PH responsive plant fiber functional material as well as preparation method and application thereof

A plant fiber and functional material technology, applied in separation methods, chemical instruments and methods, liquid separation, etc., can solve the problems of non-adjustable pH-responsive materials, low sensitivity, material loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

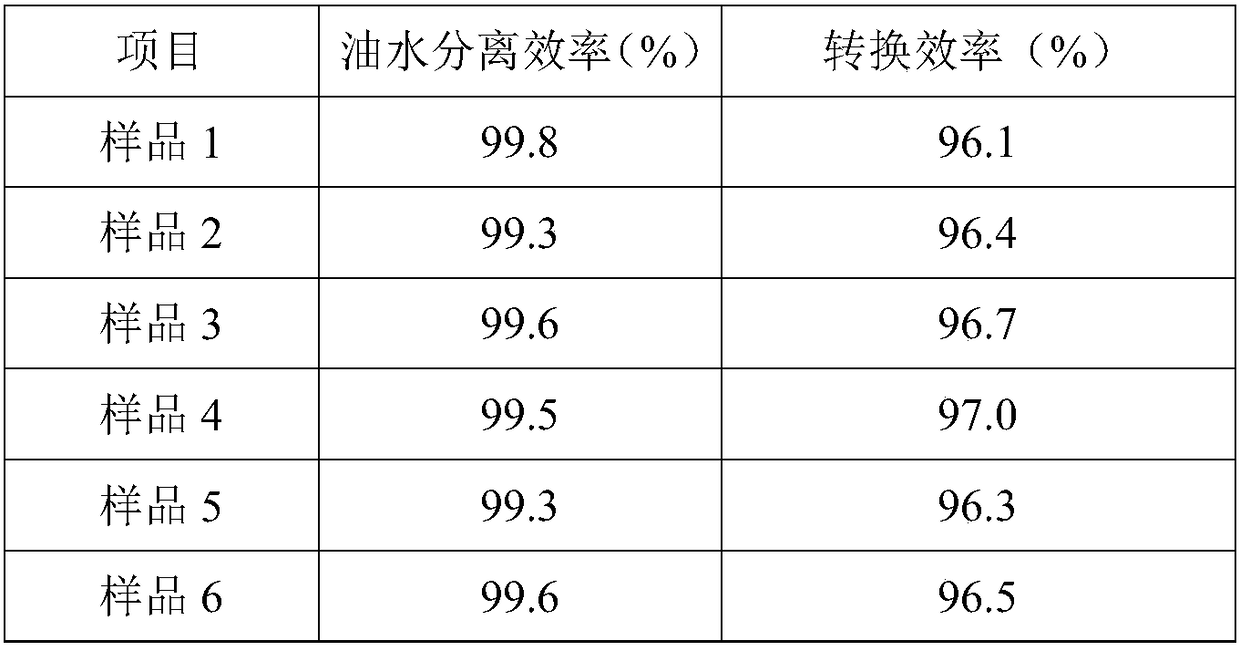

Embodiment 1

[0041] Example 1: Preparation of pH-responsive plant fiber functional material

[0042] ① Fully disperse 1 g of bagasse pulp fibers in 600 g of water, add 1.2 g of ferrous ammonium sulfate, and at a stirring speed of 250 rpm, pass through nitrogen gas for 40 minutes to remove oxygen, so that free radicals are generated on the fiber surface, and a bagasse pulp fiber dispersion is obtained;

[0043] ②Dissolve 1g of buthenic acid in the bagasse pulp fiber dispersion prepared in step ①, react at a constant temperature of 90°C and a stirring speed of 190rpm, and use attenuated total reflection-ultraviolet / visible spectroscopy to analyze the reaction during the grafting process in real time The concentration of butene acid in the system was adjusted to maintain the concentration of butene acid at 0.138mol / L, and the reaction time was controlled at 7h to obtain a bagasse pulp fiber dispersion with negative pH responsiveness;

[0044] ③Dissolve 4g of crotonamide in the negative pH-res...

Embodiment 2

[0047] Example 2: Preparation of pH-responsive plant fiber functional material

[0048] ① Fully disperse 1g of bamboo pulp fibers in 600g of water, add 1.8g of cyclohexanone peroxide, and at a stirring speed of 300rpm, pass nitrogen gas for 30min to remove oxygen, so that free radicals are generated on the fiber surface, and a bamboo pulp fiber dispersion is obtained ;

[0049] ②Dissolve 1g of pentenoic acid in the bamboo pulp fiber dispersion prepared in step ①, react at a constant temperature of 60°C and a stirring speed of 180rpm, and use attenuated total reflection-ultraviolet / visible spectroscopy to analyze the reaction during the grafting process in real time The concentration of pentenoic acid in the system was adjusted to maintain the concentration of pentenoic acid at 0.138mol / L, and the reaction time was controlled at 4h to obtain a bamboo pulp fiber dispersion with negative pH responsiveness;

[0050] ③Dissolve 3g of pentenamide in the negative pH-responsive bamboo...

Embodiment 3

[0053] Example 3: Preparation of pH-responsive plant fiber functional material

[0054] ① Fully disperse 1g of bamboo pulp fibers in 600g of water, add 2.0g of cyclohexanone peroxide, and at a stirring speed of 200rpm, pass nitrogen gas for 30min to remove oxygen, so that free radicals are generated on the surface of the fibers to obtain a bamboo pulp fiber dispersion ;

[0055] ②Dissolve 1g of pentenoic acid in the bamboo pulp fiber dispersion prepared in step ①, react at a constant temperature of 60°C and a stirring speed of 150rpm, and use attenuated total reflection-ultraviolet / visible spectroscopy to analyze the reaction during the grafting process in real time The concentration of pentenoic acid in the system was adjusted to maintain the concentration of pentenoic acid at 0.138mol / L, and the reaction time was controlled at 4h to obtain a bamboo pulp fiber dispersion with negative pH responsiveness;

[0056] ③Dissolve 2g of pentenamide in the negative pH-responsive bambo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| oil-water separation rate | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com