Supercharged gasoline direct-injection engine piston ring set

A gasoline engine and piston ring technology, applied in the field of engine parts, can solve problems that are difficult to meet engine reliability and durability requirements, local abnormal wear, opening shrinkage, etc., and achieve good oil return and self-cleaning capabilities, high compliance, Effect of reducing frictional power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] Example: see Figure 1 to Figure 5 .

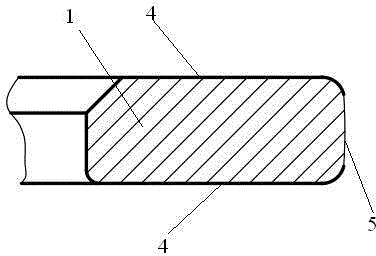

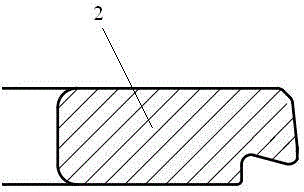

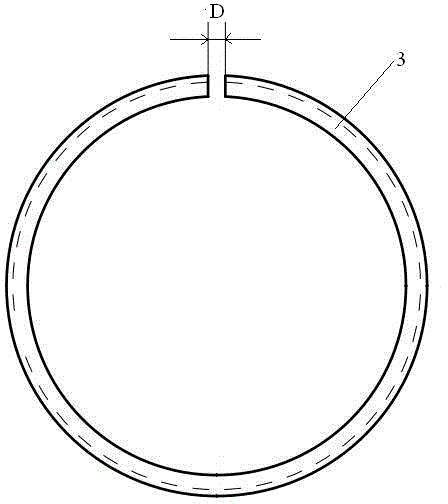

[0023] A piston ring set for a supercharged direct injection gasoline engine, including a first gas ring 1, a second gas ring 2 and an oil ring assembly 3, the cross section of the first gas ring 1 is barrel-shaped, and the second gas ring 2. The cross-section is nose-shaped conical ring, and the oil return hole 6 on the ring of the oil ring joint 3 is in the shape of a long hole.

[0024] There is a nitride layer on the ring body surface of the first gas ring 1 , and there is a PVD layer besides the nitride layer on the outer circular surface 5 .

[0025] The thickness of the nitride layer on the upper and lower end surfaces 4 of the first gas ring 1 is greater than 0.01 mm, the thickness of the nitride layer on the outer surface 5 is greater than 0.03 mm, and the thickness of the PVD layer outside the nitride layer is greater than 0.01 mm.

[0026] The closing gap D of the second air ring 2 is 0.5-0.65 mm.

[0027] The oil ret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com