Trans-critical carbon dioxide refrigeration method and device thereof

A carbon dioxide and refrigeration method technology, which is applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of low refrigeration energy efficiency and small refrigeration capacity, and achieve the goal of increasing internal volume, large cooling range, and odorless latent heat of evaporation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

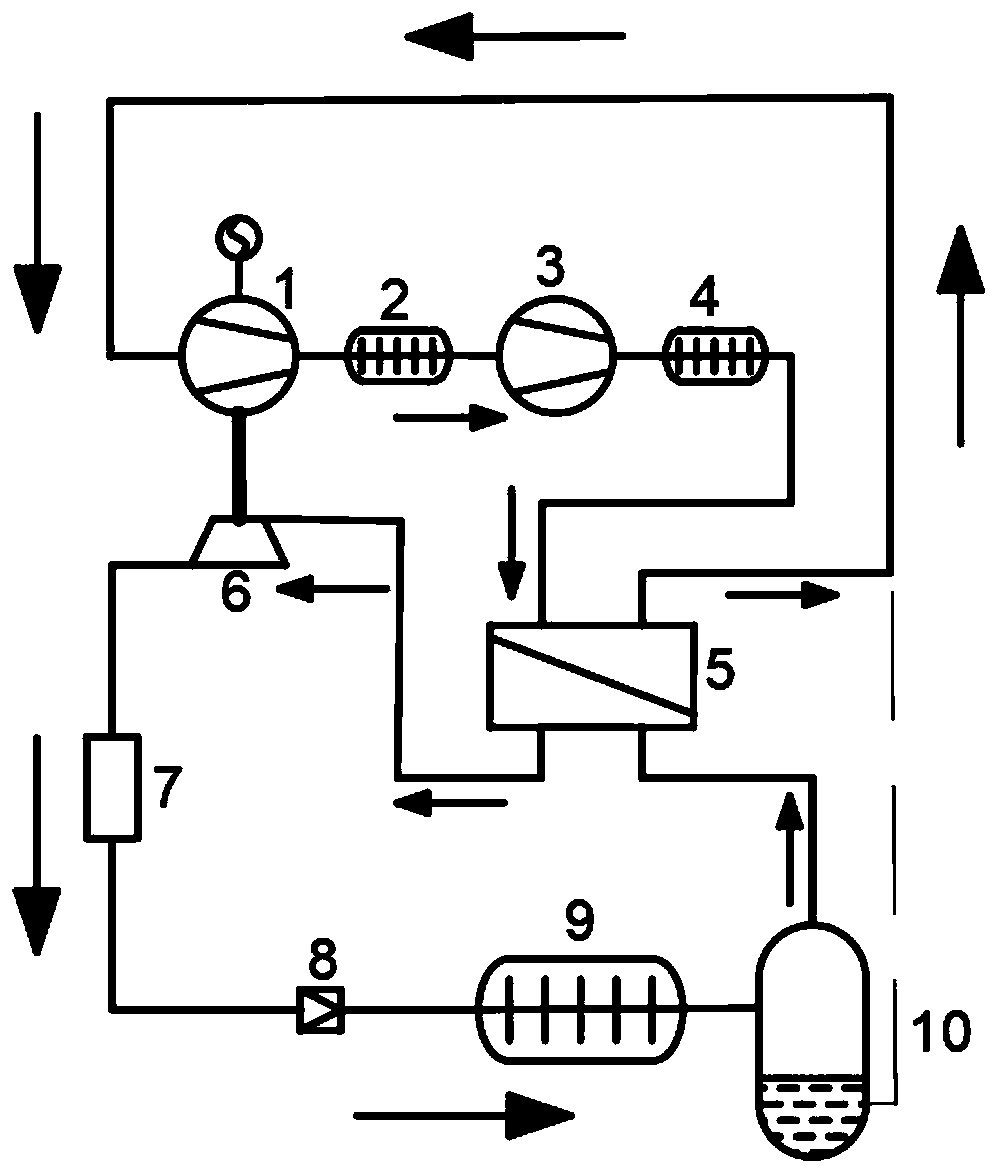

[0045] see figure 1 As shown, the present embodiment provides a transcritical carbon dioxide refrigeration method, which specifically includes the following steps:

[0046] (1) After the superheated carbon dioxide vapor flowing through the low-pressure side of the internal regenerator is pressurized by the first compressor 1 to perform a compression treatment, the first gas cooler 2 is used to perform a cooling treatment; specifically, the low-pressure superheated carbon dioxide vapor is The first compressor 1 is compressed to a subcritical state (temperature T 1 , pressure P 1 ), then enter the first gas cooler 1 and be cooled by the cooling medium (temperature T 2 );

[0047] (2) After the subcritical carbon dioxide that enters the first gas cooler 1 for primary cooling is pressurized by the second compressor 2 for secondary compression, the second gas cooler 4 is used for secondary cooling; CO after cooler 2 2 The gas is compressed to a supercritical state (temperature...

