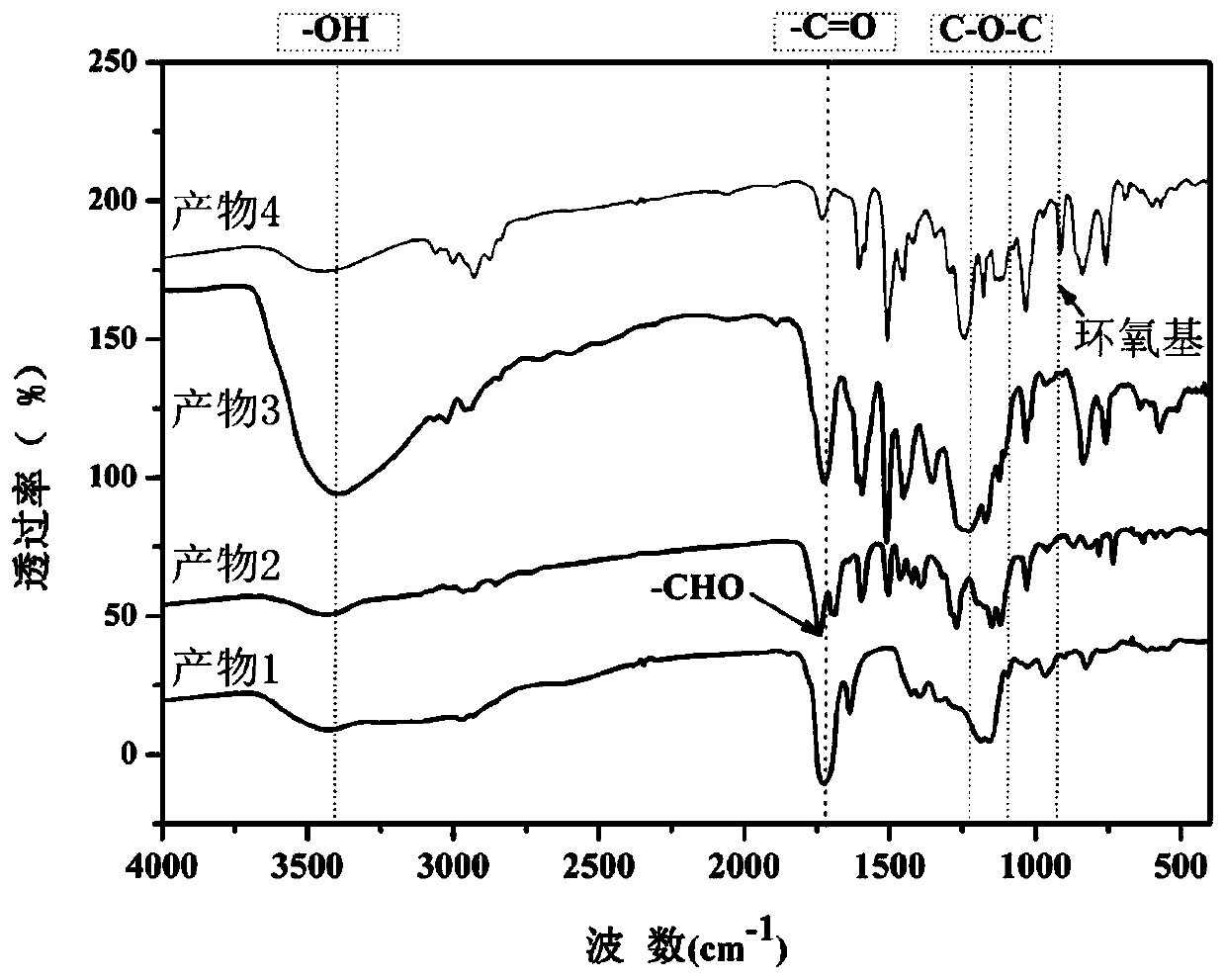

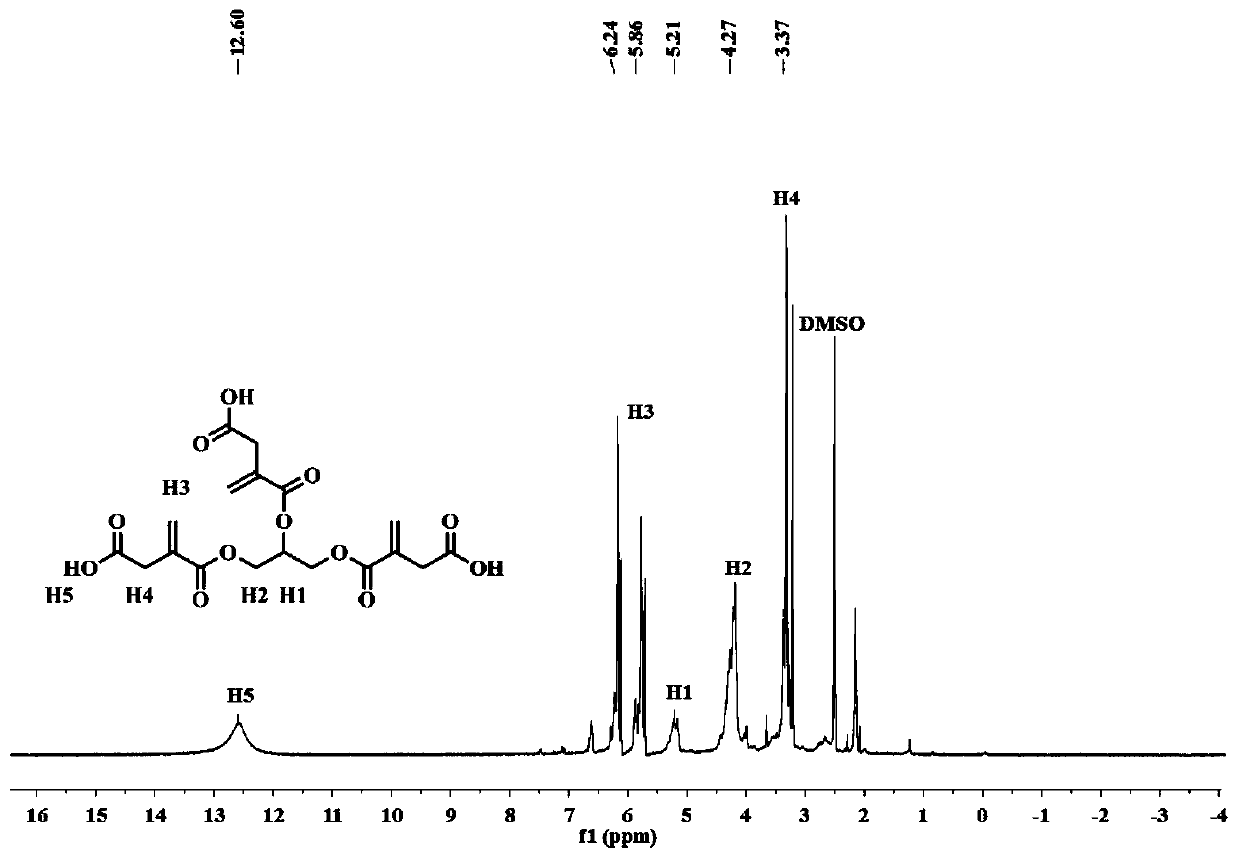

[0064] Step 1. Add 0.3mol powdered itaconic acid, 0.1mol glycerin, 50ml toluene, and 5wt% catalyst methanesulfonic acid into a three-neck round bottom flask, one of which is equipped with a stirrer and the other for nitrogen flow, a third neck toluene reflux and azeotropic distillation apparatus, the internal temperature was set to 150 °C and the reaction was continued for 10 hours. From toluene, gradually extract the condensed release water (1.5mol); Anhydrous toluene is continuously refluxed in the reactor to obtain product 1; the nuclear magnetic spectrum is as figure 2 shown.

