Novel laser welding piston with forged steel structure

A technology of laser welding and forging steel, applied in pistons, engine components, machines/engines, etc., it can solve the problems of controlling or reducing oil consumption without a clear structural plan, achieving small deformation, increasing flexibility, and increasing structural rigidity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

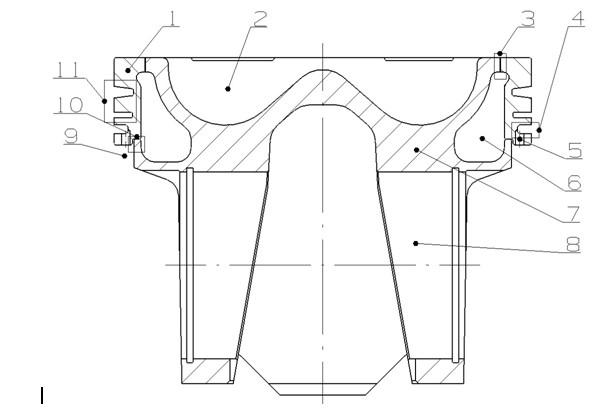

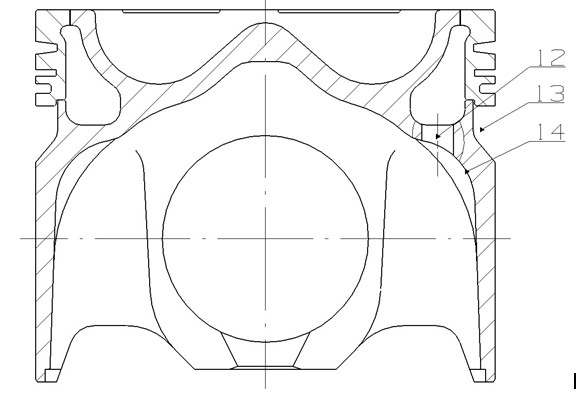

[0025] as attached figure 1 , figure 2 As shown, the new laser welded forged steel structure piston includes forged piston ring body 1 and piston body 7. The piston ring body 1 and piston body 7 are first combined through the welding area 3 and the mating area 10, and the The welding area 3 is welded and formed; the upper part of the piston body 7 is processed to form the combustion chamber 2, and the outer circle of the piston ring body 1 is processed to form a ring groove (including the lower oil ring groove 4 and several gas ring grooves 11 in the upper part). A closed cooling oil cavity 6 is formed between the combustion chamber 2, and the cooling oil cavity 6 communicates with the outside or the inner cavity 14 through the oil inlet and outlet holes 12, and the position where the side of the piston body 7 contacts the piston ring body 1 is processed with an annular groove 9 , There is a ring belt between the oil ring groove 4 and the ring groove 9, and a number of Ge oi...

Embodiment 2

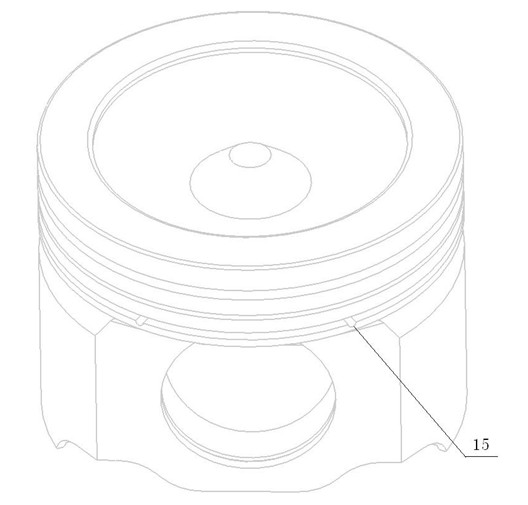

[0033] In this embodiment, several oil return blind holes 15 can also be designed, and the oil return blind holes 15 are arranged on the lower side of the oil ring groove 4. The centerline of the oil return blind holes 15 is on the lower side of the oil ring groove 4 or higher than the oil On the lower side of the ring groove 14, the axial direction of the oil return blind hole 15 is perpendicular to the centerline of the piston. Oil at the oil ring groove 4, especially at the bottom, flows back into the annular groove 9 through the oil return blind hole 15 on the lower side of the oil ring groove 4 and the ring belt with a smaller diameter. The rest are the same as in Embodiment 1 and will not be repeated here.

Embodiment 3

[0035] The difference from Embodiment 1 is that: under the piston ring groove, the annular groove 9 processed above the piston body 7 communicates with the piston inner cavity 14 in the direction perpendicular to the pin hole 8 .

[0036] The rest are the same as in Embodiment 1, and will not be repeated here.

[0037]

[0038]

[0039]

[0040]

[0041]

[0042]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com