Embodiment 2

[0058] see figure 1 As shown, this embodiment provides a transcritical carbon dioxide refrigeration device based on the refrigeration method described in Embodiment 1 above, including a first compressor 1, a first gas cooler 2, a second compressor 3, and a second gas cooler 4. Internal regenerator 5, expander 6, evaporation tank 9 and liquid storage tank 10.

[0059] Such as figure 1 As shown, the low-pressure side of the internal regenerator 5 is connected to the first gas cooler 2 through the first compressor 1 through a pipeline, which is used to transfer the superheated carbon dioxide flowing through the low-pressure side of the internal regenerator 5 Steam is initially compressed into subcritical carbon dioxide, and the temperature is initially lowered by the first gas cooler 2; the first gas cooler 2 is connected to the second compressor 3 and the second gas cooler 4 through pipelines The high-pressure side of the internal regenerator 5 is used for secondary compressio...

Embodiment 3

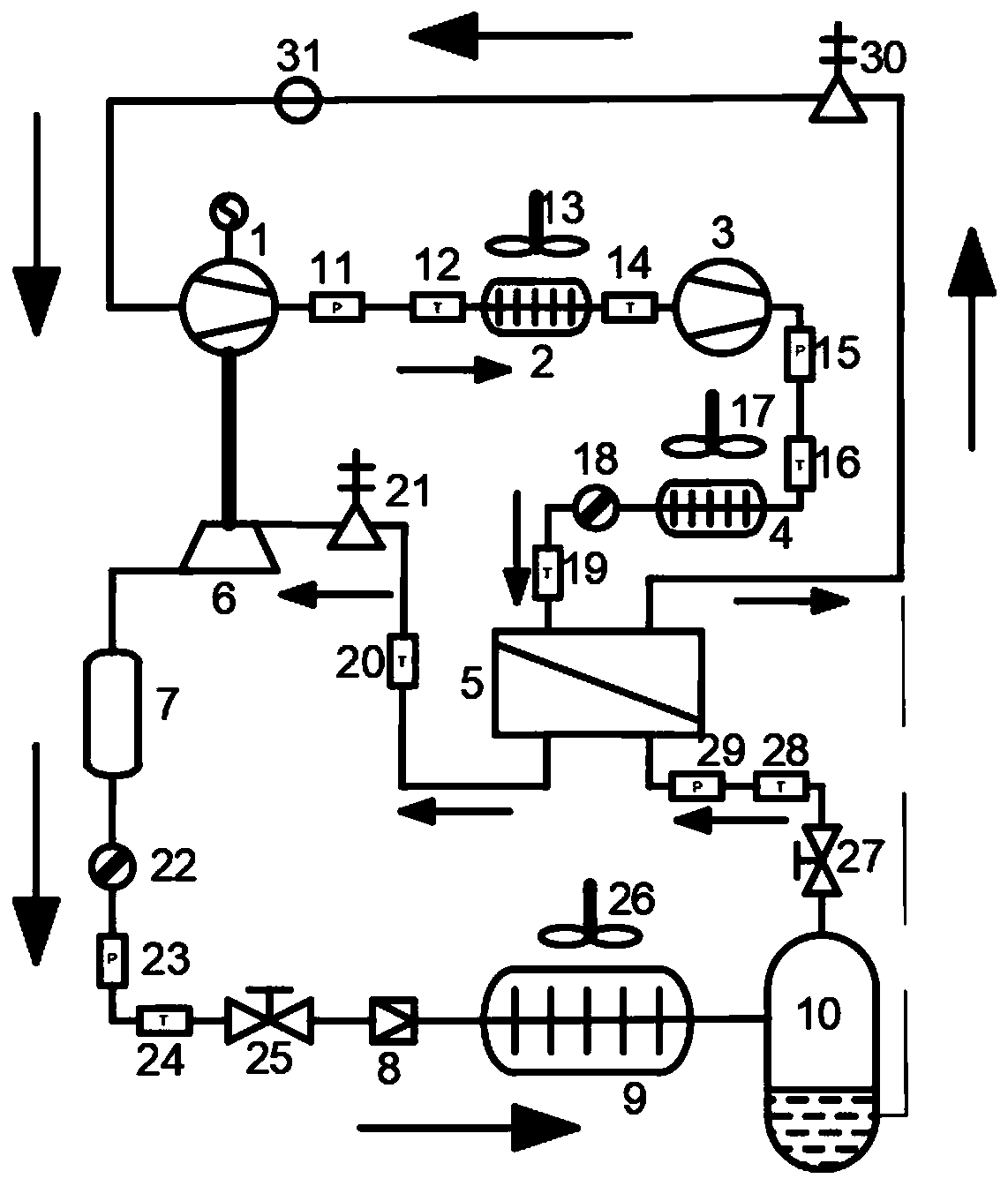

