Drying device of film printing machine

A drying device and printing machine technology, applied to printing machines, general parts of printing machinery, printing, etc., can solve problems such as adhesion and poor printing quality of films, and achieve less space, long drying stroke and long drying time Long lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

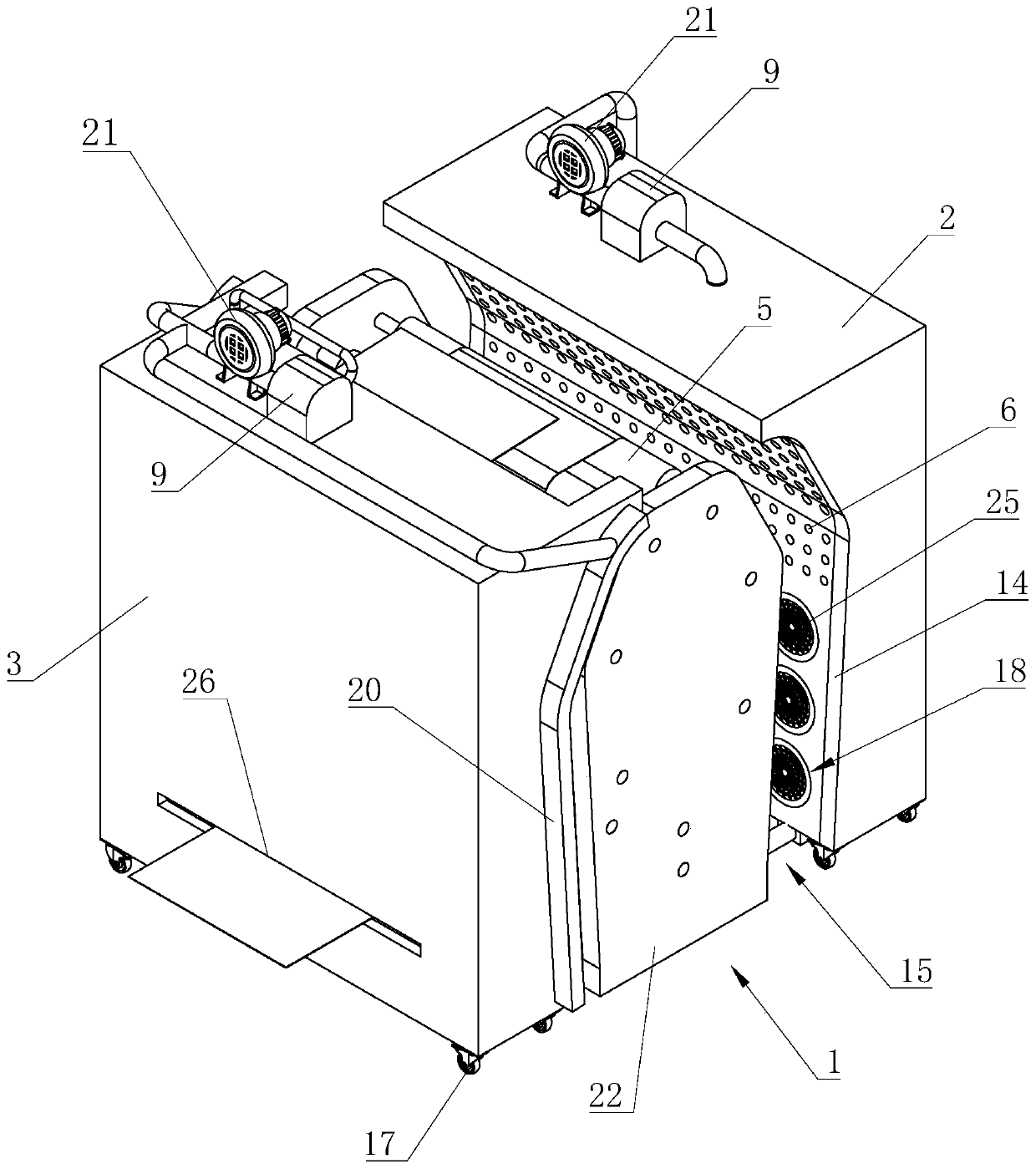

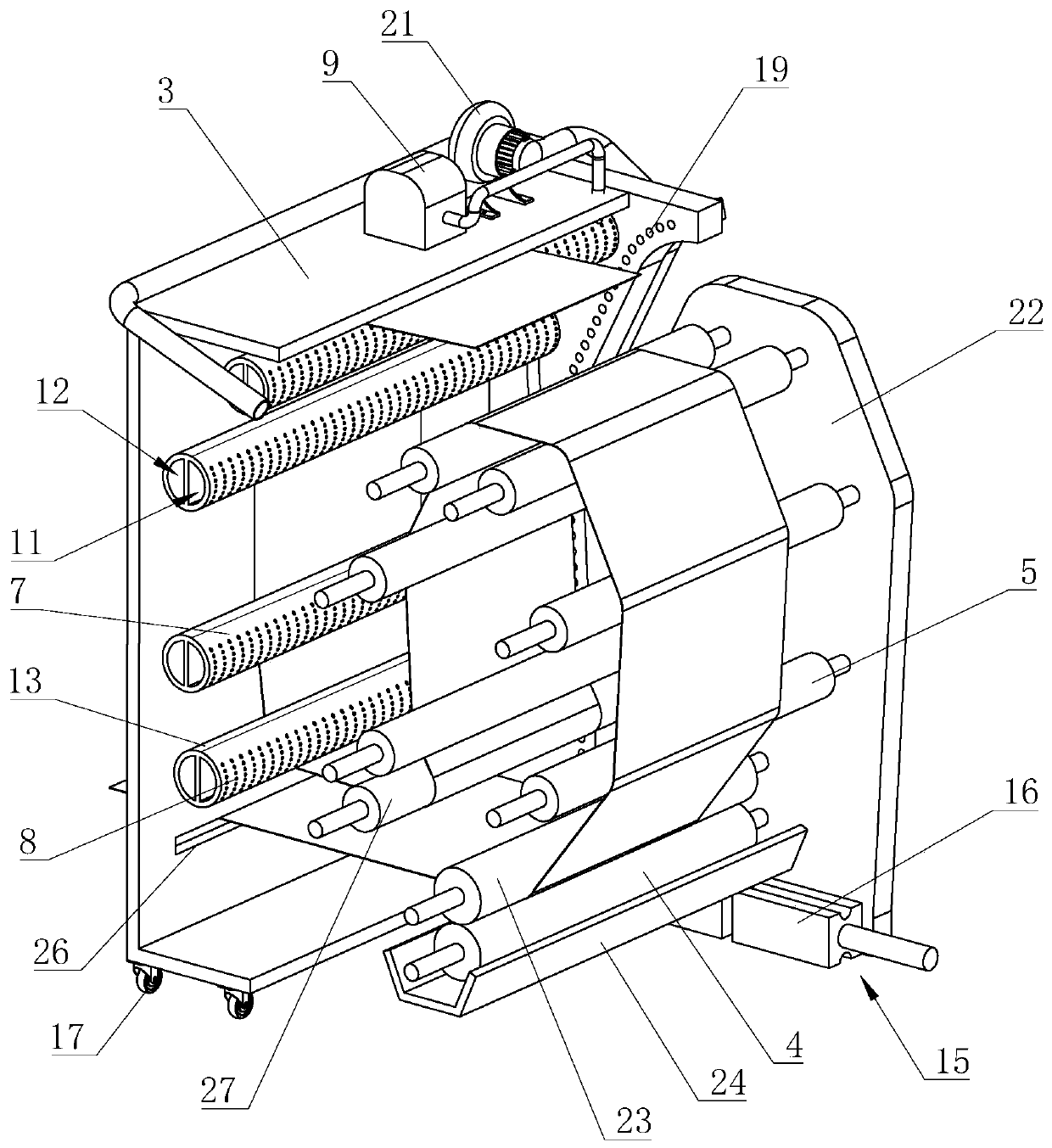

