Method for manufacturing drag reduction surface

A manufacturing method and anti-corrosion technology, which are applied in the process of producing decorative surface effects, manufacturing microstructure devices, decorative arts, etc., can solve the problems of poor stability of the surface morphology drag reduction effect, etc. Process pressure loss and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method of manufacturing a drag reducing surface, comprising the following steps:

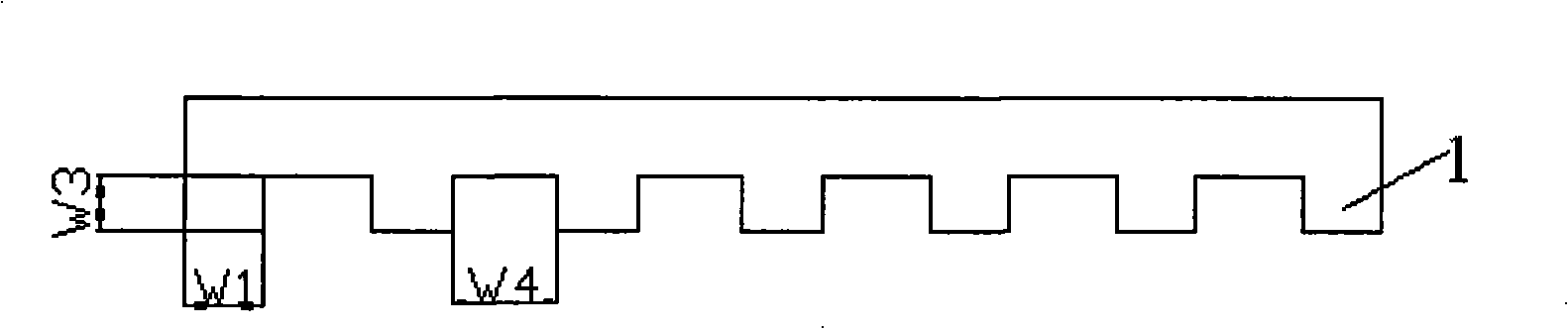

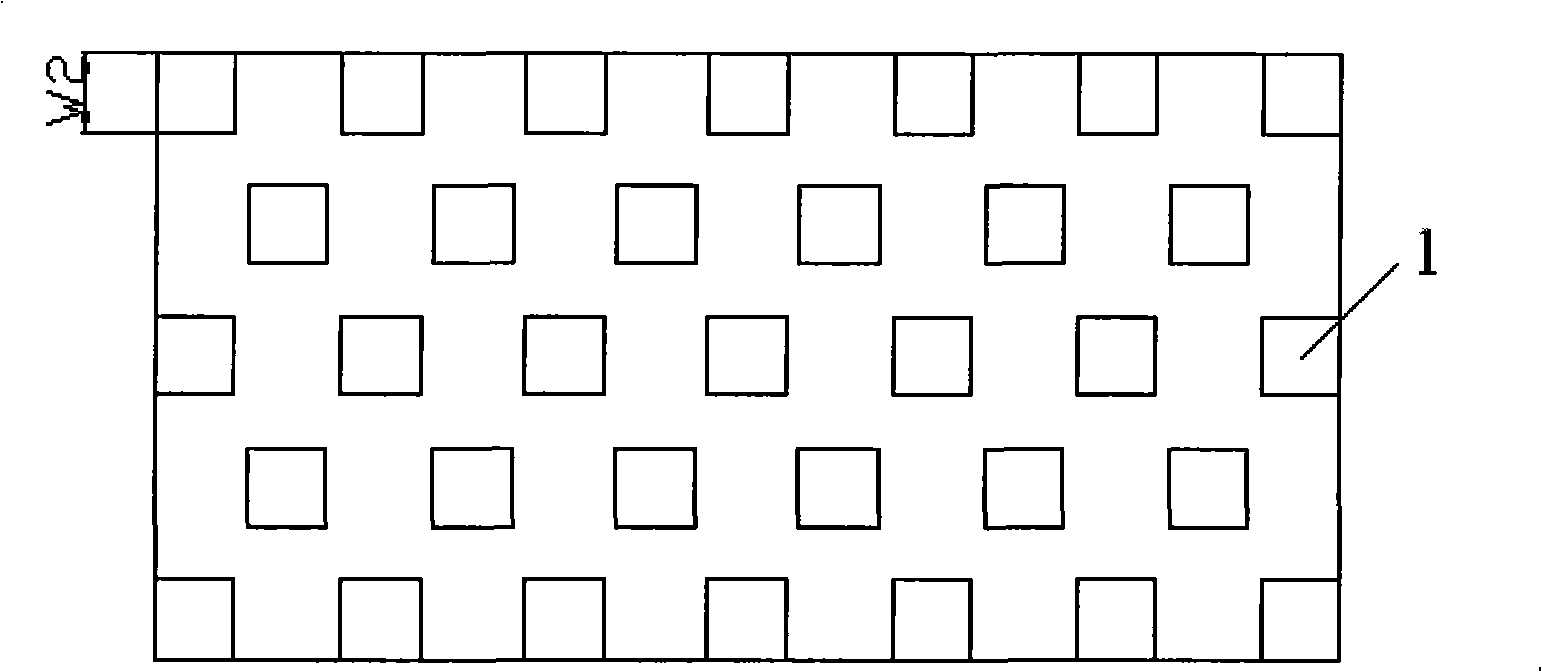

[0034] (1) Preparation of imprint template. A staggered microstructure template with a microcolumn length x width of 3 μm x 3 μm, a height of 5 μm, and a spacing of 6 μm between the microcolumns was prepared on the quartz template by wet etching.

[0035] (2) Coating of high molecular polymer corrosion inhibitor. Use a corrosion inhibitor with a viscosity of 50cp on a silicon or silicon dioxide substrate, at a low speed of 800rpm for 10s, then gradually increase the speed to 8000rpm for 45s, and the thickness of the glue layer is 5μm.

[0036] (3) Press the stencil into the anti-corrosion rubber layer, the imprint force is 75N, and the anti-corrosion rubber is polymerized and hardened by exposure to ultraviolet light, and the curing time is 10s;

[0037] (4) Release the pressure and separate the template from the silicon or silicon dioxide substrate, and the release force is 65N;

[...

Embodiment 2

[0041] A method of manufacturing a drag reducing surface, comprising the following steps:

[0042] (1) Preparation of imprint template. A staggered microstructure template with a microcolumn length x width of 60 μm x 60 μm, a height of 30 μm, and a spacing of 120 μm between microcolumns was prepared by wet etching;

[0043] (2) Coating of high molecular polymer corrosion inhibitor. SU-8 (2075) glue is used on the engineering plastic substrate, the speed at low speed is 800rpm, the time is 10s, and the speed is gradually increased to 1800rpm, the time is 45s, and the thickness of the glue layer is 30μm;

[0044] (3) Press the stencil into the anti-corrosion adhesive layer with an imprinting force of 80N, and expose the anti-corrosion adhesive to polymerize and harden to form, and the curing time is 15s;

[0045] (4) Release the pressure and separate the template from the engineering plastic substrate, and the demoulding force is 70N;

[0046] (5) Perform reactive ion etching o...

Embodiment 3

[0048] Embodiment 3 A method of manufacturing a drag-reducing surface, comprising the following steps:

