Method for processing sludge and kitchen wastes

A technology of food waste and treatment methods, which is applied in the directions of sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., which can solve the problems of low gas production rate, low nitrogen content, and easy occurrence Acid inhibition and other issues, to achieve the effect of reducing operating costs, good microbial survival and metabolic environment, and improving system operation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

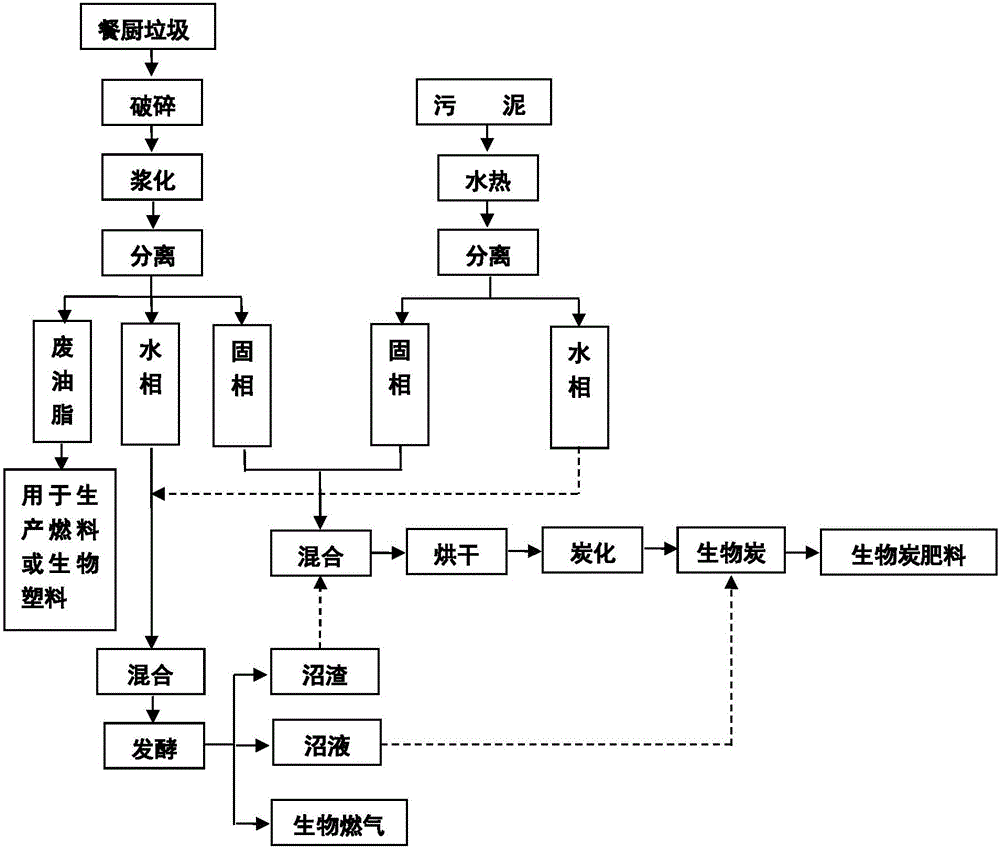

[0034] A treatment method for sludge and kitchen waste, such as figure 1 shown, including the following steps:

[0035] 1) Crushing, pulping, and separating food waste to obtain waste oil, food waste separation water phase and food waste separation solid phase;

[0036] 2) The sludge is subjected to hydrothermal treatment, and the hydrothermal liquid phase and the hydrothermal solid phase of the sludge are obtained after the product is separated;

[0037] 3) Mix the separated water phase of food waste with the hydrothermal liquid phase of the sludge, and separate the products after anaerobic fermentation to obtain biogas, biogas residue and biogas slurry;

[0038] 4) Mixing the separated solid phase of the food waste, the hydrothermal solid phase of the sludge and the biogas residue obtained in step 3), drying, and carbonizing to prepare pyrolytic biochar;

[0039] Among them, the waste oil obtained in step 1) is used as a raw material for producing fuel or bioplastics; the ...

Embodiment 2

[0051] This example is basically the same as Example 1, the difference is that the temperature of the hydrothermal treatment in step 2) is 100-°C, the pressure is 2bar, and the time is 120min;

[0052] The method for product separation in step 2) is a plate and frame filter press method;

[0053] The method for product separation in step 3) is a plate and frame filter press method;

[0054] Step 3) Mix the separated water phase of Chinese food waste with the sludge hydrothermal liquid phase, and the mixing time is 5 minutes;

[0055] The anaerobic fermentation conditions in the step 3) are that the carbon-nitrogen ratio is 15:1, and the pH value is 6;

[0056] In step 4) the mixing ratio of the solid phase of food waste separation, sludge hydrothermal solid phase and biogas residue is: the total weight of food waste separation solid phase and biogas residue accounts for 5% of the total weight of sludge hydrothermal solid phase %, the mixing time is 5min;

[0057] The drying...

Embodiment 3

[0061] This example is basically the same as Example 1, the difference is that the temperature of the hydrothermal treatment in step 2) is 200°C, the pressure is 10bar, and the time is 30min;

[0062] The method for product separation in step 2) is vacuum filtration;

[0063] The method for product separation in step 3) is vacuum filtration;

[0064] Step 3) Mix the separated water phase of Chinese food waste with the hydrothermal liquid phase of the sludge, and the mixing time is 10 minutes;

[0065] The anaerobic fermentation conditions in the step 3) are that the carbon-to-nitrogen ratio is 35:1, and the pH value is 8;

[0066] In step 4), the mixing ratio of the solid phase of food waste separation, sludge hydrothermal solid phase and biogas residue is: the total weight of food waste separation solid phase and biogas residue accounts for 50% of the total weight of sludge hydrothermal solid phase %, the mixing time is 30min;

[0067] The drying temperature in step 4) is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com