Reaction system of synthesizing polyoxymethylene dimethyl ether

A technology of polyoxymethylene dimethyl ether and reaction system, which is applied in the field of reaction systems for synthesizing polyoxymethylene dimethyl ether, can solve the problems of shortening the reaction residence time and small bed resistance, and achieves the benefits of reaction conversion rate, Not easy to dead zone, ensure mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

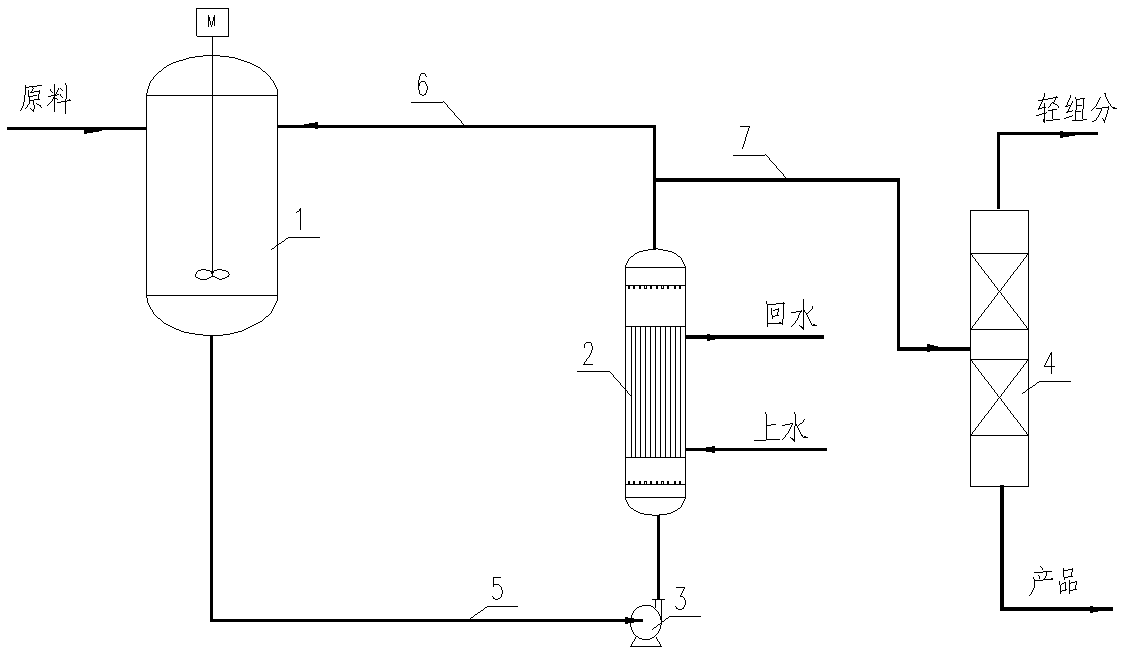

[0027] see figure 1 A reaction system for synthesizing polyoxymethylene dimethyl ether includes a raw material mixer 1 and a tube-and-tube floating bed reactor 2. The bottom of the tubular floating bed reactor 2 is provided with a reaction liquid inlet N1, and the top of the tubular floating bed reactor 2 is provided with a reaction liquid outlet N2; the outlet of the raw material mixer 1 is connected with the tubular floating bed reactor The reaction solution inlets N1 of 2 are connected through a circulation pipeline 5, a circulation pump 3 is installed in the circulation pipeline 5, and the reaction solution outlet N2 of the tubular floating bed reactor 2 is respectively connected to one end of the return pipeline 6 and the discharge pipe 7, the other end of the return pipe 6 is connected to the raw material mixer 1, and the other end of the outlet pipe 7 is connected to the downstream rectification tower 4.

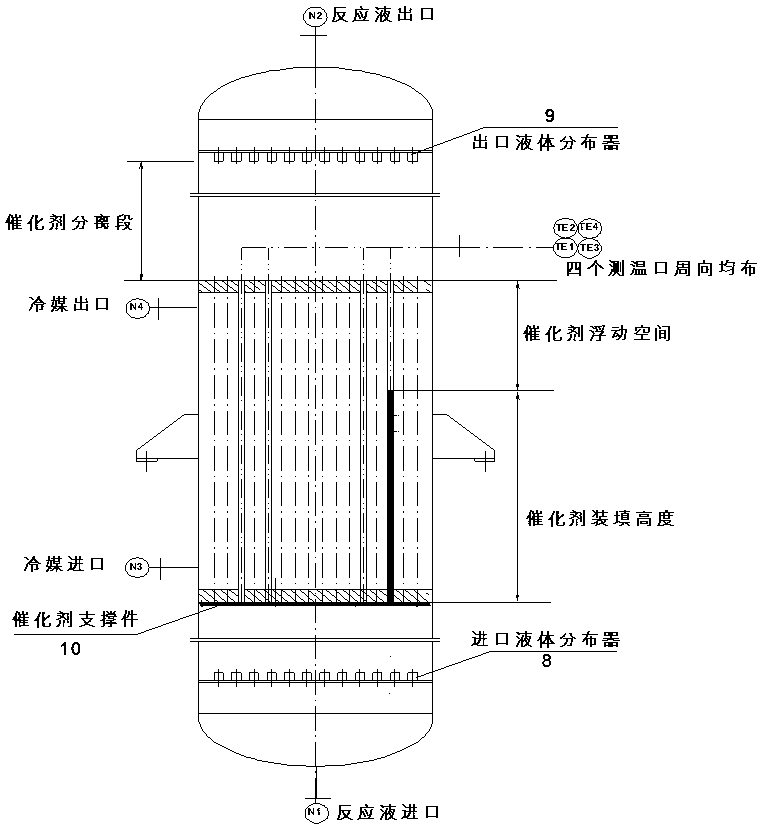

[0028] see figure 2 , The tube-and-tube floating bed reactor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com