Low-cost separation method and device for fatty acid mixture

A technology of mixed fatty acid and separation method, applied in the field of low-cost separation method and separation device of mixed fatty acid, can solve the problems of difficult separation of high value-added products, low product yield and purity, and excessive heat-sensitive decomposition, etc. Condensation, good product quality, good heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

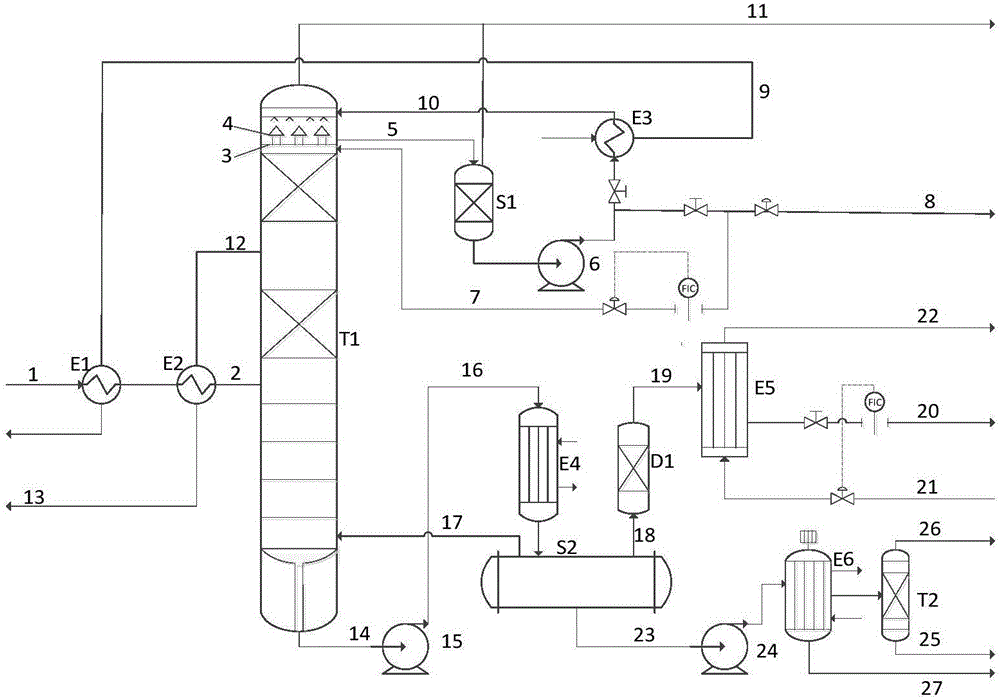

[0018] Example 1: A 5kt / aC12~C22 fatty acid continuous refining project

[0019] The continuous refining process of fatty acids such as figure 1 shown. The component mass fractions of fatty acid raw materials are as follows: C12-C14: 5%-15%; C16: 20%-30%; C18: 55%-65%; C22: 1%-3%, and the heavy component is less than 1%. The processing capacity is 625kg / h. The diameter of the vacuum rectification tower T1 is 1400mm, the total height is 32000mm, and its distillation section is provided with 16000mm SINOPAK-B2 wallless flow structured wire mesh filler, which is divided into 3 sections. The liquid distribution adopts LQ-II infinite point liquid distributor, and the top reflux part adopts spray equipment. The stripping section is equipped with 18 STV super valve trays. The tower kettle of the rectification tower is funnel-shaped, wherein the diameter of the thin tube part is 250mm, the height of the thin tube part is 2800mm, and the height of the necking part at the upper part...

Embodiment 2

[0022] Example 2: A 10kt / aC12~C22 fatty acid continuous refining project

[0023] The continuous refining process of fatty acids such as figure 1 shown. The component mass fractions of fatty acid raw materials are as follows: C12~C14: 4%~10%; C16: 25%~30%; C18: 55%~60%; C22: 1%~2%, and the heavy component is less than 1%. The amount is 1250kg / h. The vacuum rectification tower T1 has a diameter of 2000mm and a total height of 36000mm, and its rectification section is equipped with a regular wire mesh packing of 18000mm, which is divided into 3 sections. The top reflux part adopts spray equipment, and the liquid distribution adopts infinite point liquid distributor. The stripping section is equipped with a regular wire mesh packing of 16000 mm, and the bottom of the rectification tower is funnel-shaped, in which the diameter of the thin tube part is 500 mm, the height of the thin tube part is 3000 mm, and the height of the narrow part of the upper part of the funnel is 600 mm. ...

Embodiment 3

[0025] According to measurement and calculation, compared with the existing technology for separating mixed fatty acids by using this method and device, the yield can be increased by 6.6%, the energy consumption per unit product can be saved by 40.6%, and the investment in raw material equipment per ton can be saved by more than 42%. Example 3: A 100kt / aC12~C22 fatty acid continuous refining project

[0026] The continuous refining process of fatty acids such as figure 1 shown. The component mass fractions of fatty acid raw materials are as follows: C12~C14: 5%~10%; C16: 23%~35%; C18: 50%~68%; C22: 2%~3%, the heavy component is less than 1%. The amount is 12500kg / h,

[0027] The rectification tower T1 has a diameter of 6000mm and a total height of 40000mm. The rectification section is set at 20000mm, and the structured wire mesh packing is divided into 3 sections. Liquid distribution uses an infinite point liquid distributor. The stripping section is equipped with 24 STV s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com