Patents

Literature

51results about How to "Apply stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

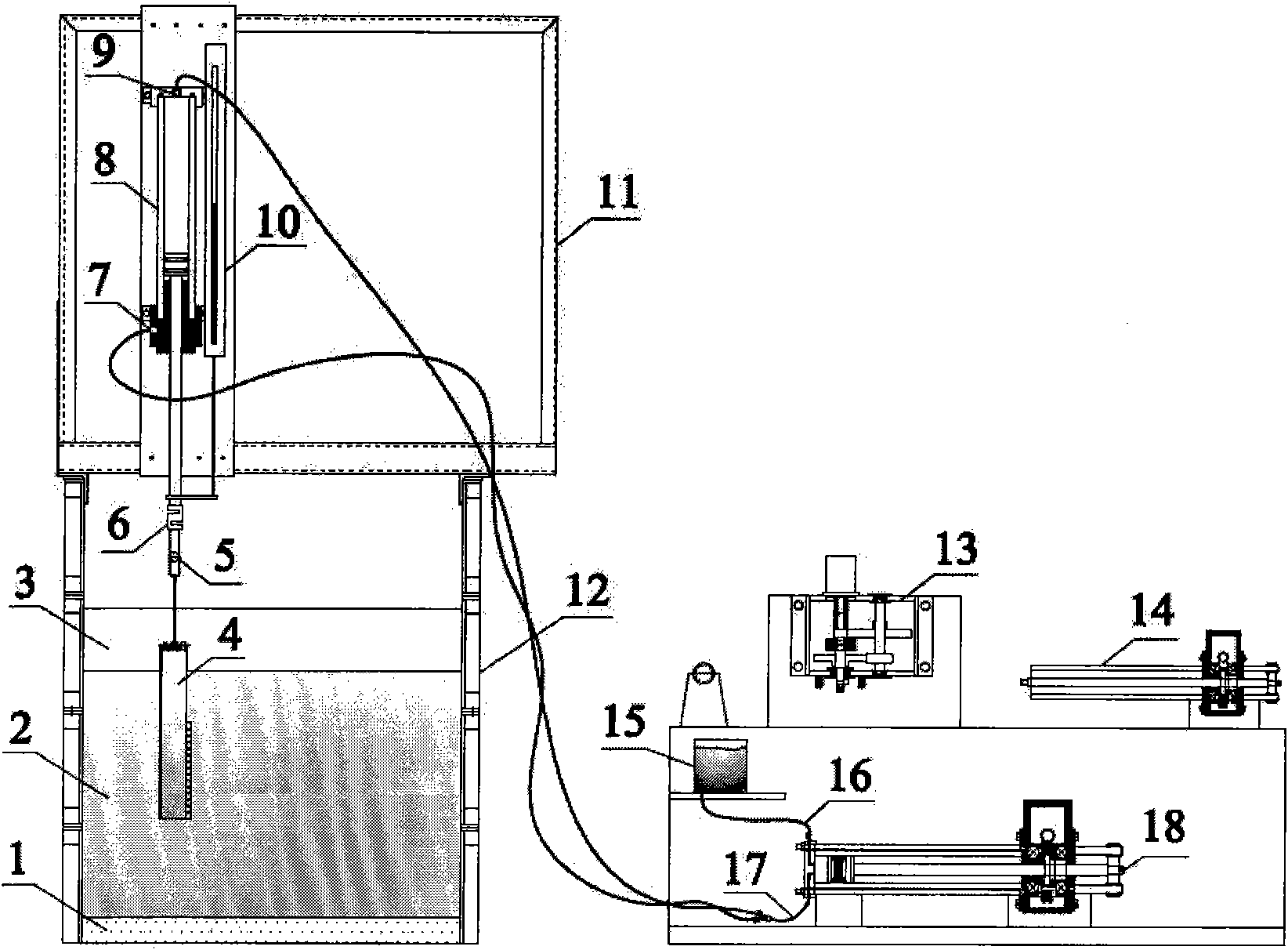

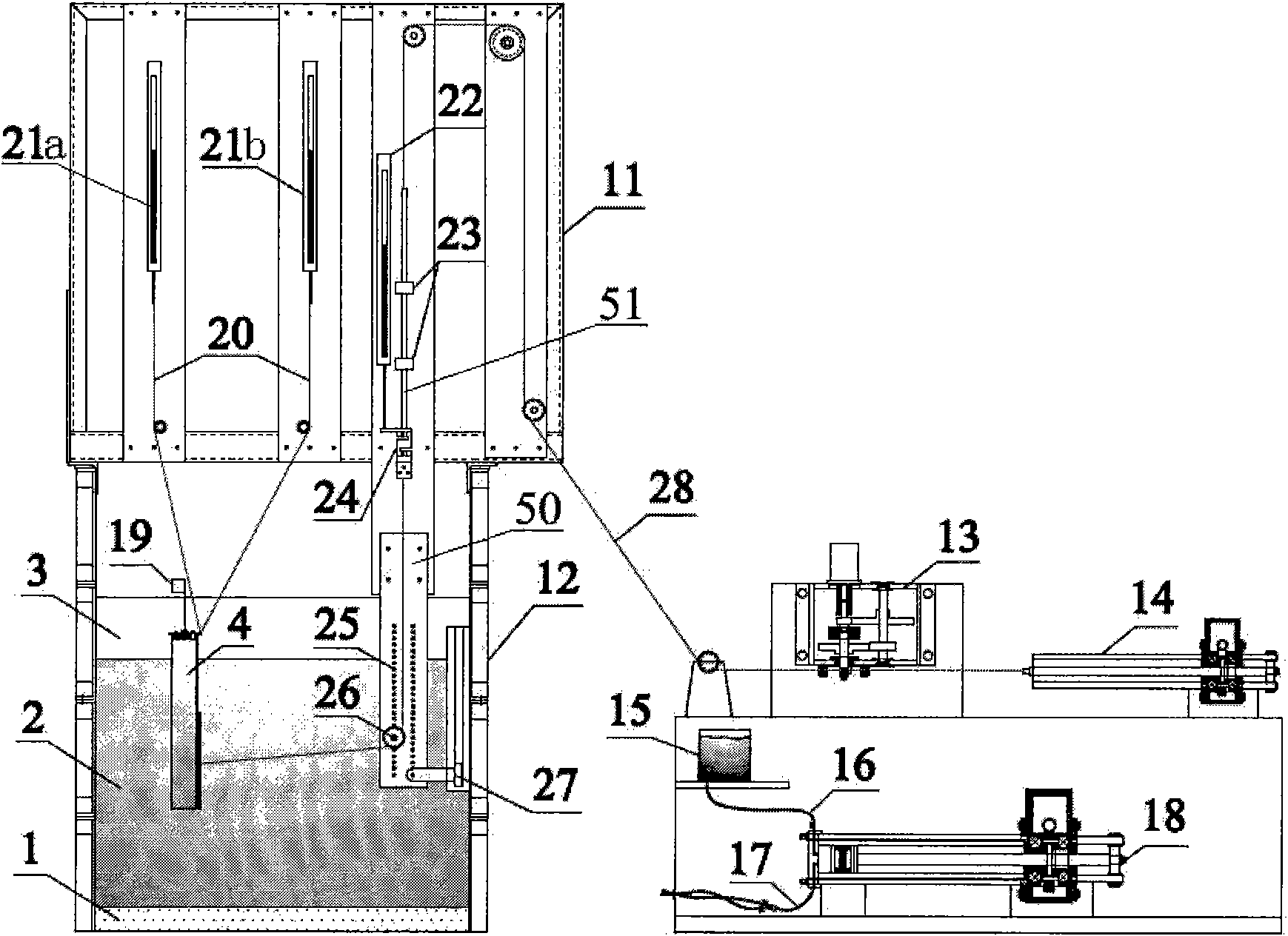

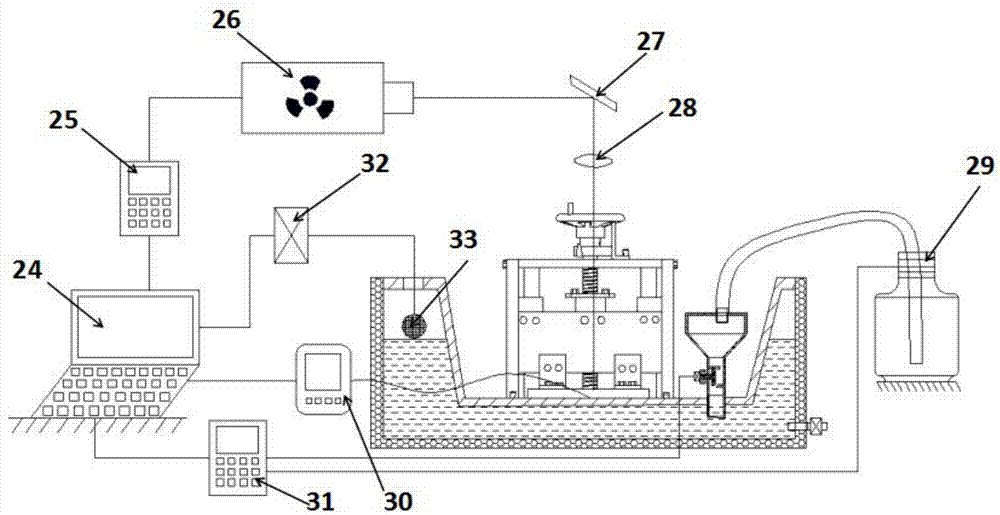

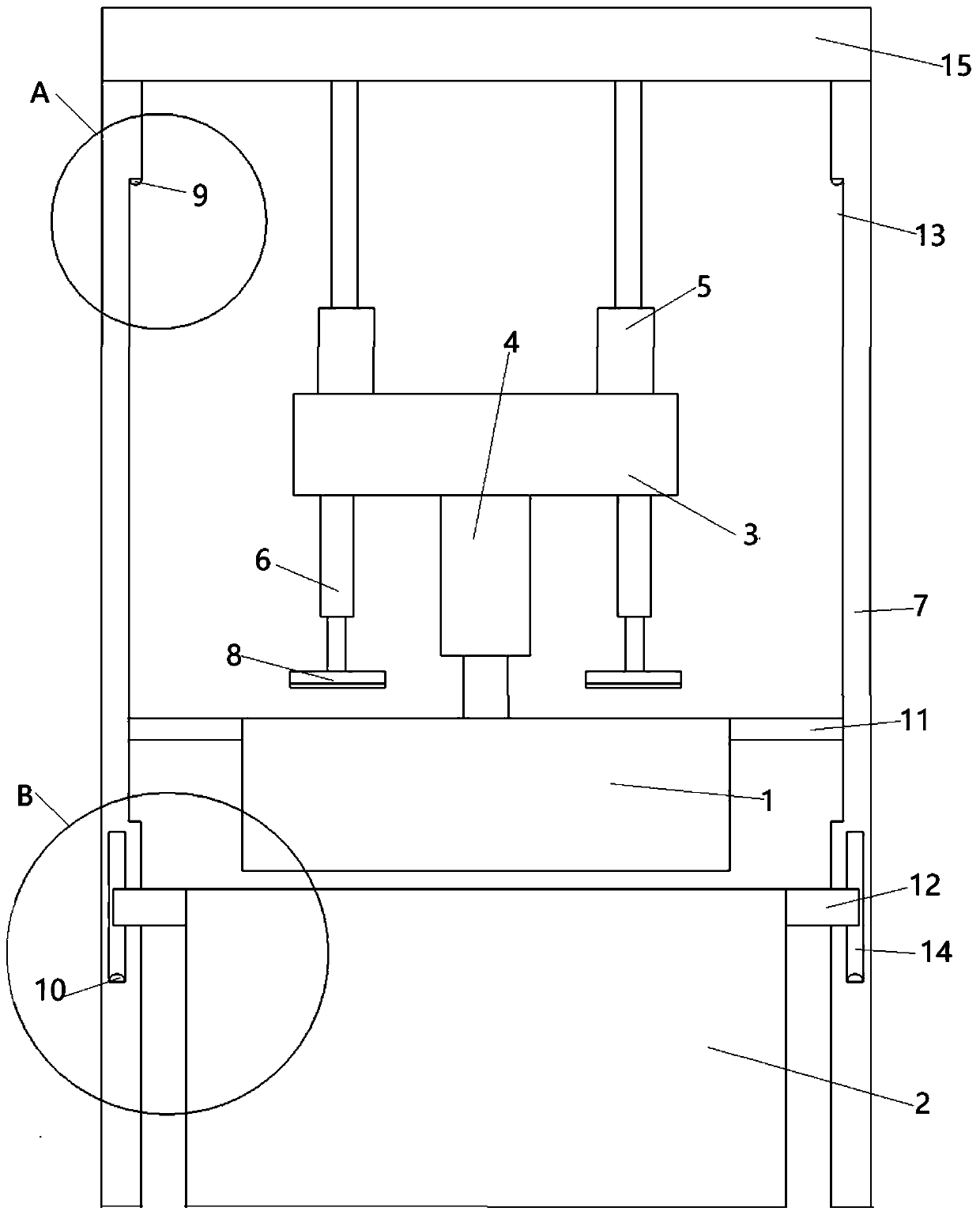

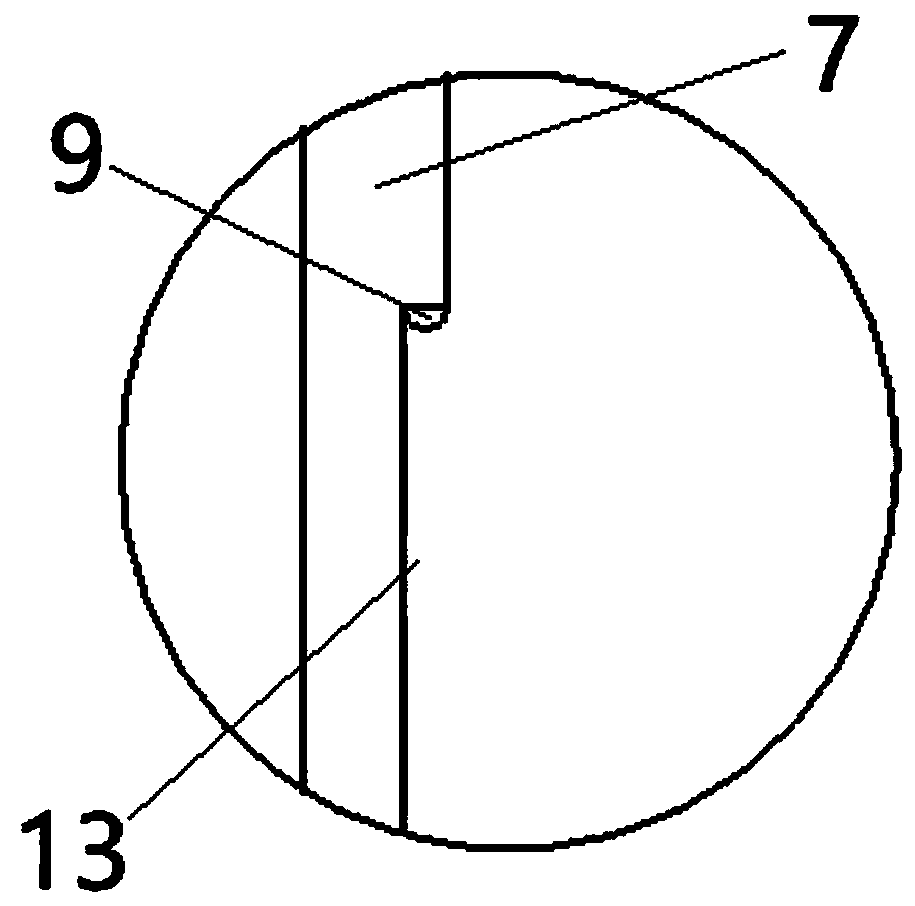

