Assembling method for fiber filtration cloth filter and sewage treating method

A sewage treatment method and fiber filtration technology, applied in mobile filter element filters, chemical instruments and methods, filtration separation, etc., can solve the problems that the whole system cannot be moved conveniently, cannot be produced in batches, and the backwashing intensity is high, etc., to achieve Excellent separation characteristics, low operation and maintenance costs, and the effect of saving floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

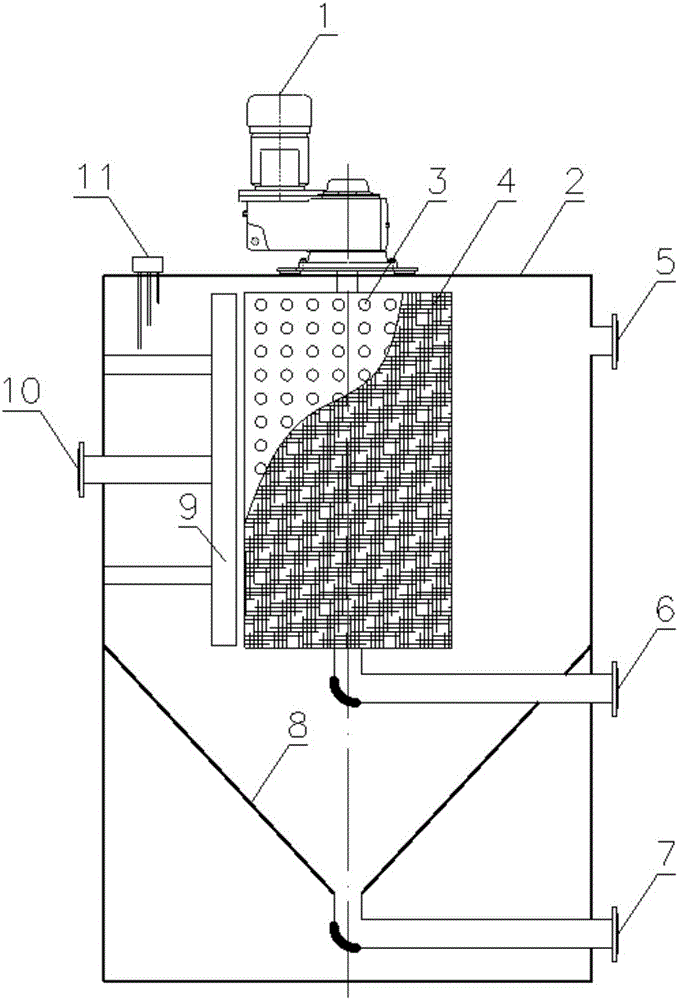

[0043] Such as figure 1 As shown, a fiber filter cloth filter includes a driving device (including a drive motor 1), a closed cylindrical housing 2, a filter drum 3, a fiber filter cloth 4, a water inlet 5, a housing outlet 6, a shell Body mud discharge port 7 (a mud discharge valve is provided at the mud discharge port), a mud collecting bucket 8, a backwash device 9, a backwash water outlet 10 (a backwash valve is provided at the backwash water outlet), and a pressure sensor 11.

[0044] A filter drum is installed vertically in the inner cavity of the shell, the filter drum is hollow cylindrical, water holes are set on the side wall of the cylindrical filter drum, the filter drum is wrapped with fiber filter cloth, and the bottom of the filter drum is provided with a water outlet and Housing outlet connection. The filter drum is also connected with the drive device, and the drive device drives the filter drum to rotate.

[0045] The filter drum is a water collection drum m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com