Anti-scratch, fold-resistant and solvent-resistant thermosetting transferring system paint and preparation method thereof

A solvent-resistant and folding-resistant technology, which is applied in coatings and other directions, can solve the problems of high surface flatness of coatings, poor operability, and unusable ingredients, etc., and achieve simple production and preparation, improved solvent resistance, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

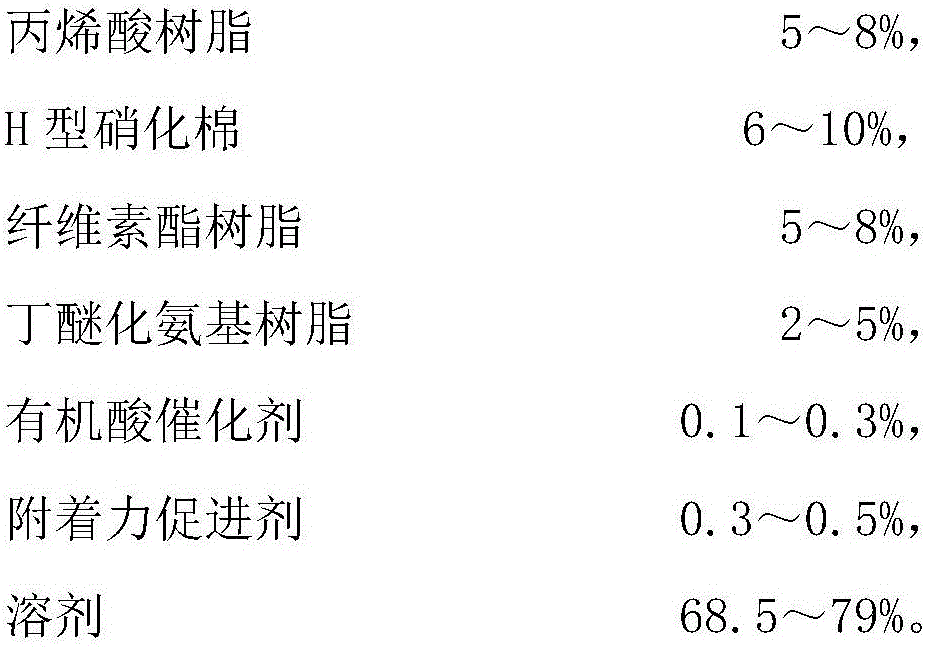

[0035] This embodiment relates to a coating composition of a thermosetting transfer system with abrasion resistance, folding resistance and solvent resistance, including the components and weight content shown in Table 1:

[0036] Table 1

[0037]

[0038] The preparation of the rubbing-resistant, folding-resistant, solvent-resistant thermosetting transfer system coating of the present embodiment is as follows:

[0039] (1) Put the solvent in the reaction kettle according to the recipe, turn on the stirring and heating device, mix the solvent evenly, and keep the temperature at 50°C;

[0040] (2) Next, put each resin component into the reaction kettle, control the stirring rate to 150-250 rpm, and stir for 1-5 hours to fully dissolve the resin components;

[0041] (3) After each resin component is completely dissolved, put the adhesion promoter and acid catalyst into the reaction kettle, control the stirring rate to 100-150rpm, and 20min to fully disperse, and finally, use...

Embodiment 2

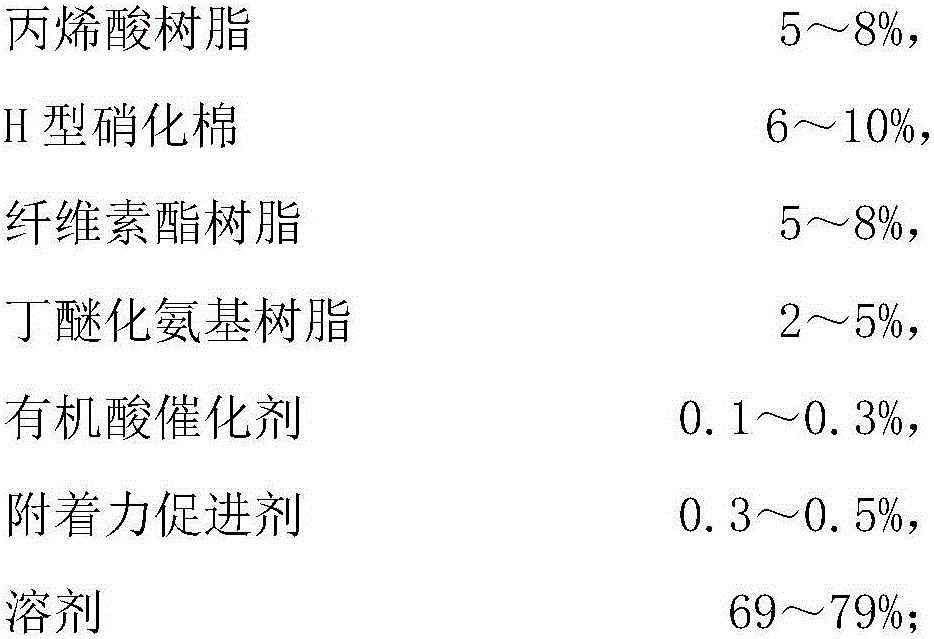

[0043] This embodiment relates to a thermosetting transfer system coating composition with abrasion resistance, folding resistance and solvent resistance, including the components and weight content shown in Table 2:

