Rectangular vacuum insulation structural board and heat preservation box assembled by same

A vacuum insulation and structural plate technology, which is applied in the directions of thermal insulation, thermal insulation containers, and pipeline protection through thermal insulation, can solve the problem of high development cost, and achieve the effect of low development cost, easy assembly, installation and use, and reduced development cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

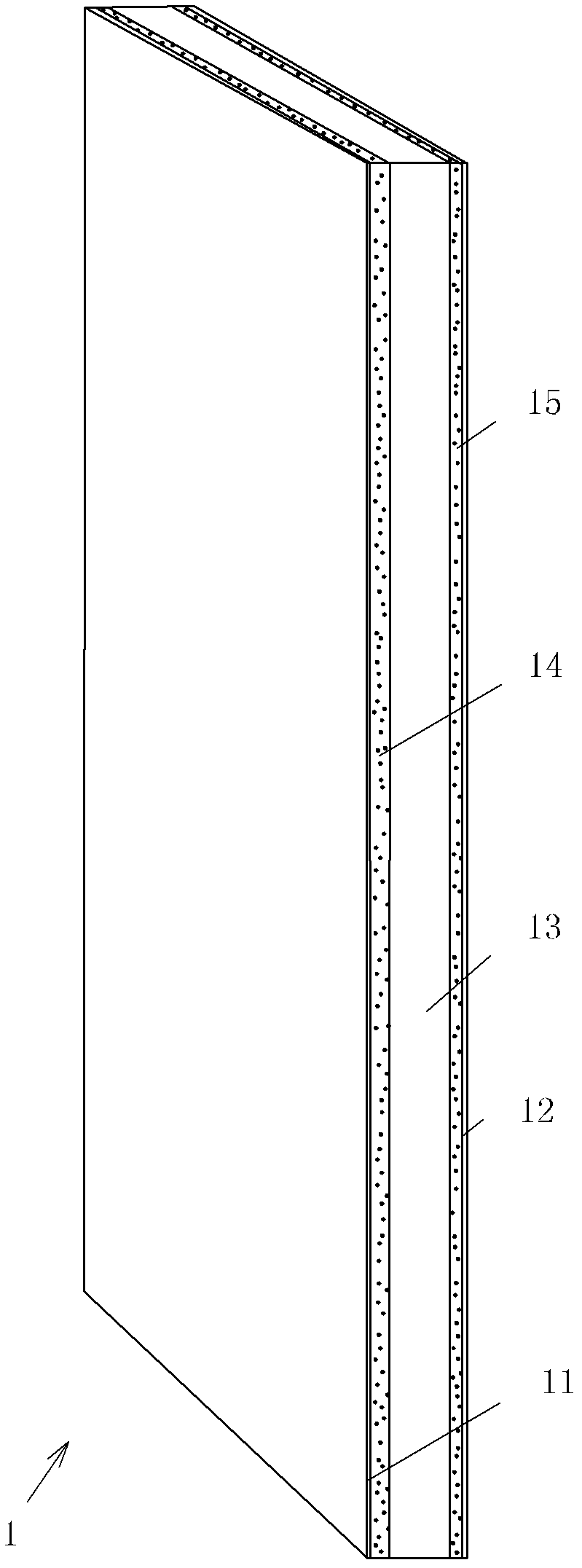

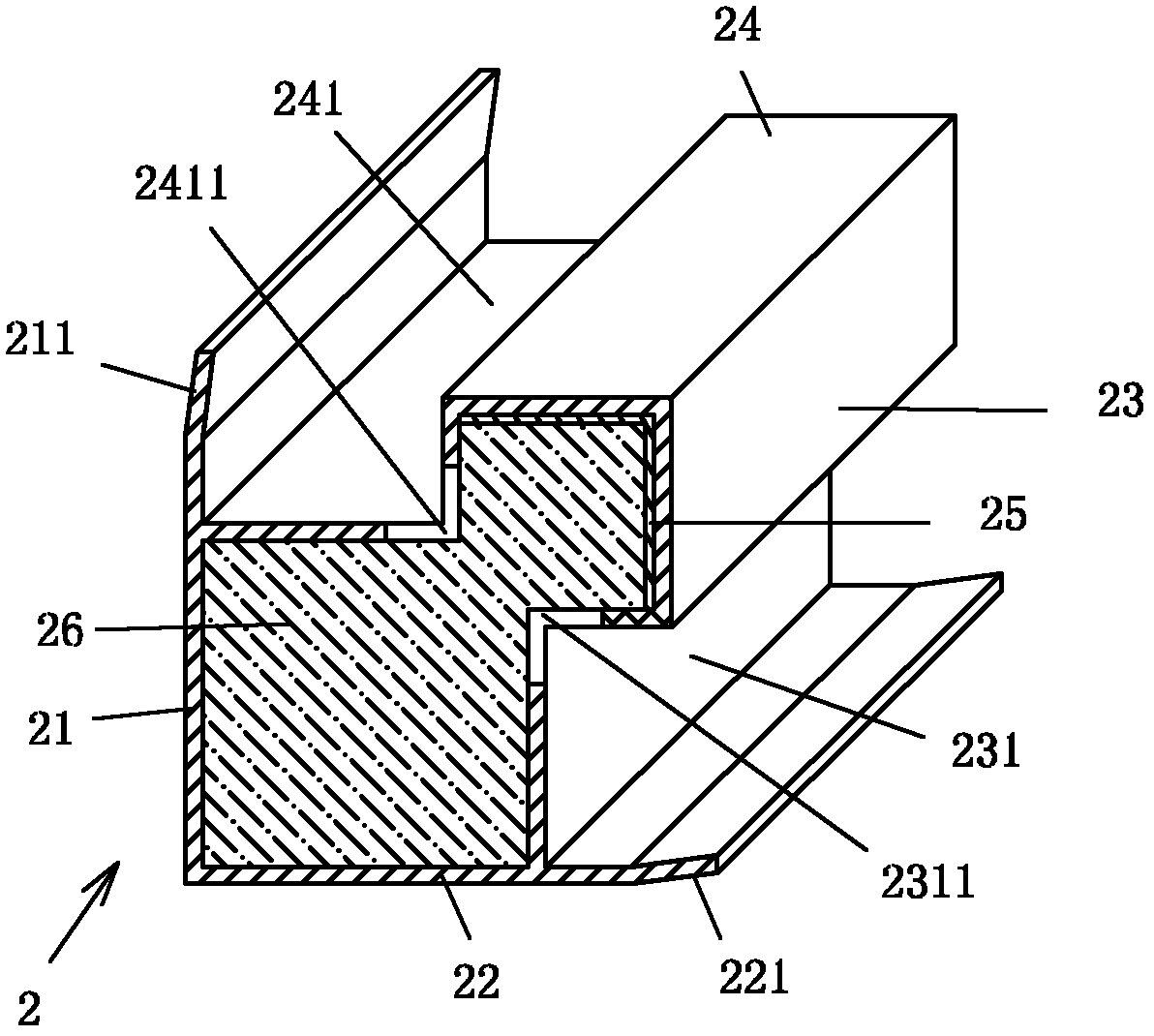

[0044] The structure of an embodiment of the rectangular vacuum insulation structural panel of the present invention, such as figure 1 shown. The vacuum heat insulation structural panel 1 is composed of an outer panel 11 , an inner panel 12 , a vacuum insulation panel 13 and two layers of heat insulating adhesive 14 , 15 . The outer panel 1 is a rectangular flat plate made of metal, engineering plastics, wood, flame-retardant plywood and other decorative and rigid materials. The size and shape of the inner panel 12 are the same as those of the outer panel 11 . The inner panel 12 is made of a rigid material that is easy to scrub and has good corrosion resistance. It is known that there are many rigid plastics that are easy to scrub and have good corrosion resistance. For example, ABS engineering plastic boards can be scrubbed with water for their water resistance, and do not contain toxic and harmful chemicals. Food can be stored in the box. Anti-rust aluminum plate, embosse...

