Patents

Literature

94 results about "P-toluidine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hole-transporting type blue luminescent material as well as preparation and uses thereof

InactiveCN101225298AHigh fluorescence quantum yieldImprove thermal stabilitySolid-state devicesSemiconductor/solid-state device manufacturingSolventNitrogen gas

The invention relates to a hole-transporting blue color compound, which is a fluorine derivative based on 9, 9-bi-(4-(bi-p-methypheny) aminophenyl). The preparation method is to first mix 9, 9-bi-[4-(N, N-bi-p-toluidine) phenyl]-2-dibromofluorine and boric acid pinacol ester of conjugate radicle, or to mix 9, 9-bi-[4-(N, N-bi-p-tolyl-amino) phenyl] fluorine -2, 7-bi-boric acid pinacol ester and bromide of conjugate radicle; and then add in toluene, potash solution, aliquat336 and catalyst tetrakis (triphenylphosphine) palladium, and heat and reflow for 10 to 30 hours in nitrogen environment; when the reaction is done, decompress, remove the solution and get the target product, the derivative based on 9, 9-bi-(4-(bi-p-methypheny) aminophenyl) fluorine substituted by unilateral conjugate radical. The compound can be used as the hole-transporting layer and the luminescent layer as well in electroluminescent devices.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

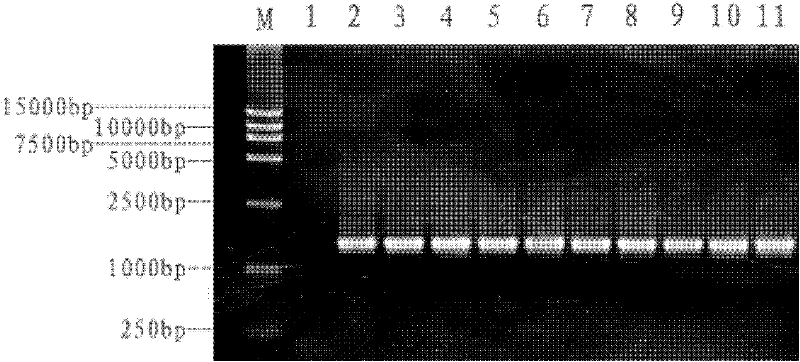

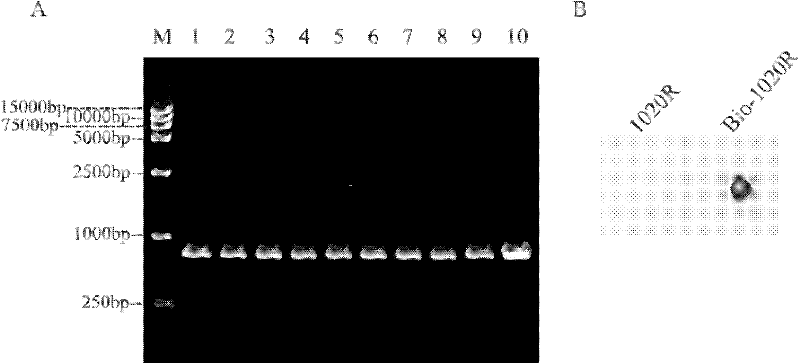

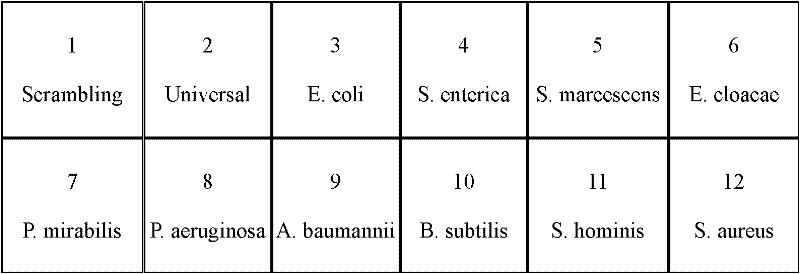

Gene detecting film strip for multiple bacteria and primer thereof

InactiveCN102229992ALow costMicrobiological testing/measurementAgainst vector-borne diseasesCelluloseBiotin-streptavidin complex

The invention discloses a gene detecting film strip for multiple bacteria and a primer thereof. Ten common bacteria are selected as detected objects and 16SrRNA (Ribosomal Ribonucleic Acid) is used as a detection target gene; and a detection probe of the ten common bacteria and a matched primer thereof are designed. A cellulose nitrate thin film strip is used as a substrate for fixing the probe and used for preparing a gene detecting film strip of the ten common bacteria. The 16SrRNA gene segment of the bacteria and a biotin mark are subjected to PCR (Polymerase Chain Reaction) amplification.After the PCR amplified segment is hybridized with the film strip, the biotin mark is detected by streptavidin marked by alkaline phosphatase and then an NBT (Nitroblue Tetrazolium) / BCIP (5-bromo-4-chloro-3'-indolyphosphate P-toluidine salt) color development is carried out. The result shows that the film strip can independently detect any one or more of the ten bacteria. The invention successfully researches the gene detecting film strip for the ten common bacteria and establishes a method for detecting bacteria by the film strip; and the method provided by the invention has the advantages of high throughput, high speed, accuracy and lower cost and has a good clinical application prospect.

Owner:CENT SOUTH UNIV

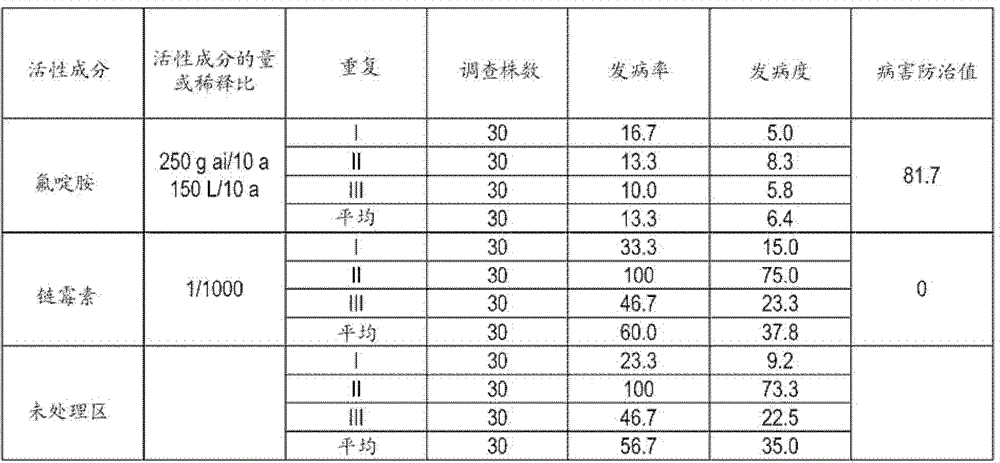

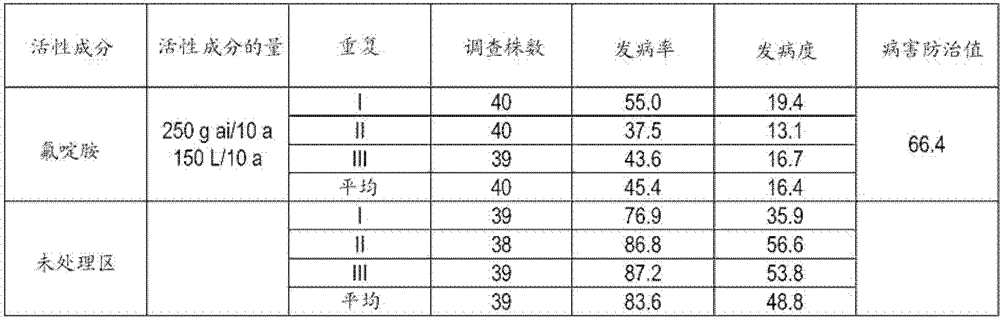

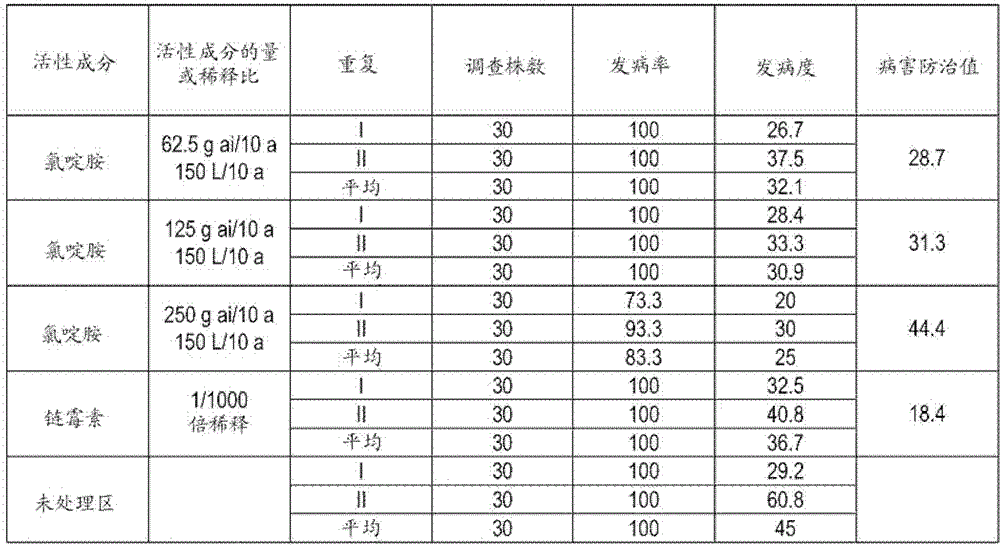

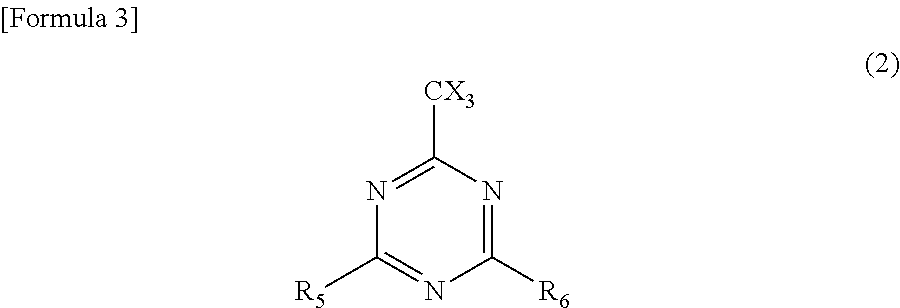

Control Agent For Soft Rot And Control Method For The Same

ActiveCN102802422AGood control effectIncrease concentrationBiocideFungicidesPlant cultivationBULK ACTIVE INGREDIENT

Provided is a novel control agent for soft rot and a novel control method for the same. The control agent for soft rot of a plant contains 3-chloro-N-(3-chloro-5-trifluoromethyl-2-pyridyl)-alpha,alpha,alpha-trifluoro-2,6-dinitro-p-toluidine as an active ingredient, which is applied to plant cultivation soil.

Owner:ISHIHARA SANGYO KAISHA LTD

Cyclodextrin-modified hypercrosslinked resin and method for adsorbing and recovering aniline compounds in industrial wastewater by using same

ActiveCN107434852AReduce contentImprove stabilityOther chemical processesWater contaminantsP-chloroanilineMaterials preparation

The invention discloses cyclodextrin-modified hypercrosslinked resin and a method for adsorbing and recovering aniline compounds in industrial wastewater by using the same. The method is used for adsorbing aniline compounds such as aniline, p-toluidine, p-chloroaniline and p-aminobenzoic acid in wastewater by taking the synthesized cyclodextrin-modified polystyrene-chloromethylstyrene hypercrosslinked resin as an adsorption material, and the maximum adsorption capacities can respectively reach 149mg / g, 198mg / g, 294mg / g and 623mg / g. Experimental results show that the adsorption capacity is obviously higher than the maximum adsorption capacities of adsorption materials such as activated carbon, coal ash and modified zeolite to the aniline compounds. The method disclosed by the invention has the advantages such as simple material preparation process, repeated utilization, mild adsorption condition, energy saving, environment friendliness and low cost.

Owner:HUIZHOU RES INST OF SUN YAT SEN UNIV

Methanol gasoline additive with stable performance

InactiveCN104357111AImprove performanceEmission reductionLiquid carbonaceous fuelsOil additiveButylated hydroxytoluene

A methanol gasoline additive with stable performance is prepared from the following raw materials in parts by weight: 4-6 parts of dimethylbenzene, 3-5 parts of propanol, 5-10 parts of methyl tertiary butyl ether, 1-5 parts of isopropanol, 4-9 parts of paratoluidine, 3-8 parts of 2,6-butylated hydroxytoluene, 4-8 parts of dimethoxymethane, 1-5 parts of n-propanol, 2-6 parts of gasoline hydrocarbon, 1-4 parts of petroleum ether, 3-10 parts of polyisobutylene diimide, 3-7 parts of maleic anhydride, 8-15 parts of methanol and 5-9 parts of methyl tertiary butyl ether. The methanol gasoline additive with the stable performance has the benefits as follows: the methanol gasoline additive with the stable performance is stable in performance, can be used for a long time, can reduce emission of harmful substances in tail gas, and reduces environment pollution.

Owner:QINGDAO TOPLINK INFORMATION TECH

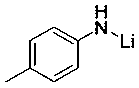

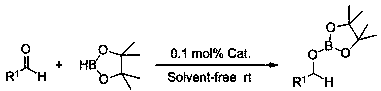

Method for preparing borate by utilizing p-toluidine lithium

InactiveCN108373480AReduce pollutionHigh catalytic activityOrganic-compounds/hydrides/coordination-complexes catalystsGroup 3/13 element organic compoundsKetoneOxygen

The invention discloses a method for preparing borate by utilizing p-toluidine lithium. The method comprises the following steps: in a water-free and oxygen free environment and in an inert gas atmosphere, adding boron into a reaction bottle subjected to dehydration and deoxygenation treatment, then adding a catalyst (p-toluidine lithium), uniformly mixing, then adding ketone, carrying out hydroboration reaction, and carrying out termination reaction by being exposed to the air, so that borate is obtained, wherein the ketone is aromatic ketone or heterocyclic ketone. The invention firstly finds that p-toluidine lithium can catalyze the hydroboration reaction on the aromatic ketone or heterocyclic ketone and borane, and a new scheme is provided for preparation of borate by carrying out thehydroboration reaction on a carbonyl compound and borane.

