Method for smelting bismuth-molybdenum or bismuth-tungsten concentrates

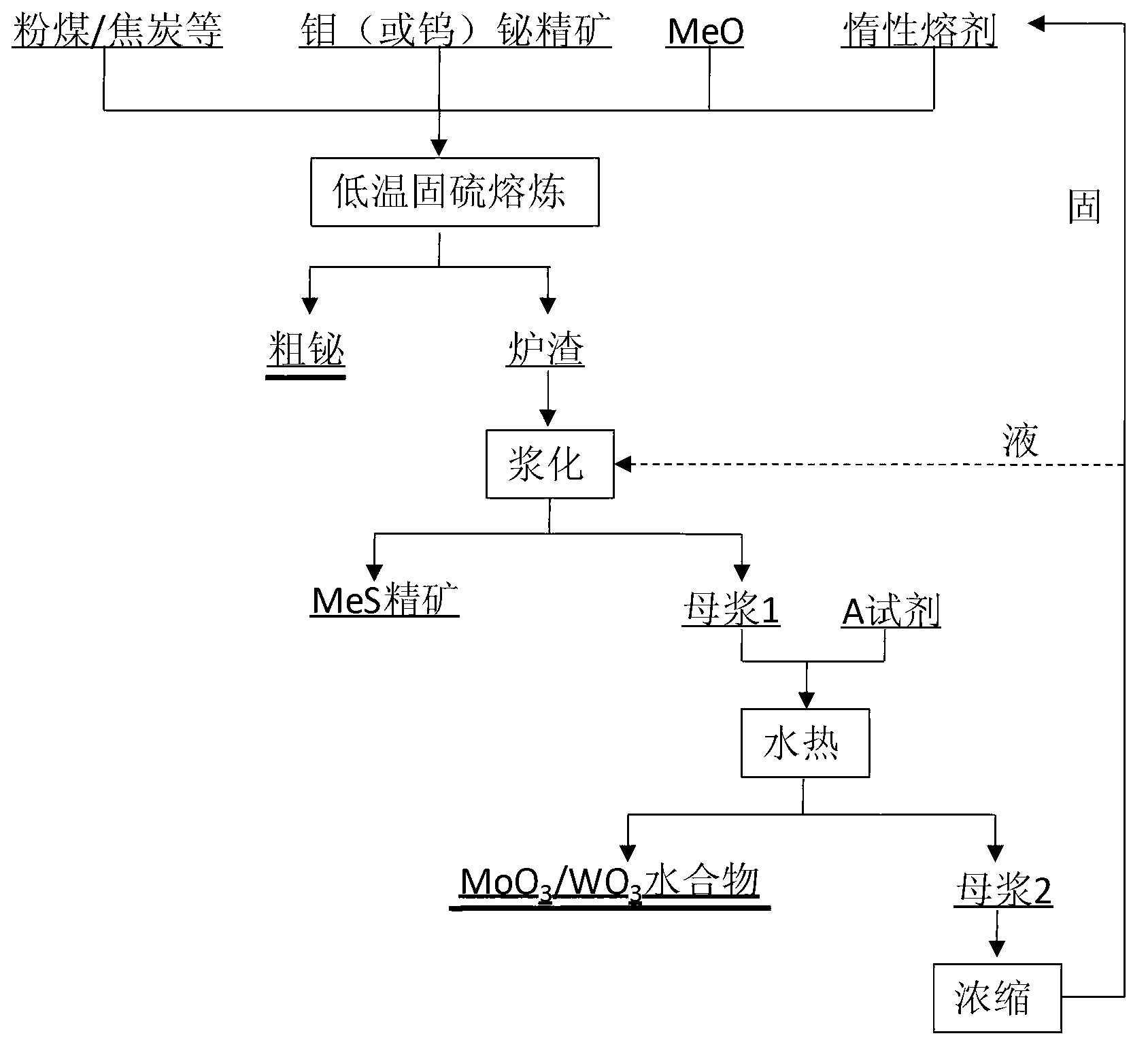

A smelting method and tungsten concentrate technology, applied in the smelting field of bismuth molybdenum or bismuth tungsten concentrate, can solve the problems of long process and high environmental pressure, and achieve the effects of reducing energy consumption, cleaning and efficient recovery, and avoiding difficult treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The composition of molybdenum bismuth concentrate provided is: Bi 21.02%, Mo 5.33%, Fe 13.24%, SiO 2 14.56%, Cu 0.77%, S 27.2%.

[0048] Get above-mentioned molybdenum bismuth concentrate powder 100g, and 70g ZnO, 300g Na 2 CO 3 and 8g of pulverized coal were evenly mixed, and smelted at 870°C for 120 min. After the reaction, 18.5 g of crude bismuth was obtained by cooling and separation, and the grade of bismuth was 97.24% through chemical analysis. Add 600ml of tap water to the cooled smelting slag, shear and stir to make slurry, the slurry temperature is 60°C, and the slurry time is 60min. Afterwards, the slurry was separated from the liquid to the solid to obtain slurry slag and lye containing 71.3% ZnS, respectively. The pH of the lye is adjusted to about 8 with concentrated hydrochloric acid, and then placed in an autoclave for hydrothermal precipitation. The hydrothermal temperature is 330°C, the pressure is 20MPa, and the time is 180min. After the reaction...

Embodiment 2

[0050] The composition of bismuth tungsten concentrate provided is: Bi 16.45%, WO 3 3.17%, Fe 20.19%, SiO 2 6.21%, Cu 0.14%, S 21.5%.

[0051] Get above-mentioned tungsten-bismuth concentrate powder 100g, and 90g ZnO, 500g Na 2 CO 3 and 12g of pulverized coal were evenly mixed, and smelted at 950°C for 90 min. After the reaction was finished, 15.27 g of crude bismuth was obtained by cooling and separation, with a crude bismuth grade of 96.11%. Add 1000ml of tap water to the cooled smelting slag, shear and stir to make slurry, the slurry temperature is 75°C, and the slurry time is 90min. Afterwards, the slurry was filtered to obtain pulped slag and lye containing 73.17% ZnS, and the lye was adjusted to a pH of about 9 with acetic acid. The pH-adjusted solution was placed in an autoclave for hydrothermal precipitation at a temperature of 360 °C, a pressure of 22 MPa, and a time of 240 min. After the reaction is over, the solution is cooled and filtered to separate to obt...

Embodiment 3

[0053] The chemical composition of the bismuth molybdenum concentrate provided is (%): Bi 25.29, Mo 3.11, Fe 19.4, S 26.1, Cu 0.2, Pb 0.49, SiO 2 6.13.

[0054] Weigh 1000g of molybdenum-bismuth concentrate, 100g of coke, 850g of copper oxide soot containing 71% Cu and 4000g of sodium carbonate and mix them evenly. Smelting at 750°C for 2 hours yielded 249g of crude bismuth containing 98.2% Bi; after cooling, 4000mL of tap water was added to slurry at a temperature of 90°C for 2 hours, and then the slurry was filtered to obtain 61.4% CuS Slurry residue and lye. The pH of the lye is adjusted to about 9 with 50% concentrated nitric acid. The pH-adjusted solution was placed in an autoclave for hydrothermal precipitation at a temperature of 350° C., a pressure of 21 MPa, and a time of 400 minutes. After the reaction, the solution was cooled, filtered and separated to obtain molybdenum oxide hydrate powder (MoO 3 ·xH 2 O) 42.8g.

[0055] In the present invention, the bismuth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com