Method and device for purifying asphalt smoke

A technology of asphalt fume and asphalt fume, which is applied in the field of flue gas purification, can solve problems such as failure to meet environmental protection requirements, equipment, pipeline ash clogging, and large dust, so as to improve equipment operation rate, improve production environment, and improve purification efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

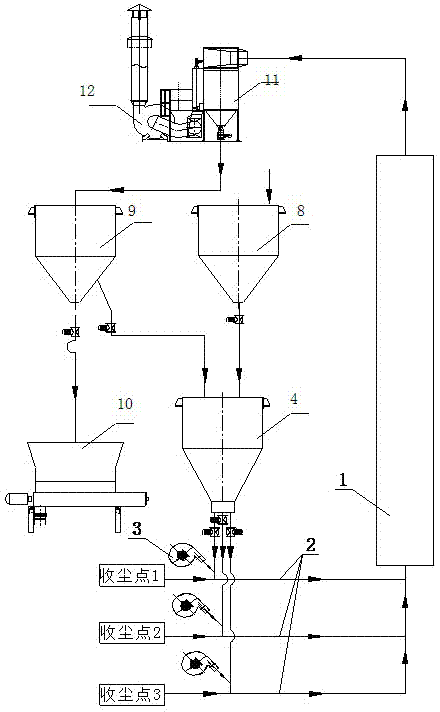

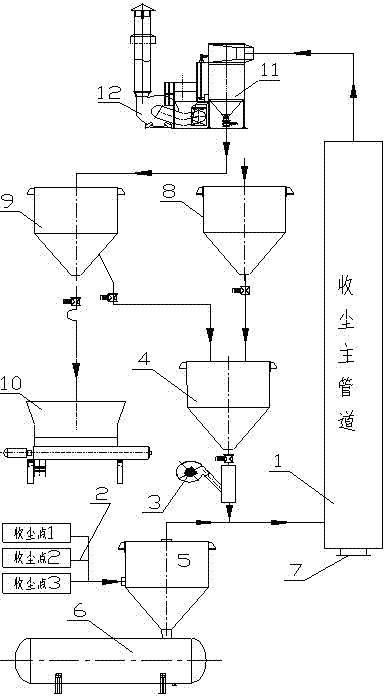

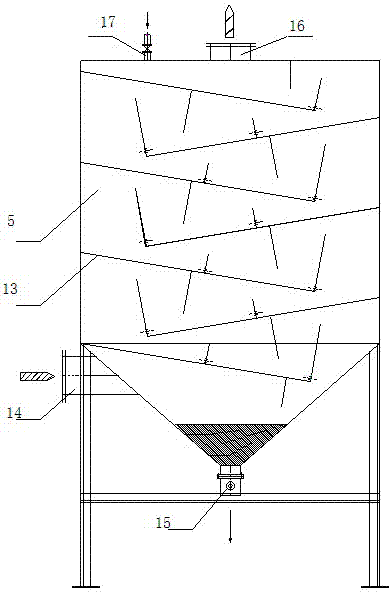

[0042] as attached figure 2 As shown, the temperature is 85°C and the dust concentration is 250mg / m 3 Under the action of negative pressure, the asphalt fume first enters the asphalt fume branch pipe 2, and then enters the cold oil collection device 5. In this device, the minimum negative pressure of the flue gas inhalation is 5×10 -5 MPa, the number of layers of the baffle 13 is 8 layers, when the asphalt fume flows through each layer of baffles, the flow velocity drops, and a continuous turbulent vortex is generated, thereby reducing the temperature of the high-temperature asphalt fume to 20 -30°C, let part of the soot settle, and finally flow to the discharge port at the bottom of the cone through the oil leakage ports of each layer and enter the asphalt storage tank 6; then, the low-temperature asphalt fume discharged from the asphalt fume outlet 16 of the cold oil collection device Mix with solid adsorbent petroleum coke powder from high-pressure fan 3, wherein the tota...

Embodiment 2

[0048] as attached figure 2 As shown, the temperature is 50°C and the dust concentration is 350mg / m 3 Under the action of negative pressure, the asphalt fume first enters the asphalt fume branch pipe 2, and then enters the cold oil collection device 5. In this device, the minimum negative pressure of the flue gas inhalation is 3×10 -5 MPa, the number of layers of the baffle 13 is 5 layers, when the asphalt fume flows through each layer of baffles, the flow velocity drops, and a continuous turbulent vortex is generated, so that the temperature of the high-temperature asphalt fume drops to 20 -30°C, let part of the soot settle, and finally flow to the discharge port at the bottom of the cone through the oil leakage ports of each layer and enter the asphalt storage tank 6; then, the low-temperature asphalt fume discharged from the asphalt fume outlet 16 of the cold oil collection device Mix with solid adsorbent petroleum coke powder from high-pressure fan 3, wherein the total a...

Embodiment 3

[0054] as attached figure 2 As shown, the temperature is 65°C and the dust concentration is 300mg / m 3 Under the action of negative pressure, the asphalt fume first enters the asphalt fume branch pipe 2, and then enters the cold oil collection device 5. In this device, the minimum negative pressure of the smoke inhalation is 4×10 -5 MPa, the number of layers of the baffle 13 is 7 layers, when the asphalt fume flows through each layer of baffles, the flow velocity drops, and a continuous turbulent vortex is generated, thereby reducing the temperature of the high-temperature asphalt fume to 20 -30°C, and let part of the oil settle, and finally flow to the discharge port at the bottom of the cone and enter the asphalt storage tank 6 through the oil leakage ports of each layer; then, the low-temperature asphalt fume discharged from the asphalt fume outlet 16 of the cold oil collection The air is mixed with the solid adsorbent petroleum coke powder from the high-pressure fan 3, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com