Owner:SUZHOU UNIV

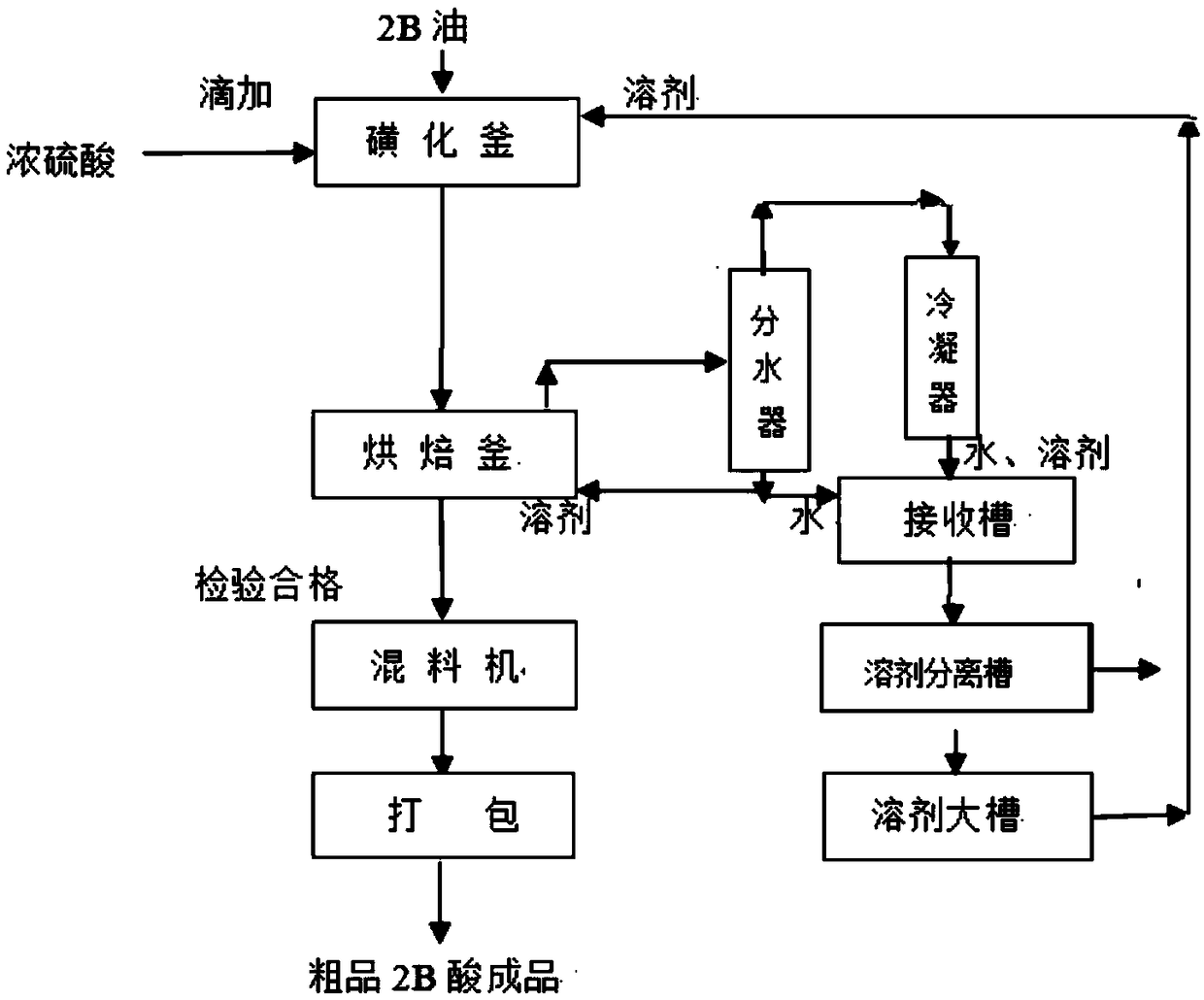

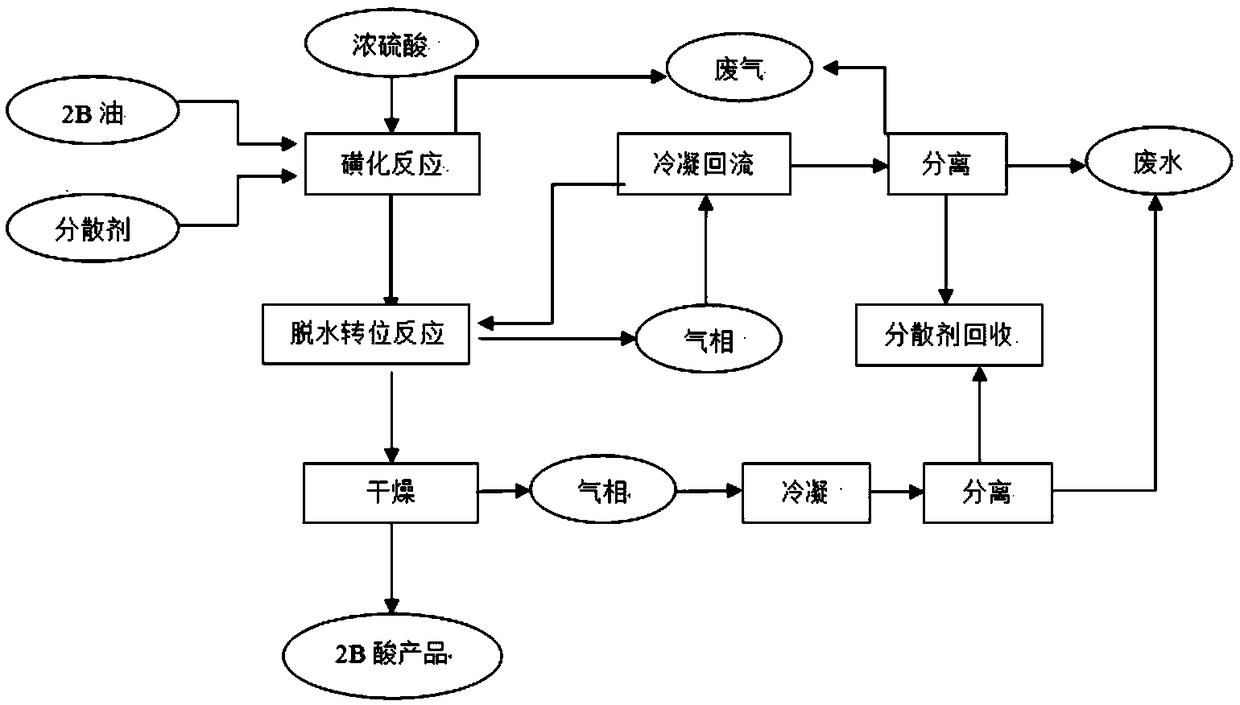

Method for preparing 3-chloro-p-toluidine-6-sulfonic acid by liquid-phase baking method

ActiveCN109180537AThorough responseUniform heat and mass transferSulfonic acid preparationOrganic solventToluidine

The invention provides a method for preparing 3-chloro-p-toluidine-6-sulfonic acid by a liquid-phase baking method. The method comprises the following steps: mixing high-purity 2B oil as a raw material with an organic solvent serving as a liquid dispersant, performing a sulfonation reaction on the 2B oil and concentrated sulfuric acid in the liquid phase dispersant, and dehydrating and drying thesulfonated product to obtain 2B acid. By adopting the method, the high quality 2B acid is directly prepared by dehydrating and translocating in a liquid phase, and refining processes such as alkali dissolving, decolorizing, filtering, acid separating, dehydrating, drying and the like, so that the 'Three Wastes' can be greatly reduced, no solid waste is generated, waste gas and waste water have extremely small amount and can be easily treated, energy consumption can be reduced, and the existing sulfonating process is broken through. The method has the advantages of high conversion rate, low carbonization, few processes and low energy consumption.