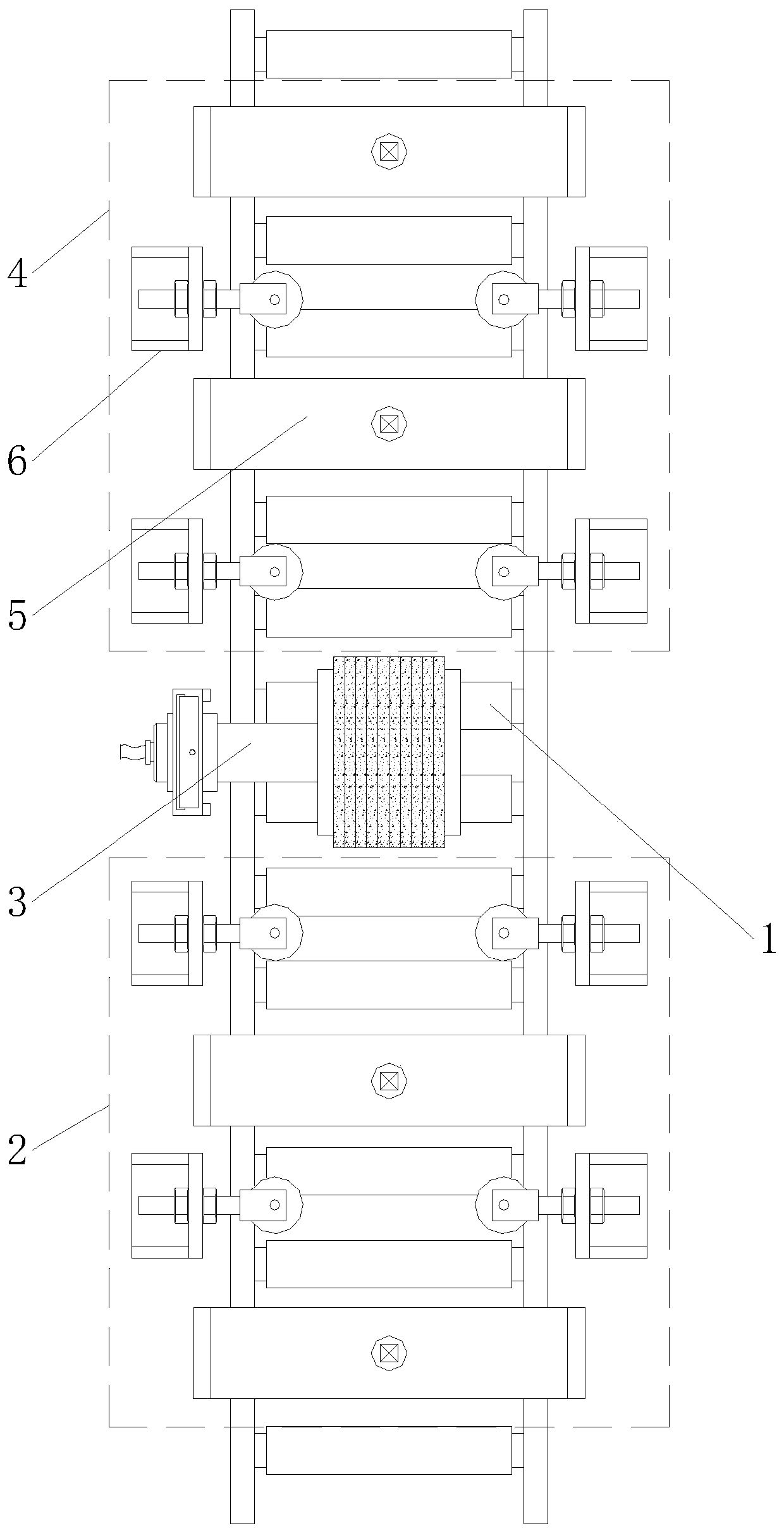

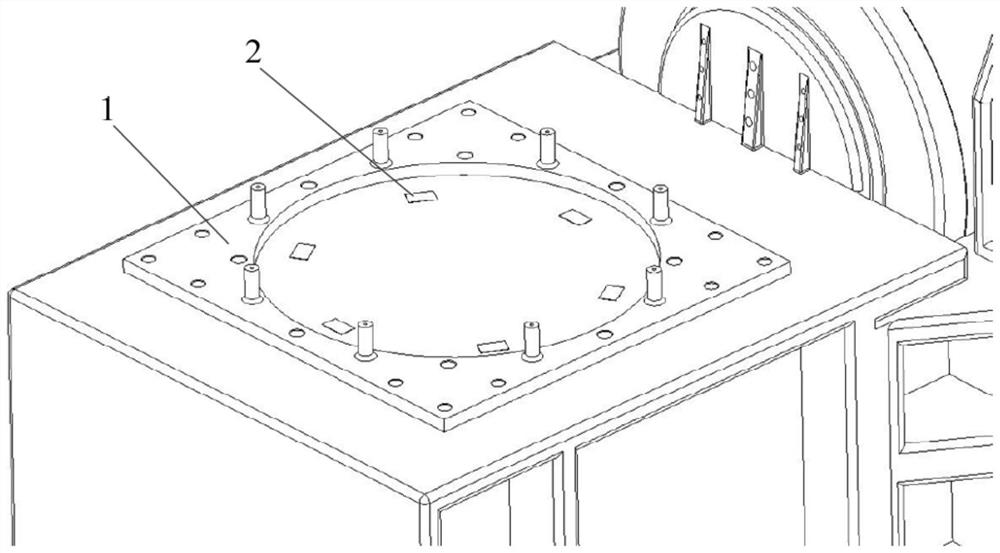

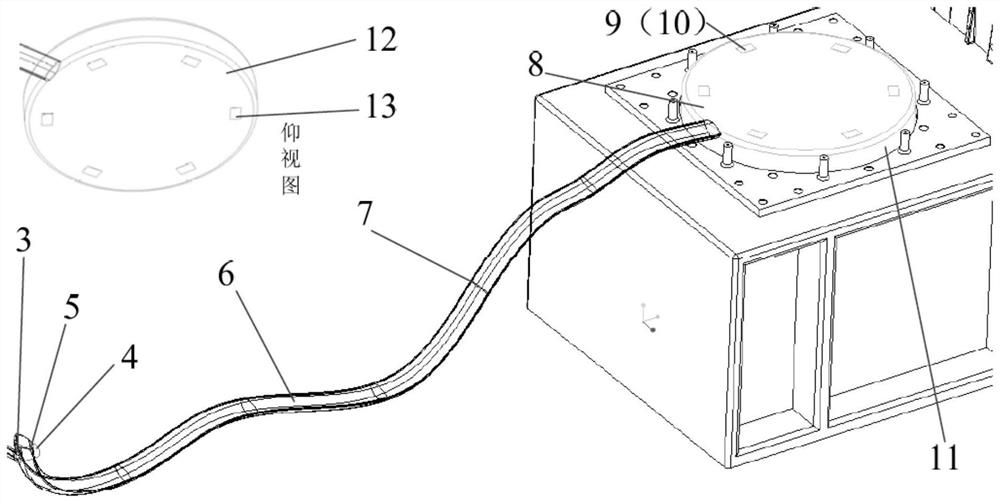

Installation and complex loading model testing platform for novel deep sea mooring foundation

ActiveCN101839815AEasy to changeImprove efficiency and stability of resultsStructural/machines measurementCable tensionFixed frame