[0044] Table 2

[0045]

[0046] The preparation of the rubbing-resistant, folding-resistant, solvent-resistant thermosetting transfer system coating of the present embodiment is as follows:

[0047] (1) Put the solvent in the reaction kettle according to the recipe, turn on the stirring and heating device, mix the solvent evenly, and keep the temperature at 50°C;

[0048] (2) Next, put each resin component into the reaction kettle, control the stirring rate to 150-250 rpm, and stir for 1-5 hours to fully dissolve the resin components;

[0049] (3) After each resin component is completely dissolved, put the adhesion promoter and acid catalyst into the reaction kettle, control the stirring rate to 100-150rpm, and 20min to fully disperse, and finally, use 250 ...

Embodiment 3

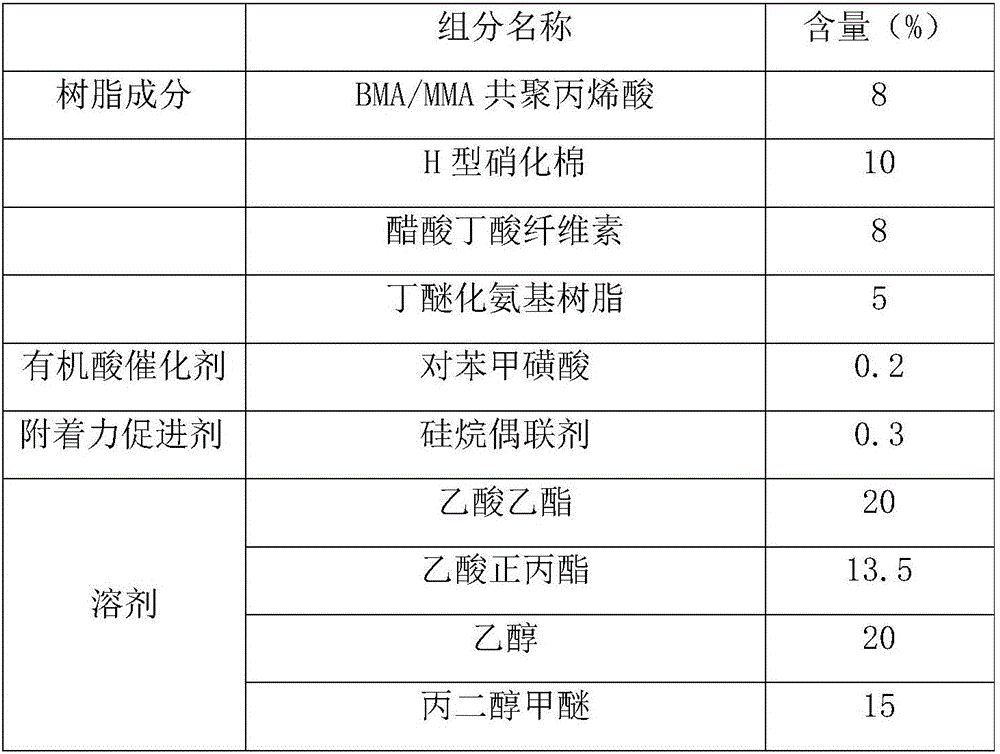

[0051]This embodiment relates to a thermosetting transfer system coating composition with abrasion resistance, folding resistance and solvent resistance, including the components and weight content shown in Table 3:

[0052] table 3

[0053]

[0054] The preparation of the rubbing-resistant, folding-resistant, solvent-resistant thermosetting transfer system coating of the present embodiment is as follows:

[0055] (1) Put the solvent in the reaction kettle according to the recipe, turn on the stirring and heating device, mix the solvent evenly, and keep the temperature at 50°C;

[0056] (2) Next, put each resin component into the reaction kettle, control the stirring rate to 150-250 rpm, and stir for 1-5 hours to fully dissolve the resin components;

[0057] (3) After each resin component is completely dissolved, put the adhesion promoter and acid catalyst into the reaction kettle, control the stirring rate to 100-150rpm, and 20min to fully disperse, and finally, use 250 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com