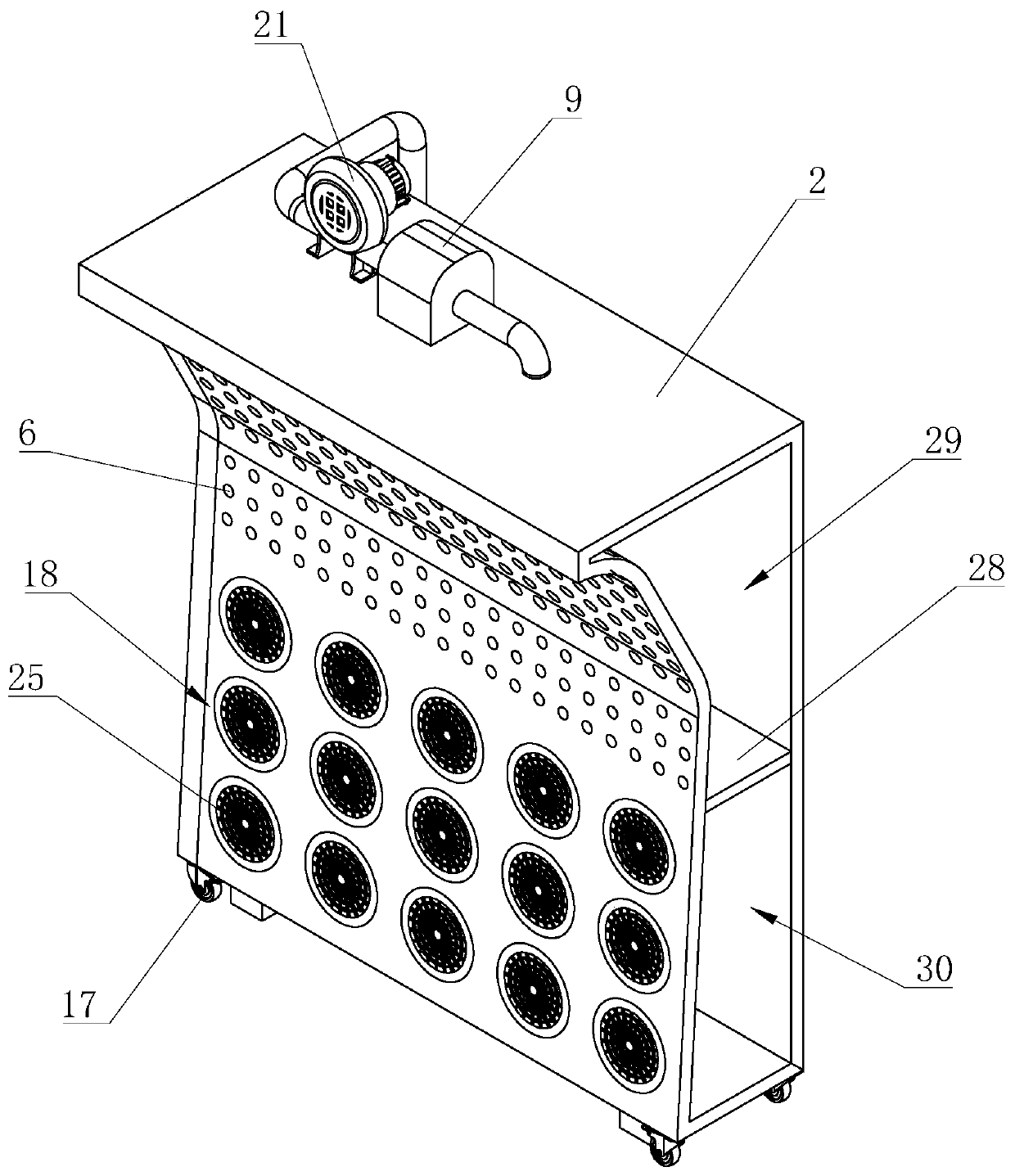

[0035] refer to figure 1 with figure 2 , is a drying device for a film printing machine disclosed in the present invention, including a frame 1, a primary oven 2 and a secondary oven 3. The frame 1 includes two vertical boards 22 arranged oppositely, and the two vertical boards 22 are in the shape of a vertical waist protruding from both sides in the horizontal direction. Two vertical plates 22 are equipped with printing roller 4 and pressure roller 23 near the midpoint position of the bottom, between the two vertical plates 22 below the printing roller 4, ink trough 24 is fixed, and pressure roller 23 and printing roller 4 are facing up and down and The film passes between the press roller 23 and the printing roller 4 . The two vertical plates 22 are equipped with six feed rollers 5 along the waist-shaped edge, and the six feed rollers 5 are symmetrically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com