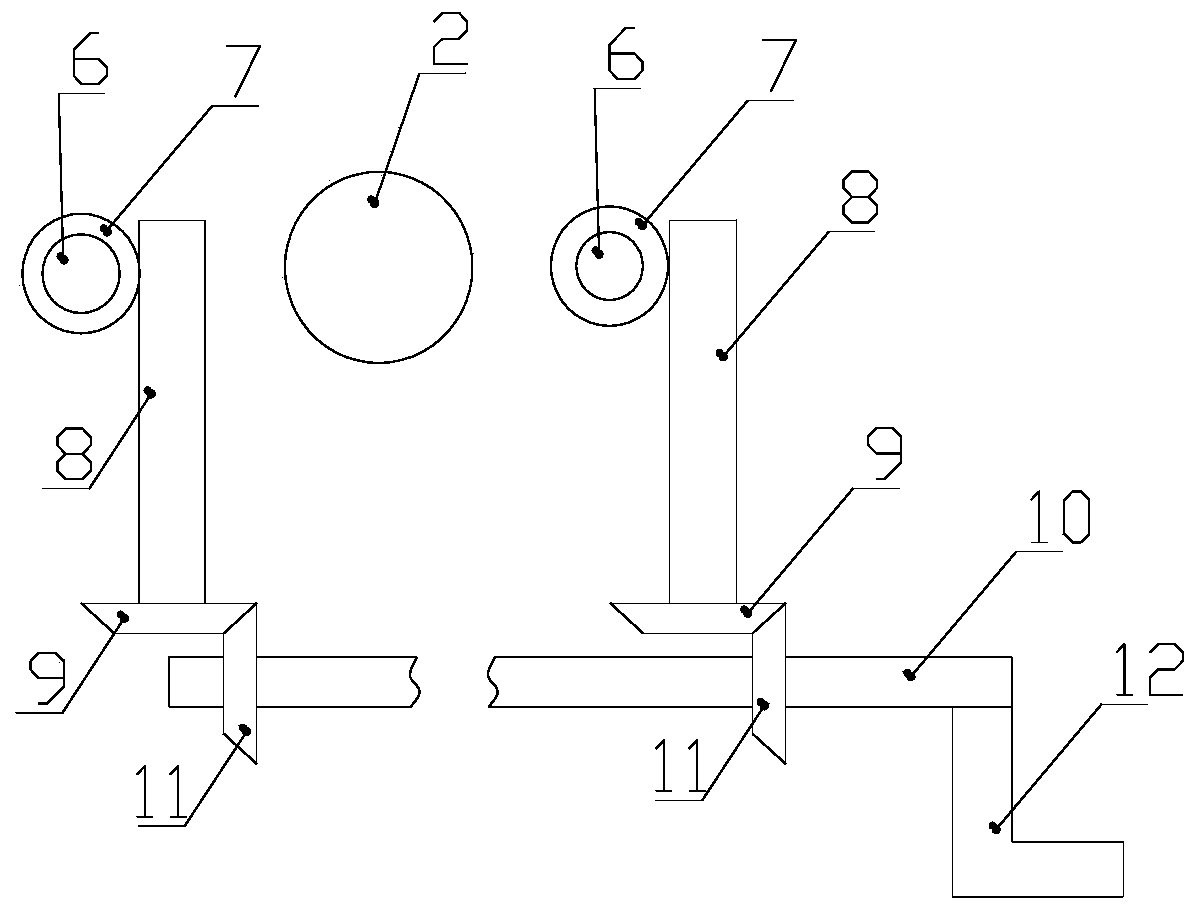

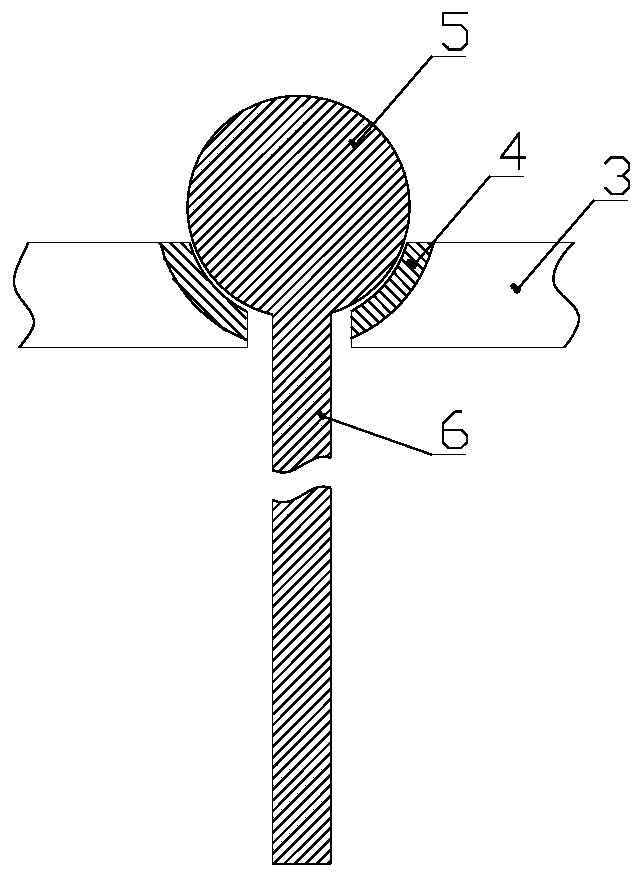

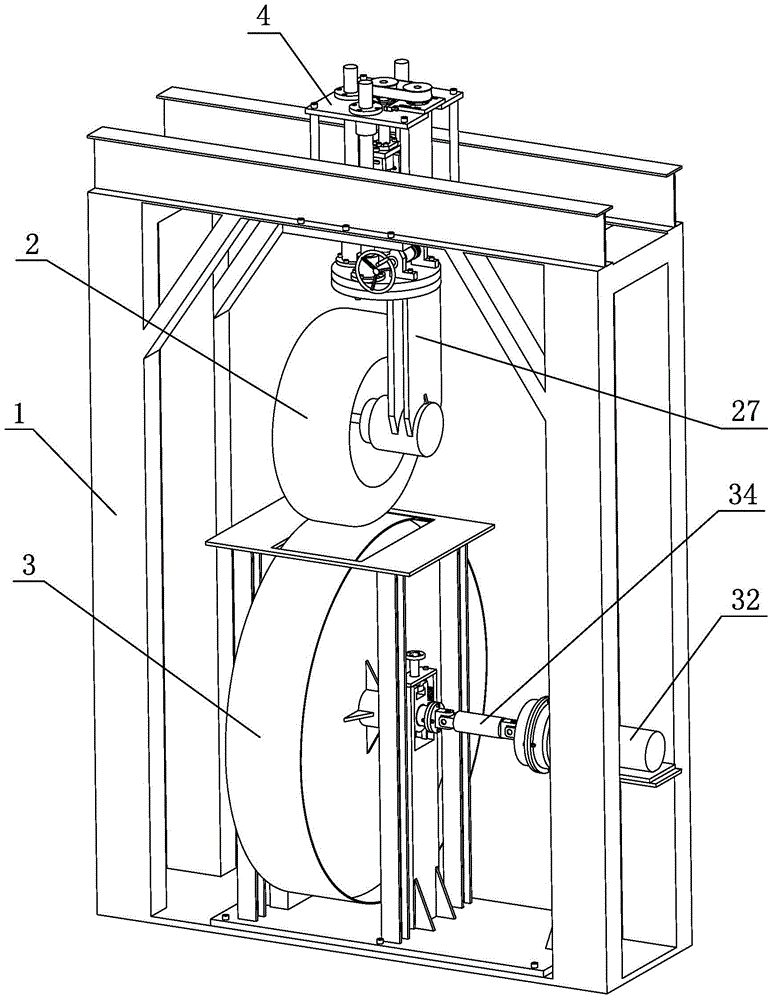

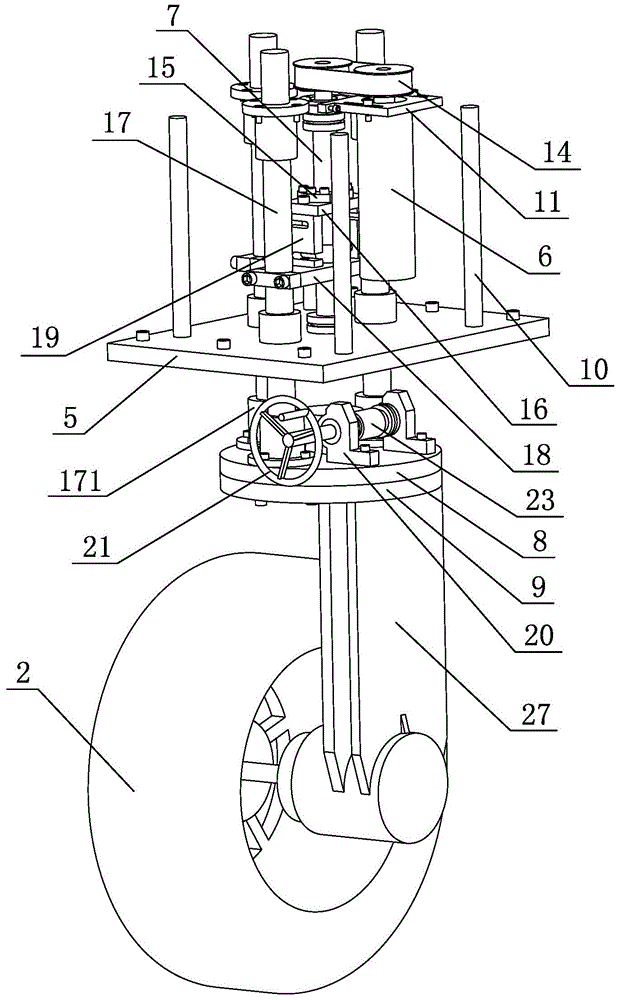

The invention provides an installation and complex loading model testing platform for a novel deep sea mooring foundation. The testing platform comprises anchors, testing grooves, a loading fixed frame, a vertical power device, a connecting mechanism, a vertical power device pulling force sensor, a first displacement sensor, an inclinometer, a tension regulator, a pulling cable, a pulling cable guide pulley block, a pulling force direction regulating mechanism, a pulling cable tension measurement sensor, a second displacement sensor, a pulling cable circulating load regulator, a third displacement sensor and a fourth displacement sensor. The invention can realize the model testing research of the bearing capacity characteristics of the novel mooring foundation in deep sea complex static and dynamic loading environments, improves the efficiency of the model testing and the stability of results, and has great promotion and pushing functions on the research of the novel deepwater mooring foundations.

Owner:ZHEJIANG UNIV

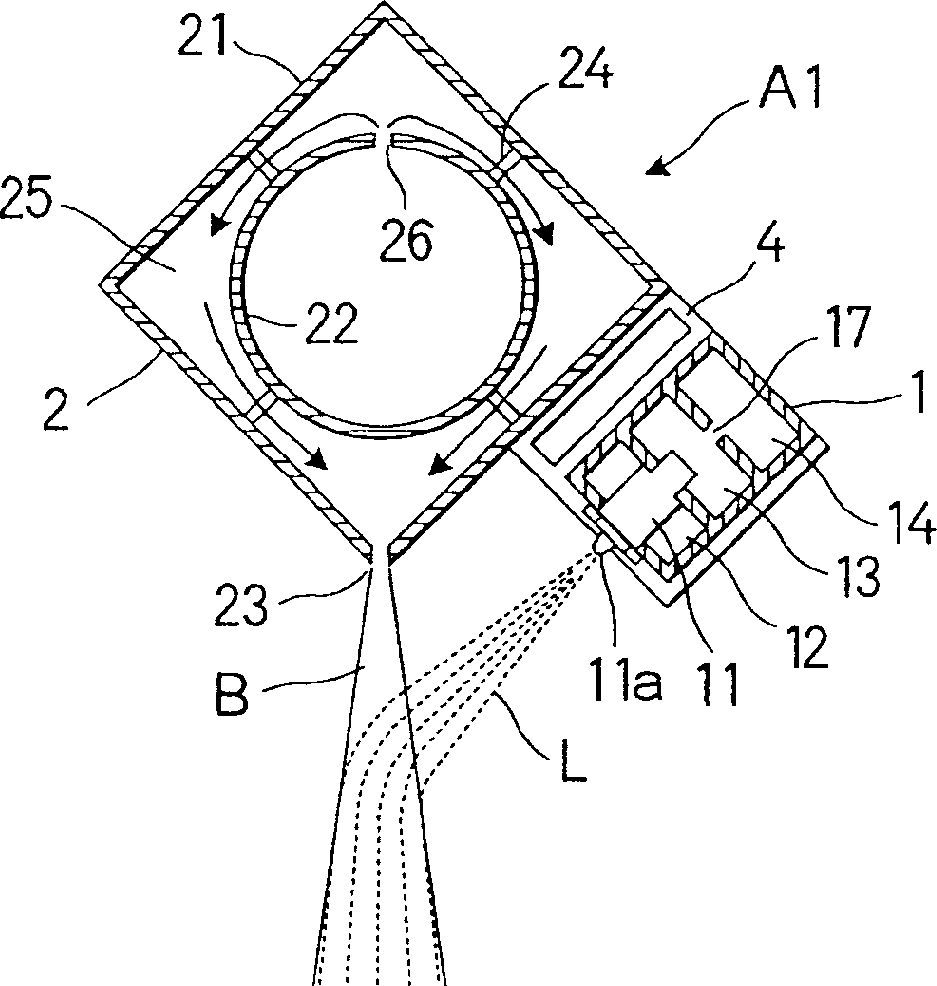

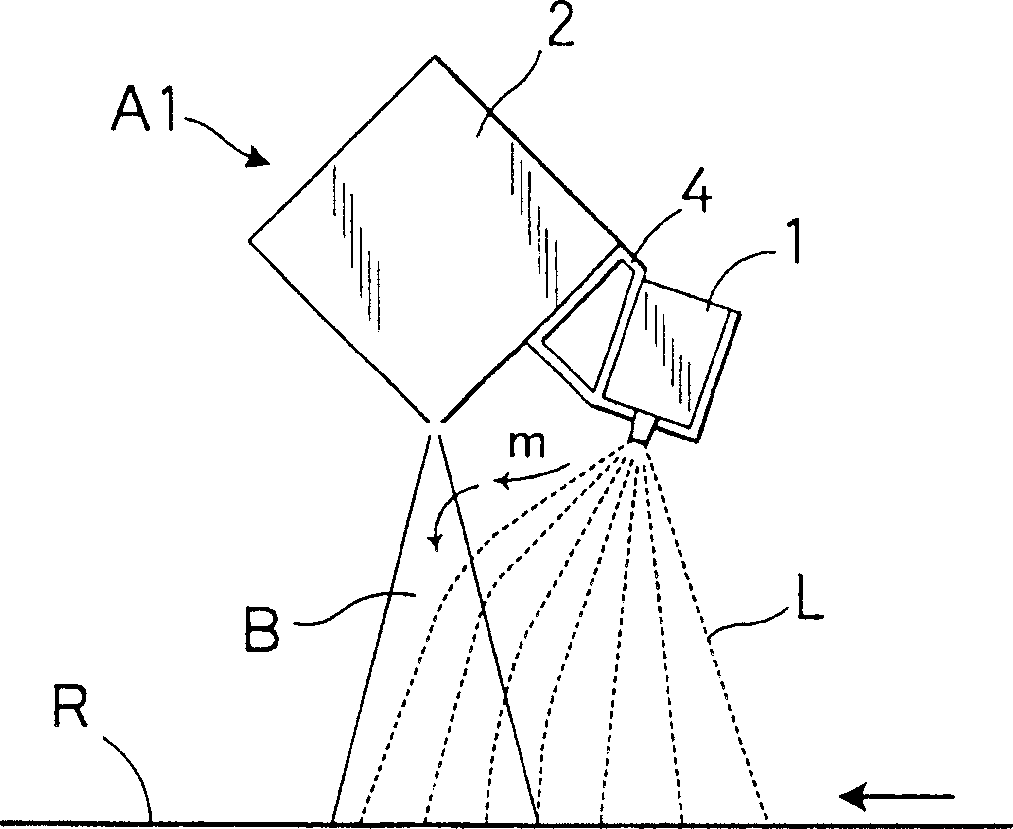

Liquid spray unit, method for spraying liquid using it, and chemical

InactiveCN1668382ASpeed up sprayingApply stabilityWater-repelling agents additionReinforcing agents additionInterior spaceSpray nozzle

A liquid spray unit which can impart liquid (treating liquid, medicine, or the like) surely to a traveling body even in a high speed paper making machine. The liquid spray unit for spraying liquid to a traveling body comprises a spray tube provided with a nozzle for spraying liquid, and an air box provided with an opening for jetting an air flow, wherein the spray tube and the air box are arranged such that the air flow is jetted from the air jet opening toward the liquid sprayed from the spray nozzle and the sprayed liquid can be blown to the traveling body after being accelerated by the air flow. The liquid can be sprayed more effectively to the traveling body by making compact the unit depending on the quantity of liquid being imparted or the inner space of a paper making machine, or the like, or by employing a unit of a type of reciprocating a single nozzle.