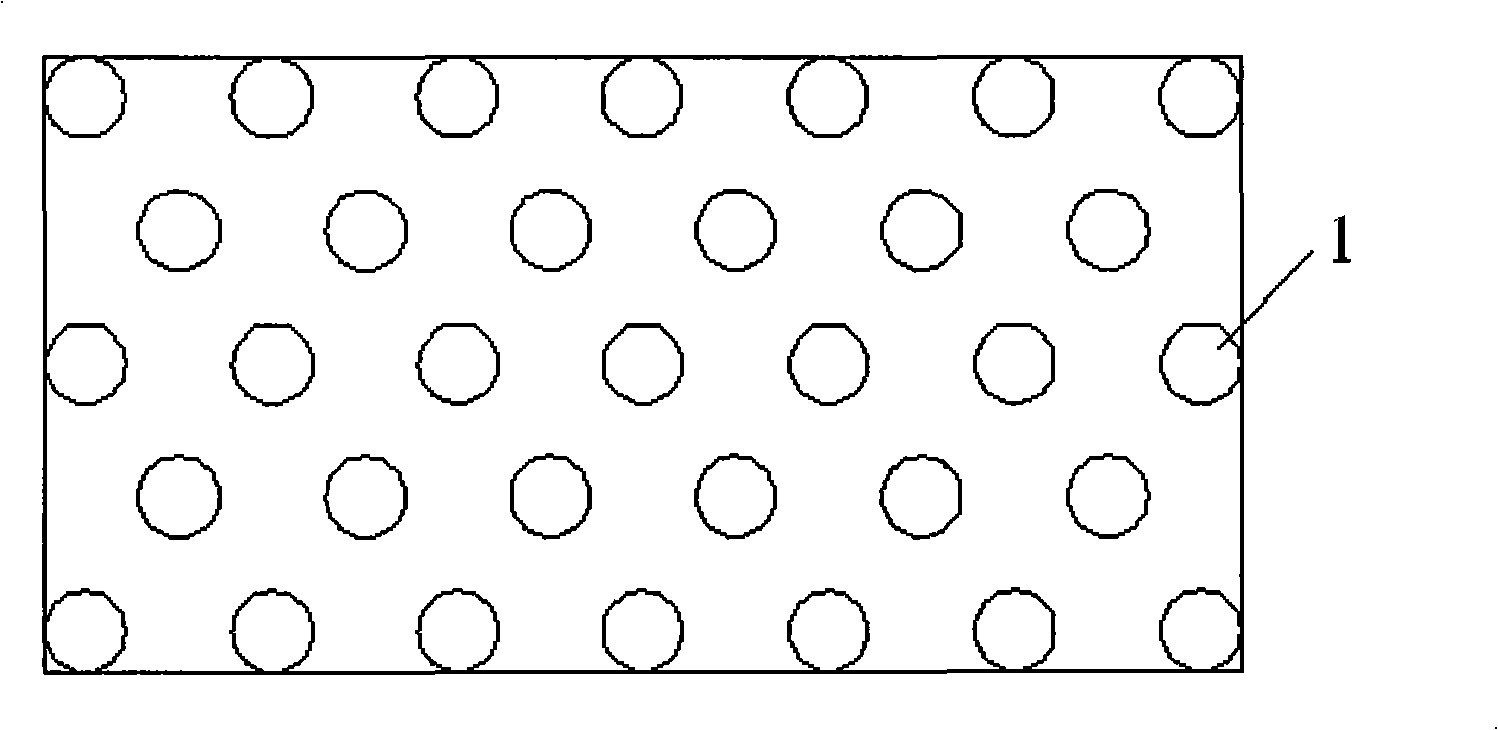

[0049] (1) Preparation of imprint template. A staggered microstructure with a length of 130 μm x 130 μm in length, a width of 60 μm, and a spacing of 130 μm between the microcolumns is prepared on the master Si sheet or metal sheet by laser processing, and then cast polydimethylformaldehyde Polydimethylsiloxane PDMS material, cured and peeled off to obtain a polydimethylsiloxane PDMS material template;

[0050] (2) Coating of high molecular polymer corrosion inhibitor. Use a corrosion inhibitor with a viscosity of 150cp on the Si wafer or metal substrate, the low speed is 600rpm, the time is 15s, the high speed is 1200rpm, the time is 35s, and the thickness of the glue layer is 60μm;

[0051] (3) Press the template into the anti-corrosion rubber layer, the imprint force is 90N, and the anti-corrosion rubber is polymerized and hardened by exposure to ultraviolet light, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com