Cooked food packaging film and preparation method thereof

A technology for packaging film and cooked food, which is applied in the field of cooked food packaging film and its preparation, can solve the problems of poor support production, human safety impact, long film degradation cycle, etc., and achieve good temperature insulation effect, low cost, and environment-friendly The effect of destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

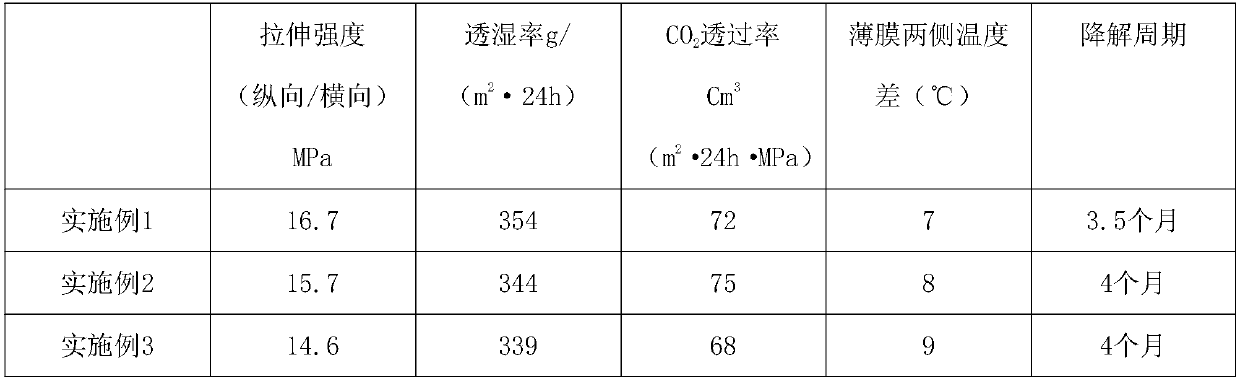

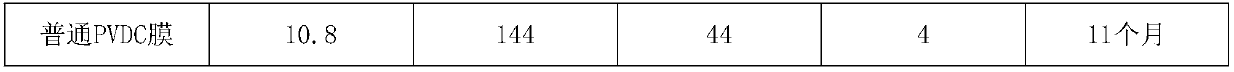

Examples

Embodiment 1

[0031] A cooked food packaging film, characterized in that: it is made of the following materials by weight,

[0032] 14 parts of resin, 5 parts of calcium sulfate, 1 part of polyhydroxyalkanoate, 4 parts of nano-silica, 22 parts of hardened oil, 6 parts of p-methylaniline, 9 parts of artemisia gum, 60 parts of purple potato starch, Pulu 7 parts of ranan polysaccharide, 4 parts of sorbitol, 9 parts of accelerator, 20 parts of bio-aids;

[0033] The particle size of the nano silicon dioxide is 10-70mm;

[0034] The resin is one of polyvinyl chloride resin, epoxy resin, phenolic resin, organic silicon resin;

[0035] The accelerator is one of DMP-30, DBMA, stannous octoate, cobalt isooctanoate, tetramethylthiourea, and accelerator BZ;

[0036] The biological aid is made of the following materials in parts by weight,

[0037] 7 parts of apple peel, 6 parts of sycamore bark, 1 part of Chinese rose petal, 5 parts of betel nut, 4 parts of cherry pit, 3 parts of kiwi fruit, 2 part...

Embodiment 2

[0045] A cooked food packaging film, characterized in that: it is made of the following materials by weight,

[0046] 20 parts of resin, 9 parts of calcium sulfate, 3 parts of polyhydroxyalkanoate, nano silicon dioxide, 27 parts of hardened oil, 11 parts of p-methylaniline, 13 parts of artemisia gum, 68 parts of purple potato starch, pullulan 12 parts of polysaccharide, 9 parts of sorbitol, 14 parts of accelerator, 26 parts of bio-aid;

[0047] The particle size of the nano silicon dioxide is 10-70mm;

[0048] The resin is one of polyvinyl chloride resin, epoxy resin, phenolic resin, organic silicon resin;

[0049] The accelerator is one of DMP-30, DBMA, stannous octoate, cobalt isooctanoate, tetramethylthiourea, and accelerator BZ;

[0050] The biological aid is made of the following materials in parts by weight,

[0051] 7 parts of apple peel, 6 parts of sycamore bark, 1 part of Chinese rose petal, 5 parts of betel nut, 4 parts of cherry pit, 3 parts of kiwi fruit, 2 part...

Embodiment 3

[0059] A cooked food packaging film, characterized in that: it is made of the following materials by weight,

[0060] 16 parts of resin, 7 parts of calcium sulfate, 2 parts of polyhydroxyalkanoate, 8 parts of nano-silica, 25 parts of hardened oil, 9 parts of p-methylaniline, 11 parts of artemisia gum, 64 parts of purple potato starch, Pulu 10 parts of blue polysaccharide, 7 parts of sorbitol, 11 parts of accelerator, 23 parts of bio-aids;

[0061] The particle size of the nano silicon dioxide is 10-70mm;

[0062] The resin is one of polyvinyl chloride resin, epoxy resin, phenolic resin, organic silicon resin;

[0063] The accelerator is one of DMP-30, DBMA, stannous octoate, cobalt isooctanoate, tetramethylthiourea, and accelerator BZ;

[0064] The biological aid is made of the following materials in parts by weight,

[0065] 7 parts of apple peel, 6 parts of sycamore bark, 1 part of Chinese rose petal, 5 parts of betel nut, 4 parts of cherry pit, 3 parts of kiwi fruit, 2 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com