Capacity adjusting control method of multi-nose screw compressor

A screw compressor and capacity adjustment technology, which is applied in the direction of machines/engines, mechanical equipment, liquid fuel engines, etc., can solve problems such as poor lubrication, lower compressor lubricating oil level, lower refrigerant flow rate, etc., to achieve good oil return and improved The effect of quality of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

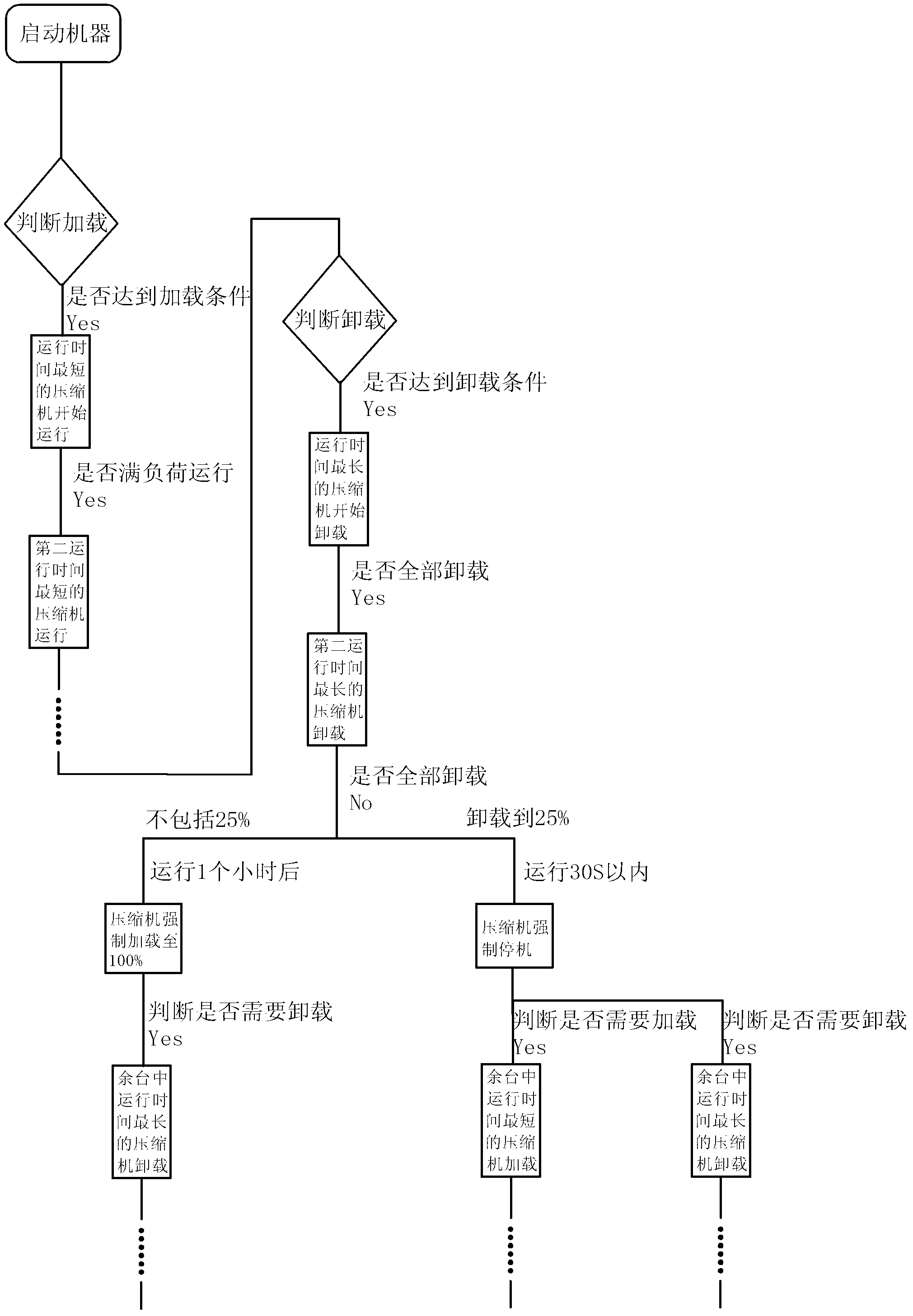

[0022] Such as figure 1 As shown, the multi-head screw compressor capacity adjustment control method includes the following operating steps:

[0023] (1) When the multi-head equipment is turned on and running, judge whether its load needs to be loaded;

[0024] (2) Loading operation, first detect the running time of each compressor;

[0025] (3) The compressor with the shortest running time is used as the first compressor to start, so that the compressor is first started and loaded from 25%-50%-75%-100% full load;

[0026] (4) Continue to judge whether it is running at full load. If it still needs to be loaded, start the second compressor with short running time and load it from 25%-50%-75%-100%;

[0027] (5) Load the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com