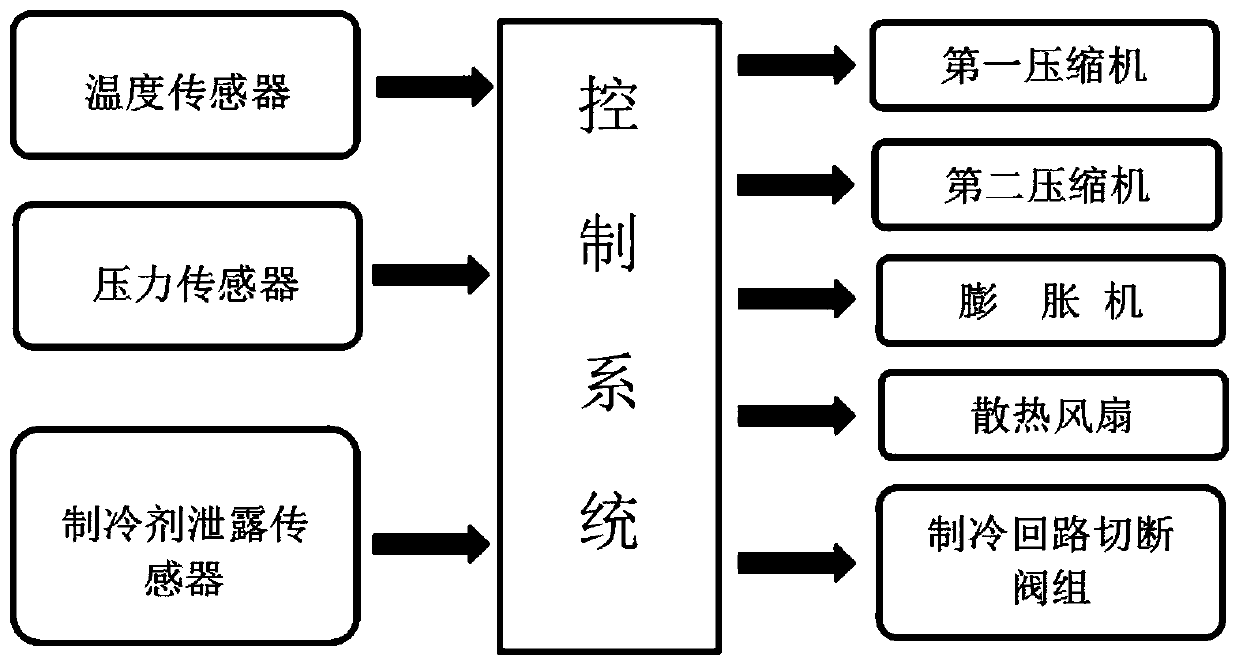

[0066] see figure 2 As shown, this example provides another method for transcritical CO 2 Refrigeration control device, which is used for transcritical CO 2 The cooling control device adds temperature sensors 12, 14, 16, 19, 20, 24, 28 and pressure sensors 12, 15, 23, 29 on the basis of the cooling device described in the above-mentioned embodiment 2; The first filter 18, the second filter 22, the first stop valve 25, the second stop valve 27, the first safety valve 21, the second safety valve 30, the system leak detection device 31 and the first gas cooler 2 and the cooling fan 13,17,26 on the second gas cooler 4 and the evaporator 9.

[0067] In this example, if figure 2 As shown, temperature sensors 12, 14, 16, 19, 20, 24, 28 and pressure sensors 12, 15, 23, 29 are used to collect the temperature and pressure values of each part, and the control system judges and controls the operation status of each part of the device. The refrigeration circuit cut-off valve group ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com