Method for preparing dry high-performance water reducer powder of polycarboxylic acid

A technology of water reducer and polycarboxylate, which is applied in the field of preparation of polycarboxylate high-performance water reducer dry powder, can solve problems such as potential safety hazards, high solid content, unsuitable drying, etc., to eliminate the possibility of accumulation and solve the problem of Secondary dust raising, to achieve the effect of secondary dehumidification and drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

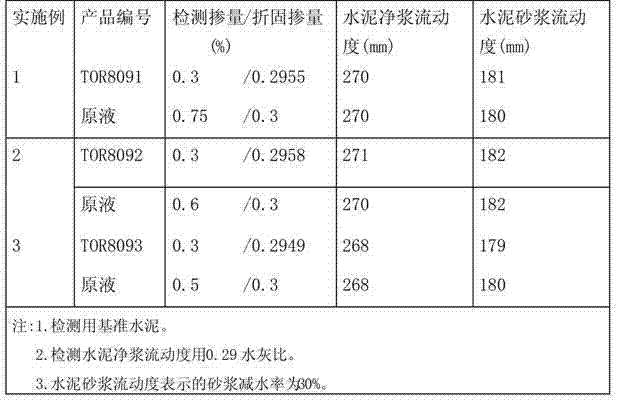

Embodiment 1

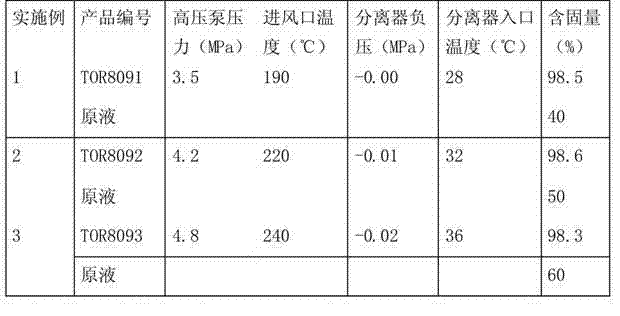

[0020] 1. Ignite the JRF6-100 hot air stove with coal to prepare hot air energy, and turn on the 4-72-8C induced draft fan to send the hot air into the 9m diameter drying room for preheating.

[0021] 2. Put 1000KG polycarboxylate high-performance superplasticizer liquid with a solid content of 40% into the material tank, and connect the high-pressure pump pipeline.

[0022] 3. Turn on the 3L125 Roots vacuum pump to continuously extract the air entering the separator to generate negative pressure, which is controlled at –0.00MPa.

[0023] 4. Turn on the LN-500W (outlet dew point –17~–23°C) air freeze dryer to produce dry and cold air, and pass it into the pipeline before the separator inlet.

[0024] 5. When the air inlet temperature of the drying chamber reaches 250°C, press the polycarboxylate high-performance water reducer liquid into the nozzle with a 2GH54 high-pressure pump to atomize it into mist and spray it into the drying chamber. The pressure is controlled at 3.5MPa...

Embodiment 2

[0028] 1. Ignite the JRF6-100 hot air stove with coal to prepare hot air energy, turn on the 4-72-8C induced draft fan to send the hot air into the 9m diameter drying room for preheating.

[0029] 2. Put 1000KG polycarboxylate high-performance water reducer liquid with 50% solid content into the material barrel, and connect the high-pressure pump pipeline.

[0030] 3. Turn on the 3L125 Roots vacuum pump to continuously extract the air entering the separator to generate negative pressure, which is controlled at –0.01MPa.

[0031] 4. Turn on the LN-500W (outlet dew point –17~–23°C) air freeze dryer to produce dry and cold air, and pass it into the pipeline before the separator inlet.

[0032] 5. When the temperature at the air inlet of the drying chamber reaches 250°C, press the polycarboxylate high-performance water reducer liquid into the nozzle with a 2GH54 high-pressure pump to atomize it into mist and spray it into the drying chamber. The pressure is controlled at 4.2MPa an...

Embodiment 3

[0036] 1. Ignite the JRF6-100 hot air stove with coal to prepare hot air energy, turn on the 4-72-8C induced draft fan to send the hot air into the 9m diameter drying room for preheating.

[0037] 2. Put 1000KG polycarboxylate high-performance superplasticizer liquid with a solid content of 60% into the material barrel, and connect the high-pressure pump pipeline.

[0038] 3. Turn on the 3L125 Roots vacuum pump to continuously extract the air entering the separator to generate a negative pressure, which is controlled at -0.01MPa.

[0039] 4. Turn on the LN-500W (outlet dew point –17~–23°C) air freeze dryer to produce dry and cold air, and pass it into the pipeline before the separator inlet.

[0040] 5. When the air inlet temperature of the drying chamber reaches 250°C, press the polycarboxylate high-performance water reducer liquid into the nozzle with a 2GH54 high-pressure pump to atomize it into mist and spray it into the drying chamber. The pressure is controlled at 4.8MPa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com