Extrusion-type deslagging device for oxygen lance

An extrusion type, oxygen lance technology, applied in the manufacture of converters and other directions, can solve the problems of uncontrollable impact force, unsuitable taper oxygen lances, damage to slag scrapers, etc., and achieves broad prospects for promotion and use, disassembly and maintenance. Convenience and the effect of eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

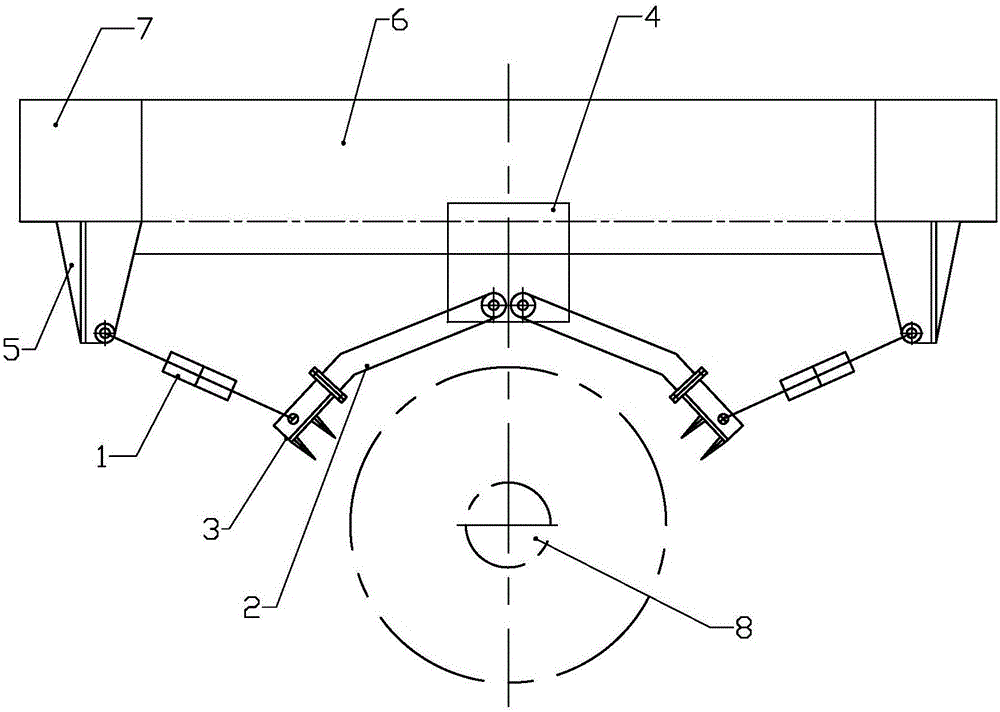

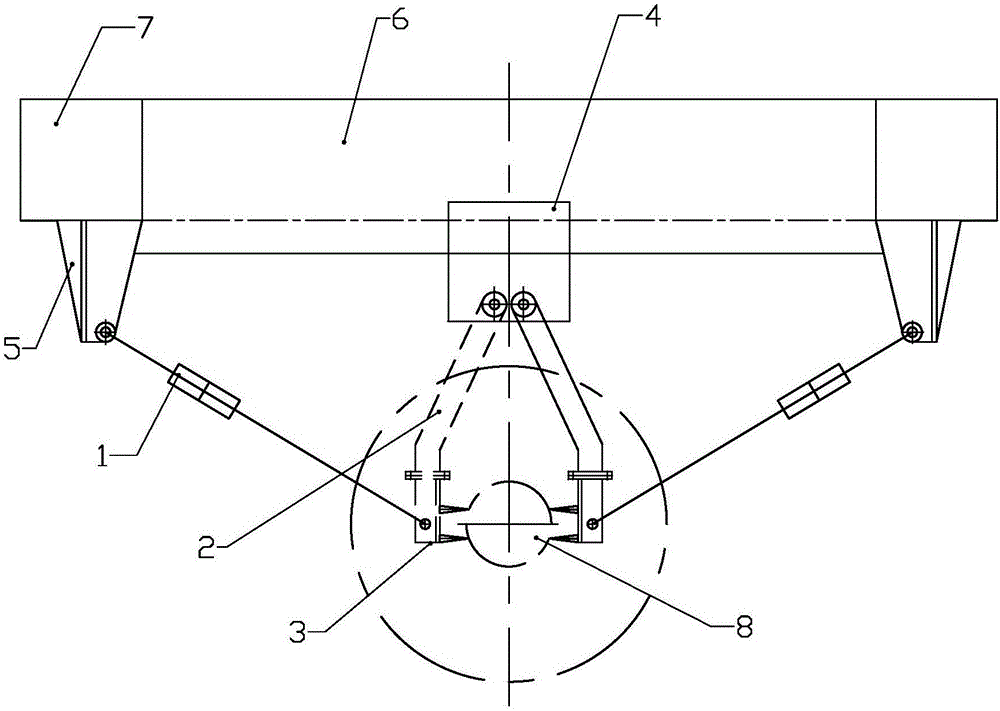

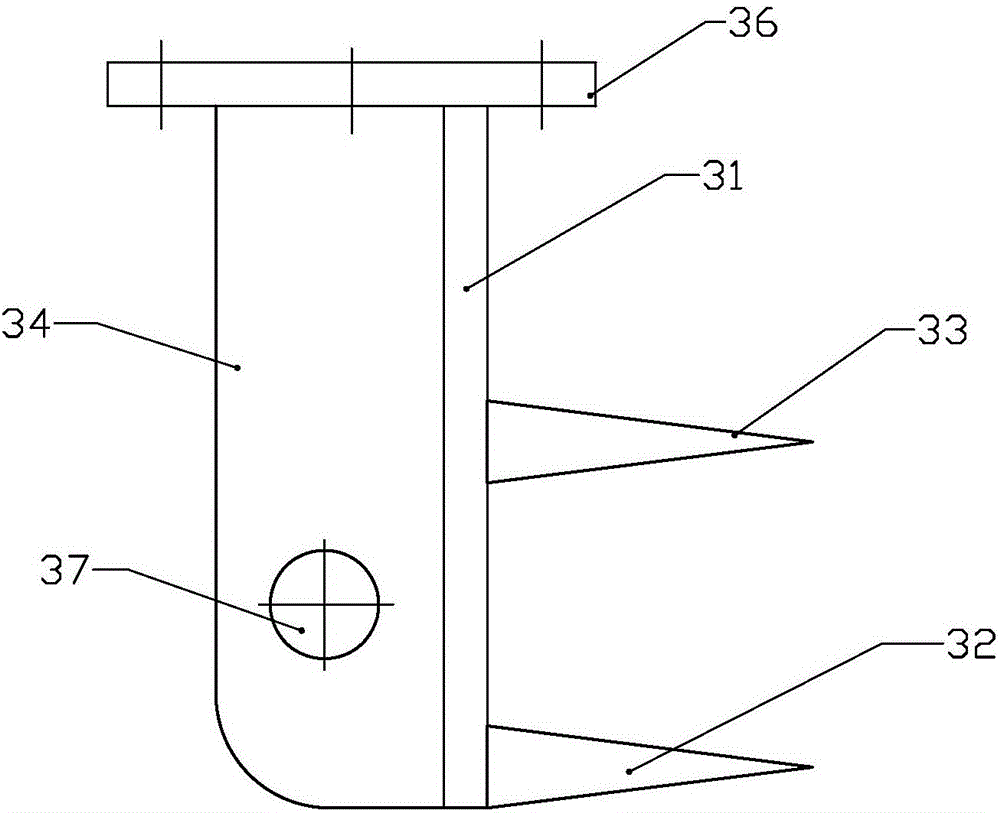

[0024] Refer to the attached figure 1 to attach Figure 10 A kind of extruding oxygen lance deslagging device of the present invention is described in detail below.

[0025] A kind of extruding type oxygen lance slag removal device of the present invention, its structure comprises swing cylinder 1, rotating arm 2, slag removal cutter head 3, fixed support 4 and swing cylinder support 5, described swing cylinder support 5 , swing cylinder 1, rotating arm 2 and slag removal cutter head 3 respectively comprise two, and are arranged symmetrically respectively, and described swing cylinder support 5 links to each other with the oxygen lance track column 7 of oxygen lance track beam 6 two ends respectively, The fixed support 4 is arranged on the oxygen lance track beam 6 in the middle of the two swing cylinder supports 5, each swing cylinder support 5 is hinged with a swing cylinder 1, and the other end of each swing cylinder 1 is connected to the The slag removal cutter heads 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com