Acrylic ester waterproof gasket cement

A waterproof sealing, acrylate technology, applied in the direction of ester copolymer adhesives, adhesive types, etc., can solve the problem of poor adhesion of acrylic building sealant and not resistant to water immersion, etc., to achieve good waterproof and adhesive properties , to overcome the effect of not waterproof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

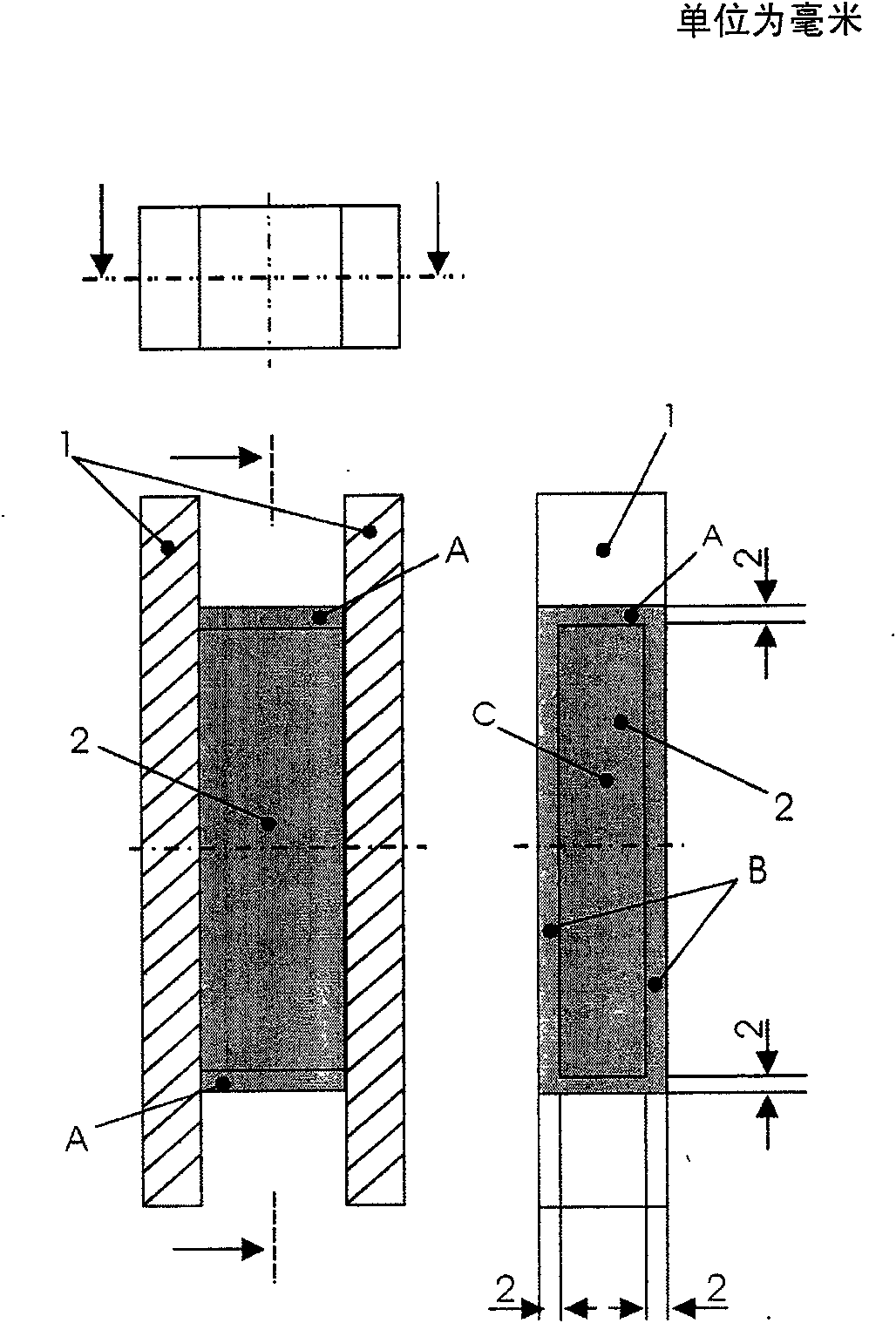

Image

Examples

Embodiment 1

[0012] The acrylic waterproof sealant described in the embodiment of the present invention comprises the following components by weight; polyacrylate emulsion 30g (solid content ≥ 60%), sodium tripolyphosphate 0.4g; DA-01 0.3g; Swire oil 0.5g; Dioctyl phthalate 2g; 52 ° chlorinated paraffin 4g; silica sol (content 28-30%, pH value 10-11) 6.5g; heavy calcium carbonate (400 mesh) 50g; ammonia water (content 20%) 0.2 ml; 0.25ml of 3-glycidoxytrimethoxysilane; 0.25ml of α-aminopropyltriethoxysilane; 1g of 2,2,4-trimethyl-1,3-diol monoisobutyrate .

[0013] Preparation

[0014] Dioctyl phthalate 2g, 52° chlorinated paraffin 4g, 2,2,4-trimethyl 1,3-diol monoisobutyrate 1g, r-aminopropyltriethoxysilane 0.25 ml into a stirring container, stir and mix evenly to form A liquid; put the silica sol into a stirring container, slowly add 0.25ml of 3-glycidoxytrimethoxysilane during the stirring process and mix to form B liquid; Add 30g of polyacrylic acid emulsion into a stirring containe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com