Embodiment 2

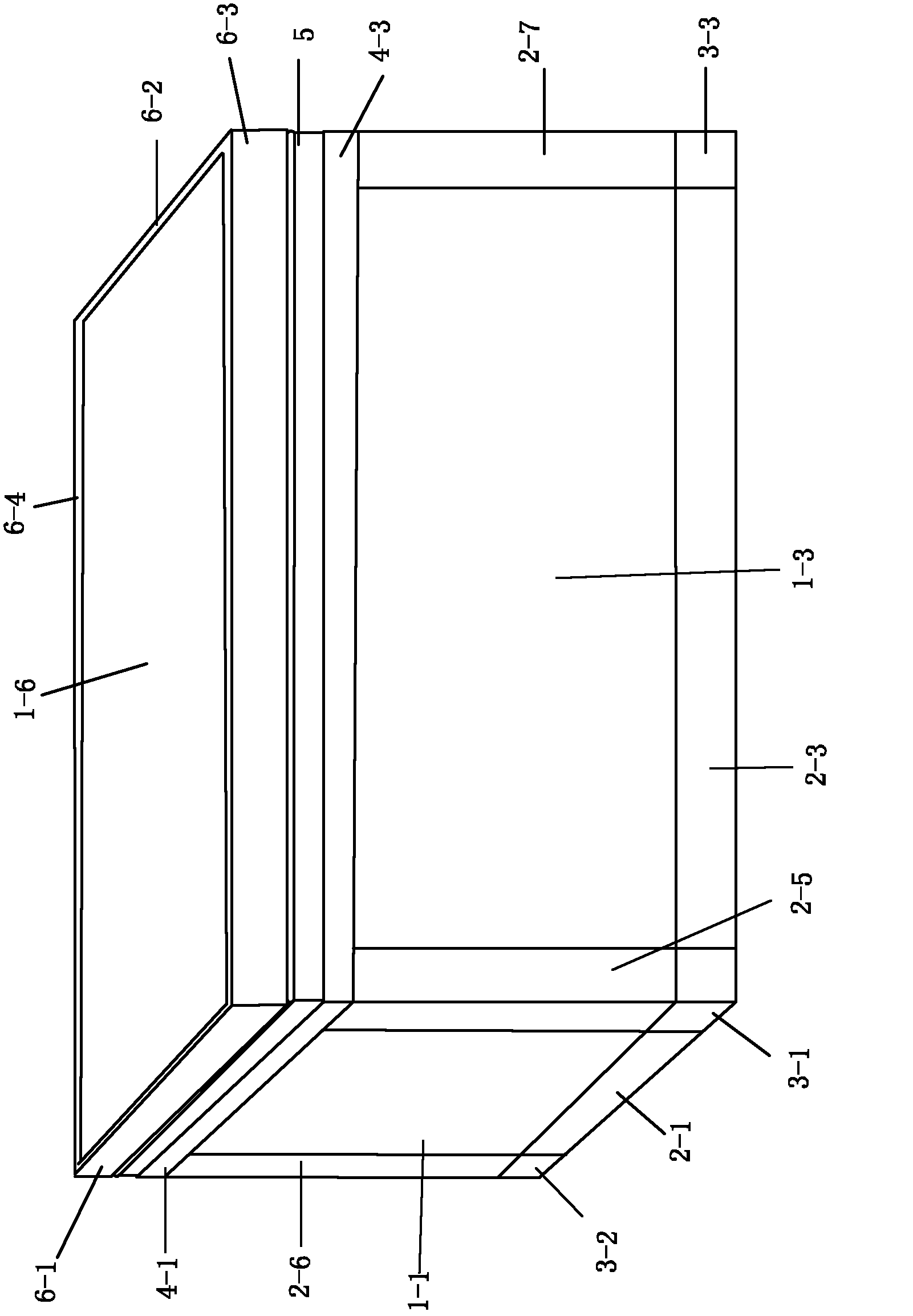

[0063] For the structure of another optimized embodiment of the incubator assembled with rectangular vacuum insulation structural panels of the present invention, please refer to Figure 16 . It is based on eight hollow edge profiles 2'-1, 2'-2, 2'-3, 2'-4, 2'-5, 2'-6, 2'-7, 2'-8 and four The hollow box mouth profiles 4-1, 4-2, 4-3, 4-4 form a rectangular box frame; the bottom of the box frame is provided with the aforementioned rectangular vacuum insulation structural panels 1-5, and the four sides are respectively equipped with the aforementioned The rectangular vacuum insulation structural panels 1-1, 1-2, 1-3, 1-4 form a box body with an upper end opening; a rectangular ring-shaped door seal 5 containing magnetic material strips 53 on four sides is set in the opening of the box body The outer periphery of the place; a piece of the aforementioned rectangular vacuum insulation structural panel 1-6 with edge sealing profiles 6-1, 6-2, 6-3, 6-4 constitutes a door panel that i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com