Owner:明答克株式会社

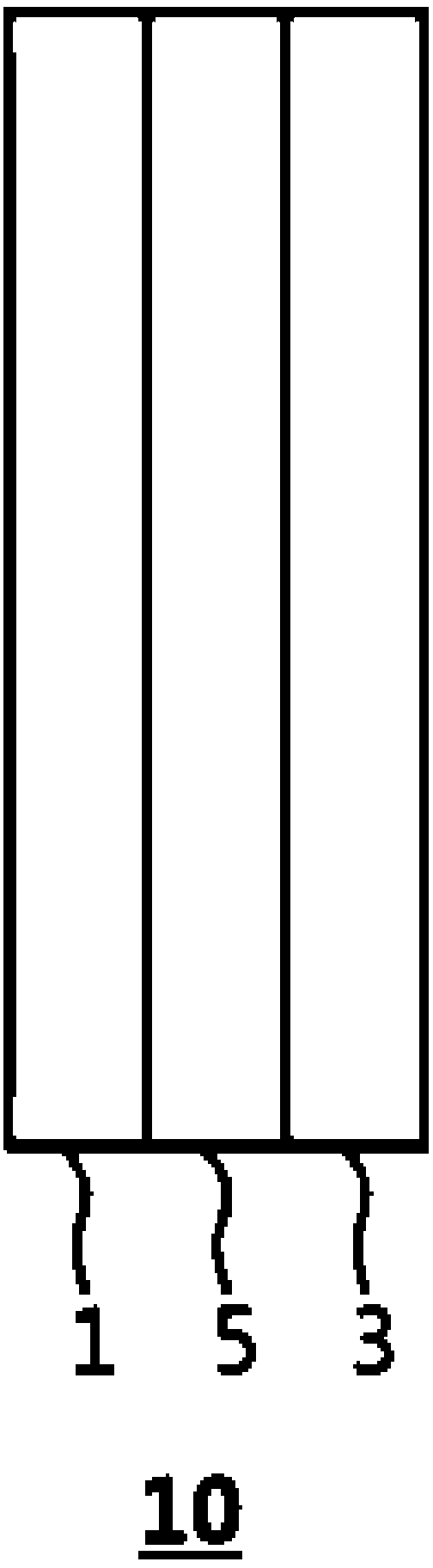

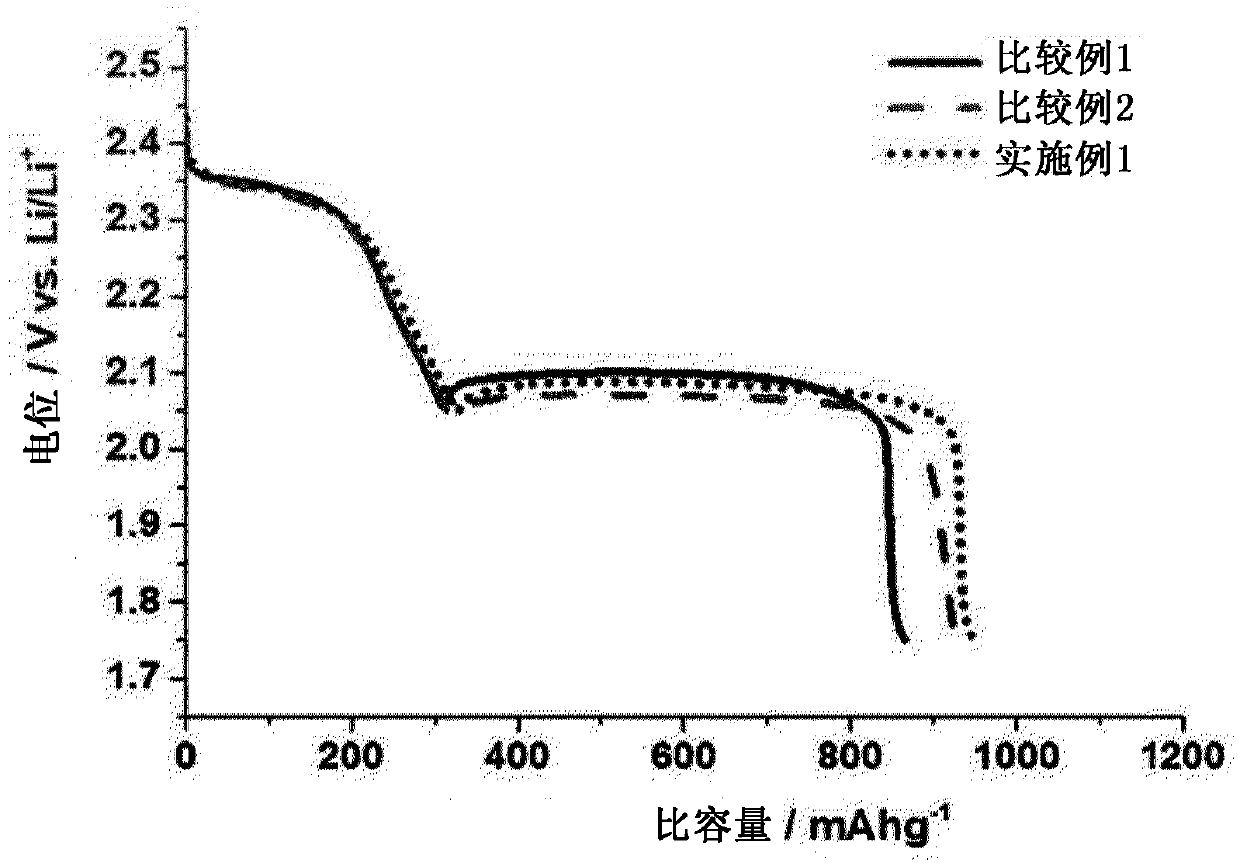

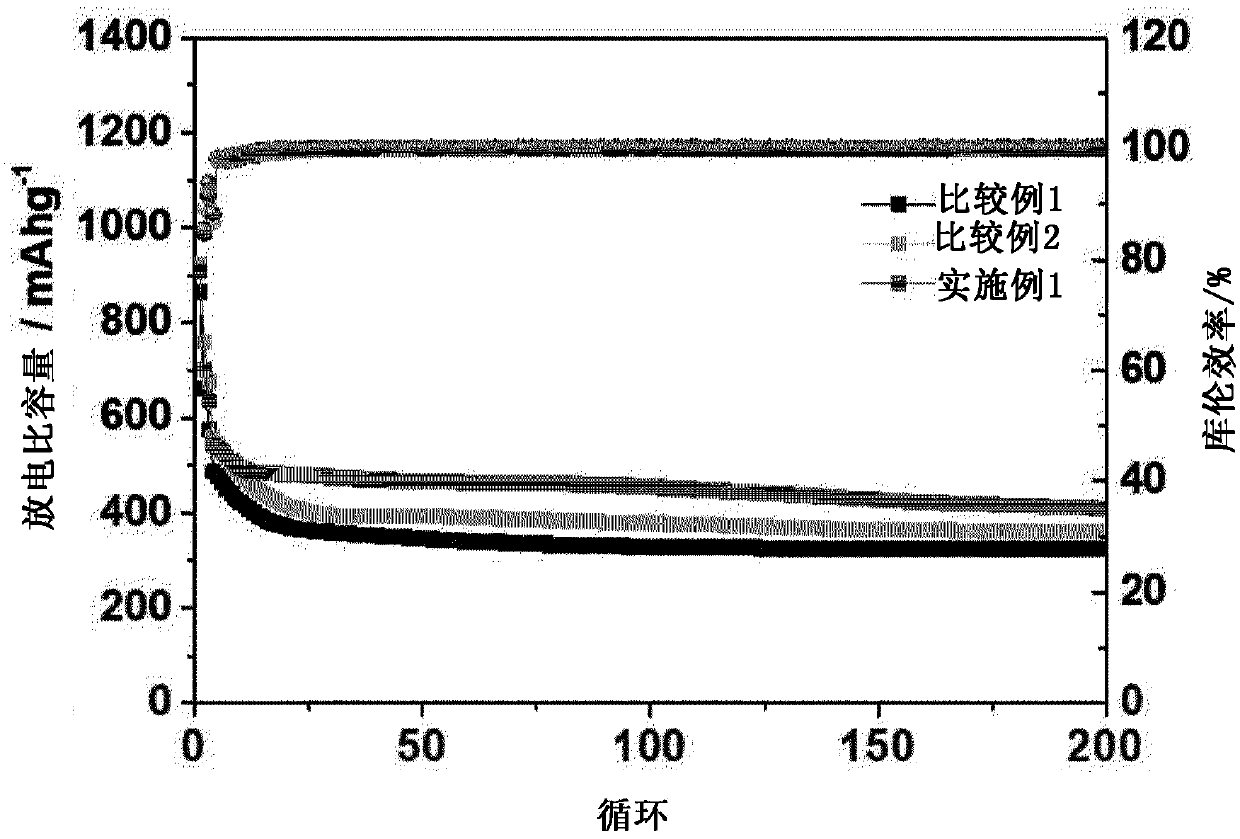

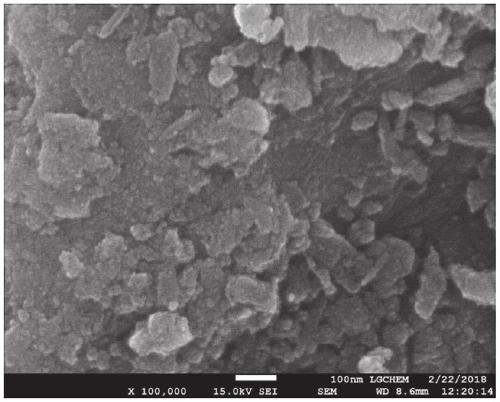

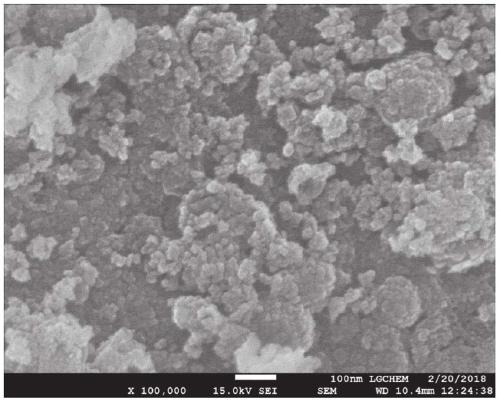

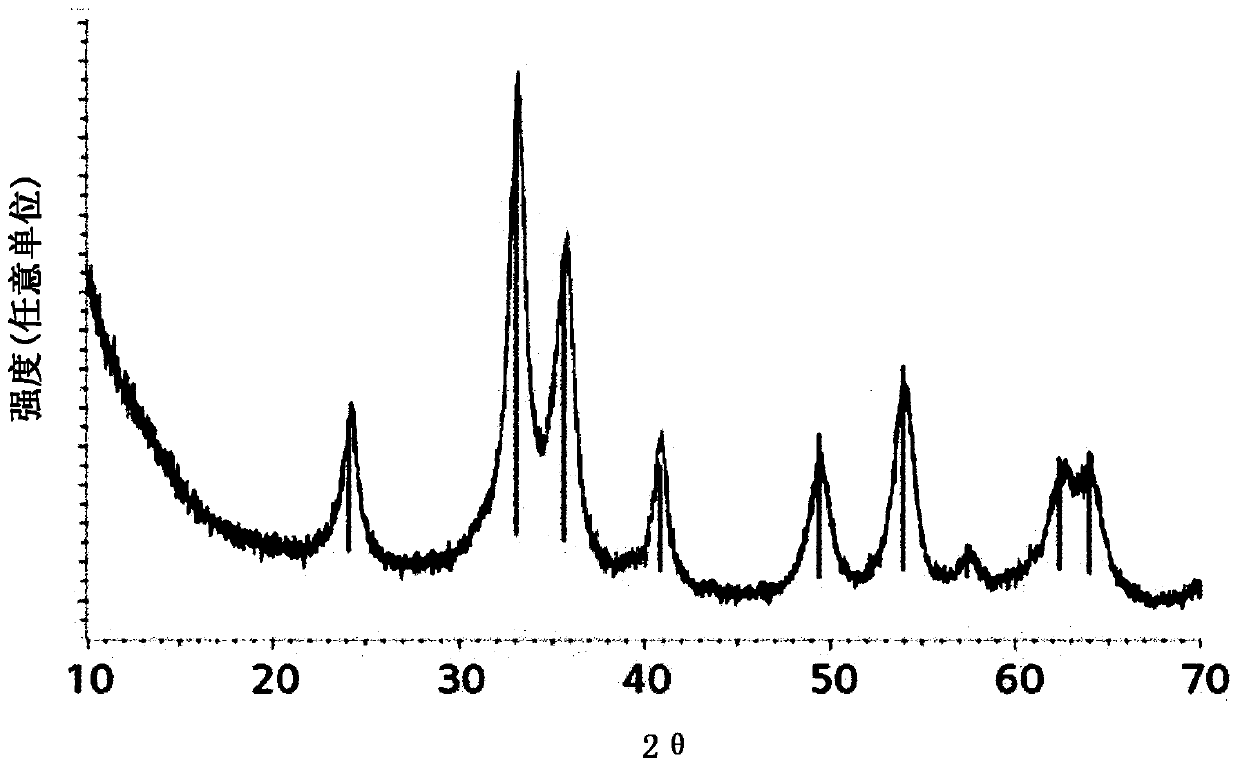

Separator and lithium-sulfur battery comprising same

ActiveCN109565018ASolve the generated lithium polysulfideSolving problems caused by lithium dendritesCell seperators/membranes/diaphragms/spacersCell electrodesPorous substrateLithium–sulfur battery

The present invention relates to a separator and a lithium-sulfur battery comprising same, the separator having at least one side of a porous substrate thereof coated with graphene oxide and boron nitride and thereby being capable of simultaneously solving problems caused by lithium polysulfides and lithium dendrites occurring in conventional lithium-sulfur batteries.

