A self-feeding dust explosion engine

A dust explosion and engine technology, applied in the directions of powdered engine fuel, combustion engine, engine components, etc., can solve the problems of complex device structure, and achieve the effect of simplifying the mechanical structure, good sealing effect, and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

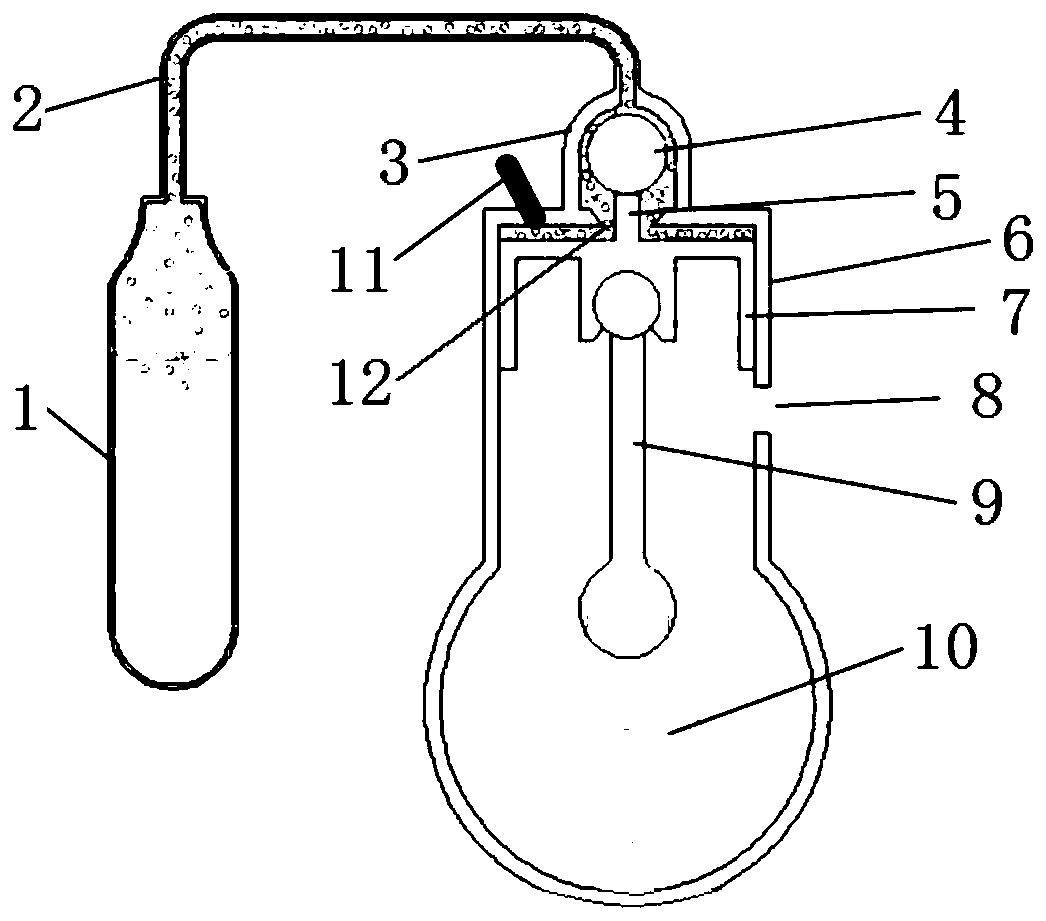

[0036] combine figure 1 , a self-feeding dust explosion engine of the present embodiment is mainly composed of a fuel tank 1, a feed chamber 3 and a piston 7, wherein: the fuel tank 1 is fed into the combustion chamber 6 through the feeding device 2; in the present embodiment The combustion chamber 6 includes a combustion chamber part and a compressed gas part, which is structurally equivalent to a cylinder block, and the feeding device 2 is used to deliver dust fuel to the combustion chamber of the combustion chamber 6 . The dust fuel can be metal dust, coal dust, grain dust, feed dust or forest product dust, etc., without specific limitation, and grain dust can be selected in this embodiment.

[0037] In this embodiment, one end of the feed chamber 3 is communicated with the feeding device 2, and the other end is communicated with the combustion chamber 6 through the feed port 12. The cavity of the feed chamber 3 is provided with a retaining ball 4, which can be placed in th...