Owner:浙江友联化学工业有限公司

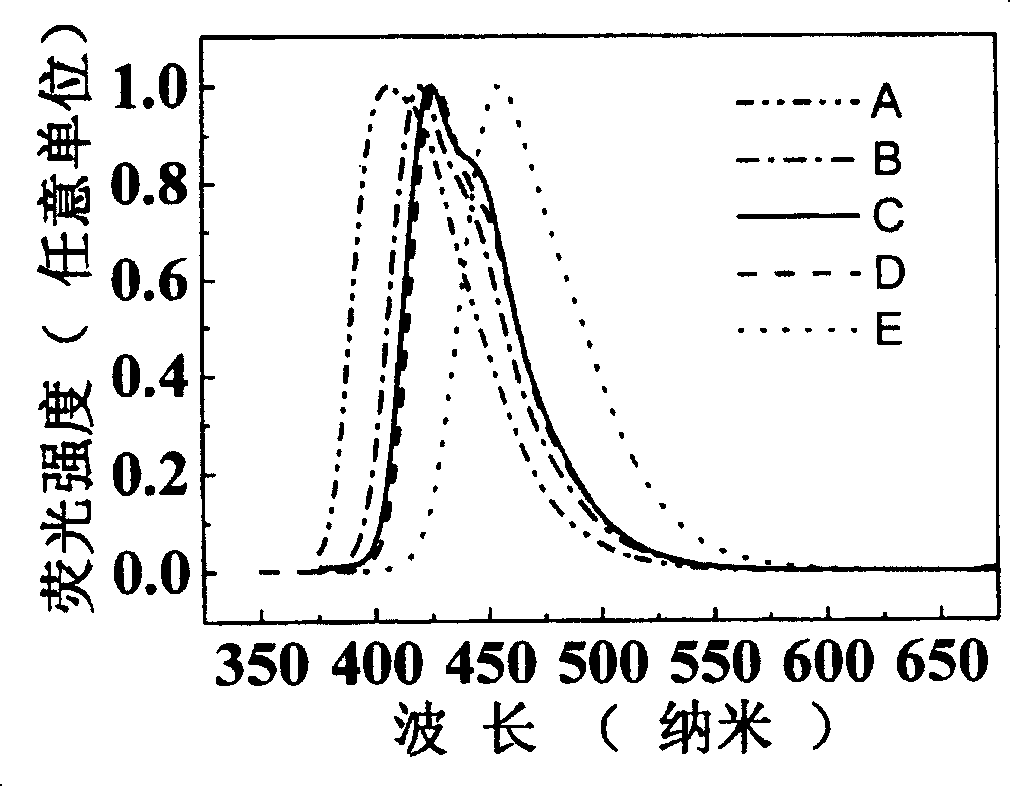

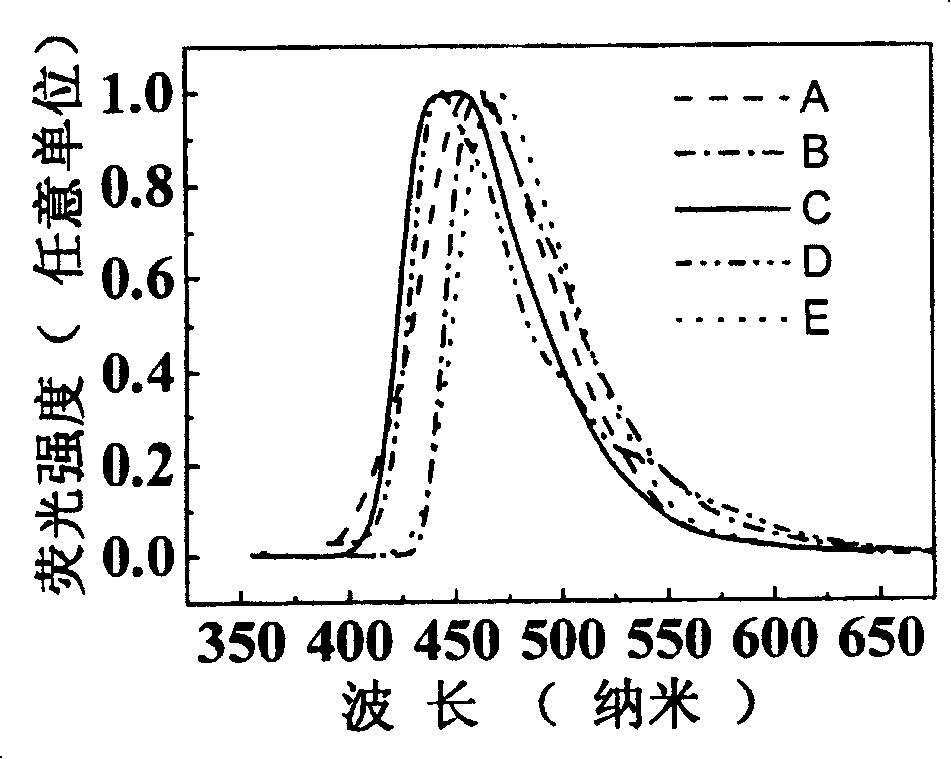

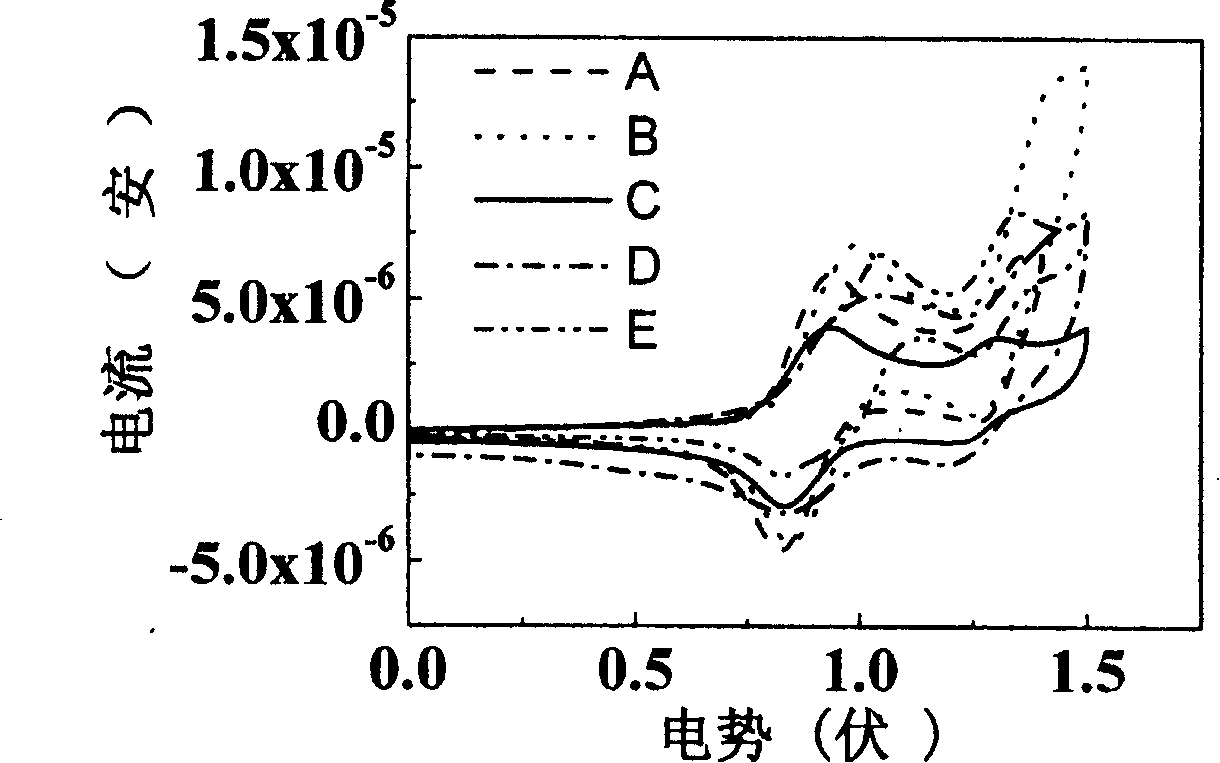

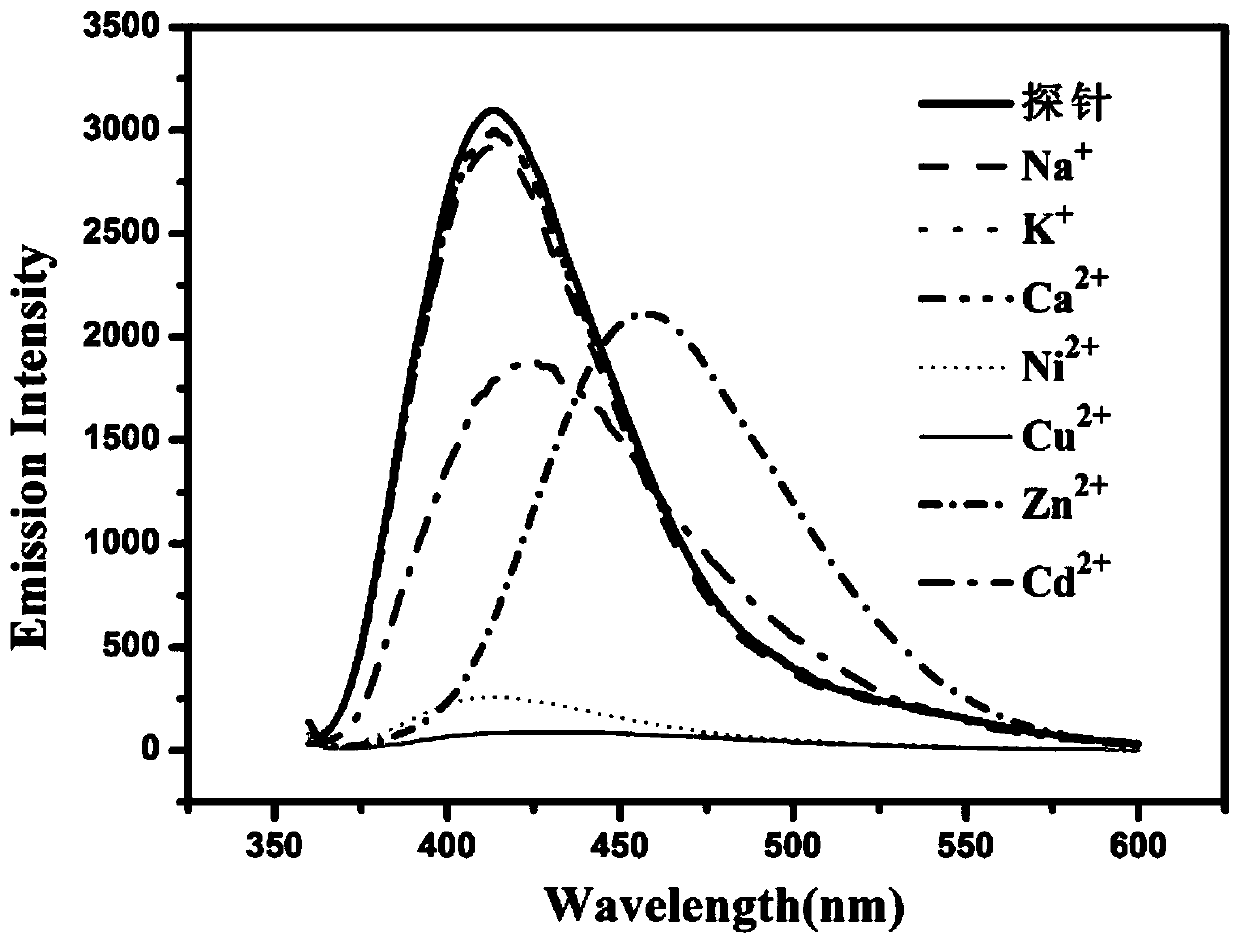

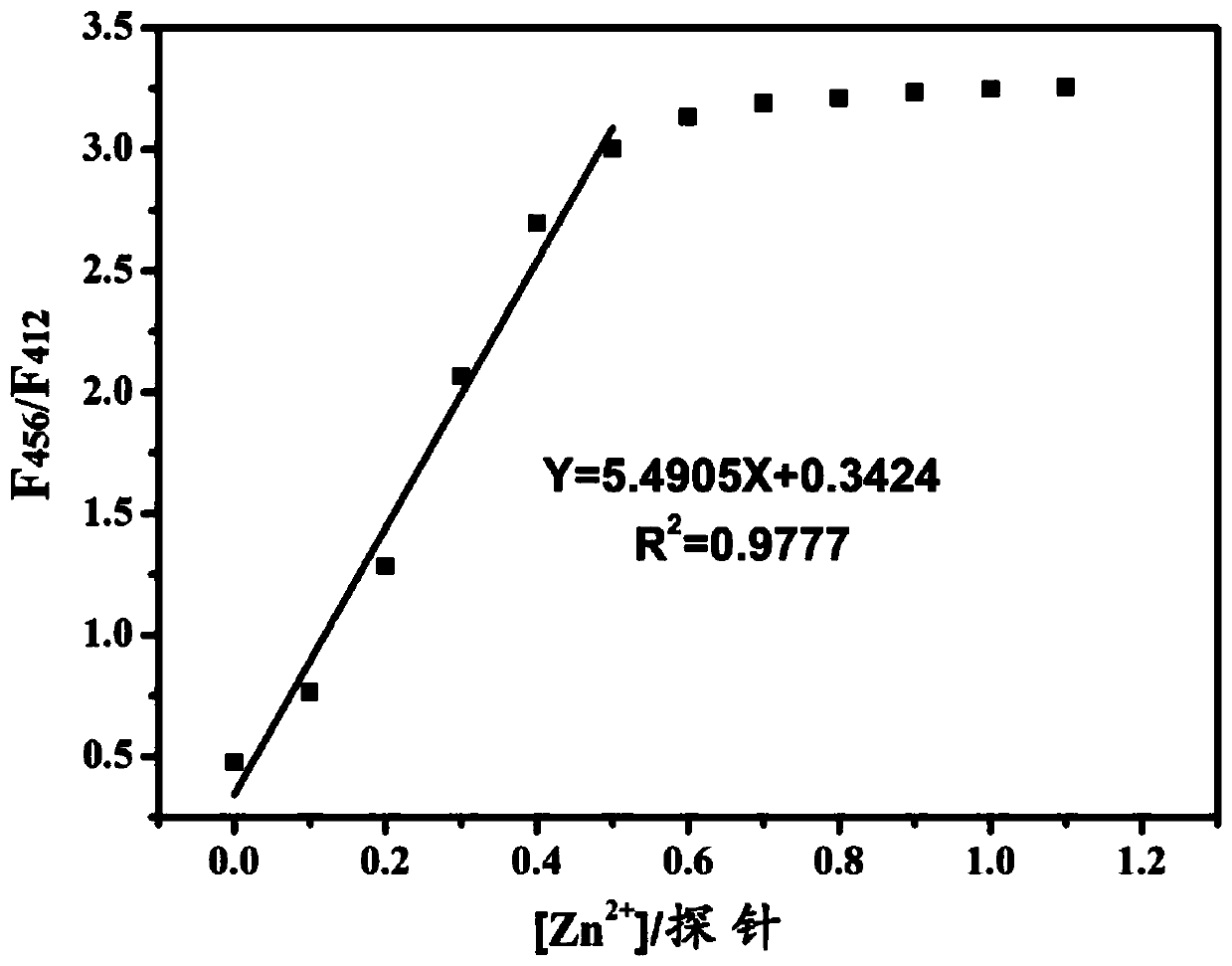

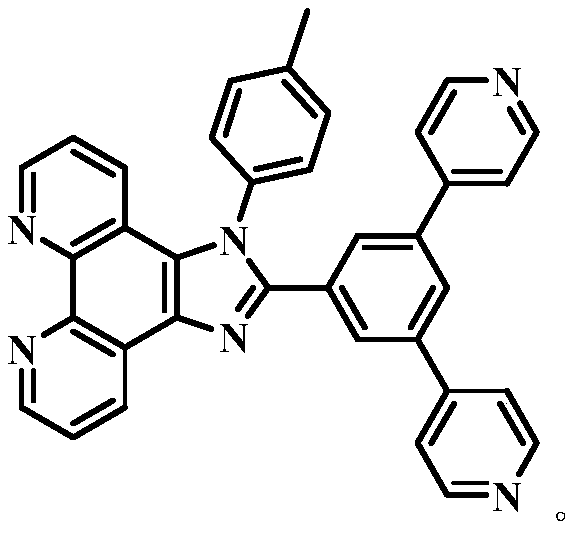

Proportional sensing type zinc ion fluorescence probe and preparing method and application thereof

ActiveCN109776534AQuantitative detection concentrationGood choiceOrganic chemistryFluorescence/phosphorescenceBenzaldehydeFluorescence

The invention belongs to the technical field of ion recognition and particularly relates to a proportional sensing type zinc ion fluorescence probe and a preparing method and application thereof. Thestructure of the probe is shown in the specification. The probe can quantitatively detect the zinc ion concentration and has good selectivity, high sensitivity and low zinc ion detection limit. The preparing method of the probe is also provided and includes adding 3,5-dibromobenzaldehyde, pyridine-4-boronic acid and potassium carbonate into a solvent mixture including toluene, ethanol and water, heating, refluxing and reacting the mixture to obtain 3,5-di(4-pyridinyl) benzaldehyde, with tetrakis(triphenylphosphine) palladium being adopted as a catalyst; then dissolving 1,10-phenanthroline-5,6-dione, the 3,5-di(4-pyridinyl) benzaldehyde, p-toluidine and ammonium acetate into acetic acid, and heating, refluxing and reacting the mixture to obtain 2-(3,5-di(4-pyridinyl)phenyl)-1-p-tolyl-1H-imidazo[4,5-f][1,10]phenanthroline. The synthetic process is simple and easy to achieve. Applications of the probe are also provided.

Owner:SHANDONG UNIV OF TECH

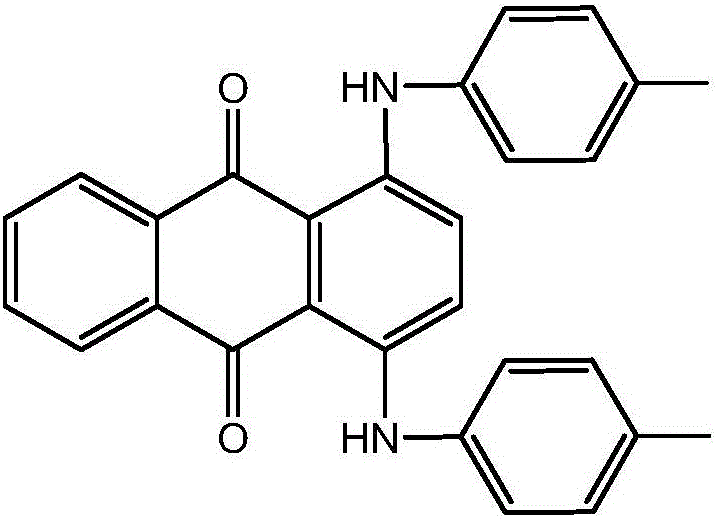

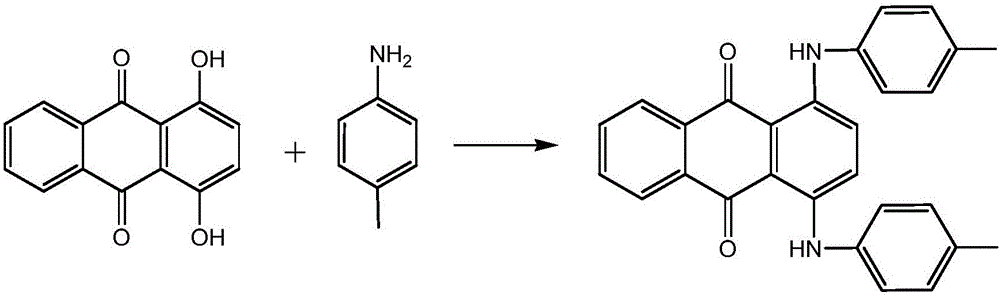

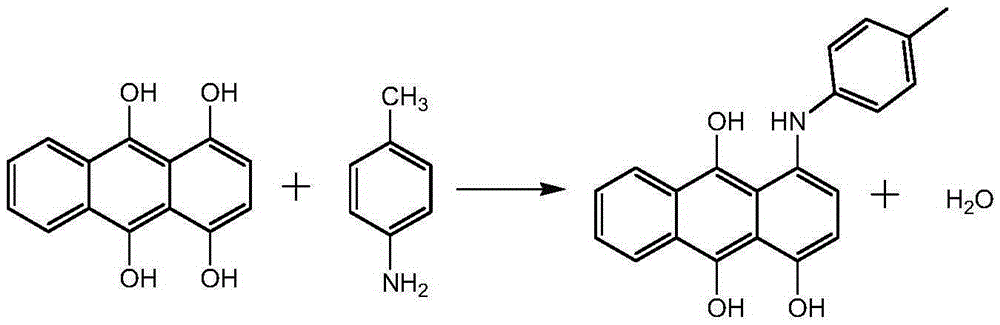

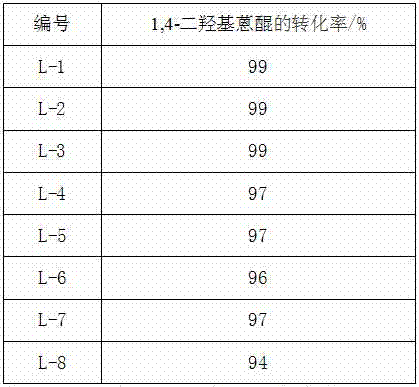

Synthesis method of solvent green 3

ActiveCN106675080AReduction of recycling energy consumptionHigh yieldAnthracene dyesSynthesis methodsAntioxidant

