Novel printed circuit board type heat exchanger based on 3D printing technology

A printed circuit board, 3D printing technology, applied in the field of 3D printing, can solve the problems of fluid leakage loss, reduce heat exchange performance of heat exchangers, resistance loss, etc., to improve working capacity, improve utilization rate, and reduce resistance loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

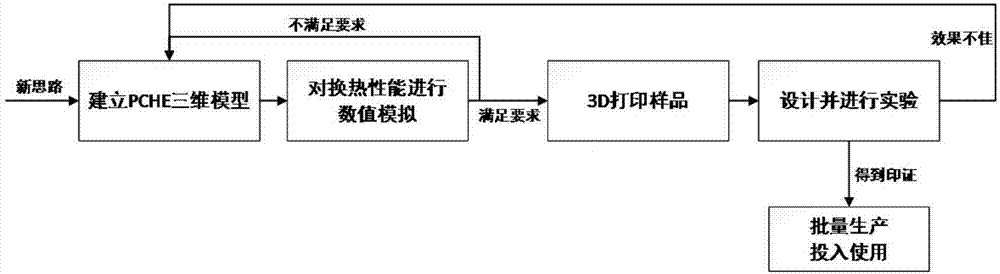

[0038] refer to figure 1 , the present invention proposes a PCHE research process based on 3D printing technology. Firstly, a three-dimensional model of PCHE is established, and then its heat transfer performance is numerically simulated to obtain various performance parameters. If the requirements are not met, then go back and modify the three-dimensional model. Produce samples in the 3D printer, design and carry out corresponding experiments, if the experimental results do not meet the requirements, also return to the modeling software to modify the model, if the experimental results and numerical simulation results confirm each other, then mass production can be carried out and put into use. The heat exchanger material used in the 3D printing preparation method is an advanced alloy, including: NiCr23Co12Mo (617 alloy), HX hard alloy or 625 alloy, etc. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com