Gas guide device used for freeze dryer condenser

A technology of diversion device and condenser, which is applied in the direction of evaporator/condenser, drying solid materials, and drying solid materials without heating, etc. It can solve the problems of uneven frosting of the condenser and reduce the condensation capacity of the condenser, etc., to achieve The diversion effect is remarkable, the ability to avoid condensation, and the effect of uniform diversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

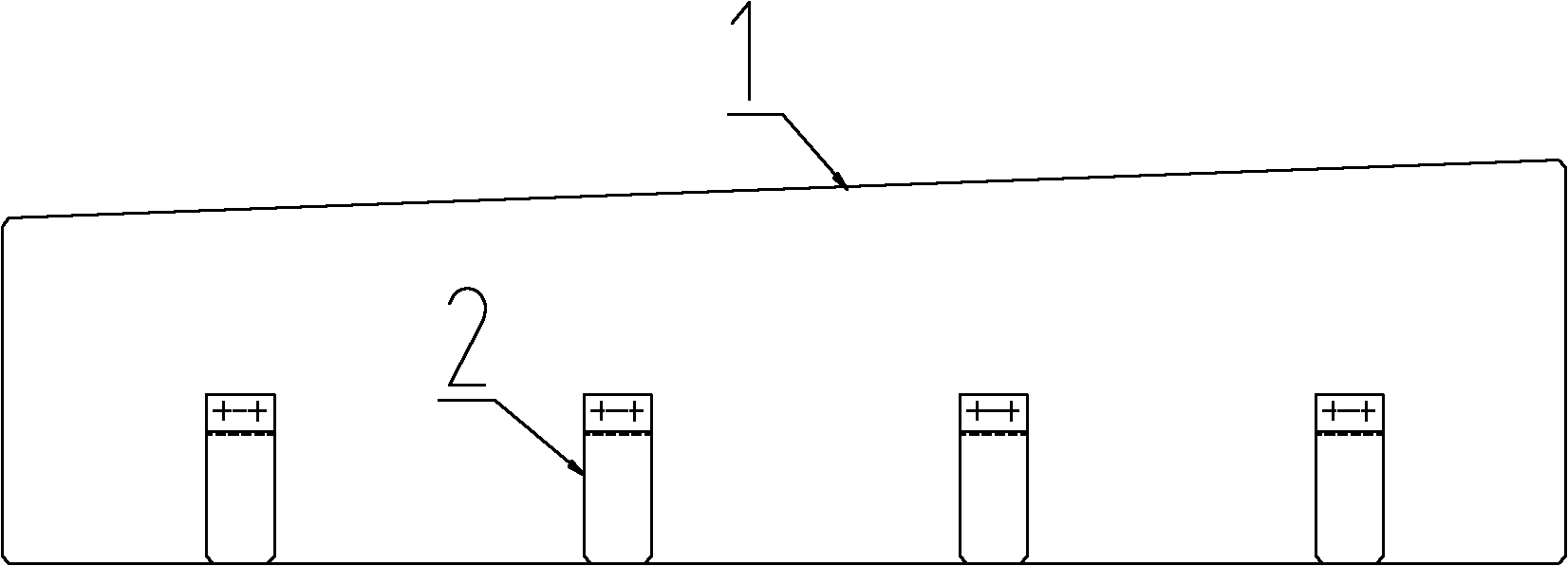

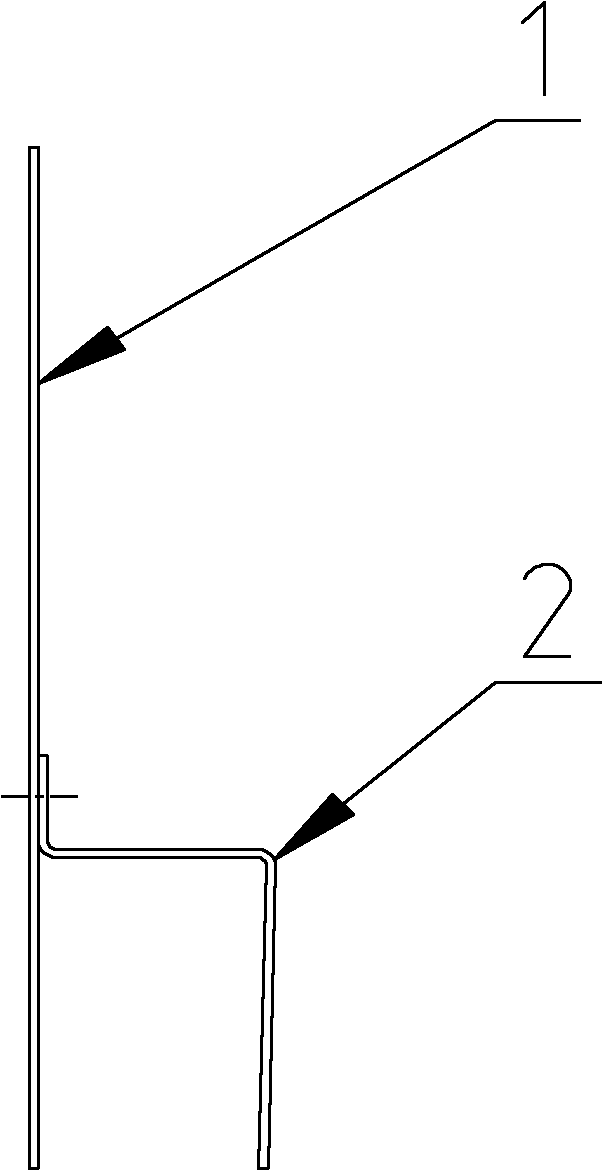

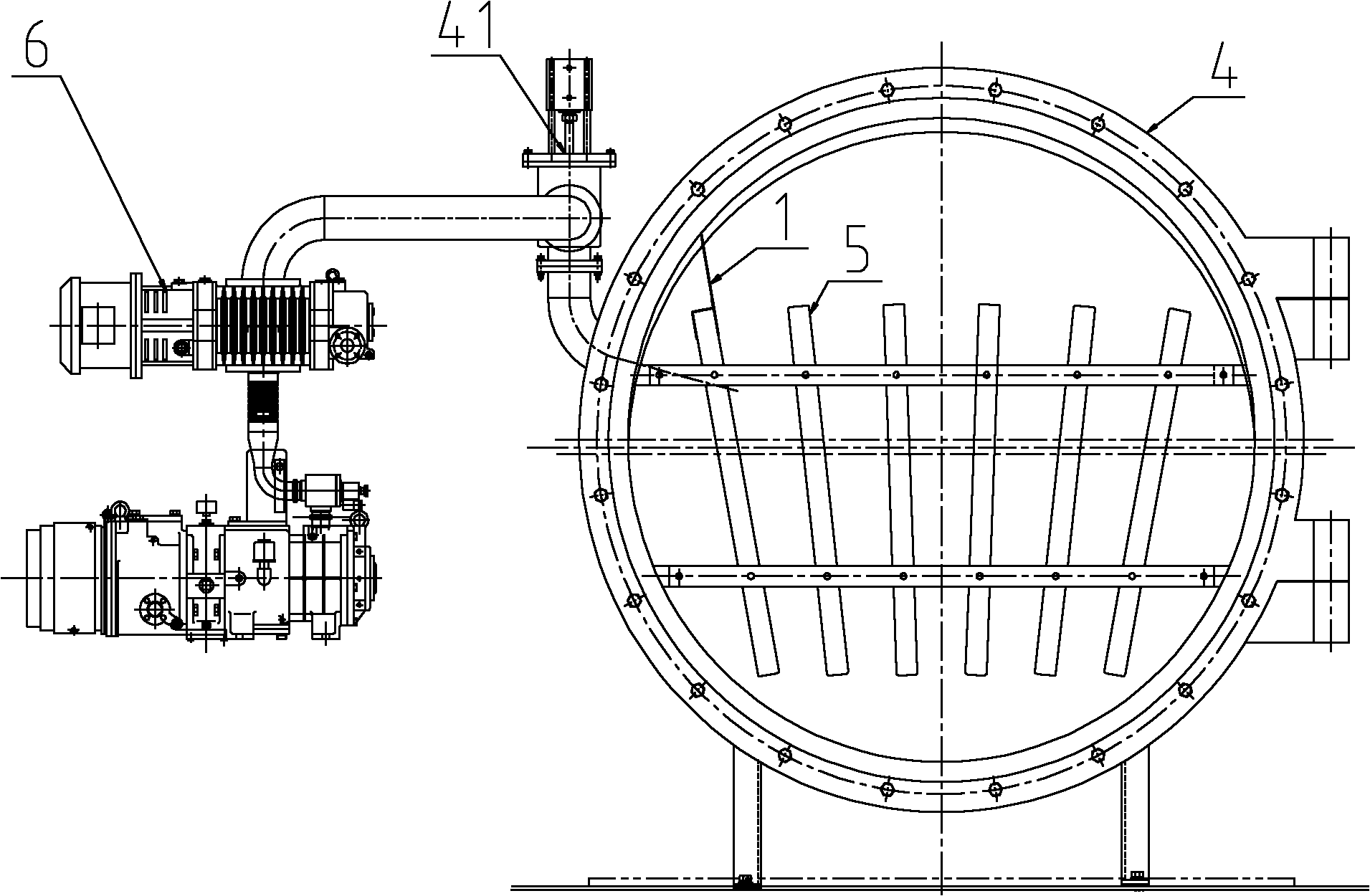

[0013] see Figure 1 to Figure 3 , the present invention, a gas guide device for the condenser of a lyophilizer, the condenser includes a cylinder 4 and several triple heat exchange plates 5 arranged in the cylinder 4 in a fan shape, and the cylinder 4 It is connected to the external vacuum pump 6 through pipeline one, and the pipeline is provided with a vacuum pumping port 41 . The gas deflector device includes a deflector 1 and a number of bent fixed plates 2 evenly distributed on one side of the deflector 1, and forms a clamping structure with an H-shaped cross section to be clamped in a position close to the vacuum. On the triple heat exchange plate 5 of the suction port 41, the width of the opening end of the clamping structure matches the thickness of the triple heat exchange plate 5, and the deflector 1 abuts against one side of the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com