Owner:LG ENERGY SOLUTION LTD

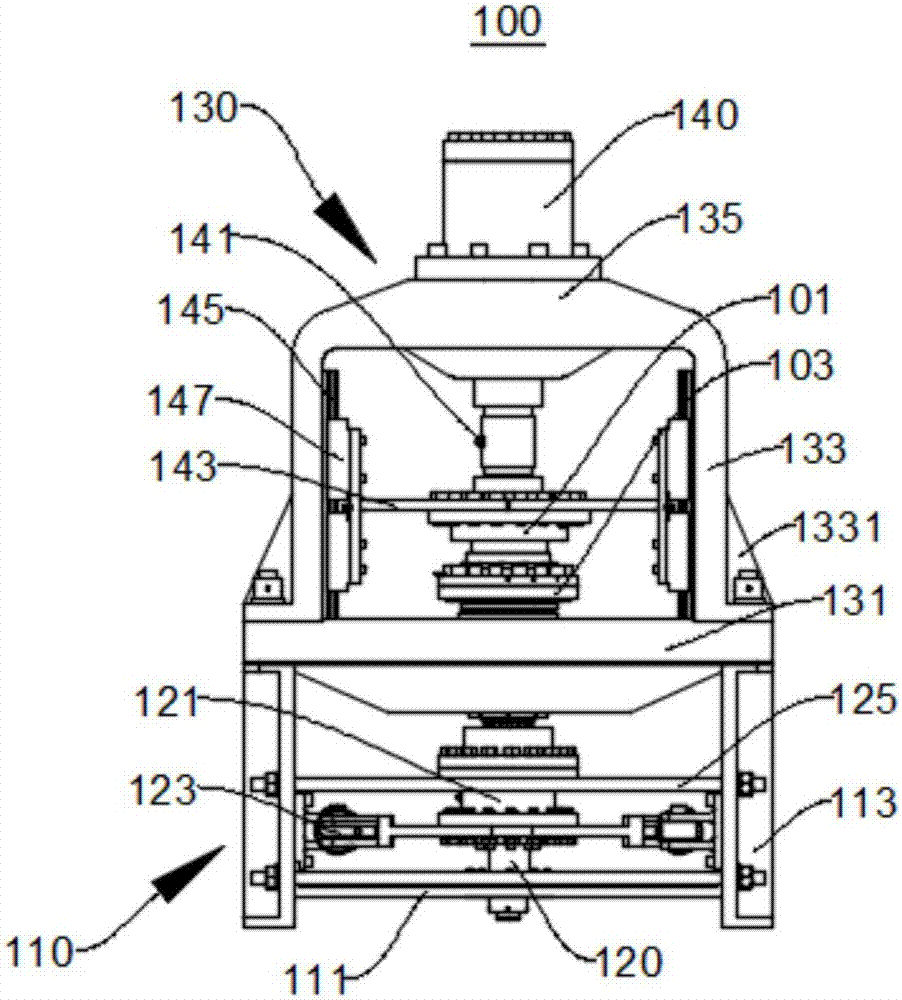

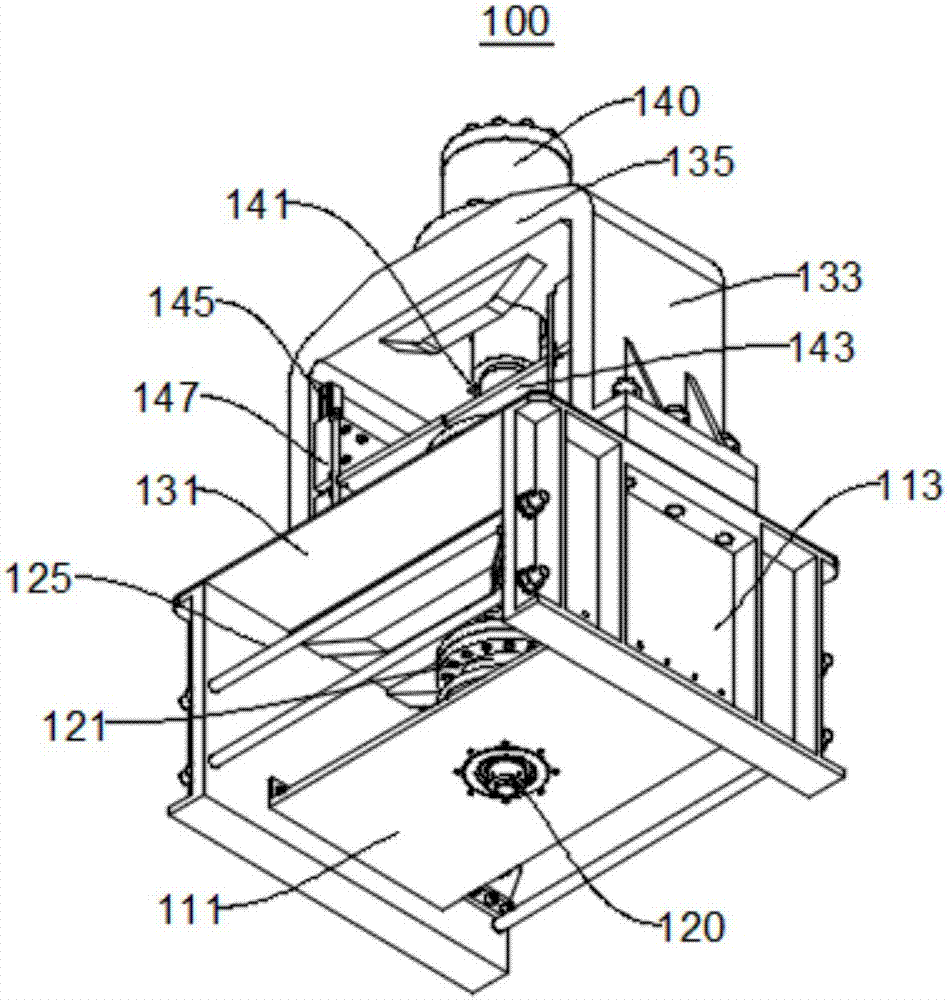

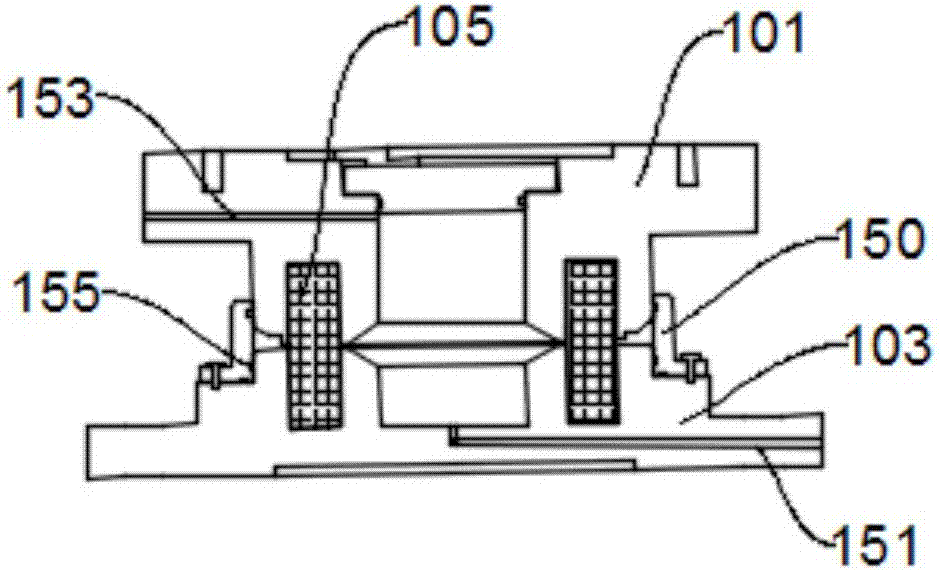

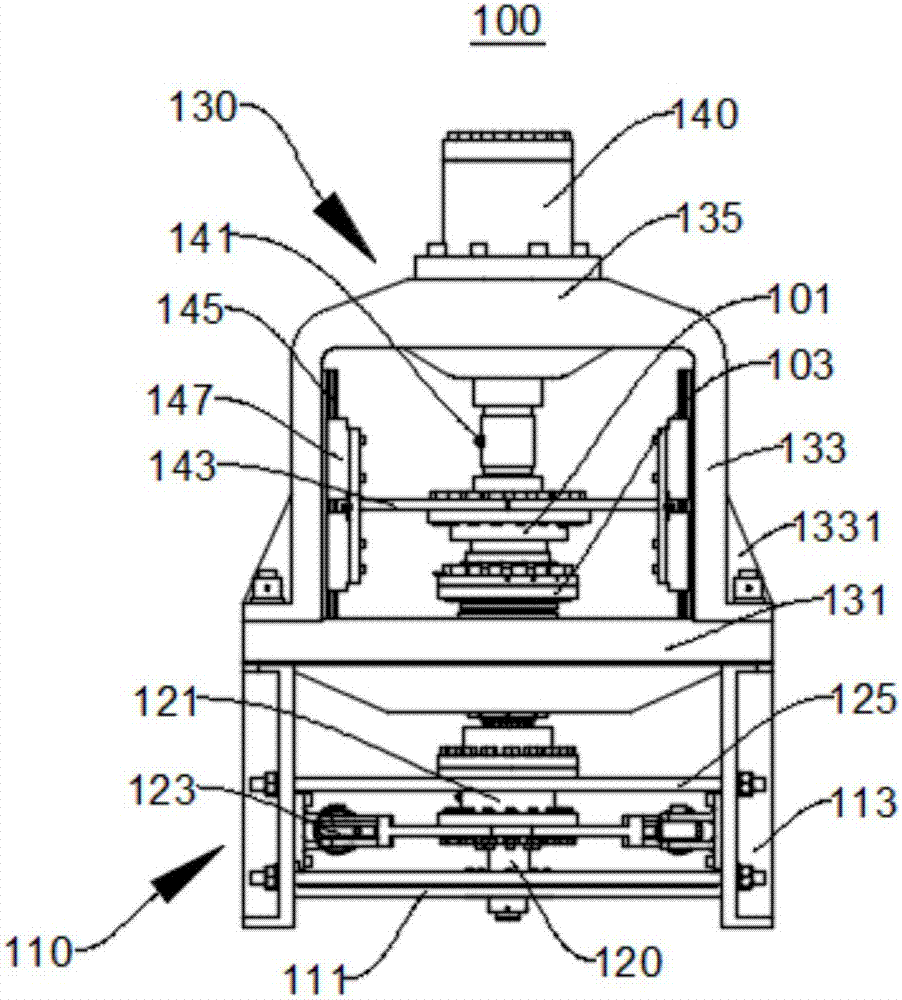

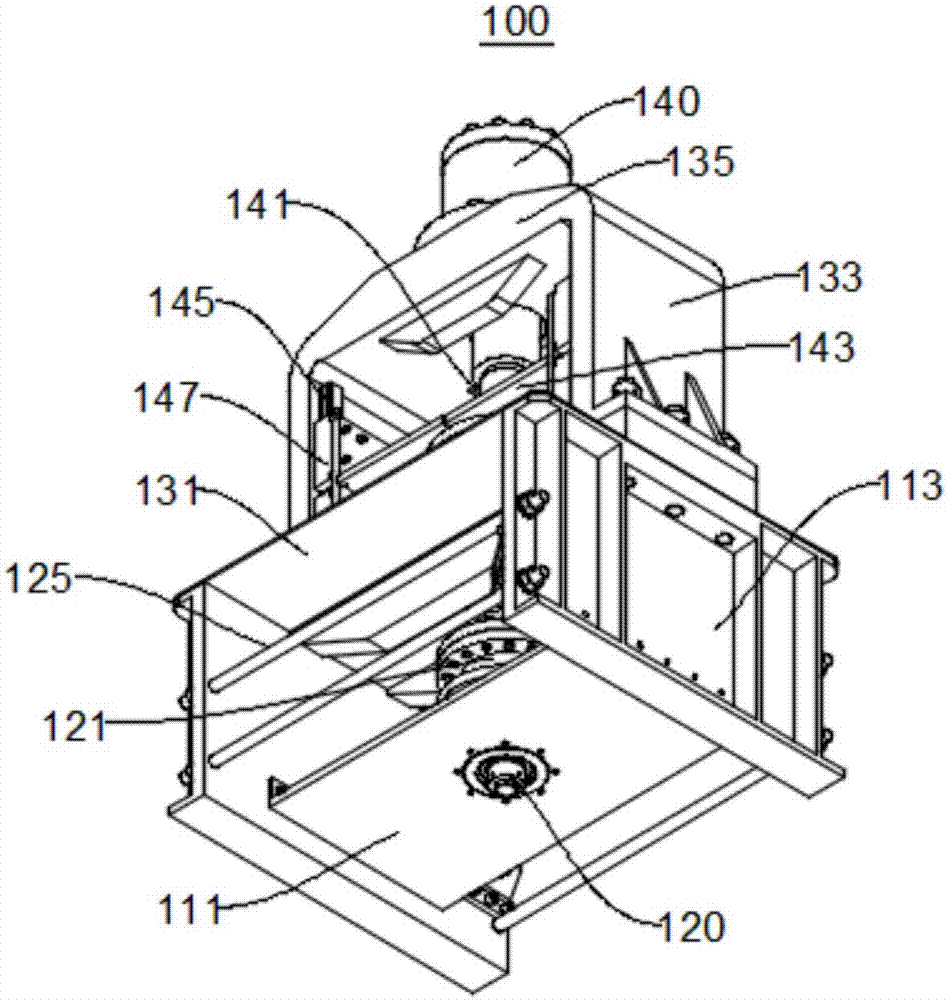

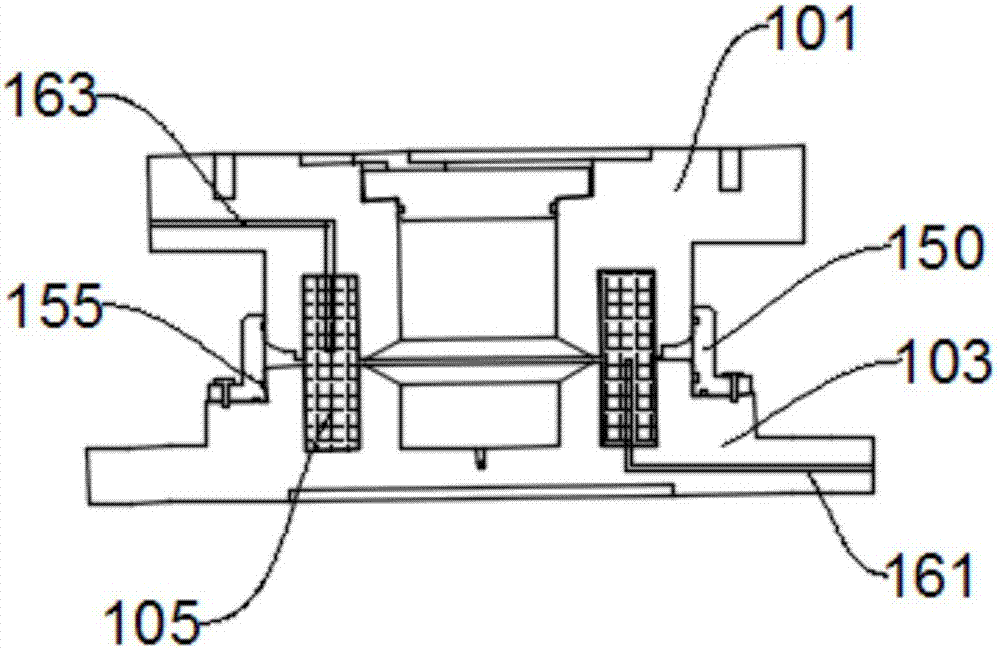

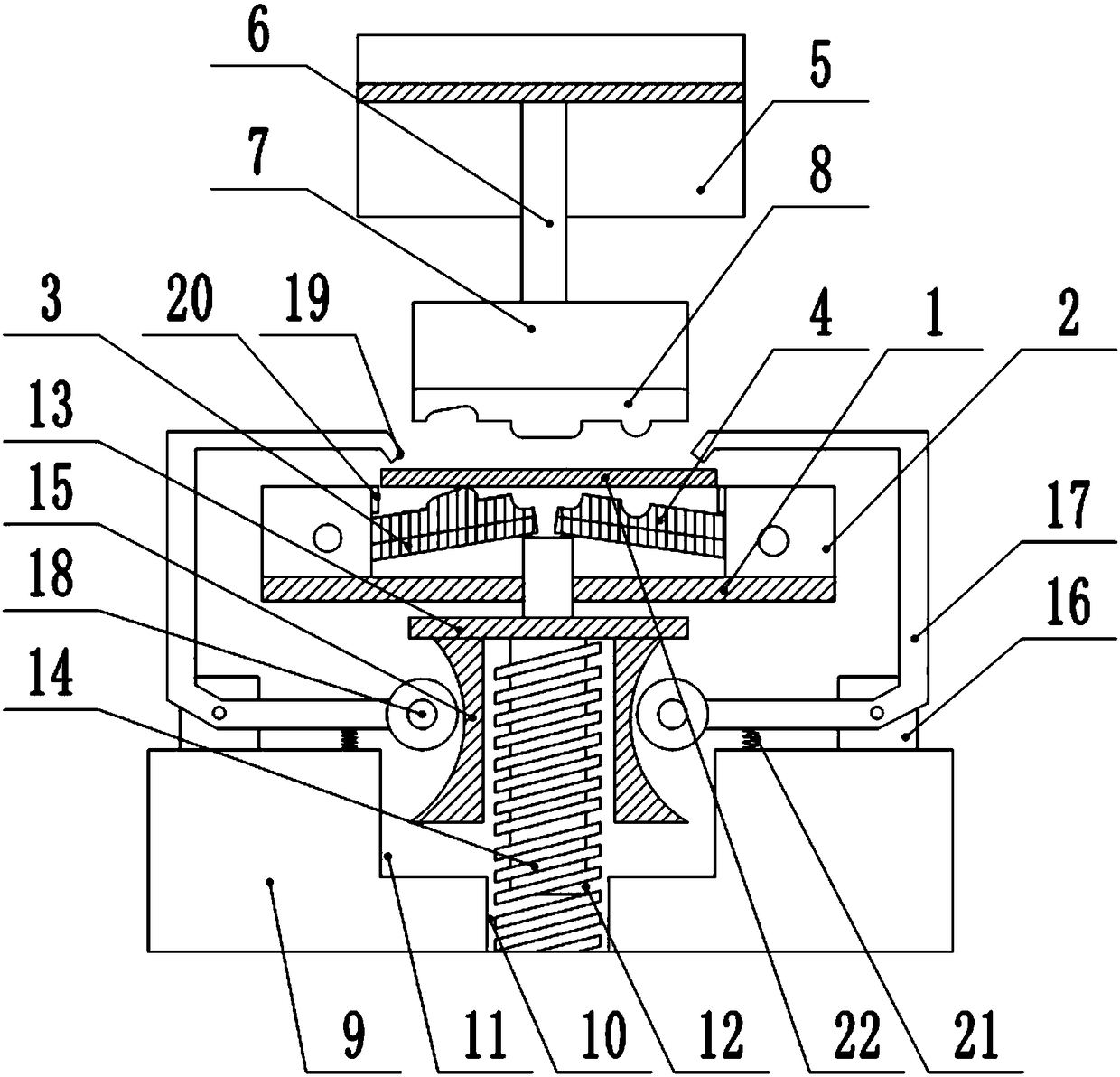

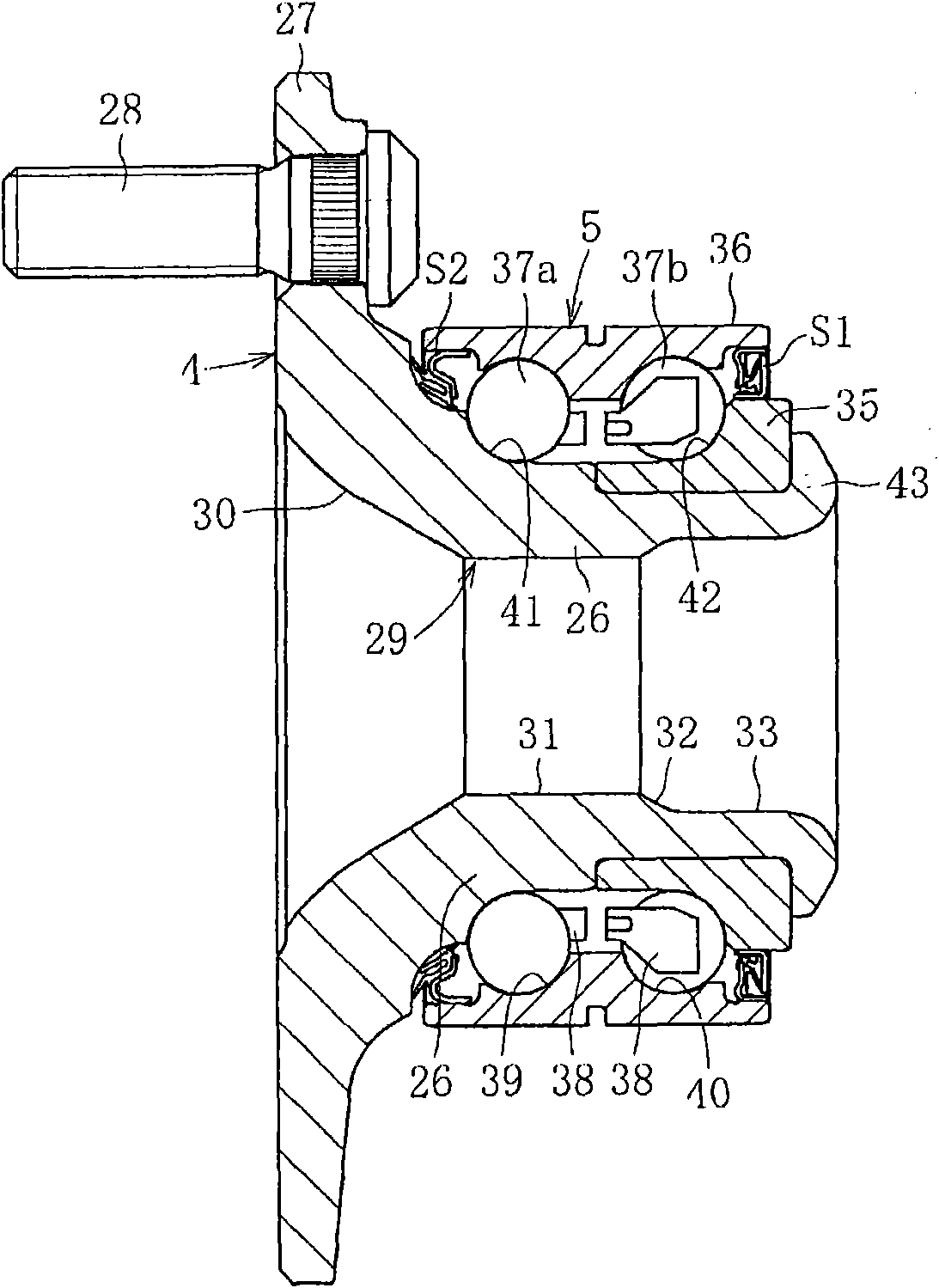

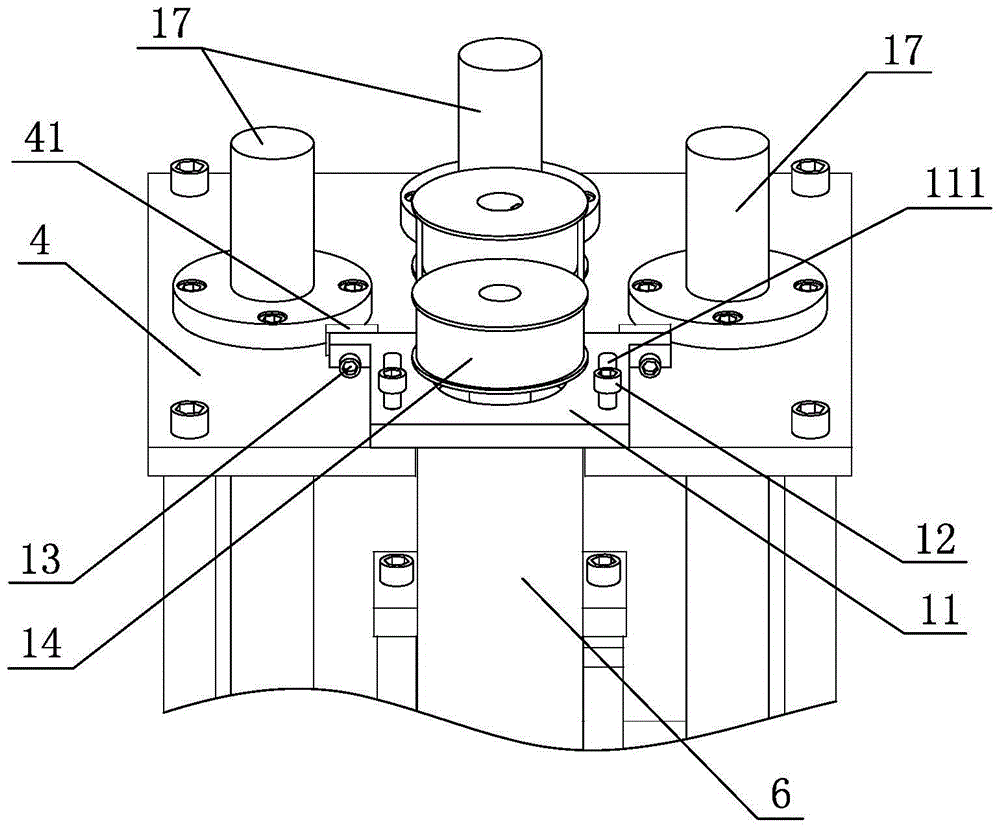

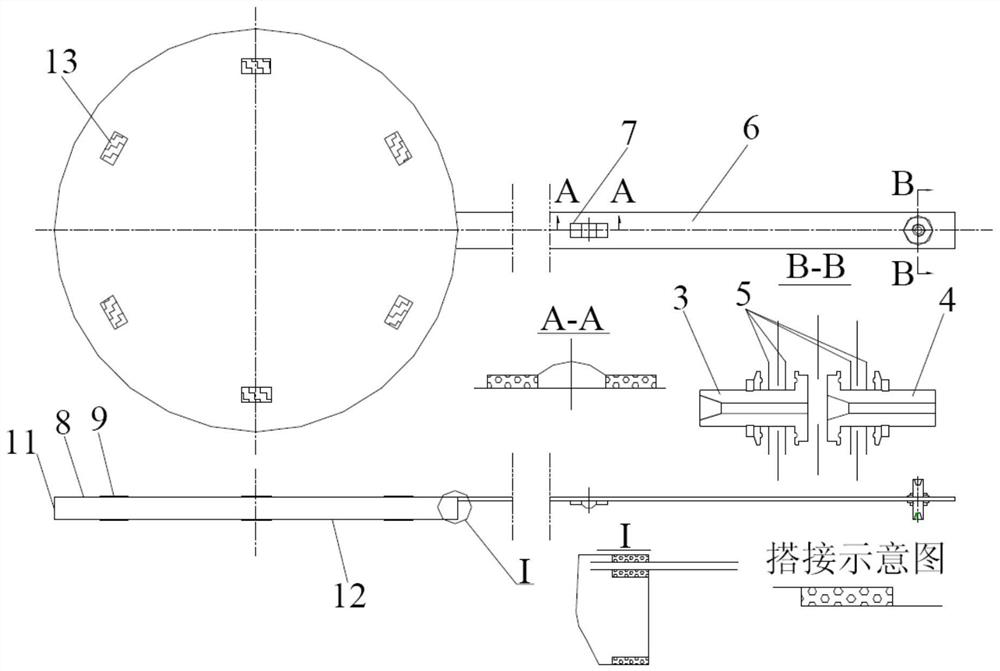

Tension-compression, ring shear and radial seepage tester and tension-compression, ring shear and radial seepage test system

ActiveCN107179245AEvenly loadedApply stabilityLiquid dispersion analysisNuclear energy generationTension compressionTorque transmission

The invention provides a tension-compression, ring shear and radial seepage tester and a tension-compression, ring shear and radial seepage test system and relates to the technical field of mechanical test devices. The tension-compression, ring shear and radial seepage tester is characterized in that an axial piston rod is connected with an upper shear box, a torque transmission shaft is connected with a lower shear box, an axial force transducer is arranged on the axial piston rod, a torque transducer is arranged on the torque transmission shaft, a force transmission plate is fixedly connected onto the upper shear box and can transmit counter-force of applied torque, and stability of the upper shear box is maintained. A radial seepage test can be realized by arrangement of a seepage structure. The tension-compression, ring shear and radial seepage tester has the advantages that independent and coupling application of axial load and torque is realized, and stability of the tester and load application stationarity in a test loading process are guaranteed. The tension-compression, ring shear and radial seepage test system comprises a servo pump and the tension-compression, ring shear and radial seepage tester, and is precise in control, small in error and good in stability.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

