Manufacturing method of gecko hair-imitating dry adhesive

A production method and a technology of imitating gecko, which are applied in the production of high aspect ratio micro-nano hierarchical structure, high aspect ratio micro-nano hierarchical structure, and the field of strong dry adhesive, which can solve the complex, cumbersome and wet adhesive of dry adhesive. Adhesives are easy to degrade and difficult to use again, so as to achieve the effect of easy production, overcoming easy degradation and easy desorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

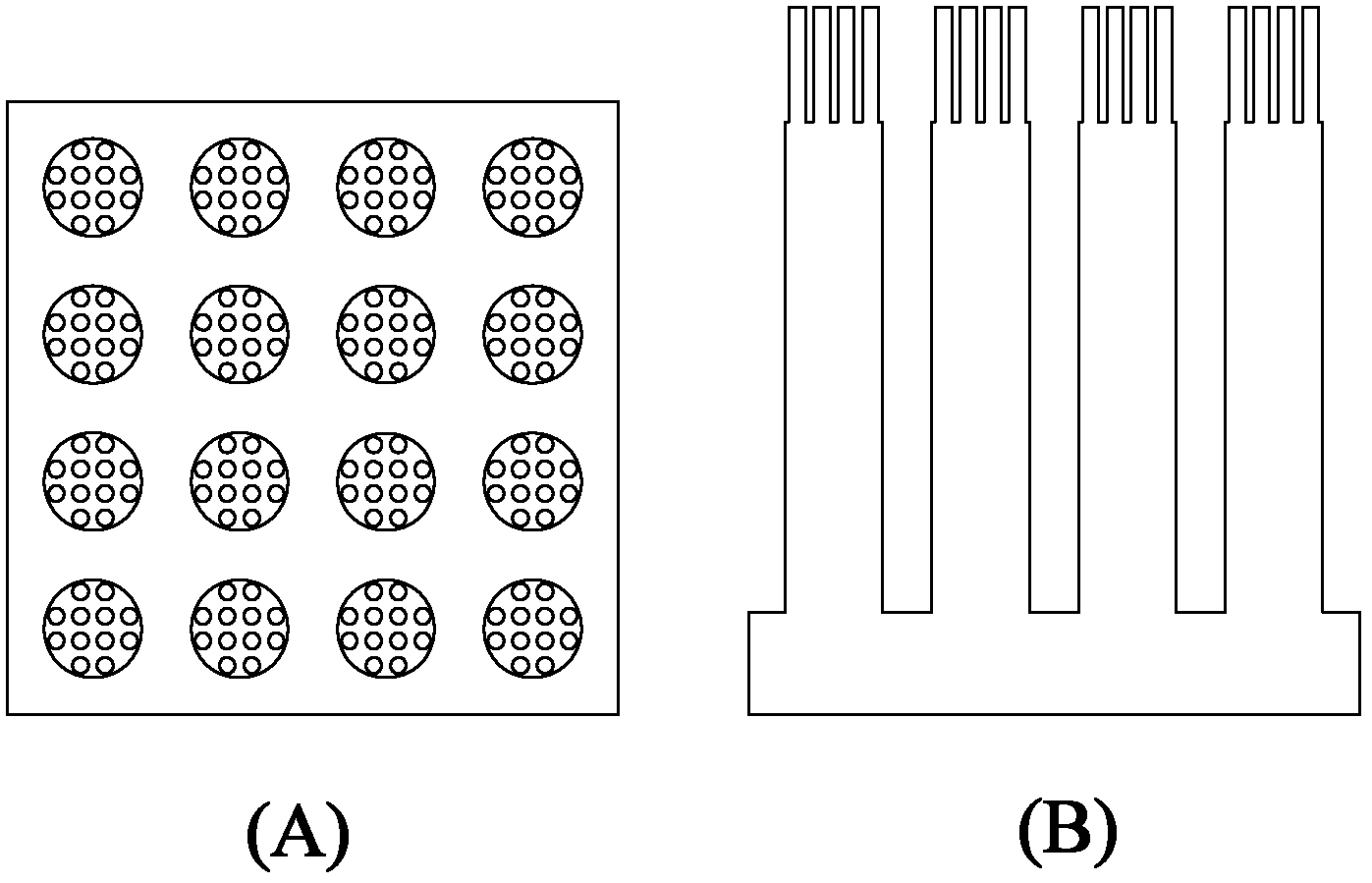

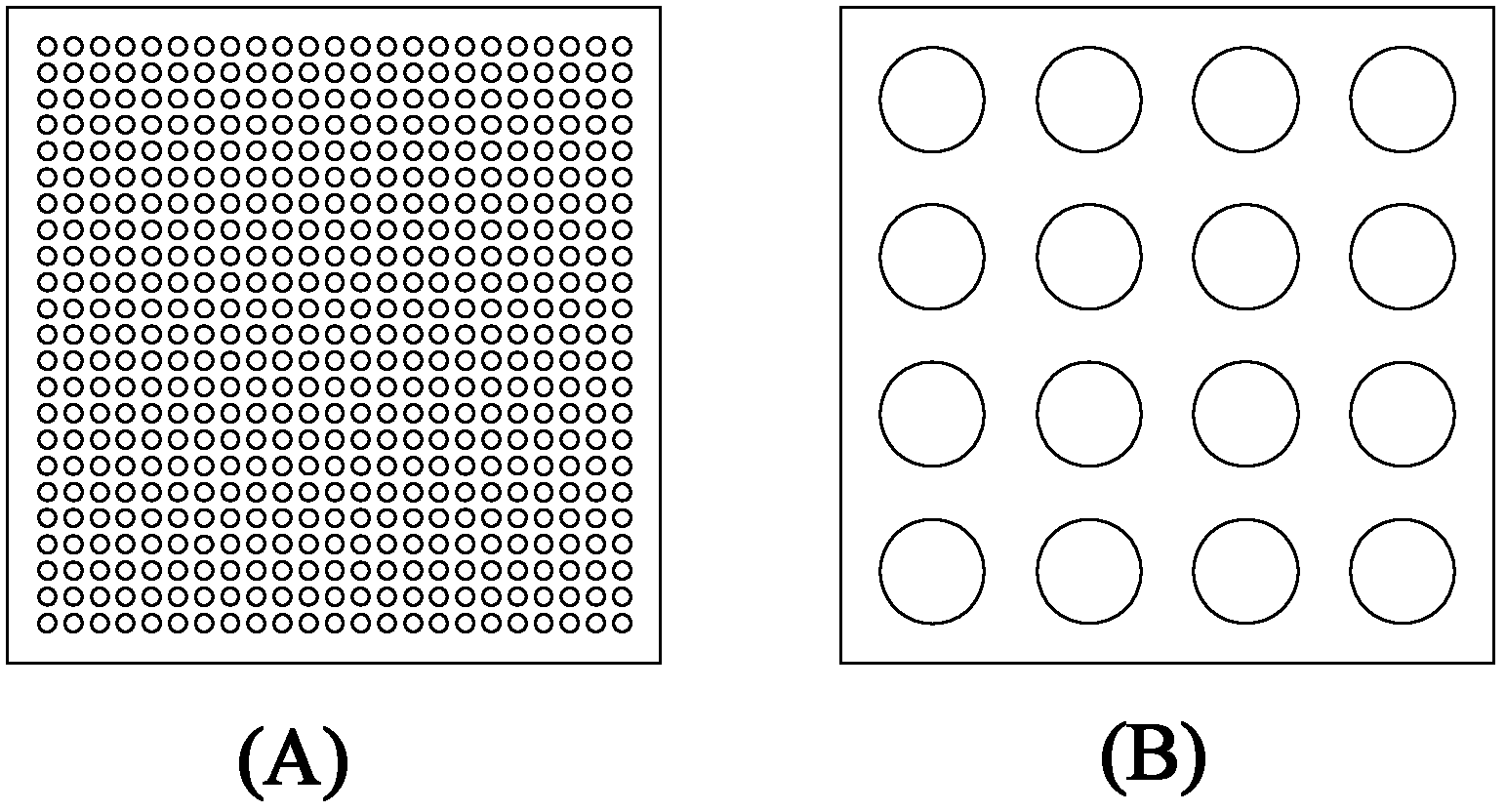

[0032] In the present invention, the diameter of the nanoscale fiber is 0.8 μm, the length is 4 μm, and the spacing is 0.4 μm; the diameter of the micron-scale fiber is 5.2 μm, the length is 30 μm, and the spacing is 5.2 μm. The specific implementation steps are as follows:

