Alcohol water-soluble modified epoxy composite glue and preparation thereof

A water-soluble composite and water-soluble technology, applied in the direction of adhesives, adhesive types, adhesive additives, etc., can solve the problems of iron equipment corrosion, unfavorable packaging and transportation, and low adhesion, achieving low production costs and reduced Drying speed and adhesion fastness, the effect of short curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

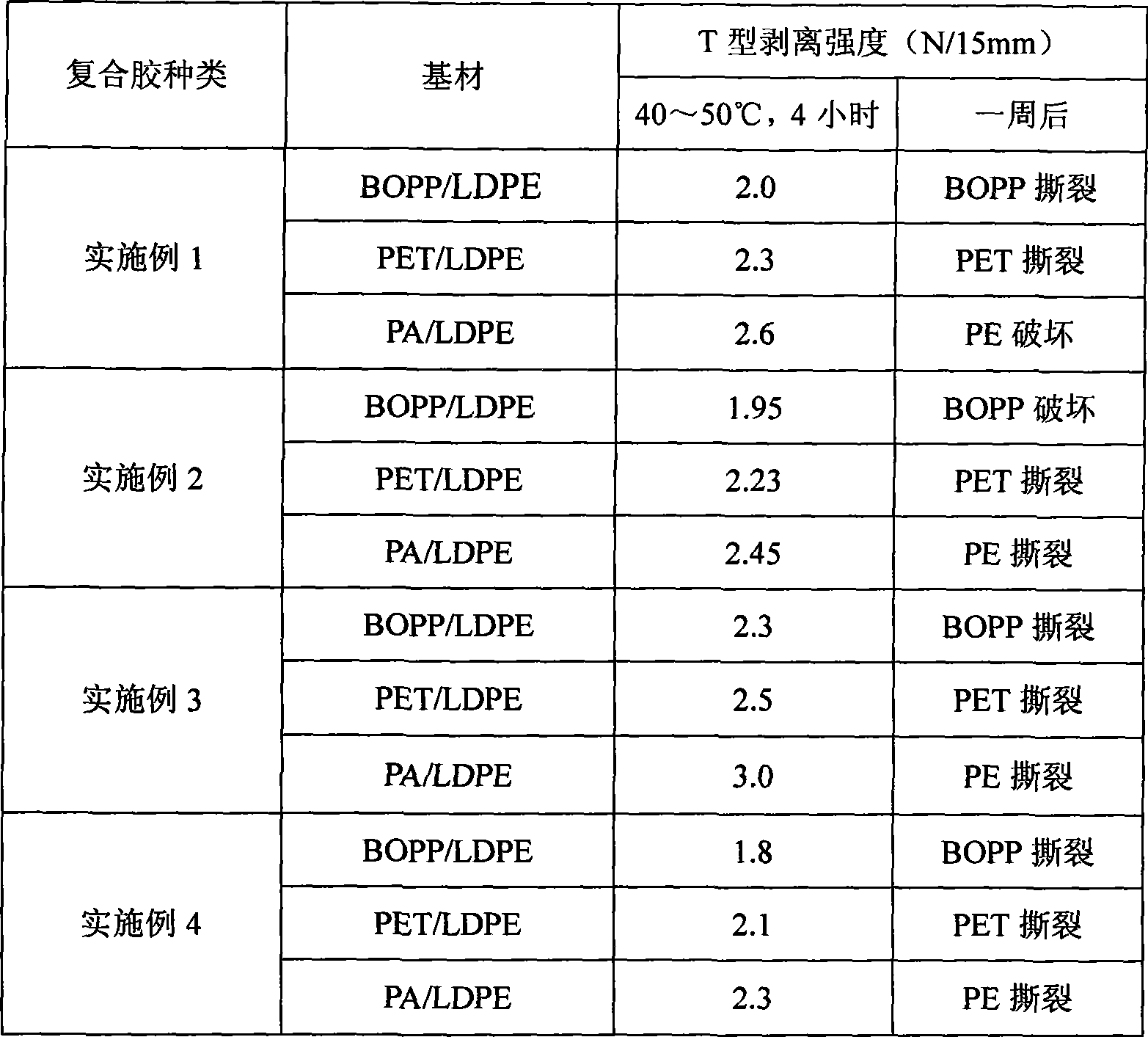

Examples

Embodiment 1

[0052] Embodiment 1: Preparation example of alcohol water-soluble modified epoxy composite glue

[0053] (1) Preparation of alcohol water-soluble modified epoxy resin copolymer:

[0054]In the reaction kettle equipped with stirring device, reflux condenser, heating temperature control and dropping device, add the mixed solution consisting of the following components in sequence. First add component A into the reaction kettle, stir and heat up to the reflux temperature of 75°C; slowly add component B into the reaction kettle for a total of 6 hours, and continue to react at 75°C for 1 hour after the dropwise addition; Slowly add component C diluent into the kettle, cool and discharge. 135 kg of alcohol water-soluble modified epoxy resin copolymers with a solid content of 73% were obtained.

[0055] A component: vinyl acetate 15kg

[0056] Ethanol or isopropanol 15kg

[0057] B component: vinyl acetate 10kg

[0058] 90% acrylic acid-epoxy adduct 20kg

[0059...

Embodiment 2

[0076] Embodiment 2: Preparation example of alcohol water-soluble modified epoxy composite glue

[0077] (1) Preparation of alcohol water-soluble modified epoxy resin copolymer:

[0078] In the reaction kettle equipped with stirring device, reflux condenser, heating temperature control and dropping device, add the mixed solution consisting of the following components in sequence. First add component A into the reaction kettle, stir and heat up to the reflux temperature of 70-75°C; slowly add component B into the reaction kettle for a total of 5 hours, and continue to cool at 75-80°C after dropping React for 2 hours; slowly add the component C diluent into the kettle, cool and discharge. 130 kg of alcohol water-soluble modified epoxy resin copolymers with a solid content of 72% were obtained.

[0079] A component: vinyl acetate 20kg

[0080] Ethanol or isopropanol 25kg

[0081] B component: vinyl acetate 20kg

[0082] 90% methacrylic acid-epoxy adduct 15kg ...

Embodiment 3

[0100] Embodiment 3: Preparation example of alcohol water-soluble modified epoxy composite glue

[0101] (1) Preparation of alcohol water-soluble modified epoxy resin copolymer:

[0102] In the reaction kettle equipped with stirring device, reflux condenser, heating temperature control and dropping device, add the mixed solution consisting of the following components in sequence. First add component A into the reaction kettle, stir and heat up to the reflux temperature of 70-75°C; slowly add component B into the reaction kettle, the total dropping time is 4 hours, and continue to cool at 75-80°C after the dropping is completed React for 1.5 hours; slowly add component C diluent into the kettle, cool and discharge. 132 kg of alcohol water-soluble modified epoxy resin copolymers with a solid content of 70% were obtained.

[0103] A component: vinyl acetate 15kg

[0104] Ethanol or isopropanol 20kg

[0105] B component: vinyl acetate 20kg

[0106] 90% maleic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com