Exhaust-driven turbo-charger central rotor device

A technology of exhaust gas turbine and supercharger, which is applied in the direction of machine/engine, engine sealing, engine components, etc., can solve the problems of unsatisfactory oil film formation effect, unsatisfactory sealing effect, and difficulty in supercharger sealing, and achieves convenient assembly. , The effect of enhancing sealing performance and reducing product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

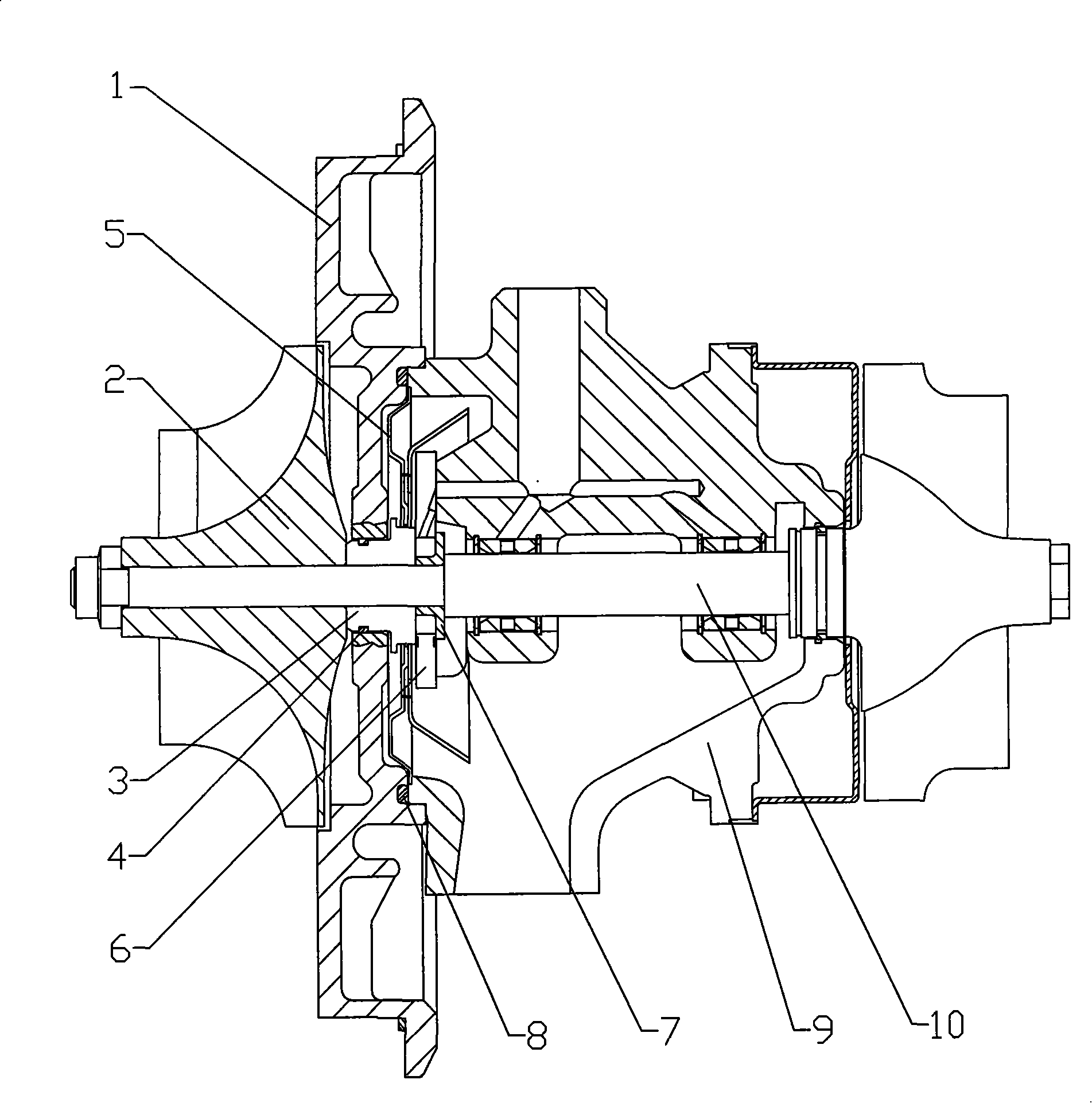

