Preparation method of 1-hydroxy-4-(p-toluidino)anthraquinone

A technology of toluidine anthracene and p-toluidine, which is applied in the field of preparation of 1-hydroxy-4-p-toluidine anthraquinone, which can solve the problem of difficult removal of anionic surfactants, additional burden of sewage treatment, harsh condensation reaction conditions, etc. problem, achieve the effect of avoiding difficult separation, stable reaction and avoiding side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

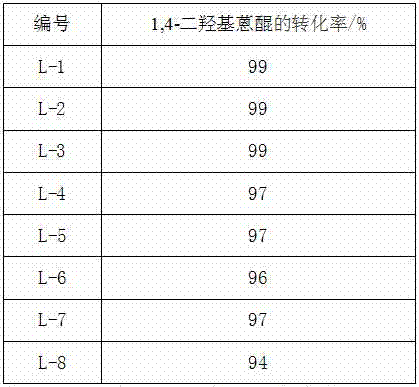

Image

Examples

Embodiment 1

[0023] A preparation method of 1-hydroxyl-4-p-toluidino anthraquinone, characterized in that the preparation steps include:

[0024] (1) Preparation of condensation catalyst: In parts by weight, swell 100 parts of thiourea resin in 700 parts of boric acid, soak for 3 hours, filter, wash with deionized water until PH = 7, add 3 parts of 2-hydroxy-5-sulfo Benzoic acid, 0.04 parts of neodymium acetate, 0.03 parts of 5,6-diamino-1,10-phenanthroline, 2 parts of 2-fluoroisonicotinic acid, stirred and reacted at 30°C for 7h, the reaction was completed, filtered , dried to obtain the condensation catalyst;

[0025] (2) Preparation of 1-hydroxy-4-p-toluidine anthraquinone:

[0026] In parts by weight, 100 parts of 1,4-dihydroxyanthraquinone, 90 parts of p-toluidine, 500 parts of diethylene glycol dibutyl ether, and 70 parts of condensation catalyst are put into the reactor, and the system gradually heats up to carry out the reaction. The reaction temperature is 110°C, and the reactio...

Embodiment 2

[0028] A preparation method of 1-hydroxyl-4-p-toluidino anthraquinone, characterized in that the preparation steps include:

[0029] (1) Preparation of condensation catalyst: In parts by weight, swell 100 parts of thiourea resin in 500 parts of boric acid, soak for 1 hour, filter, wash with deionized water until pH = 7, add 1 part of 2-hydroxy-5-sulfo Benzoic acid, 0.01 part of neodymium acetate; 0.01 part of 5,6-diamino-1,10-phenanthroline, 1 part of 2-fluoroisonicotinic acid, stirred and reacted at 20°C for 10h, the reaction was completed, filtered, drying to obtain a condensation catalyst;

[0030] (2) Preparation of 1-hydroxy-4-p-toluidine anthraquinone:

[0031] In parts by weight, 100 parts of 1,4-dihydroxyanthraquinone, 80 parts of p-toluidine, 300 parts of tetraglyme, and 30-100 parts of condensation catalyst are put into the reactor, and the system gradually heats up to react. The temperature is 100°C, and the reaction time is 20h. After the reaction, the product i...

Embodiment 3

[0033] A preparation method of 1-hydroxyl-4-p-toluidino anthraquinone, characterized in that the preparation steps include:

[0034] (1) Preparation of condensation catalyst: In parts by weight, swell 100 parts of thiourea resin and soak in 1000 parts of boric acid for 5 hours, filter, wash with deionized water until PH = 7, add 10 parts of 2-hydroxy-5-sulfo Benzoic acid, 0.1 parts of neodymium acetate; 0.1 parts of 5,6-diamino-1,10-phenanthroline, 5 parts of 2-fluoroisonicotinic acid, stirred and reacted at 50°C for 5h, the reaction was completed, filtered, drying to obtain a condensation catalyst;

[0035] (2) Preparation of 1-hydroxy-4-p-toluidine anthraquinone:

[0036] In parts by weight, 100 parts of 1,4-dihydroxyanthraquinone, 150 parts of p-toluidine, 800 parts of diphenyl ether, and 100 parts of condensation catalyst are put into the reactor, and the system gradually heats up to react, and the reaction temperature is 150°C , the reaction time is 10h. After the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com