The invention discloses a synthesis method of a solvent green 3. According to the synthesis method, a target product is obtained by taking 1,4-dihydroxy anthraquinone and p-toluidine as raw materials, ethanol as a solvent, boric acid as a catalyst, a 1,4-dihydroxy anthraquinone leuco body as an initiator, sodium hydrogensulfite as an antioxidant and benzene as an azeotrope agent of a system through condensation reaction. According to the synthesis method, the ethanol with a low boiling point is used as the solvent and the solvent green 3 is hardly dissolved in the ethanol, so that the yield of a product is improved and the recycling energy consumption of the solvent is also reduced; the 1,4-dihydroxy anthraquinone leuco body is used as the initiator, has the effect of a reaction initiator and also has a catalytic action in a reaction process; the activity of the 1,4-dihydroxy anthraquinone leuco body can be guaranteed in the presence of the antioxidant, namely the sodium hydrogensulfite, and the initiation and catalysis effects are improved.

Owner:JIANGSU DAOBO CHEM

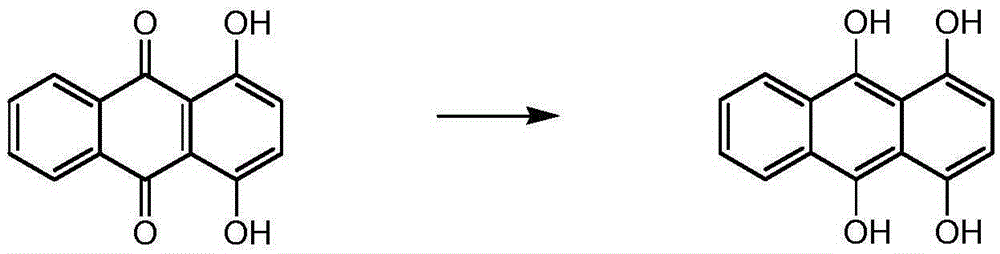

Synthetic method for solvent violet 13

ActiveCN105237417AReduced post-processingSave manpower and material resourcesOrganic chemistryOrganic compound preparationToluidineMaterial resources

The invention discloses a synthetic method for solvent violet 13, and develops a new route for synthesizing violet 13 by employing a one-pot process. The method comprises successively adding methanol, 1,4-dihydroxyanthraquinone, 4-nitrotoluene, iron powder and boric acid into a pressure container, sealing the container and performing nitrogen displacement, then heating with stirring, introducing hydrogen for hydrogenation reduction, after the reaction system stops absorbing hydrogen, performing warm-keeping reaction, heating after the reaction is finished, performing condensation reaction, cooling after the reaction is finished, releasing the pressure, introducing air and performing oxidation reaction, and finally adding hydrochloric acid for beating, filtering, washing and drying, so as to obtain violet 13. According to the method, the initial raw material p-toluidine is replaced by 4-nitrotoluene, direct usage of the highly-toxic raw material p-toluidine is avoided, and the synthetic technology is low in toxicity and friendly to environment. By pouring all of the raw materials into the container, the postprocessing process of the intermediate step is saved, and a large amount of manpower and material resource is saved.

Owner:JIANGSU DAOBO CHEM

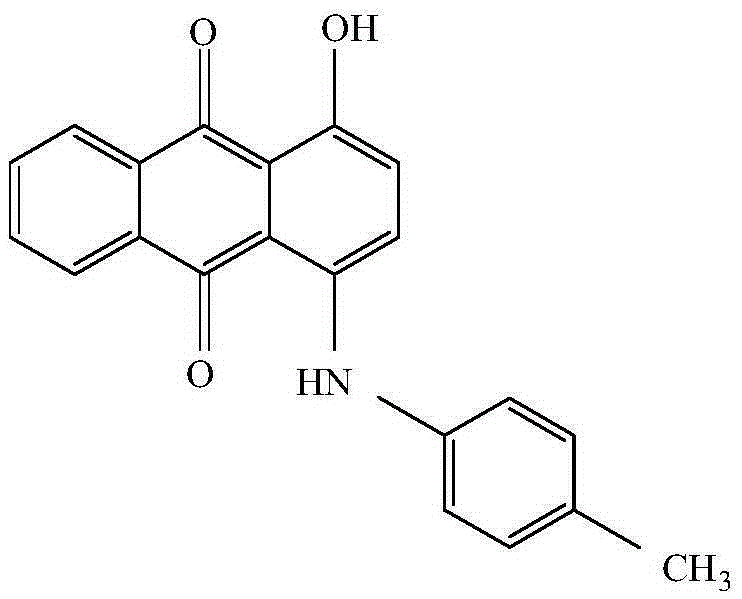

Preparation method of 1-hydroxy-4-(p-toluidino)anthraquinone

InactiveCN107501987ASmooth responseHigh yieldOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsEtherEther solvent

The invention provides a preparation method of 1-hydroxy-4-(p-toluidino)anthraquinone. 1,4-dihydroxy anthraquinone, p-toluidine, ether solvents and a condensation catalyst are added to a reaction kettle, a system is gradually heated for a reaction, a product is filtered after the reaction ends, a filter cake is washed, dried and treated with a refining process, and a finished product, namely, 1-hydroxy-4-(p-toluidino)anthraquinone is obtained.

Owner:宁波德欣科技有限公司

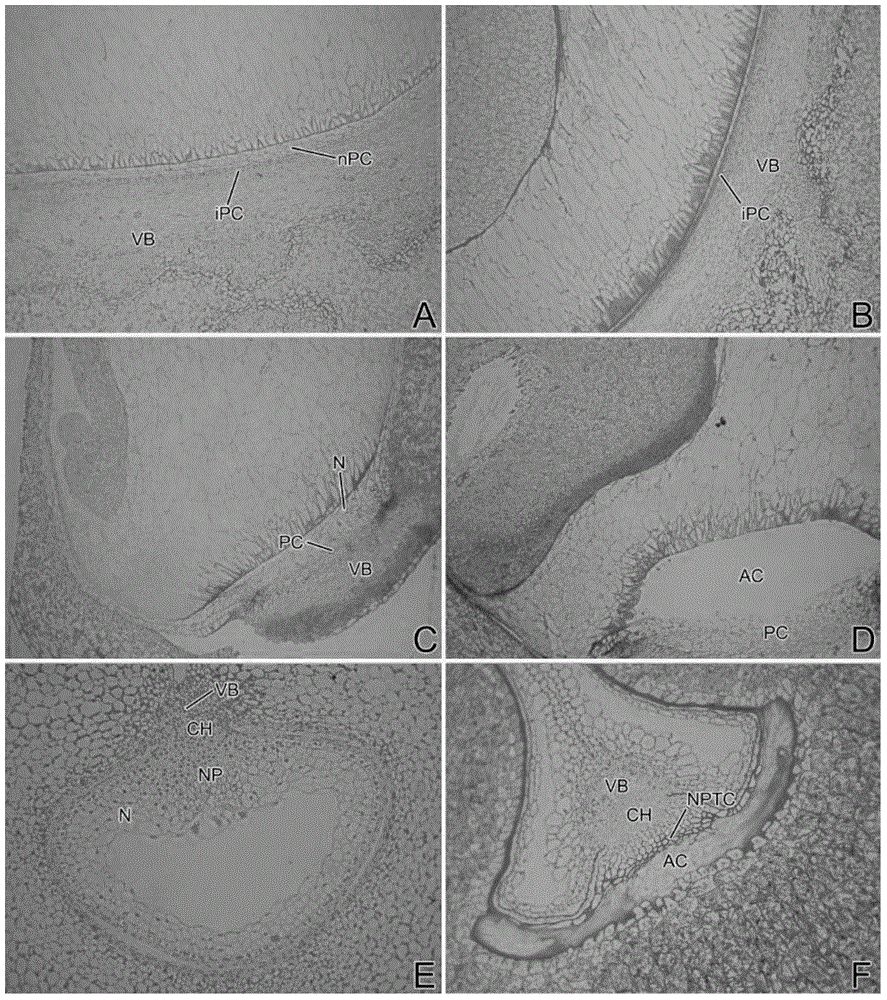

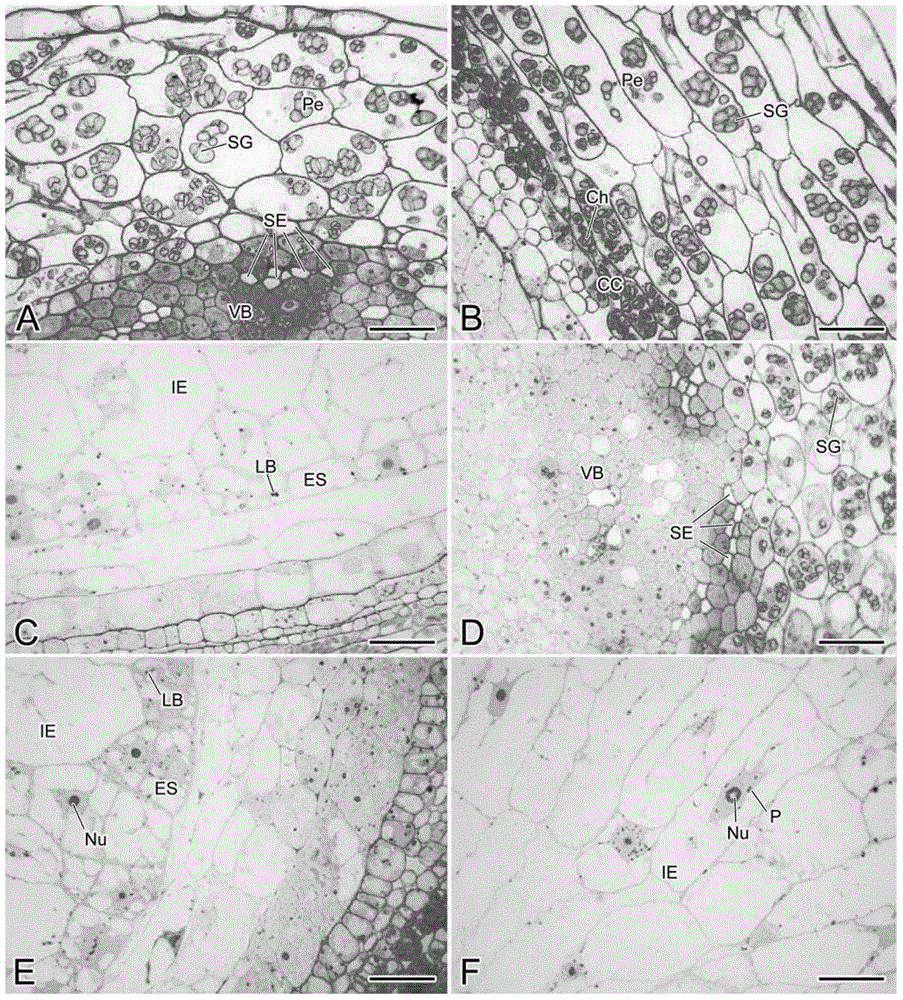

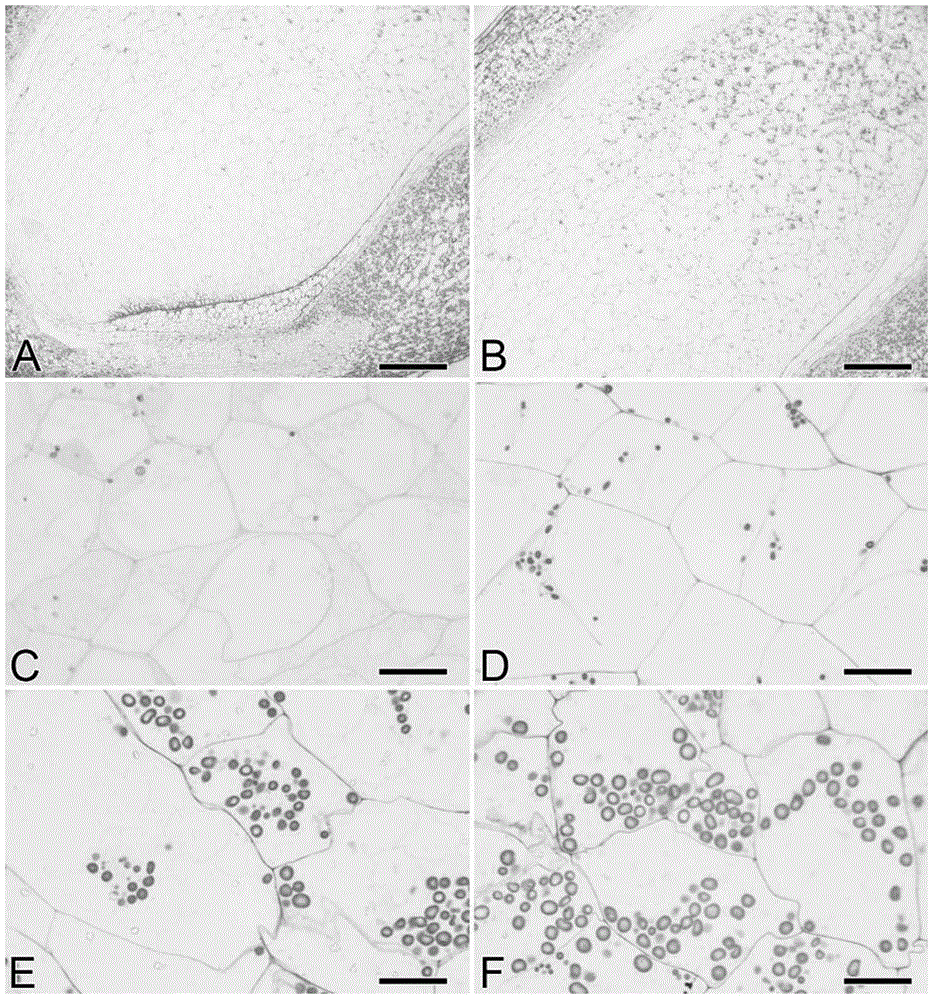

Sarranine and methyl violet mixed staining method for resin slices and staining solution thereof

