Continuous asphalt reclaimed material hot-air circulation heating device

A technology of hot air circulation and asphalt regeneration, applied in bridge construction, bridge parts, bridges, etc., can solve the problems of easy fire and combustion, high surface temperature of asphalt pavement, aging of asphalt, etc., achieve good heat transfer effect, reduce environmental pollution, and improve thermal efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific drawings and embodiments.

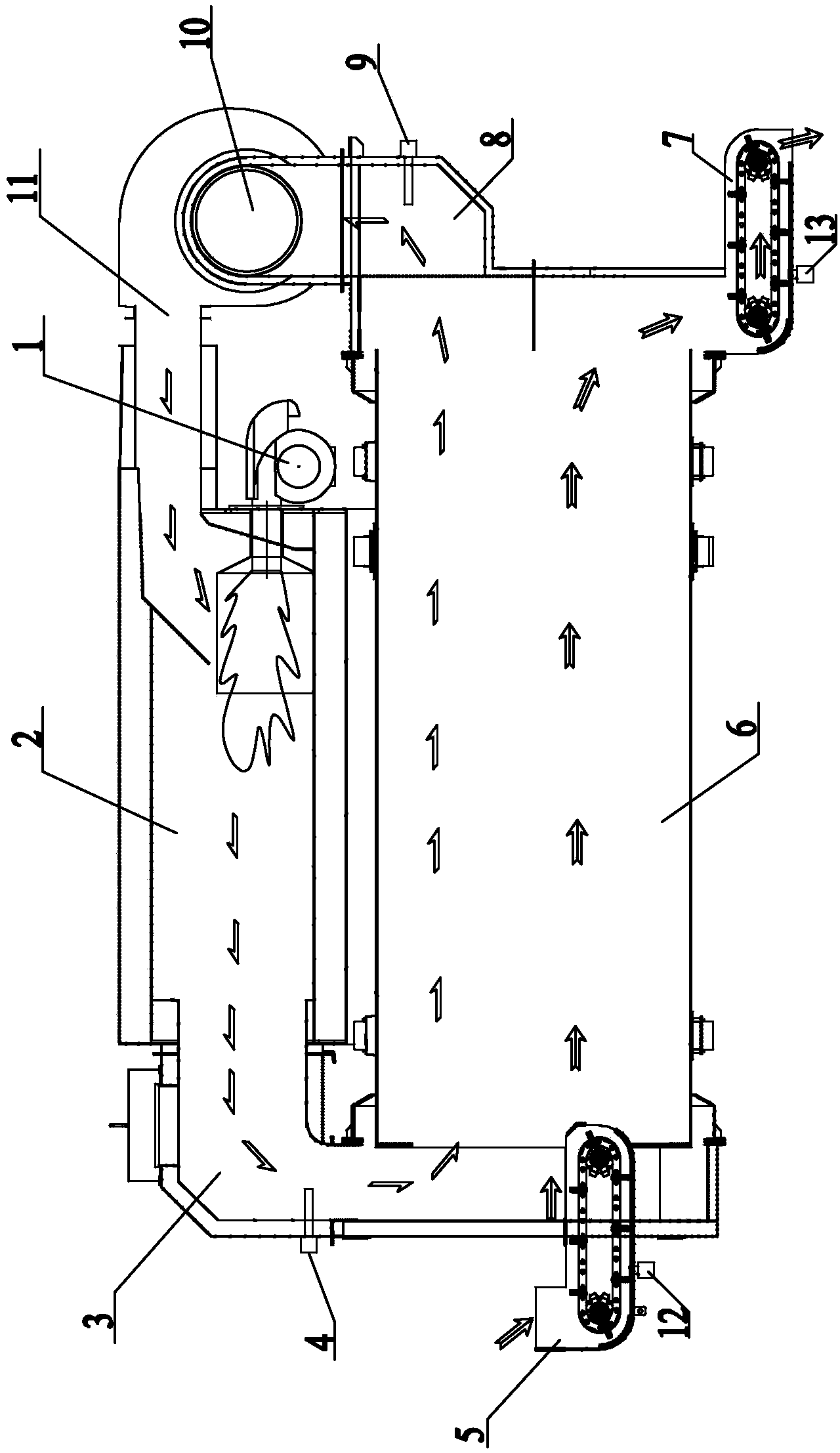

[0019] Such as figure 1 As shown: in order to uniformly heat the asphalt, improve the heating efficiency, and avoid the aging of the asphalt, the present invention includes an incineration combustion chamber 2, and a horizontal drying cylinder 6 is arranged below the incineration combustion chamber 2, and the horizontal drying cylinder 6 The feed end of the cylinder is connected to the high-temperature flue 3 of the incineration combustion chamber 2, the discharge end of the horizontal drying cylinder 6 is connected to the air inlet of the circulating fan 10 through the low-temperature flue 8, and the air outlet of the circulating fan 10 passes through the circulating air duct 11 is connected with the incineration combustion chamber 2; the incineration combustion chamber 2 is also provided with a burner 1, which is located above the horizontal drying cylinder 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com