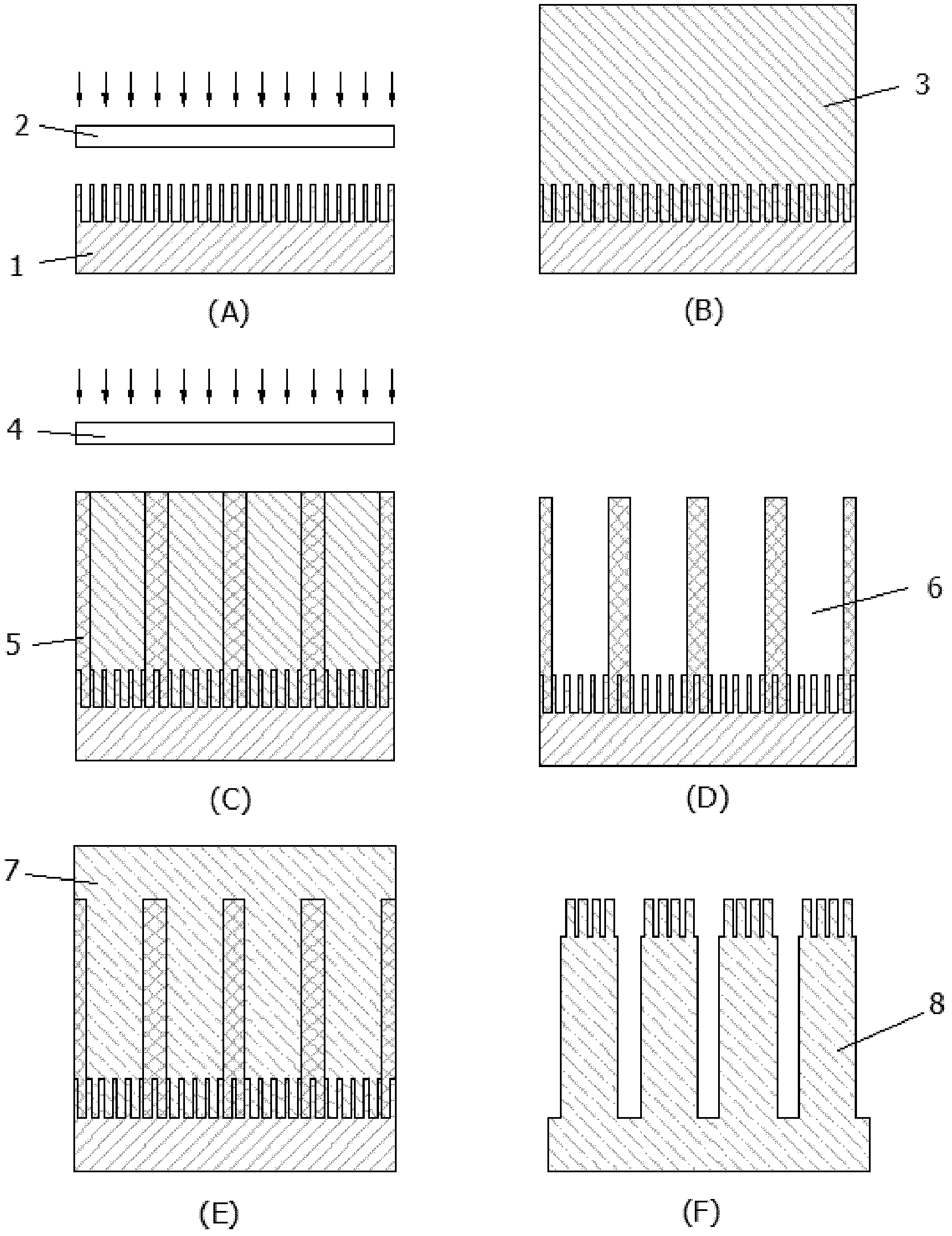

[0033] (1).ICP etching silicon motherboard:

[0034] like image 3 As shown in (A), the silicon motherboard 1 is first cleaned by the RCA cleaning method, and then etched by the ICP process. The pattern distribution of the mask plate 2 used for etching is the set nano-scale fiber array distribution, and the etching depth is 4 μm. ; Finally soak the silicon motherboard with a film remover, remove the photoresist on the surface, rinse with pure water, and blow dry with nitrogen to obtain a silicon motherboard 1 with a deep hole array;

[0035] (2). Uniform glue:

[0036] like image 3 As shown in (B), put the silicon motherboard 1 with a deep hole array on the coating machine, and spin-coat SU-8 photore...

example 2、3

[0046] According to the steps of Example 1, the dry adhesive imitating gecko hair can be prepared by using the parameters in the following table.

[0047]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com