Novel packer based on ambient pressure

An environmental pressure and packer technology, applied in sealing/packing, wellbore/well components, earth-moving drilling, etc., can solve problems such as high cost, low maintenance cost, and the inability of driving equipment to be used for multiple cycles in the well , to achieve the effect of convenient operation, cost reduction, energy saving and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

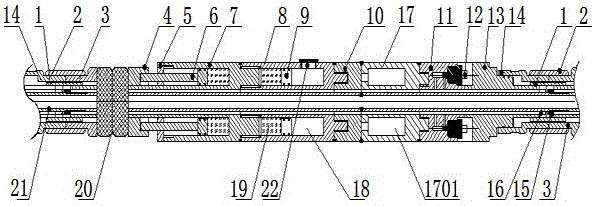

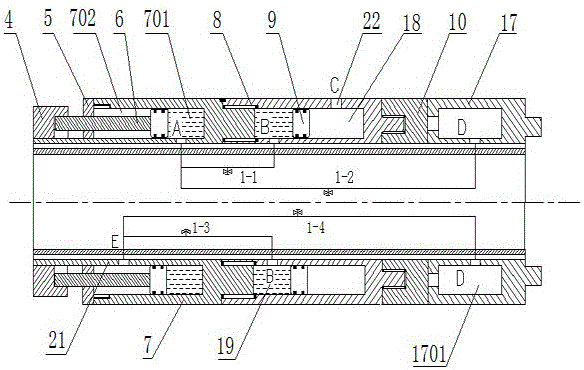

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] As shown in the figure, a new type of packer based on ambient pressure includes: a mandrel 21 fixedly arranged, the upper joint 14 and the lower joint 3 are sleeved on the mandrel 21, one end of the upper joint 14 and the end of the lower joint 3 One end is in close contact and its outer thread is sleeved with a connecting sleeve 2, the inner side of the upper joint 14 and the lower joint 3 are threaded with the mandrel 21 through the inner bushing 2, and the inner bushing plays a role of fastening to keep the cylinder coaxial Spend. The mandrel 21 is also provided with a rubber cartridge seat 4, and a rubber cartridge 20 is arranged between the lower joint 3 and the rubber cartridge seat 4. The rubber cartridge 20 is made of rubber material, which is easily deformed under pressure.

[0024] Also be provided with rear hydrauli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com