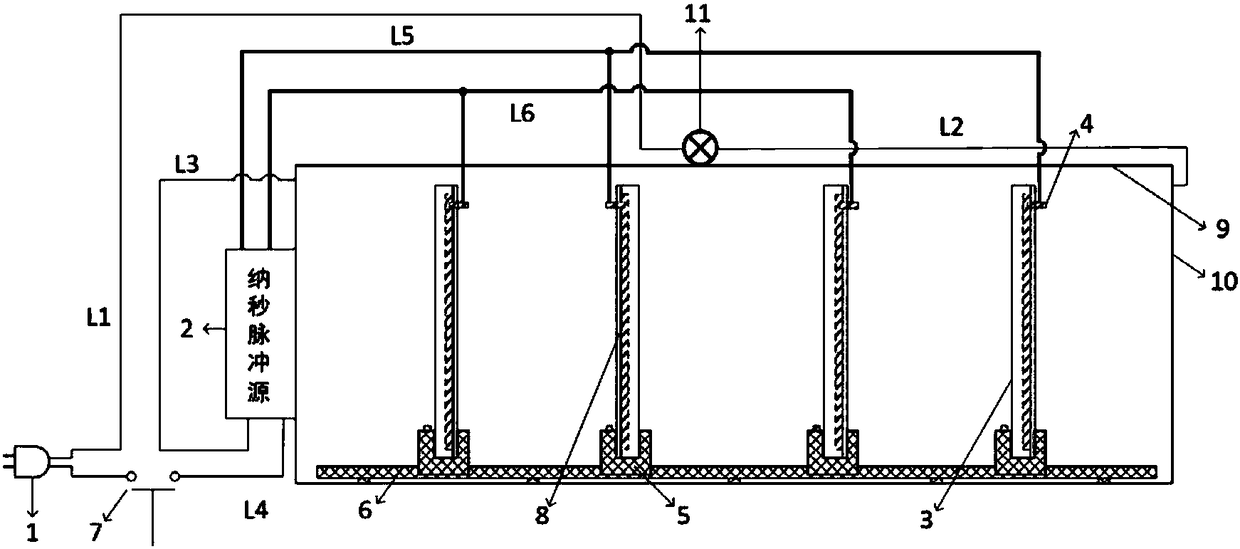

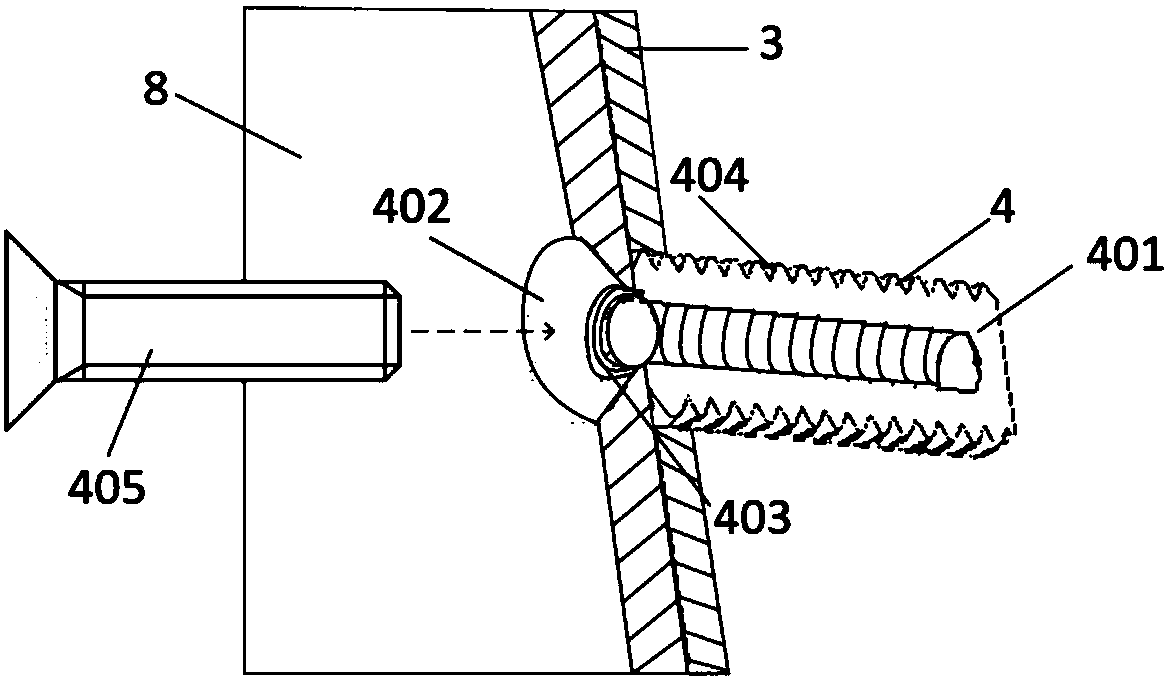

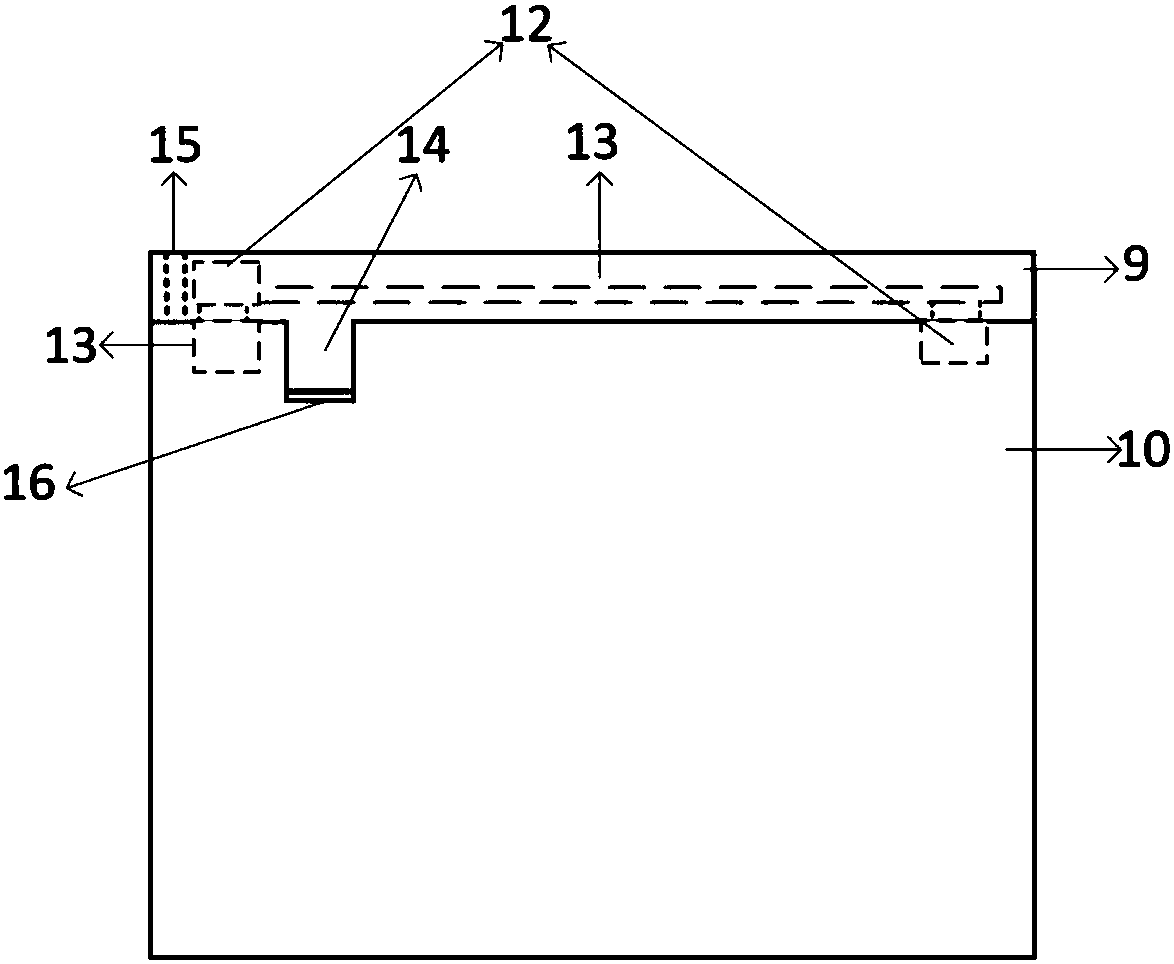

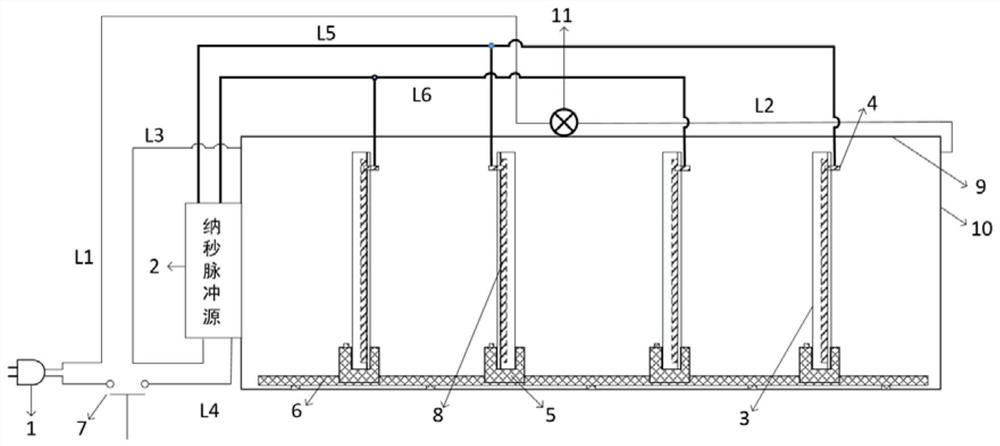

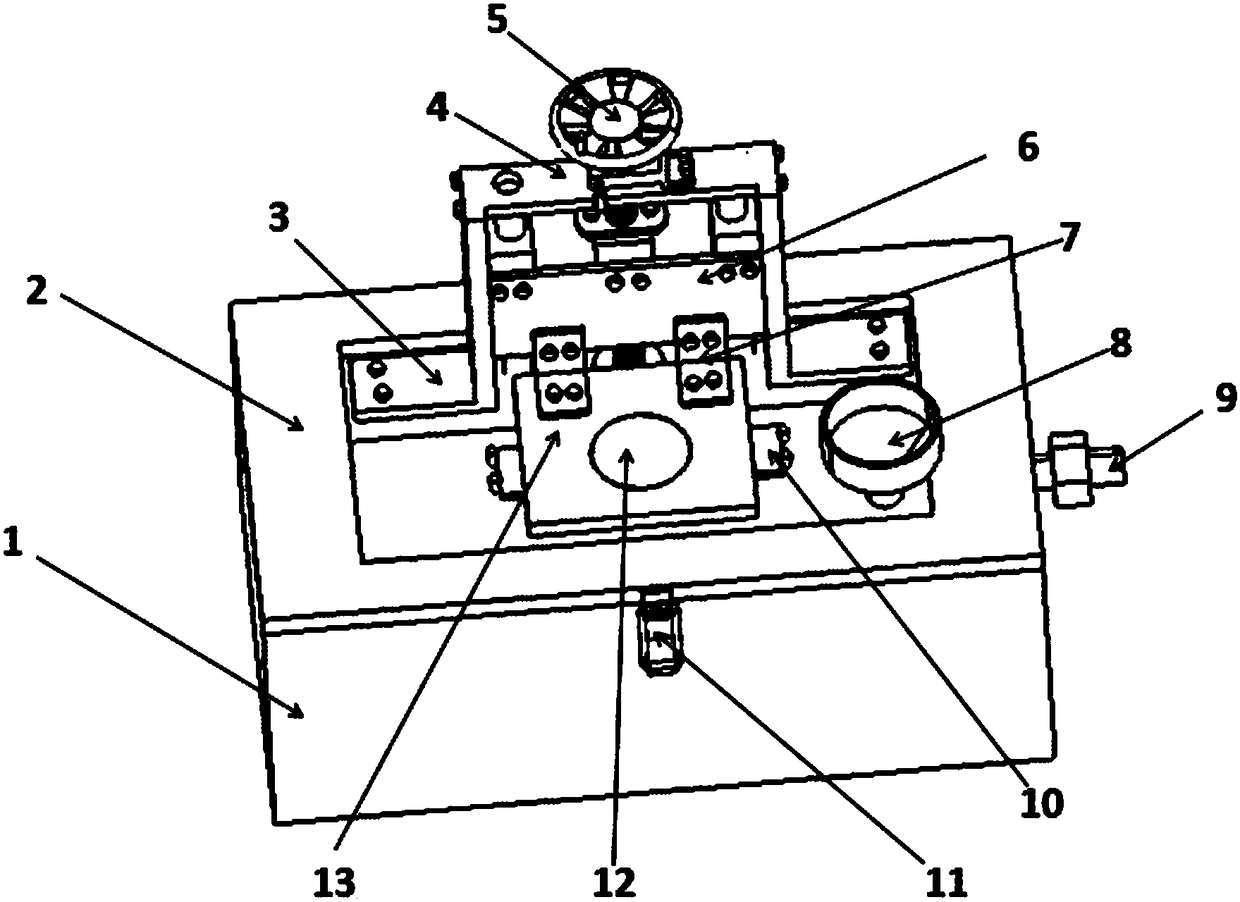

Fruit and vegetable preservation device based on nanosecond pulse low-voltage electric field

ActiveCN108271856AFlexible arrangementEnsure safetyFruits/vegetable preservation by irradiation/electric treatmentFood electrical treatmentDevice formLow voltage

The invention discloses a fruit and vegetable preservation device based on a nanosecond pulse low-voltage electric field. The fruit and vegetable preservation device comprises a treatment chamber anda nanosecond pulse electric field generating device, wherein the treatment chamber comprises a closed cavity, a box body with an open top and an upper cover arranged at the open top of the box body, the upper cover contains a copper sheet protecting path, the box body matches with the upper cover by virtue of a positioning assembly, and an electromagnetic device, the copper sheet protecting path and a work indicating lamp form a safety protection device together; and the nanosecond pulse electric field generating device comprises a nanosecond pulse power with adjustable parameters and a multichannel dual electrode sealed in an insulating barrier, and the multichannel dual electrode is connected with an electrode outgoing post. The electric field generating device forms a nanosecond pulse electric field in the box body, and fruits and vegetables are put in the nanosecond pulse electric field for performing electric field treatment, thereby achieving an enzyme inactivating