Collagen-based dura mater and preparation method thereof

A technology of collagen membrane and dura mater, applied in the field of collagen-based dura mater and its preparation, can solve the problems of discounted collagen effect and poor mechanical properties of collagen, and achieve the effects of excellent flexibility, good mechanical strength and good anti-adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

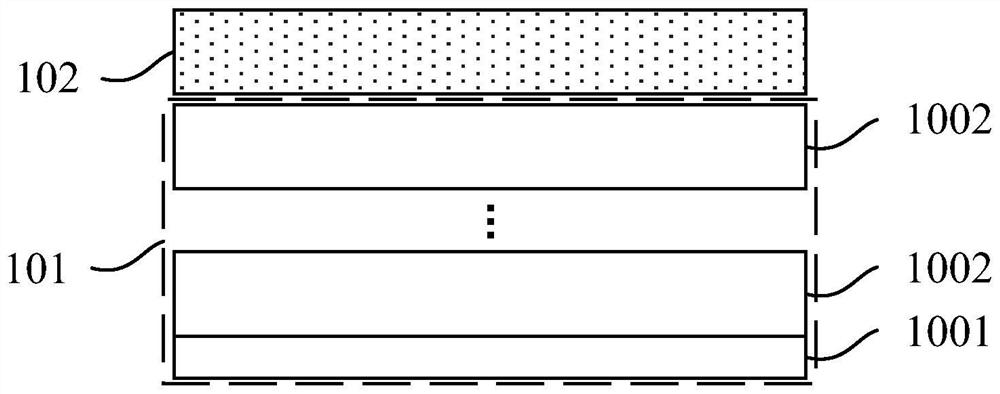

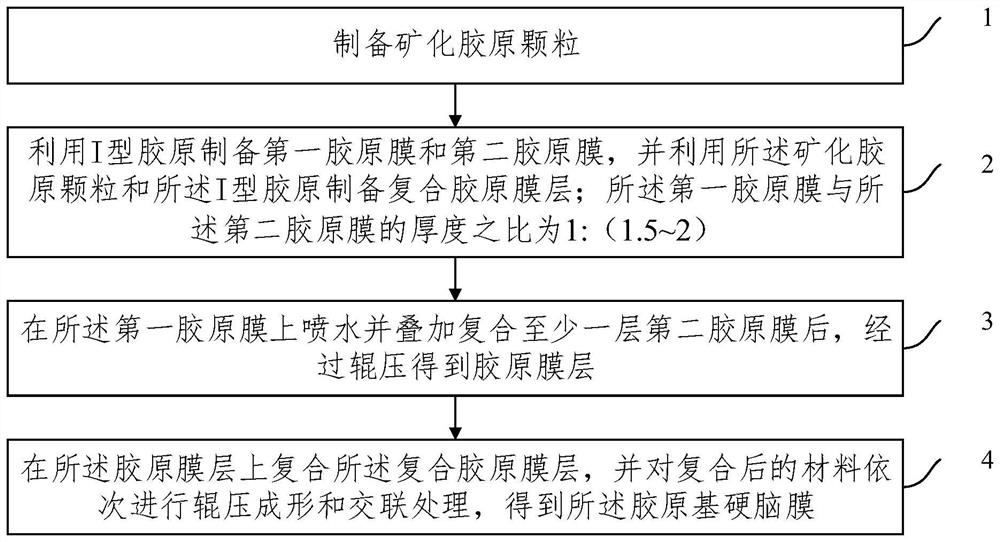

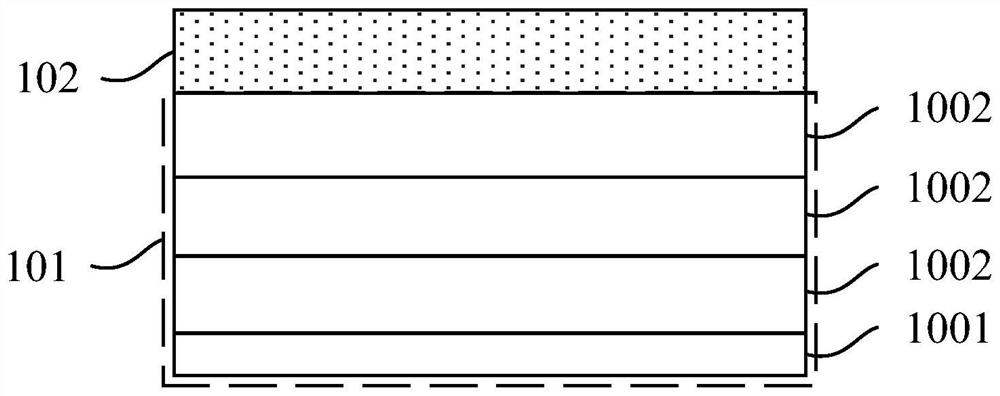

[0114] The present invention also provides a preparation method of the collagen-based dura mater provided above, the preparation method comprising:

[0115] (1) preparing mineralized collagen particles;

[0116] (2) Utilize type I collagen to prepare a first collagen film and a second collagen film, and utilize the mineralized collagen particles and the type I collagen to prepare a composite collagen film layer; the first collagen film and the second collagen The ratio of film thickness is 1:(1.5~2);

[0117] (3) After spraying the adhesive medium on the first collagen film and superimposing and compounding at least one layer of the second collagen film, the collagen film layer is obtained through rolling; the adhesive medium is prepared from type I collagen with a solid content of 0-0.015% collagen gel solution;

[0118] (4) Compounding the composite collagen film layer on the collagen film layer, and performing roll forming and cross-linking treatment on the compounded mater...

Embodiment 1

[0194] (1) Preparation of mineralized collagen particles:

[0195] (11) Dissolving type I collagen in hydrochloric acid, nitric acid or acetic acid to prepare a collagen acid solution with a concentration of 0.1 g / mL;

[0196] (12) Add calcium salt solution dropwise to the collagen acid solution; wherein, the amount of calcium ions added is 1 mol of calcium ions corresponding to each gram of collagen;

[0197] (13) drop phosphoric acid solution in step (12) gained solution; Wherein the mol ratio of the add-on of phosphate ion and calcium ion add-on in step (12) is Ca / P=1.5:1;

[0198] (14) NaOH solution is added dropwise to the solution obtained in step (13) to obtain a mixed solution; wherein, the pH value of the mixed solution is 6.5±0.5;

[0199] (15) After the mixed solution obtained in step (14) was left to stand for 8 hours, it was centrifuged at a speed of 4000r / min and the precipitate was taken out, and then the precipitate was air-dried at 60°C for 60 hours to obtain...

Embodiment 2

[0219] (1) Preparation of mineralized collagen particles:

[0220] (11) Dissolving type I collagen in hydrochloric acid, nitric acid or acetic acid to prepare a collagen acid solution with a concentration of 0.01g / mL;

[0221] (12) Add calcium salt solution dropwise to the collagen acid solution; wherein, the amount of calcium ions added is 0.1 mol of calcium ions corresponding to each gram of collagen;

[0222] (13) Add phosphoric acid solution dropwise in step (12) gained solution; Wherein the mol ratio of the add-on of phosphate ion and calcium ion add-on in step (12) is Ca / P=1:1;

[0223] (14) NaOH solution is added dropwise to the solution obtained in step (13) to obtain a mixed solution; wherein, the pH value of the mixed solution is 6.5±0.5;

[0224] (15) After the mixed solution obtained in step (14) was left to stand for 4 hours, it was centrifuged at a speed of 3000r / min and the precipitate was taken out, and then the precipitate was air-dried at 50°C for 72 hours t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com