Condenser with variable-toothform internal-thread enhanced tube

An internal thread, strengthening tube technology, applied in evaporator/condenser, refrigerator, refrigeration components, etc., can solve the problem of inability to achieve the heat exchange effect of the condenser, and achieve the best heat exchange effect and improve performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

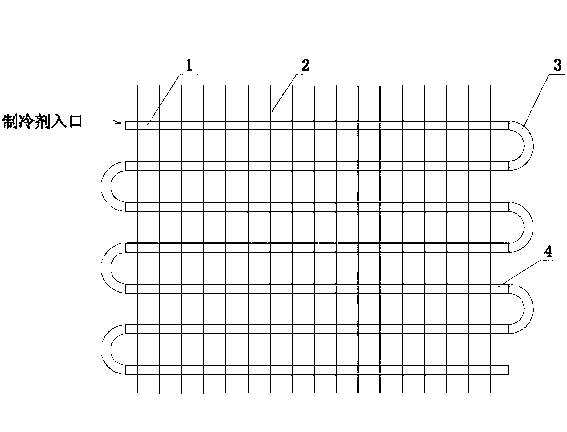

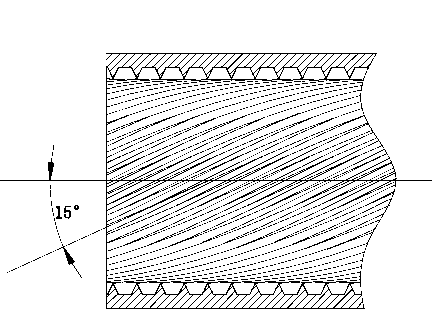

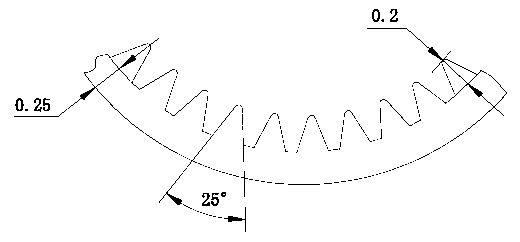

[0035] Such as Figure 1 to 5 As shown, it is a variable-tooth-shaped internally threaded strengthened tube condenser, which includes two or more first section tubes 1, three or more connecting elbows 3, two or more second section tubes 4, and two or more pieces The fin 2; wherein in the axial direction of the inner wall of the first section of the tube 1, more than three racks are uniformly arranged, the racks are helically distributed; the length of the second section of the tube 4 and the first section of the tube 1 There are more than three racks uniformly arranged in the axial direction of the inner wall of the second section of tube 4, and the racks are helically distributed; the number of racks of the first section of tube 1 and the number of racks of the second section of tube 4 The ratio range of is 1-1.5. In this embodiment, the ratio of the number of racks of the first section of tube 1 to the number of racks of the second section of tube 4 is 4 / 3. It can also be sele...

Embodiment 2

[0041] Such as Figure 6 to 12 As shown, it is a variable-tooth-shaped internally threaded strengthened tube condenser, which includes two or more first-section tubes 1, two or more second-section tubes 4, two or more third-section tubes 5, and three The above connecting elbow 3 and two or more fins 2; wherein more than three racks are uniformly provided in the axial direction of the inner wall of the first section tube 1, the second section tube 4, and the third section tube 5 , The racks are spirally distributed; the lengths of the first tube 1, the second tube 4, and the third tube 5 are all the same; the number of racks of the first tube 1 is equal to that of the second tube 4 The ratio of the number of racks is 1-1.5. In this embodiment, the ratio of the number of racks of the first section of tube 1 to the number of racks of the second section of tube 4 is 10 / 9, which can also be specified according to actual needs. Select the ratio of the number of racks of the first se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Tube wall thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com