InactiveCN104390834ADyeing effect is goodReduce storage requirementsPreparing sample for investigationMethyl violetANILINE BLUE

The invention provides a sarranine and methyl violet mixed staining method for resin slices and a staining solution thereof. The method comprises the following steps: (1) preparing a staining solution, namely preparing 0.5 mass percent of sarranine solution and 1 mass percent of methyl violet solution; and (2) respectively mixing the 0.5 mass percent of sarranine solution and the 1 mass percent of methyl violet solution according to multiple volume ratios, staining resin semithin sections, and observing the microscopic structure under a light microscope. According to the method disclosed by the invention, different histological stain requirements can be met aiming at the toluidine blue-O staining defect, and the method has the advantages of low cost and simplicity in preservation.

Owner:YANGZHOU UNIV

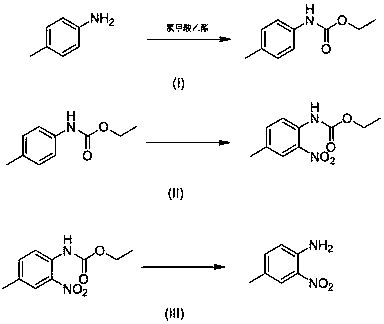

4-methyl-2-nitroaniline synthesis method

InactiveCN107759479AMild reaction conditionsNo need for high temperatureCarbamic acid derivatives preparationOrganic compound preparationNitrosoMethylaniline

The invention discloses a 4-methyl-2-nitroaniline synthesis method, which comprises: carrying out amino protection with ethyl chloroformate by using 4-methylaniline as a raw material to generate N-(p-toluene)ethyl carbamate; adding an oxidant and a copper salt catalyst, and carrying out a reaction for a certain time at a temperature of 50-120 DEG C in a reaction solvent by using a nitroso-containing compound as a nitrating agent to prepare a corresponding protected o-nitro-p-toluidine; and carrying out hydrolysis to obtain the target product. According to the present invention, the method hasadvantages of simple preparation process, mild reaction condition, high yield and environment protection.

Owner:NANJING UNIV OF SCI & TECH

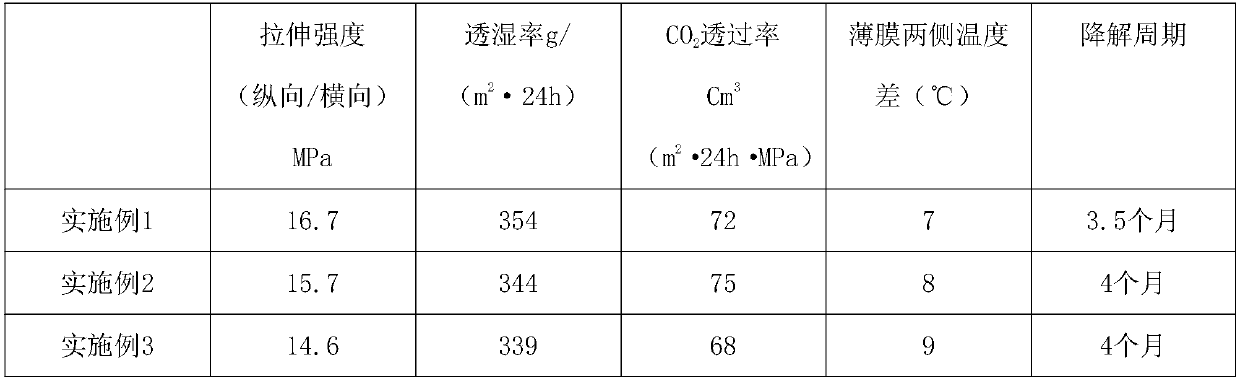

Cooked food packaging film and preparation method thereof

The invention relates to a cooked food packaging film and relates to the technical field of processing and production of a film. The cooked food packaging film is characterized by being prepared fromthe following materials in parts by weight: 14 to 20 parts of resin, 5 to 9 parts of calcium sulfate, 1 to 3 parts of polyhydroxyalkanoate, 4 to 9 parts of nano-silicon dioxide, 22 to 27 parts of hardened oil, 6 to 11 parts of p-toluidine, 9 to 13 parts of artemisia desterorum spreng gum, 60 to 68 parts of purple sweet potato starch, 7 to 12 parts of pullulan, 4 to 9 parts of sorbitol, 9 to 14 parts of an accelerant and 20 to 26 parts of biological aid. The method is reasonable and convenient in operation, the cooked food packaging film is easy to degrade, and damage to the environment is avoided.

Owner:ANHUI CHAOHU SOUTH MEMBRANE IND

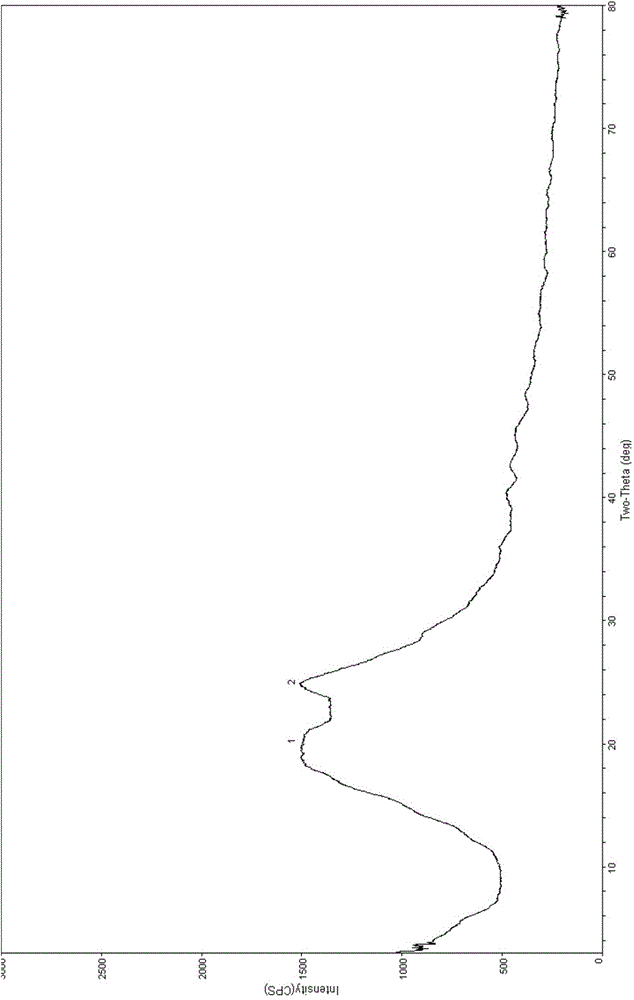

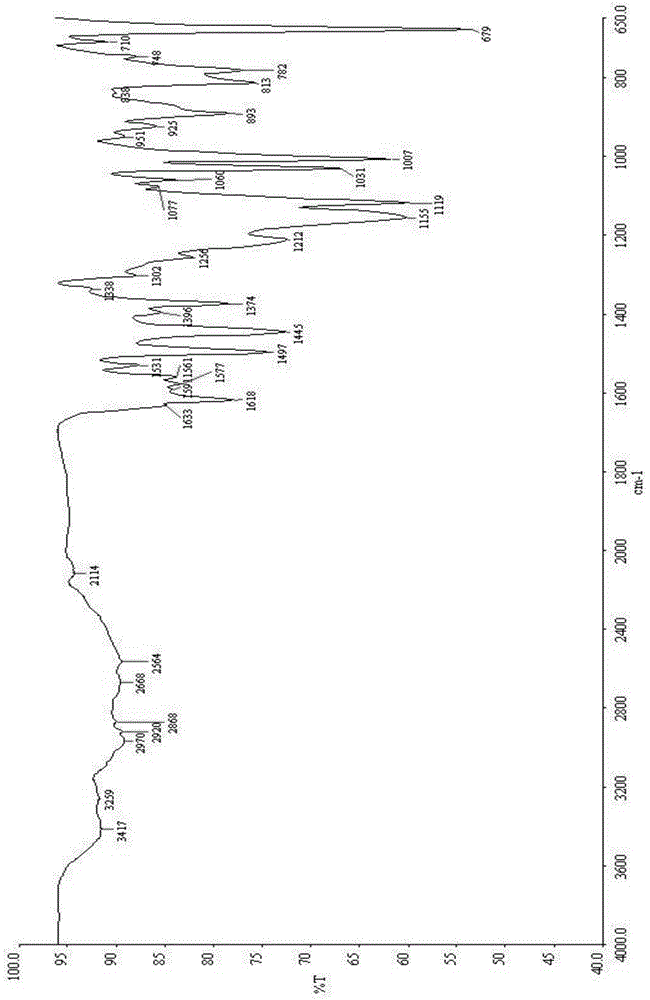

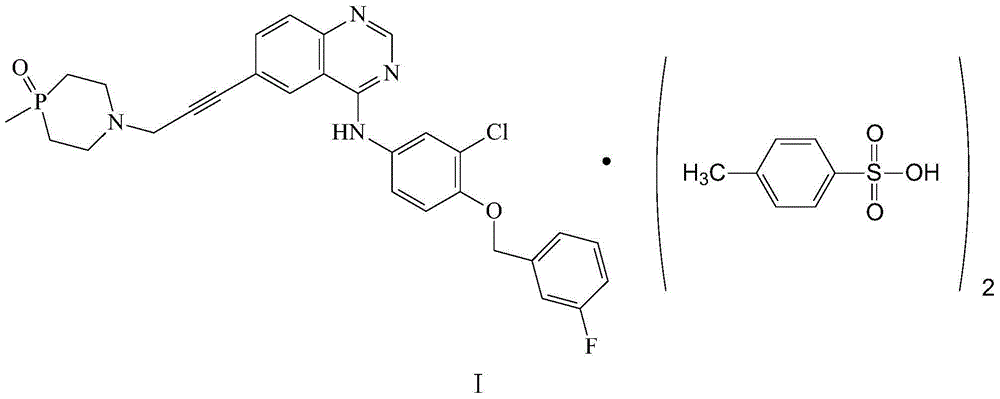

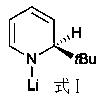

Novel crystal form of phosphorus-containing substituted quinazoline derivative as well as preparation method and application of novel crystal form

ActiveCN104558040AImprove drug activityGood for treating hyperproliferative diseasesOrganic active ingredientsAntipyreticMethyl groupPhenyl group

The invention relates to the field of compound preparation and particularly relates to a novel crystal form of N-(3-chloro-4-(3-fluorobenzyloxy)phenyl)-6-(3-(4-methyl-1,4-azaphosphine-1-yl)propyl-1-alkynyl)quinazoline-4-p-toluidine sulfonate as well as a preparation method and application of the novel crystal form. The novel crystal form of N-(3-chloro-4-(3-fluorobenzyloxy)phenyl)-6-(3-(4-methyl-1,4-azaphosphine-1-yl)propyl-1-alkynyl)quinazoline-4-p-toluidine sulfonate having a better treating effect for excessive proliferative diseases is further obtained through crystallizing a mixed solvent prepared by mixing water and methanol, ethanol, n-propanol, isopropanol, acetone, acetonitrile, tetrahydrofuran or dioxane according to different proportions, so that not only is the pharmaceutical activity of the phosphorus-containing substituted quinazoline derivative improved, but also the bioavailability of the phosphorus-containing substituted quinazoline derivative is increased, and the blank for researching a drug with the crystal form of the phosphorus-containing substituted quinazoline derivative is made up.

Owner:JIANGSU KANION PHARMA CO LTD

Method for preparing borate from aliphatic aldehyde

InactiveCN108440590AEfficient hydroboration reactionReduce pollutionGroup 3/13 element organic compoundsLithiumAtmosphere

The invention relates to an application of lithium p-toluidine, in particular to a method for preparing borate from aliphatic aldehyde. Borane is added to a reaction bottle subjected to dehydration and deoxidation treatment in a water-free and oxygen-free environment in an inert gas atmosphere, then, a lithium p-toluidine catalyst is added, the mixture is uniformly mixed, aldehyde is added, a hydroboration reaction is conducted, the reaction is ended by exposing the mixture to the air, and product borate is obtained. The aldehyde is selected from aliphatic aldehyde. It is found for the first time that lithium p-toluidine can extremely efficiently catalyze the hydroboration reaction of borane with cyclohexanecarboxaldehyde, propionaldehyde and n-heptaldehyde, and a new scheme is provided for preparing borate through the hydroboration reaction of a carbonyl compound and borane.

