Horizontal U-shaped fin tube heat exchanger of air source heat pump and fixing mode thereof

A technology of finned tube heat exchangers and air source heat pumps, applied in heating methods, space heating and ventilation details, household heating, etc., can solve problems such as high pressure in high-voltage operation of the system, tripping protection, and clean flow. Achieve the effects of reducing height space, uniform thermal power, and controlling uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

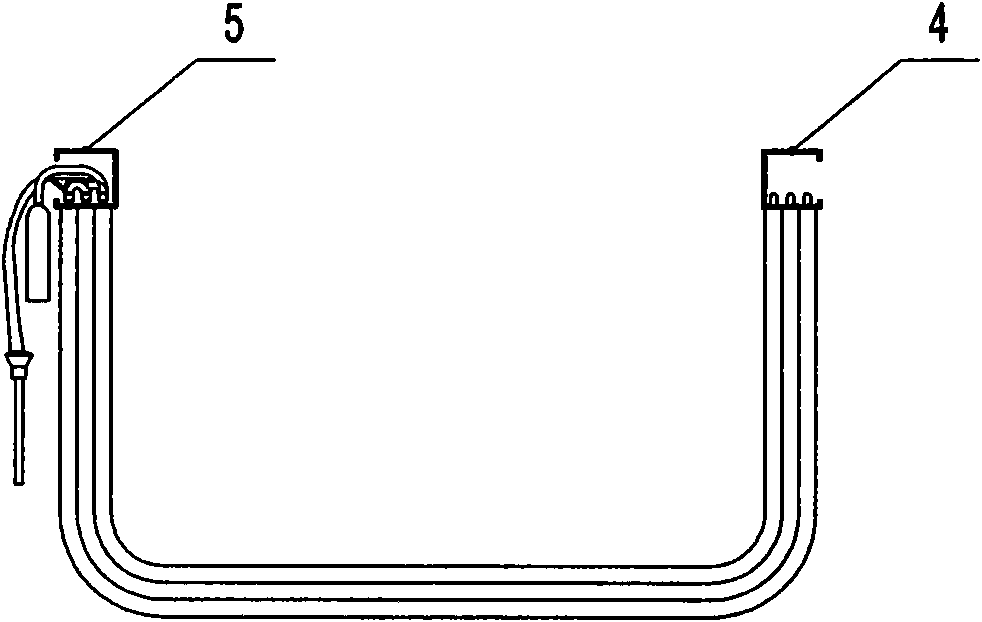

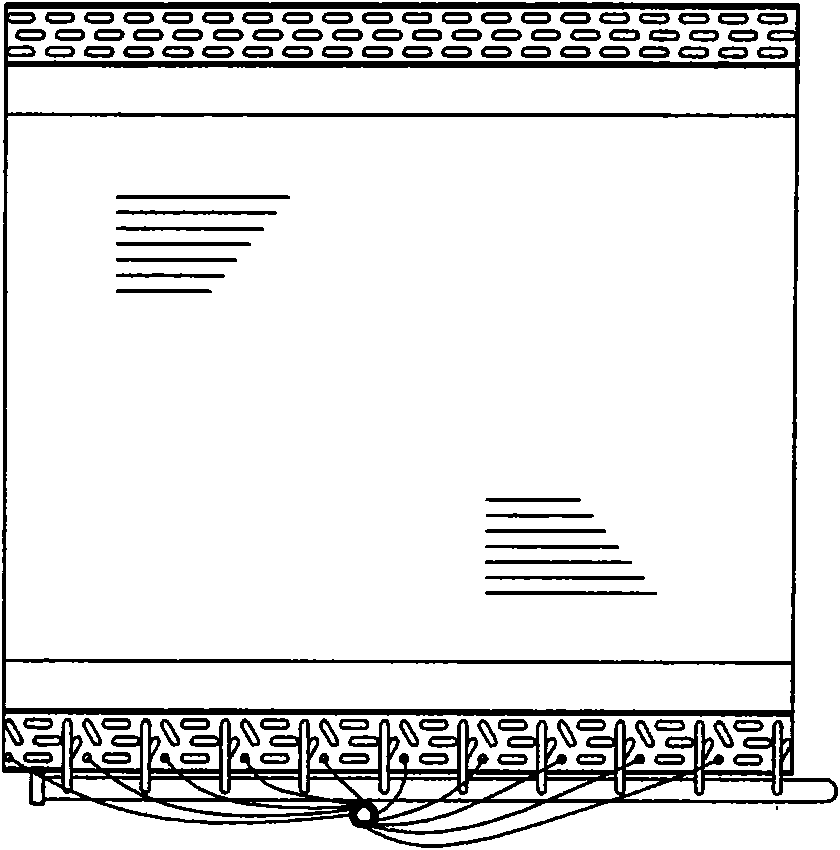

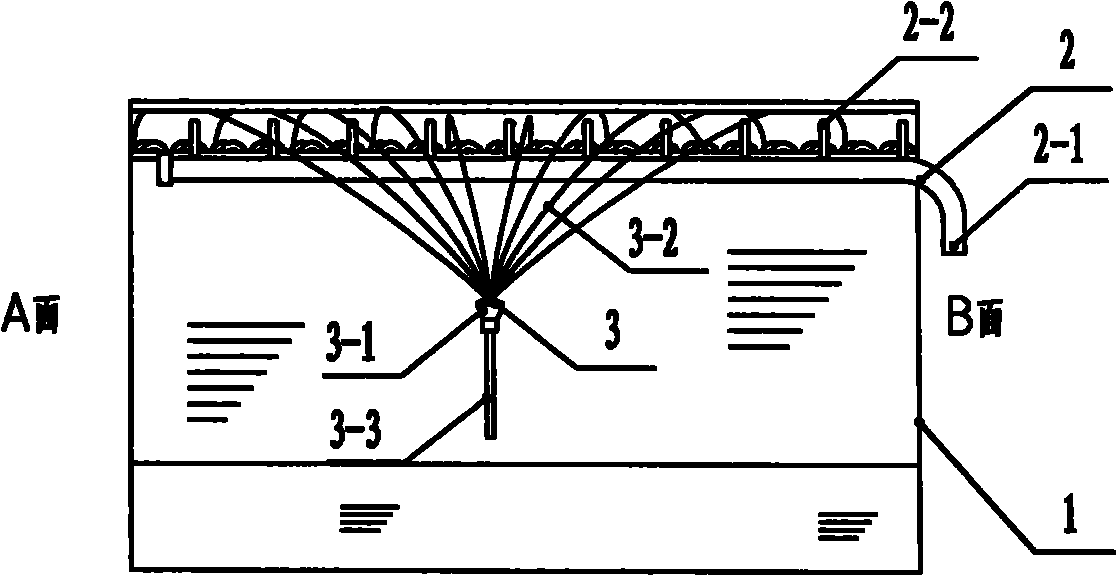

[0019] Such as figure 1 , figure 2 with image 3 As shown, the horizontal U-shaped finned tube heat exchanger includes a U-shaped finned tube heat exchanger 1, an air collecting tube assembly 2, a liquid distributor assembly 3, and an end installed at the upper end of the U-shaped finned tube heat exchanger. Plate I 4. End plate II5. The gas collecting pipe assembly 2 includes a gas collecting pipe 2-1 and a distribution pipe 2-2 welded to the gas collecting pipe; the liquid distributor assembly 3 includes a liquid distributor 3-1, a liquid distributor 3-2 and a liquid distributor connecting pipe 3 -3, where the distributor connecting pipe 3-3 is brazed and connected with the liquid inlet hole below the liquid distributor 3-1, and the liquid distributor pipe 3-2 is brazed and connected with the liquid hole above the liquid distributor 3-1; U-shape The opening of the fin tube heat exchanger 1 is upward, and the gas collector assembly 2 is placed horizontally. The gas collector ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com