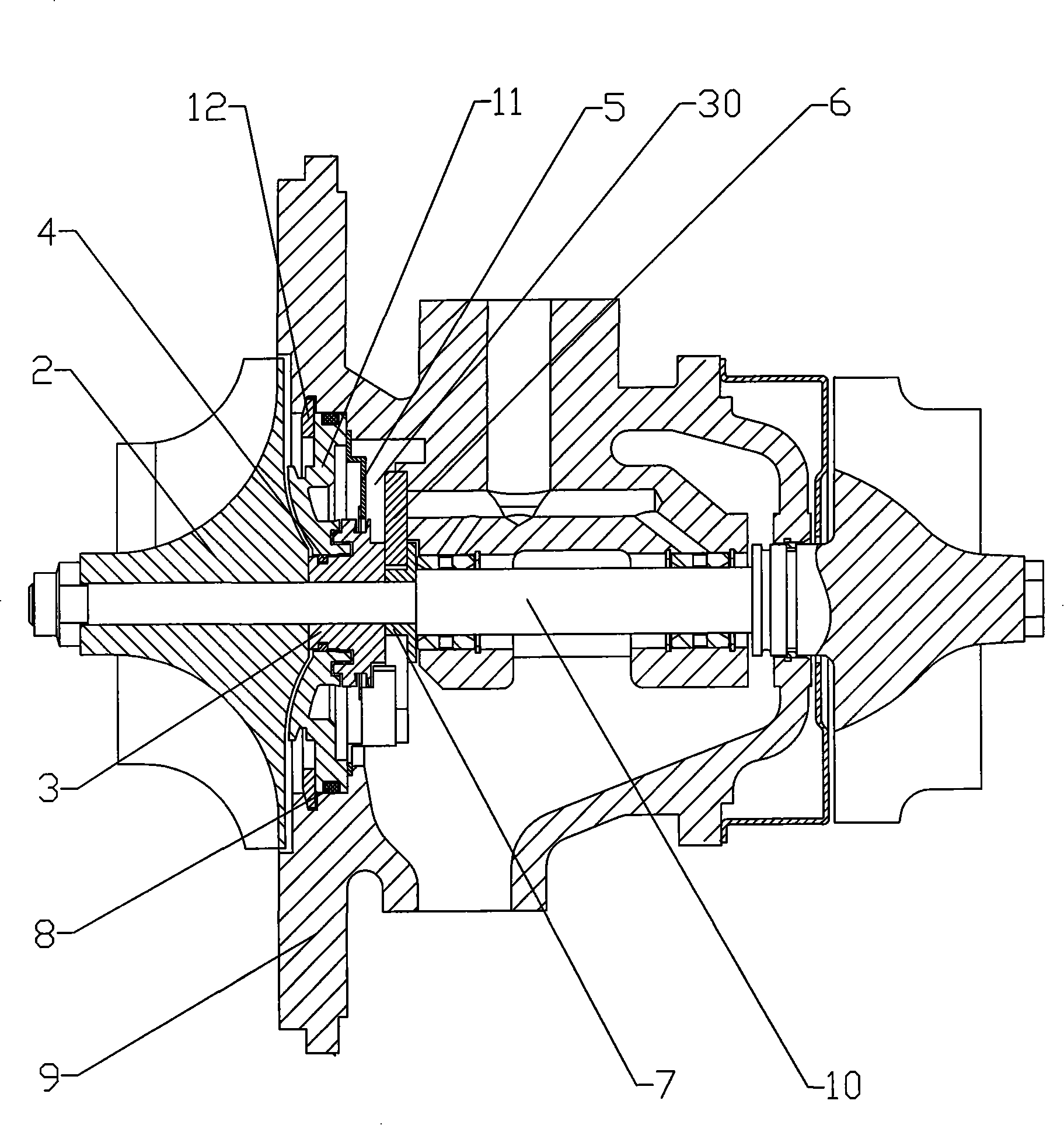

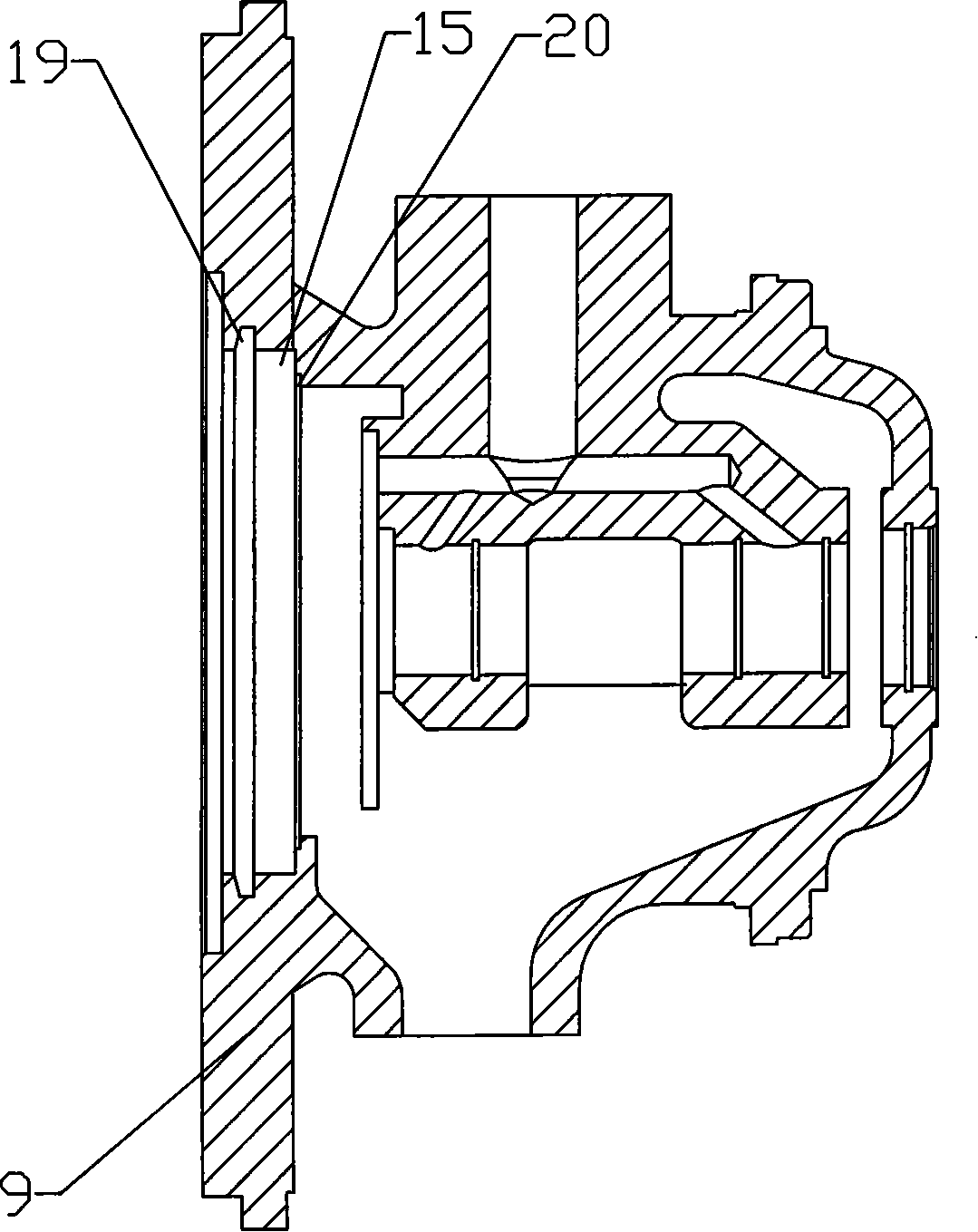

[0030] Examples such as figure 2 , image 3 As shown, a core rotor device of an exhaust gas turbocharger includes an intermediate shell 9, a thrust sleeve 7, a thrust bearing 6, an oil deflector 5, and a shaft seal 3. The thrust sleeve 7 is arranged on the turbine shaft 10, and The thrust bearing 6 is arranged on the thrust sleeve 7, the impeller 2 is arranged on the turbine shaft 10 at one end of the shaft seal 3, and the intermediate shell 9 at one end of the impeller 2 has a chamber 15, and a sealing ring sleeve 11 is arranged in the chamber 15, The inner wall of the chamber 15 is provided with an annular groove 19, and the annular groove 19 is provided with a circlip 12 for defining the position of the sealing ring housing 11. The circlip 12 is located on the side of the sealing ring housing 11 close to the impeller 2, The middle shell 9 in the chamber 15 is provided with a step 20, the step 20 is located on the side of the seal ring sleeve 11 away from the impeller 2, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com