Owner:NANTONG TEXTILE & SILK IND TECH RES INST +1

Method of preparing compound methanol gasoline additive

InactiveCN103865596ASolve unfavorable problemsSolve the swelling problemLiquid carbonaceous fuelsGasoline fuelP-Cresol

The invention relates to a method for preparing a compound methanol gasoline additive, which is characterized in that the compound methanol gasoline additive has hydrotropy, anti-rubber swelling property, oxidation resistance, metal corrosion resistance and combustion-supporting property. The additive comprises 10-55% of methyl tert-butyl ether, 0.05-10% of BTA, 15-60% of isopropyl alcohol, 0.03-25% of p-toluidine, 0.02%-12% of octadecylamine and 0.1-15% of 2,6 di-t-butyl-p-cresol. When the additive is used, firstly the prepared additive is mixed with methanol, and then mixed with a certain proportion of base gasoline uniformly to obtain methanol gasoline fuel. No ash is generated after the methanol gasoline prepared from the compound additive is combusted, and the emission of harmful substances in the exhaust can be greatly reduced. The additive has good low-temperature stability and dynamic performance, the normal operation of the engine system can not be affected on the premise of not changing the structure of the engine condition. The compound methanol gasoline additive has wide sources of raw materials, simple process and easy popularization.

Owner:陈传伟

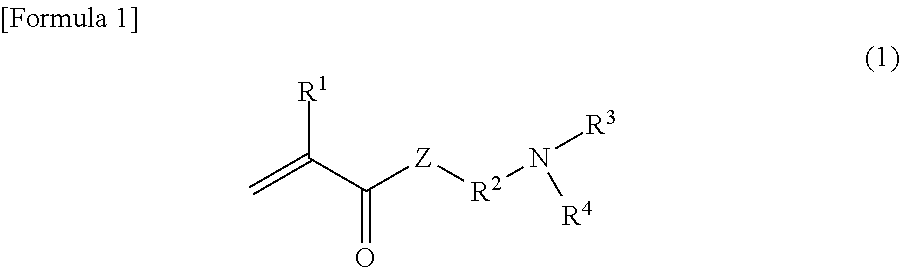

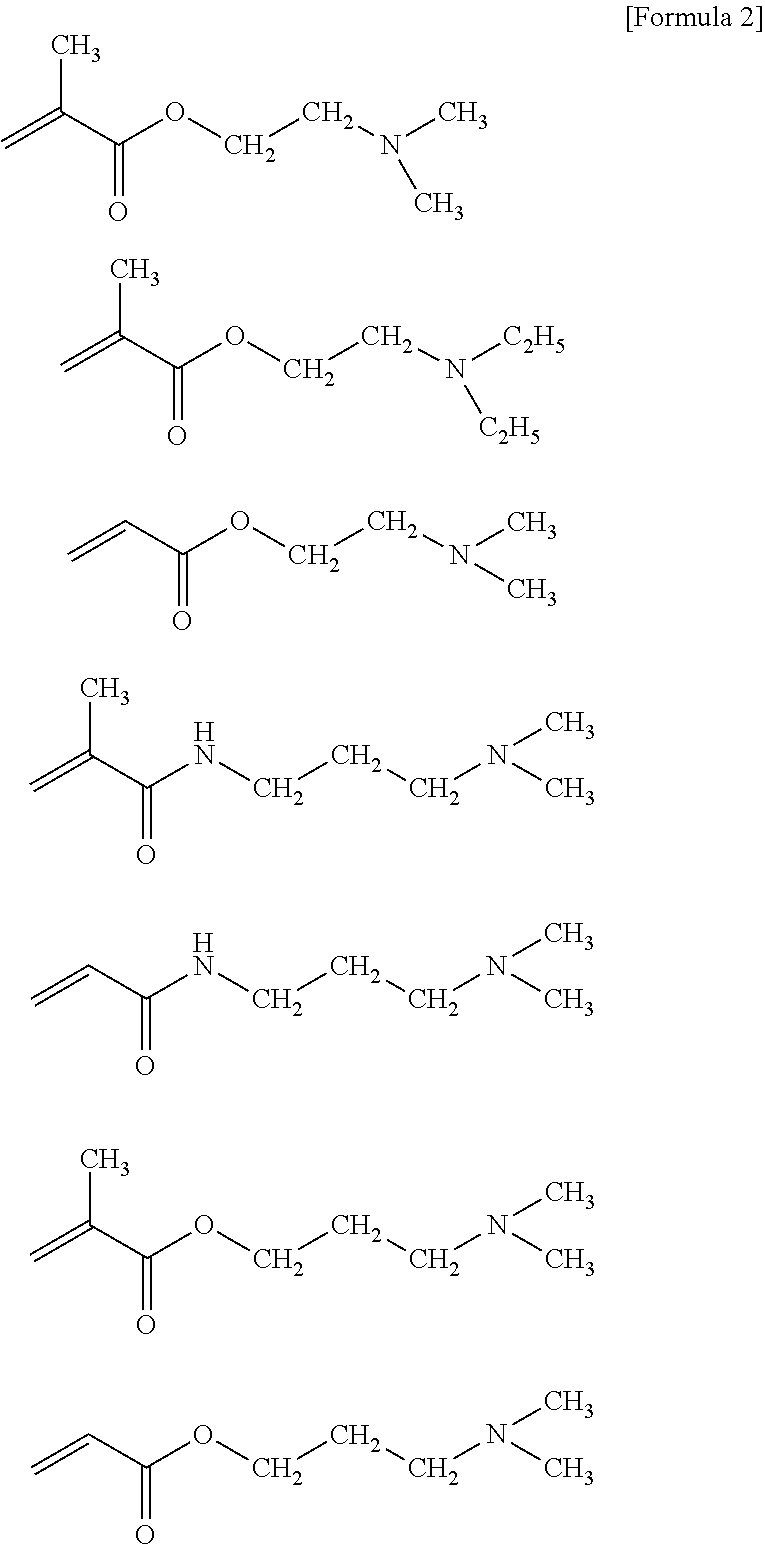

Liquid Cure Promoter Compositions With Suppressed Solids Forming Tendencies and Their Uses

This invention provides a cure promoter composition with suppressed solids forming tendencies. The composition is formed from components which prior to use in forming the composition are comprised of: a) N-methyl-N-(2-hydroxyethyl)-p-toluidine or N,N-bis(2-hydroxyethyl)-p-toluidine, or both; and b) at least one liquid monomeric ester of acrylic acid and / or at least one liquid monomeric ester of methacrylic acid; a) and b) being proportioned such that the a):b) weight ratio is in the range of about 50:50 to about 99:1.

Owner:ALBEMARLE CORP

Production method of p-toluidine

InactiveCN102180801AReduce manufacturing costLow reaction temperatureOrganic compound preparationAmino compound preparationPalladium on carbonFiltration

The invention provides a production method of p-toluidine and relates to the technical field of chemical production. In the production method, liquid phase hydrogenation reduction is directly carried out on p-nitrotoluene in the presence of a palladium-carbon catalyst so as to produce the p-toluidine. The production method has the advantages of low reaction temperature, low reaction pressure and high reaction conversion rate; and the product performs water distribution and crystallization after hermetic filtration, the yield of the product is up to 98.3%, and no three wastes are basically emitted. Because no other byproducts are generated in the production process of the produce, the purity of the product is up to 98.6%, and the next generation products can be directly produced.

Owner:GAOYOU AUXILIARY FACTORY

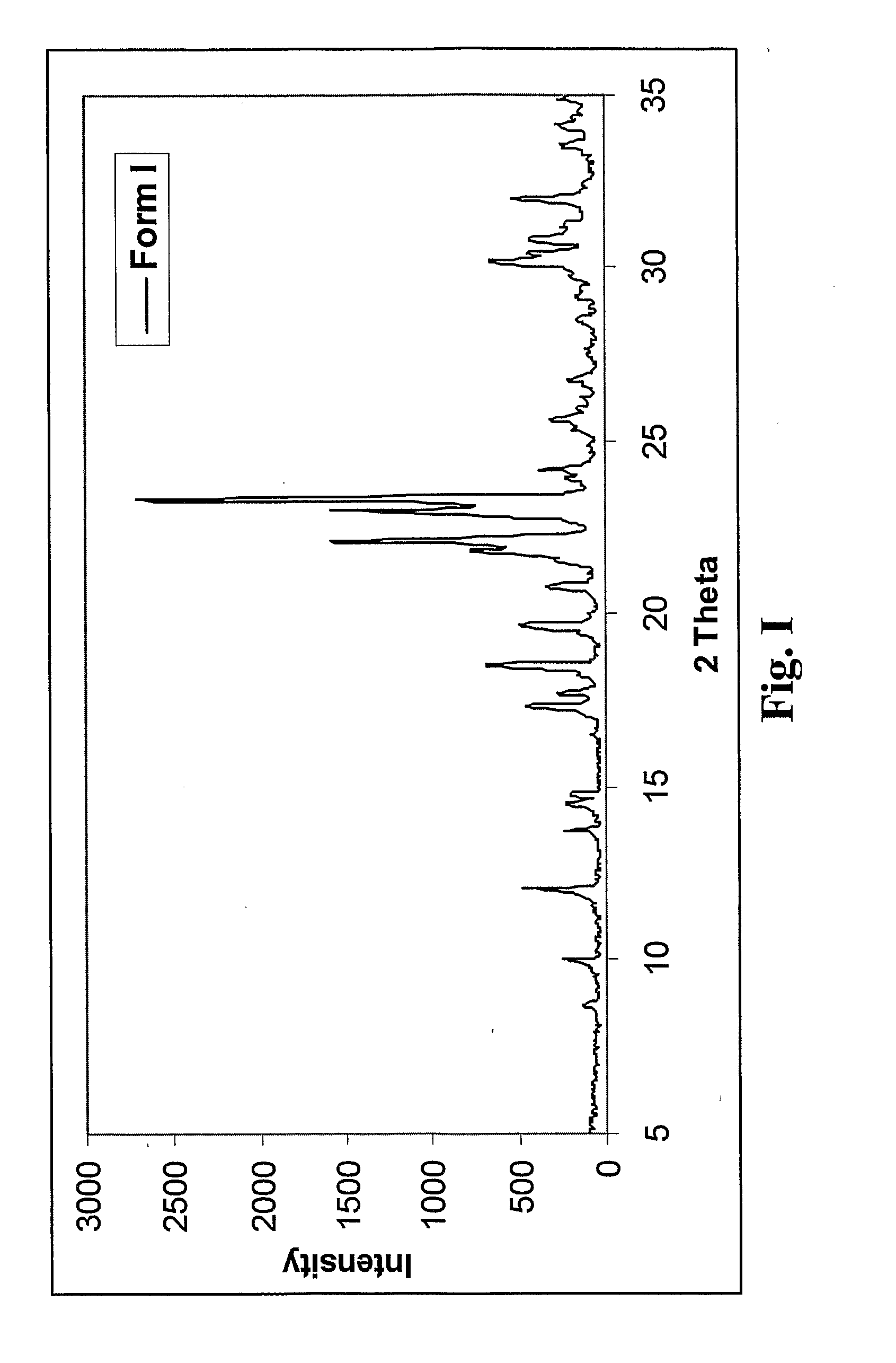

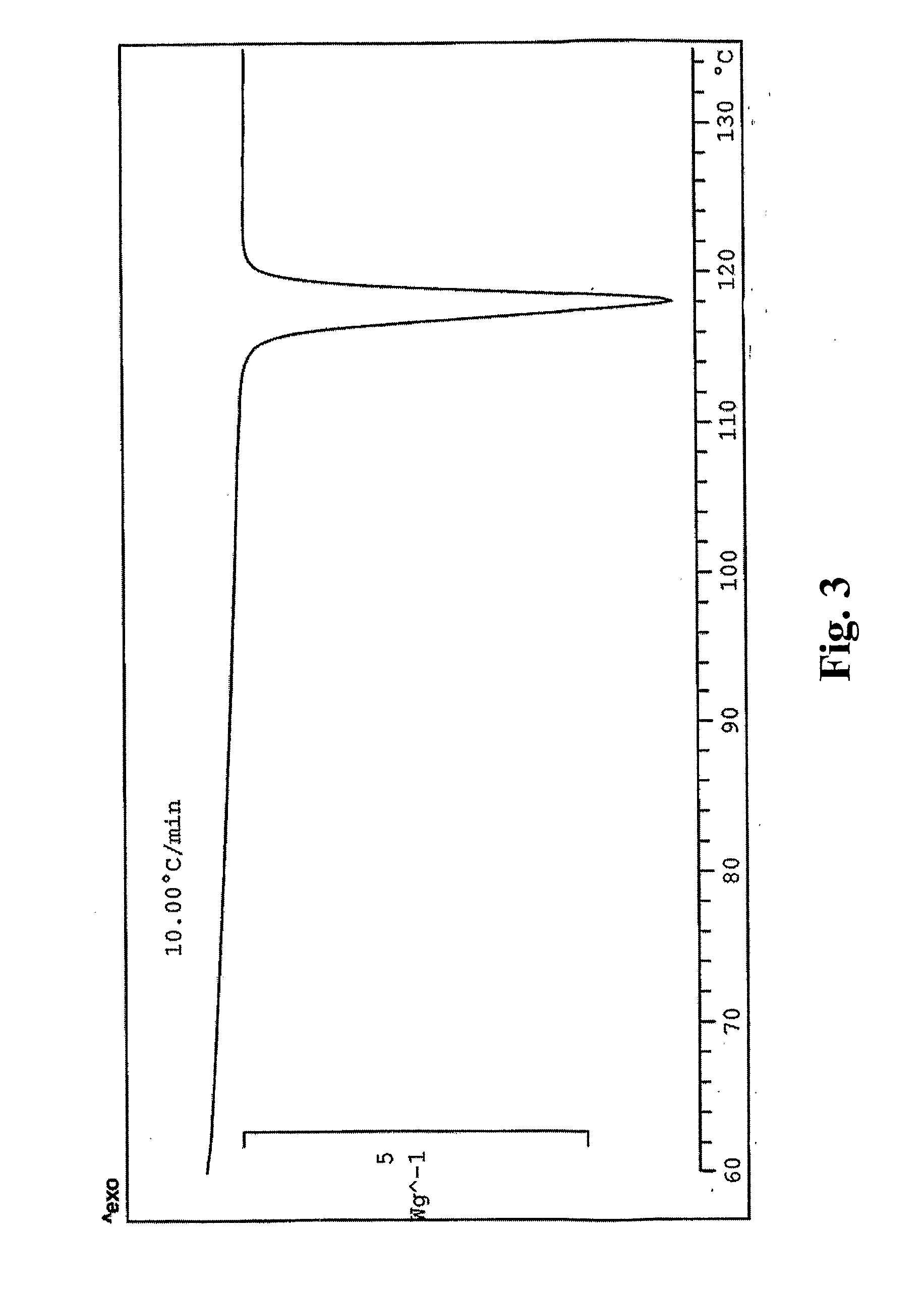

Process for preparing pyridinamines and novel polymorphs thereof

The present invention relates to an improved process for the synthesis and purification of 3-chloro-N-(3-chloro-5-tri-fluoromethyl-2-pyridyl)-a,a,a-trifluoro-2,6-dinitro-p-toluidine (fluazinam) and other pyridinamines, which implements methyl isobutyl ketone (MIBK) as the reaction solvent. The process of the invention overcomes the drawbacks of prior art methods, by reducing the side reactions such as hydrolysis, eliminating the need for difficult and labor-intensive purification methods, and providing pure products in higher yields. The present invention relates to novel crystalline polymorphic forms fluazinam, and to mixtures of the polymorphs. The present invention also provides methods for preparing the novel polymorphs, as well as pharmaceutical compositions comprising same, and methods of using the polymorphs as pesticidal agents for combating noxious living organisms on agricultural and horticultural crops.