Embodiment 2

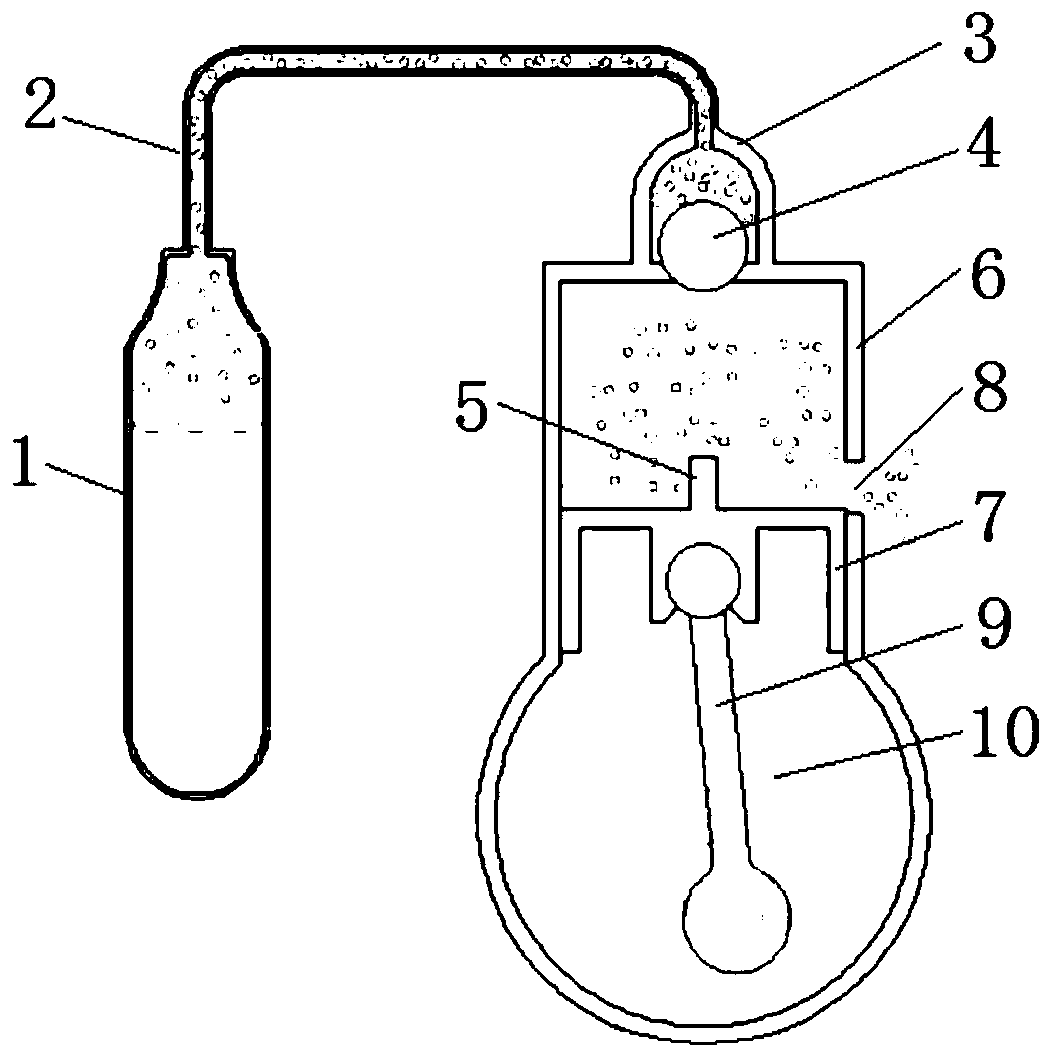

[0043] A kind of self-feeding dust explosion engine of this embodiment, its basic structure is identical with embodiment 1, and its difference is: in the present embodiment, the upper part of feeding chamber 3 is a spherical crown, namely feeding chamber 3 and feeding The connecting part of the device 2 is a spherical crown, and the diameter of the spherical crown is larger than the diameter of the retaining ball 4, so the retaining ball 4 can better cooperate with the feeding chamber 3, and the sealing is tight, which can effectively avoid the phenomenon of material leakage.

[0044] Further, the feed inlet 12 is a spherical crown opening located at the top of the combustion chamber 6, that is, the lower part of the feed chamber 3 is also a spherical crown, and the diameter of the spherical crown is larger than the diameter of the retaining ball 4. Since the diameters of both are greater than the diameter of the retaining ball, the retaining ball can completely fit closely wit...

Embodiment 3

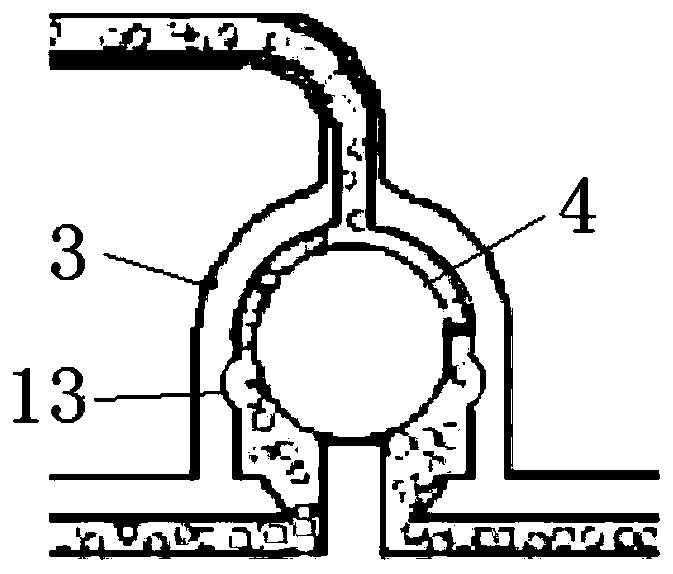

[0046] combine image 3 , a kind of self-feeding dust explosion engine of this embodiment, its basic structure is identical with embodiment 2, and its difference lies in: this embodiment is provided with material tank 13 in the middle part of the side wall of feed chamber 3, and this container The troughs 13 are grooves arranged at intervals.

[0047] Although the retaining ball 4 can move up and down in the feeding chamber 3, if the side wall gap is too small, the material that can pass through is limited, and it is difficult to flow enough dust fuel in a short time. If the gap is too large, the retaining ball 4 is easy to shift during movement, and it is difficult to realize effective sealing. The set material holding tank 13 can provide a larger storage space, and has the effect of an intermediate conversion tank, so that more materials can be circulated without affecting the movement of the material retaining ball.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com