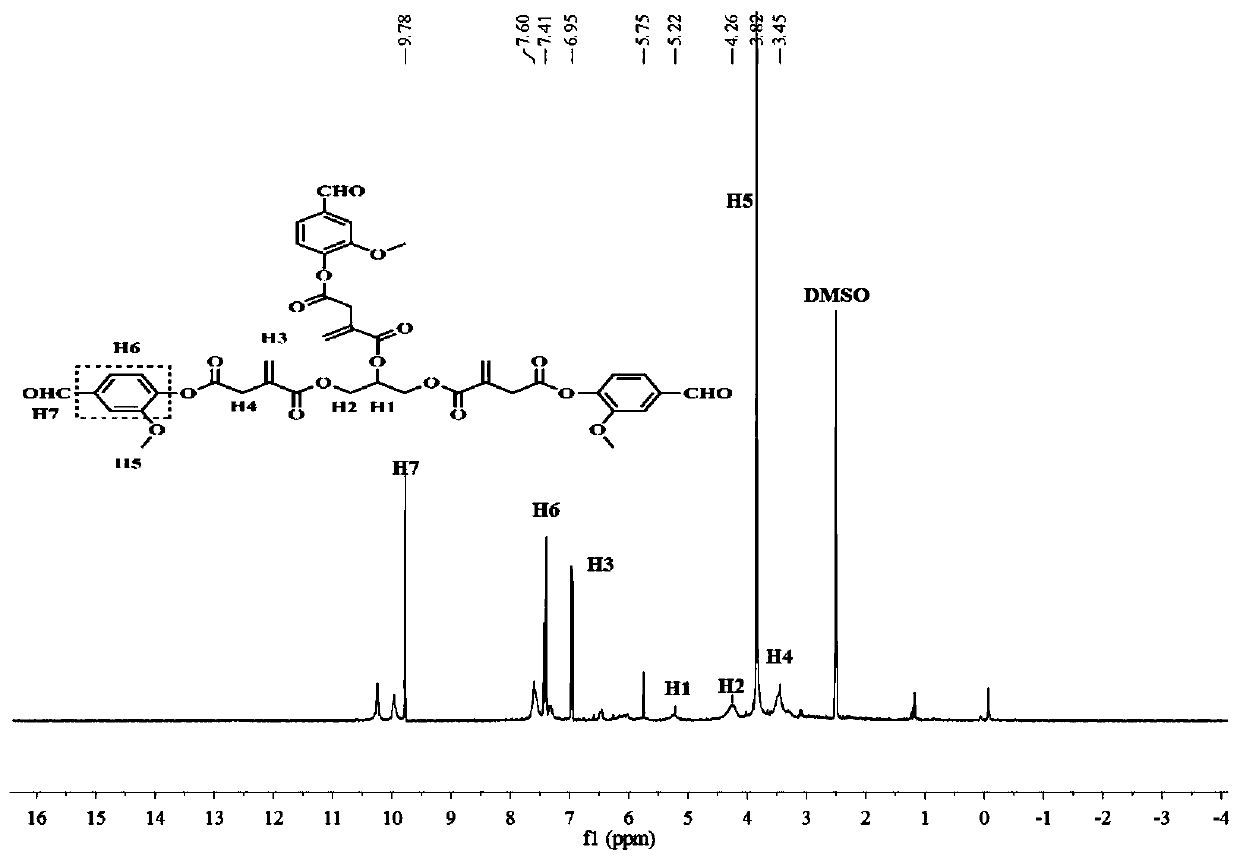

[0065] Step 2. Add the mixture of product 1 (0.1mol), THF (100ml) and DMF (catalyst, 0.05ml) to a round-bottomed flask, and add oxalyl chloride (0.3mol) drop by drop within 20min in an ice-water bath at 0°C . The reaction mixture was slowly heated and reacted at 50 °C for 4 hours until the solid was completely dissolved. The resulti...

Embodiment 2

[0071] Embodiment 2 The preparation of bio-based epoxy resin / methyltetrahydrophthalic anhydride / three (dimethylaminomethyl) phenol composition solidification

[0072] After taking 100g of bio-based epoxy resin, add 60g of methyltetrahydrophthalic anhydride curing agent and 0.2g of tris(dimethylaminomethyl)phenol accelerator according to the proportion, stir and mix evenly, and then put it into a vacuum oven to remove Air bubbles in the resin. Place the mold coated with release agent in the oven, pour epoxy resin into the mold, and then cover the upper part with a 2kg iron plate, set the temperature at 80°C / 3 hours, 100°C / 3 hours, 120°C / 3 hours The curing can be completed within 1 hour, and the cured composition (4mm thick dumbbell-shaped sample) is taken out for use in tensile testing experiments.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com