Owner:MAKHTESHIM CHEM WORKS

Dual-cure curable material kit

ActiveUS20120059079A1Extra handling timeEasy to operateImpression capsDentistry preparationsDual cureDiketone

Owner:TOKUYAMA DENTAL CORP

Technology for synthesizing and purifying p-toluidine-3-sulfonic acid

A technology for synthesizing and purifying p-toluidine-3-sulfonic acid comprises the following steps: adding p-toluidine in concentrated sulfuric acid with the same amount, stirring to react for 2-5 hours at 210-220 DEG C, cooling, curing to obtain crude 4B acid; adding the crude 4B acid in water to stir, adding alkali to neutralize at 10-50 DEG C to ensure that the PH value of the neutralized solution is 7-9 and the 4B acid is completely dissolved; in 4B acid solution, adding activated carbon at 10-50 DEG C and stirring for 30-60 minutes to absorb impurities and decolor, filtering to obtain purified aqueous solution of 4B acid, wherein the content of activated carbon is 30-50wt% of the purified 4B acid; and adding acid in the discolored 4B acid under stirring to ensure that the pH value is 1-2 and white crystals are precipitated, filtering, and washing with water to obtain high purity 4B acid. The method has the advantages of easy method, low cost and high product purity.

Owner:李崇仁

Control agent for soft rot and control method for the same

InactiveUS20120088803A1Good control effectImprove compoundBiocideOrganic chemistryPlant cultivationBULK ACTIVE INGREDIENT

Provided is a novel control agent for soft rot and a novel control method for the same. The control agent for soft rot of a plant contains 3-chloro-N-(3-chloro-5-trifluoromethyl-2-pyridyl)-alpha,alpha,alpha-trifluoro-2,6-dinitro-p-toluidine as an active ingredient, which is applied to plant cultivation soil.

Owner:ISHIHARA SANGYO KAISHA LTD

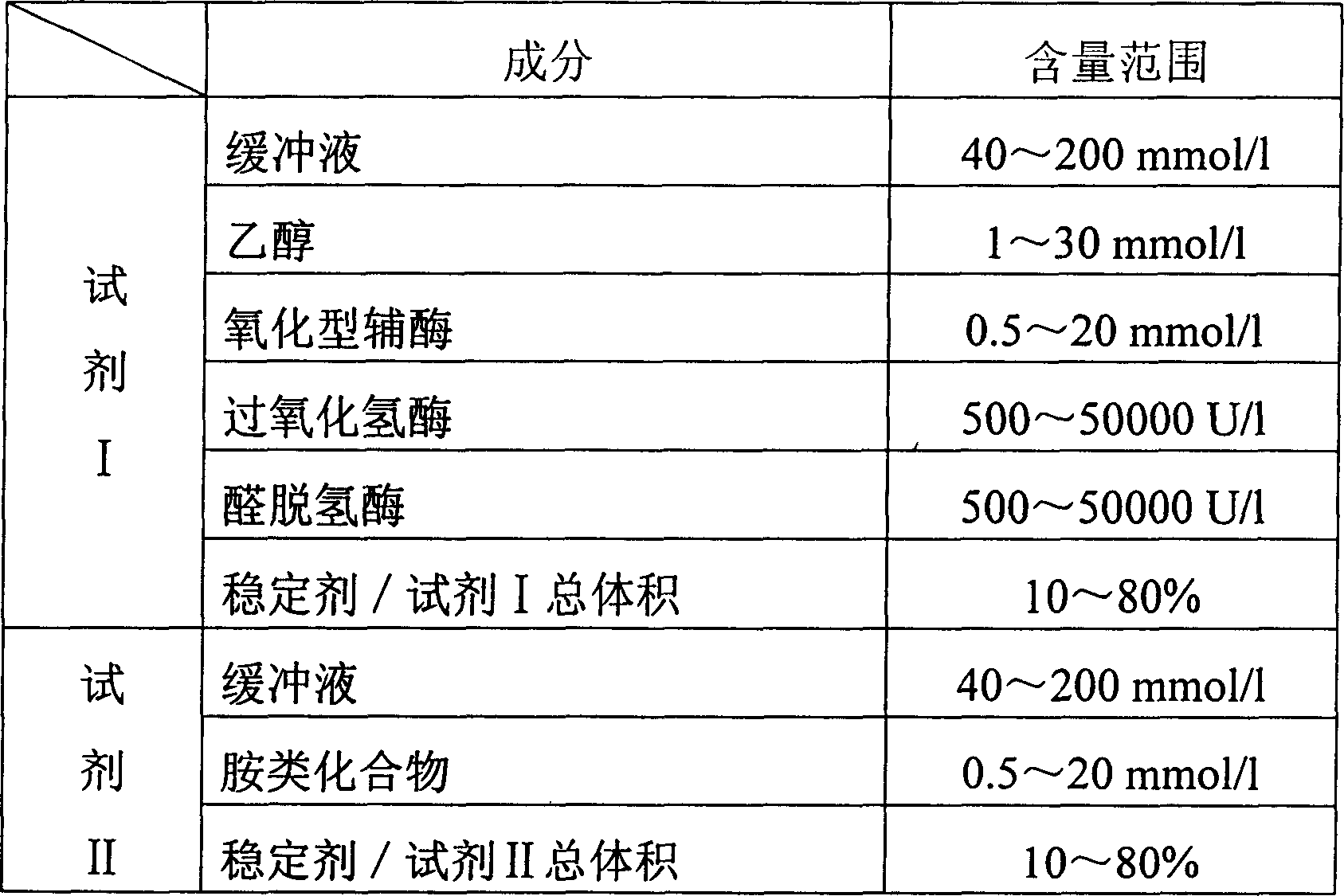

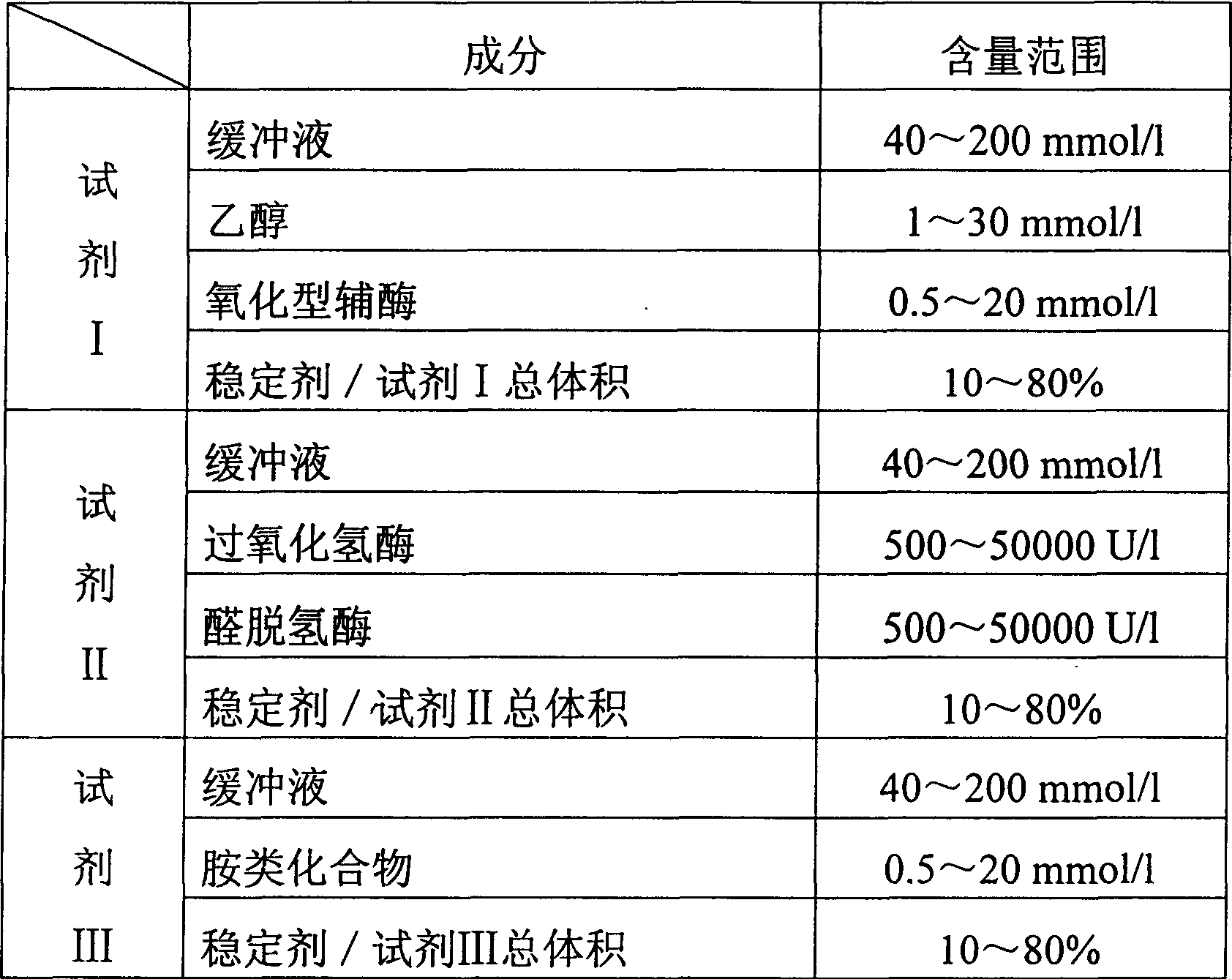

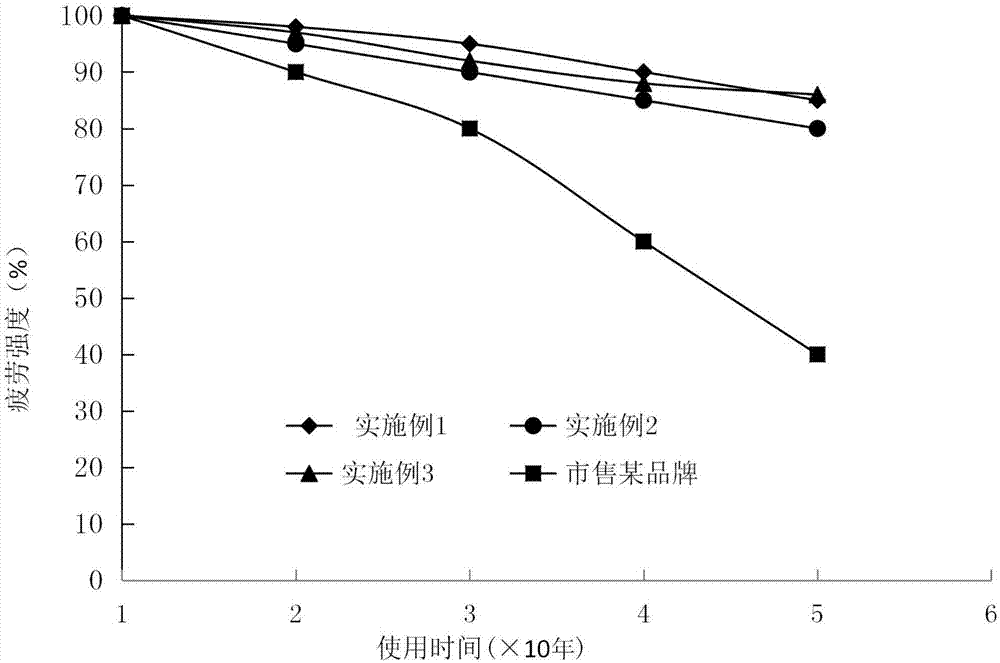

Monoamine oxidase activity determination method and monoamine oxidase diagnostic kit

InactiveCN1789427AStrong specificityQuantitatively reflect the activityMicrobiological testing/measurementMonoamine oxidase APeroxidase

The invention relates measuring method of monoamine oxidase activity and its diagnostic kit, comprising the following steps: using the benzylamine, p-toluidine red-ª‰-azo naphthol, butyl amine, amyl amine, ª‰-phenylethylamine, tyramine and other aminated compounds as substrate, it reacted with monoamine oxidase to produce auricome, then auricome carried out coupling reaction with hydrogen peroxidase and aldehyde dehydrogenase, carrying out the reaction to turn the oxidation type coenzyme to reduction type coenzyme, detecting the ascending velocity of absorbance of main wavelength 340nm to reflect the activity of monoamine oxidase in sample by definite quantity. The method has high specificity, good accuracy. The diagnostic kit is made to double agents or tri-agent to reduce the across impact and keep the agent stability and be good for long term storage. The method can be rapidly detected by the ultra-violet / visible light analysis meter or semi-automatic / full-automatic biochemical analysis meter, so the method is easy to spread and use.

