Thermal recovery technology of multielement thermal fluid of thickened oil well

A technology of multi-component thermal fluid and thermal recovery technology, which is applied in the direction of production fluid, earthwork drilling and production, wellbore/well components, etc. It can solve the problem of low oil recovery rate and ultimate recovery rate, difficulty in greatly increasing heavy oil recovery rate, Poor economic benefits and other problems, to achieve the effect of light weight, improve oil displacement efficiency, and reduce heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

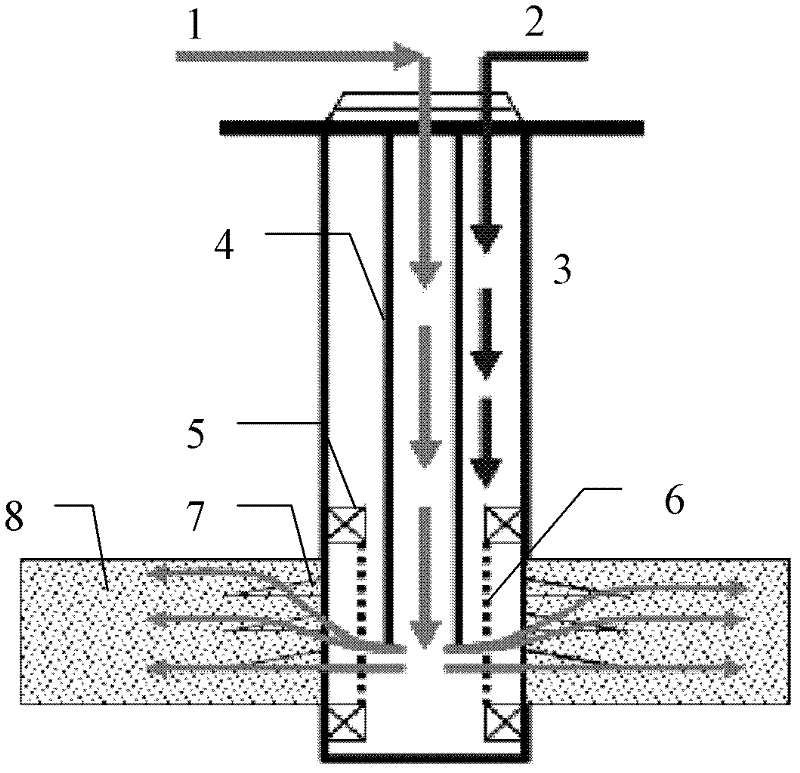

[0028] The general principle of the present invention is explained below with regard to a certain offshore heavy oil well in Bohai Bay as an example, but it should be noted that the present invention is by no means limited to offshore heavy oil wells.

[0029] The heavy oil well is a horizontal branch well with an inclination depth of 1195-1703m (the vertical depth in the middle of the oil layer is 941m), the horizontal well section is 517.25m long, and the average vertical thickness of the oil layer is 7.9m. s. The average daily oil production of this heavy oil well is 35t / d when the electric submersible pump is used for cold recovery.

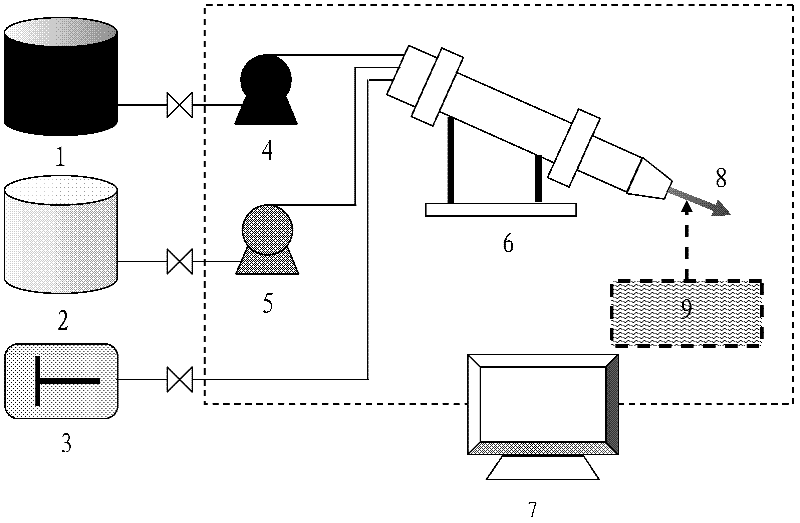

[0030] first reference figure 1 , deliver diesel oil from the fuel tank 1 to the generator 6 at a rate of 70-90kg / h through the oil injection pump 4, and deliver pressurized fuel to the generator 6 at a rate of 1000-1200kg / h through the air compressor and booster 3 The air (pressure is less than 25MPa), after the igniter in the generating d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com