Owner:SUZHOU ANJ BIOTECHNOLOGY CO LTD

Treatment method of residues from nitrotoluene rectification kettle

InactiveCN103772208ASimple processShort processOrganic compound preparationAmino compound preparationMethylanilineP-nitrotoluene

The invention discloses a treatment method of residues from a nitrotoluene rectification kettle. The method comprises the following steps: performing a hydrogenation reduction reaction on the residues from the rectification kettle and hydrogen in the presence of a catalyst, thereby generating methylaniline comprising three isomers, namely, o-toluidine, m-toluidine and p-toluidine, from the mononitrotoluene in the kettle residues and generating diaminotoluene comprising two isomerides, namely, 2,4-diaminotoluene and 2,6-diaminotoluene, from the dinitrotoluene in the kettle residues; and then performing rectification separation, thereby obtaining a methylaniline finished-product and a diaminotoluene finished-product. The method is simple in process, short in procedure, clean and environment-friendly, and realizes the rational utilization of waste resources, i.e., the products with high additional values are produced by utilizing low-value resources, thereby bringing economic benefits to enterprises. As a result, the recycling of waste materials, the energy conservation and the emission reduction are realized.

Owner:淮安嘉诚高新化工股份有限公司

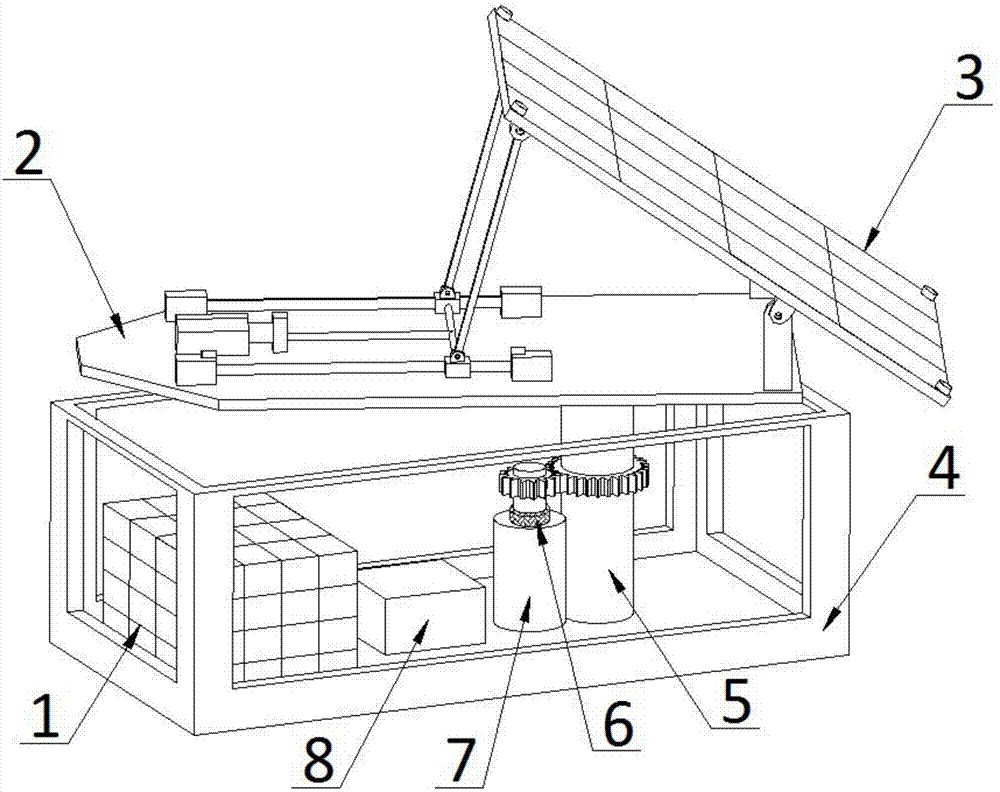

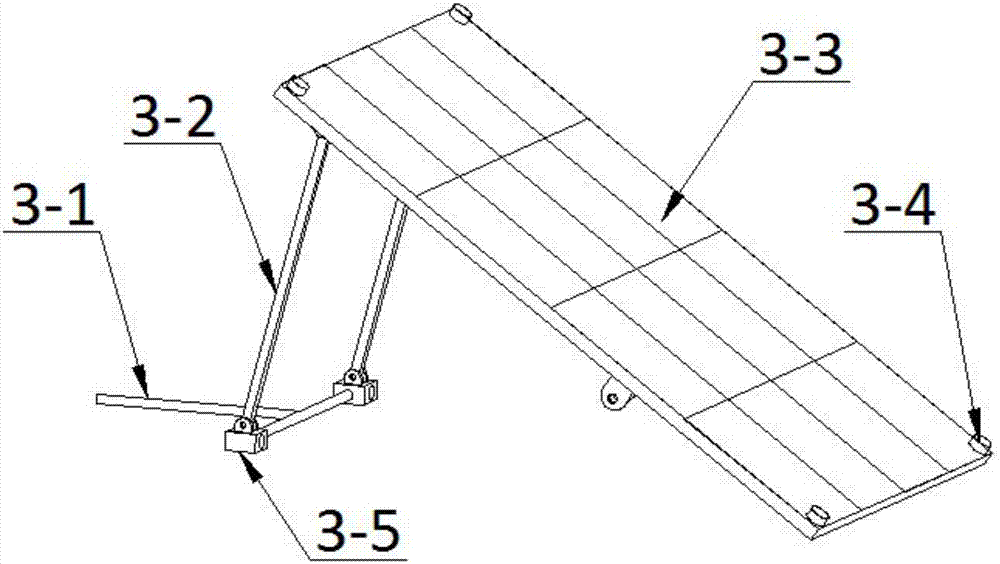

Solar energy tracking displacement platform used for sewage processing, and manufacturing method and application of solar energy tracking displacement platform

ActiveCN107315424AImprove utilization efficiencyLow maintenance efficiencyAngle measurementControl using feedbackPropanoic acidCarboxylic acid

The invention provides a solar energy tracking displacement platform used for sewage processing, and a manufacturing method and application of the solar energy tracking displacement platform. The components of the displacement platform comprise 3-methoxy dopamine hydrochloride, 3-mercapto propionic acid-2-ethyl-[(3-mercapto-oxo propoxy) methyl]-1,3-propylene diester, N-(4-hydroxy-3-methoxyphenyl)-p toluidine, 3-hydroxy-N-(4-methoxyphenyl)-4-(phenyl azo)-2-naphthalene methanamide, 3-hydroxy-4-[(2-methoxy-4-nitrophenyl)azo]-N-1-naphthaleneyl-2-naphthalene methanamide, 2,2-dimethyl-3-(2,2-dichloroethyleneyl)-cyclopropane carboxylic acid-alpha-cyan-3-phenoxyl-benzyl ester, and 3-amino-N,N-diethyl-4-methoxy benzene sulfonamide. The preparation method comprises steps of carrying out heating stirring, ray radiation, pumping-in radon gas, adding in crosslinking agent for mixing, standing and a polymerization reaction on various kinds of macromolecule materials; carrying out molding to prepare the displacement platform; and application: using the displacement platform as a component of a solar energy tracking device. The platform is stable in structure, not liable to age, and stable in control performance. The preparation method is simple in technique. Power generation efficiency can be improved.

Owner:XUZHOU UNIV OF TECH

P-bromotoluene synthesis process

InactiveCN105646139AIncrease conversion rate per passHigh yieldHalogenated hydrocarbon preparationThermal insulationWater vapor

The present invention discloses a p-bromotoluene synthesis process, which comprises: adding p-toluidine and hydrochloric acid to a reaction pot with a stirrer, a condenser, a thermometer and a dropping funnel, carrying out stirring heating to make the p-toluidine be dissolved, cooling to a temperature of less than or equal to 12 DEG C, adding a sodium nitrite solution in a dropwise manner to achieve an end point, continuously stirring for 30 min, adding a cuprous bromide hydrobromic acid solution to the reaction solution, stirring for 2 h at a temperature of 25-40 DEG C, heating the reaction solution to a temperature of 70-80 DEG C, carrying out thermal insulation for 1 h, adding water vapor to the reaction solution, distilling, separating the liquid, carrying out pressure reducing distillation, and collecting the distillate at a temperature of 104-106 DEG C to obtain the white crystal p-bromotoluene. According to the present invention, no by-product is formed during the p-bromotoluene synthesis process, the cuprous bromide easily reacts with the diazo salt under the protection of hydrobromic acid, the reaction efficiency is high, the reaction is rapid, the product yield achieves 97.82%, and the purity achieves 99.99%.

Owner:吕艳

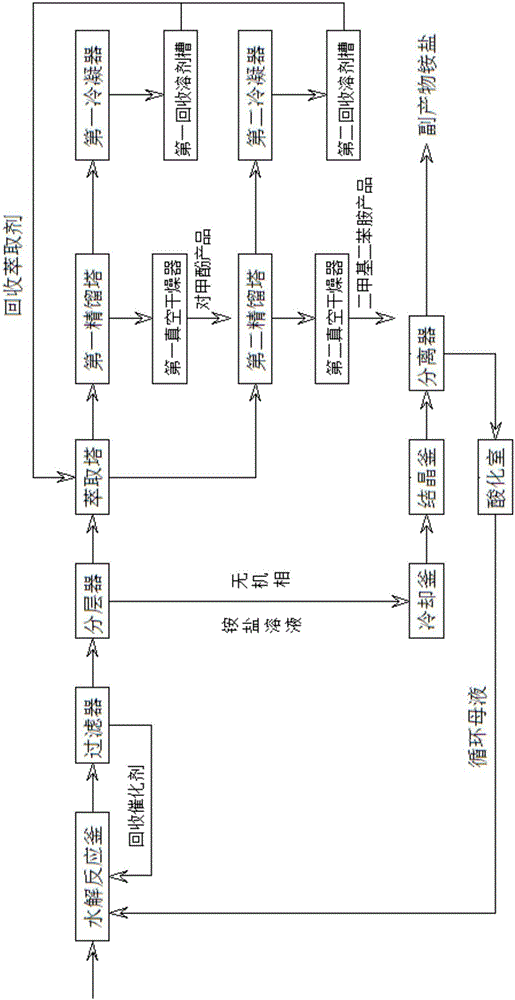

Method and production system for preparing p-cresol by catalytic hydrolysis of p-toluidine

InactiveCN105859525AHigh purityLess impuritiesOrganic chemistryOrganic compound preparationChemical synthesisCresol

The invention belongs to the technical field of chemical synthesis, and in particular relates to a method and a production system for preparing p-cresol by catalytic hydrolysis of p-toluidine. The method comprises the steps of: 1) hydrolyzing p-toluidine under a catalyst and an acidic condition to obtain a mixed solution after hydrolysis; 2) leaving the mixed solution after hydrolysis obtained in step 1) to stand for stratification, and the organic phase is subjected to extraction and After separation, crude product p-cresol solution and by-product 4,4'-dimethyldiphenylamine solution are obtained. The system includes a hydrolysis reactor, a filter connected in series with the hydrolysis reactor, a layerer connected in series with the filter, an extraction column connected in series with the layerer, and a first rectification column and a second rectification column connected in series with the extraction column respectively. , the first distillation column is connected with a first vacuum dryer, and the second distillation column is connected with a second vacuum dryer. Through the method and system provided by the present invention, high-purity p-cresol can be prepared, and 4,4'-dimethyldiphenylamine crude product can be co-produced at the same time.

Owner:HUBEI KECY CHEM

Medical denture material and molding technology

InactiveCN105434180AImprove performanceImprove bending strengthImpression capsDentistry preparationsToluidineSulfite salt

The invention relates to a medical denture material and its molding technology. The molding technology comprises the following steps: mixing 30-40 parts by weight of a urethane dimethacrylate matrix, 2-3 parts by weight of 1,6-ethylene glycol dimethacrylate, 1-2 parts by weight of N,N'-dihydroxyethyl-p-toluidine, 1-2 parts by weight of 2,6-di-tert-butyl-p-cresol, 0.5-1 part by weight of benzoyl peroxide, 1-2 parts by weight of camphorquinone, 1-2 parts by weight of dimethylamino neopentyl glycol acrylate, 1-2 parts by weight of metacrylic acid ester, 40-45 parts by weight of a fumed silica excipient, 0.1-0.2 part by weight of a shrinkage control copolymer powder, 0.2-0.3 parts by weight of a silane coupling agent and 0.3-0.5 part by weight of synthetic fibre, uniformly stirring, and vibrating to remove bubbles; coating a mixture obtained with a layer of a surface air-isolating agent composed of water-soluble matrigel and sodium sulfite or sorbitol, and carrying out photopolymerization; letting conversion rate reach 70% after 5 minutes of photopolymerization and letting conversion rate reach 95% and above after 24 hours of photopolymerization; and washing with cold water. The material of the invention has excellent performance, Brinell hardness and friction wear ability and has good biocompatibility.

Owner:SHENZHEN JIAHONG DENTAL MEDICAL CO LTD

Solvent pigment 5B green and preparation method thereof

The invention belongs to the technical field of solvent pigment 5B green, and particularly relates to solvent pigment 5B green and a preparation method thereof. The solvent pigment 5B green is prepared from the following raw materials in parts by weight: 35 to 48 parts of 1,4-dihydroxy anthraquinone; 24 to 32 parts of p-toluidine; 1-3 parts of boric acid; and 1-3 parts of hydrochloric acid, wherein the mass fraction of the hydrochloric acid is 27%-35%. The preparation method of the solvent pigment 5B green comprises the following steps: firstly, carrying out a condensation reaction on the 1,4-dihydroxy anthraquinone and the p-toluidine to prepare the solvent pigment 5B green, and carrying out primary filter pressing, refining, secondary filter pressing and drying on the solvent pigment 5Bgreen to prepare the solvent pigment 5B green. The solvent pigment 5B green has the advantages of good heat resistance, good light-resistant stability, good migration resistance and good coloring performance; tests show that the heat resistance of the solvent pigment 5B green in PS reaches 310 DEG C, the light fastness of the solvent pigment 5B green in PS can reach the 7-8 level, the migration resistance reaches the 4-5 level, and the tinting strength is larger than or equal to 99.8%.

Owner:湖北彩德新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com