effect by changing the inherent electric fields of the fruits and vegetables, inhibiting the respiratory action of the fruits and vegetables and achieving a good cold sterilization effect. The fruit and vegetable preservation device based on the nanosecond pulse low-voltage electric field has a convenient operation method, is pollution-free and suitable for preserving various perishable fruits and vegetables and has very high application value.

Owner:XI AN JIAOTONG UNIV

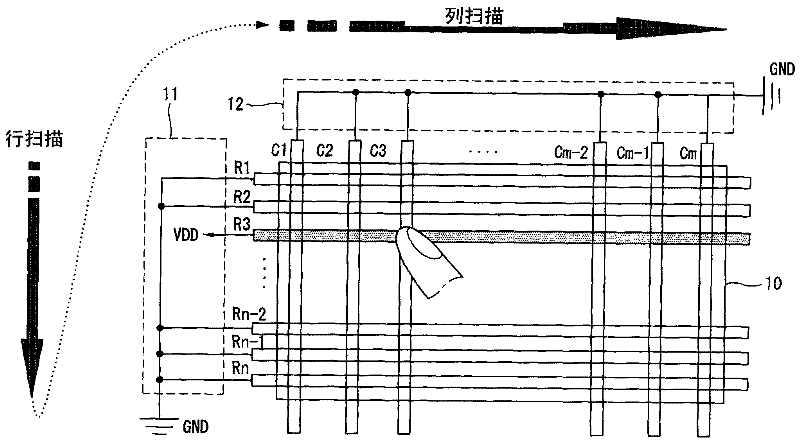

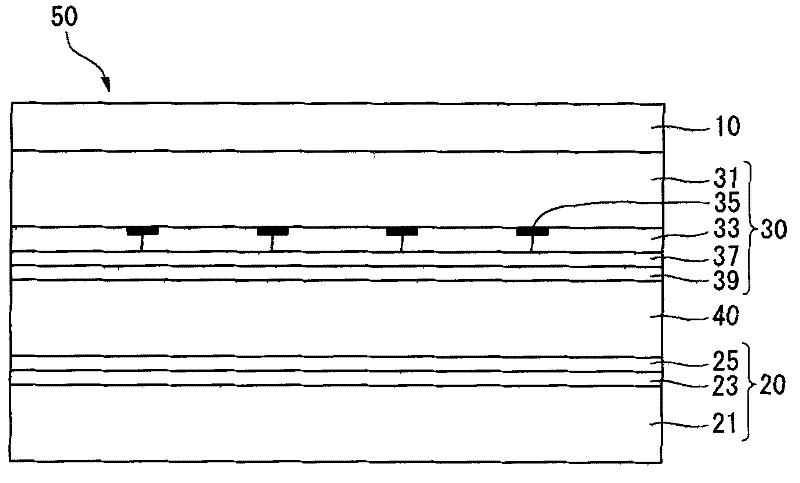

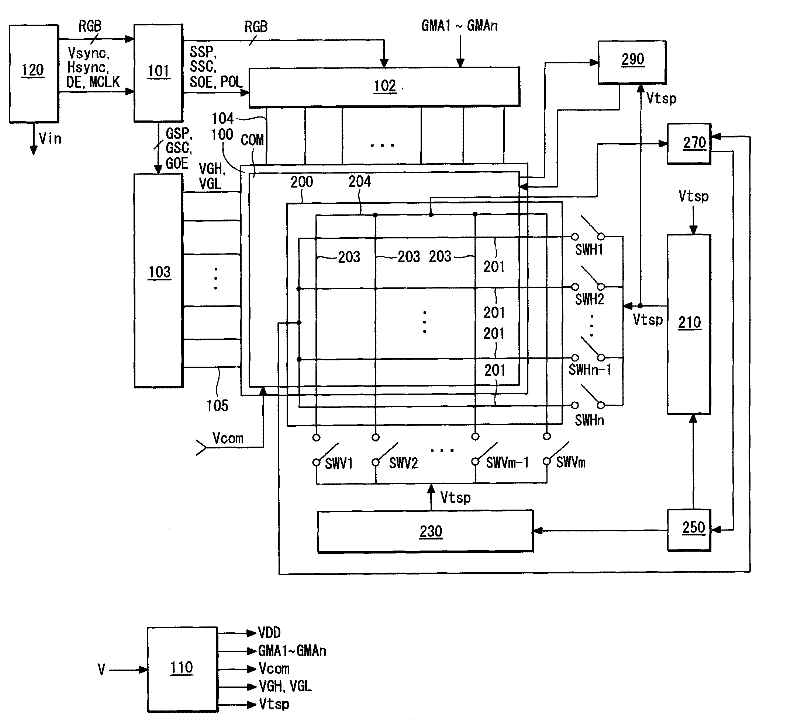

Display device having touch screen panel

InactiveCN102446026AApply stabilityNon-linear opticsInput/output processes for data processingDisplay deviceFeedback circuits

A display device having a touch screen panel includes a display panel includes a common electrode; a touch screen panel including a plurality of first conductive patterns that are formed on one surface of the display panel and arranged in a first direction, and a plurality of second conductive patterns that are electrically insulated from the plurality of first conductive patterns and arranged in a second direction to cross over the first conductive patterns; a power source circuitry to supply a first common voltage to the common electrode and to supply a pulse voltage to at least one of the plurality of first and second conductive patterns; and a common voltage feedback circuit to remove an induction voltage induced to the common electrode by the pulse voltage supplied to the at least one of the plurality of first and second conductive patterns.

Owner:LG DISPLAY CO LTD

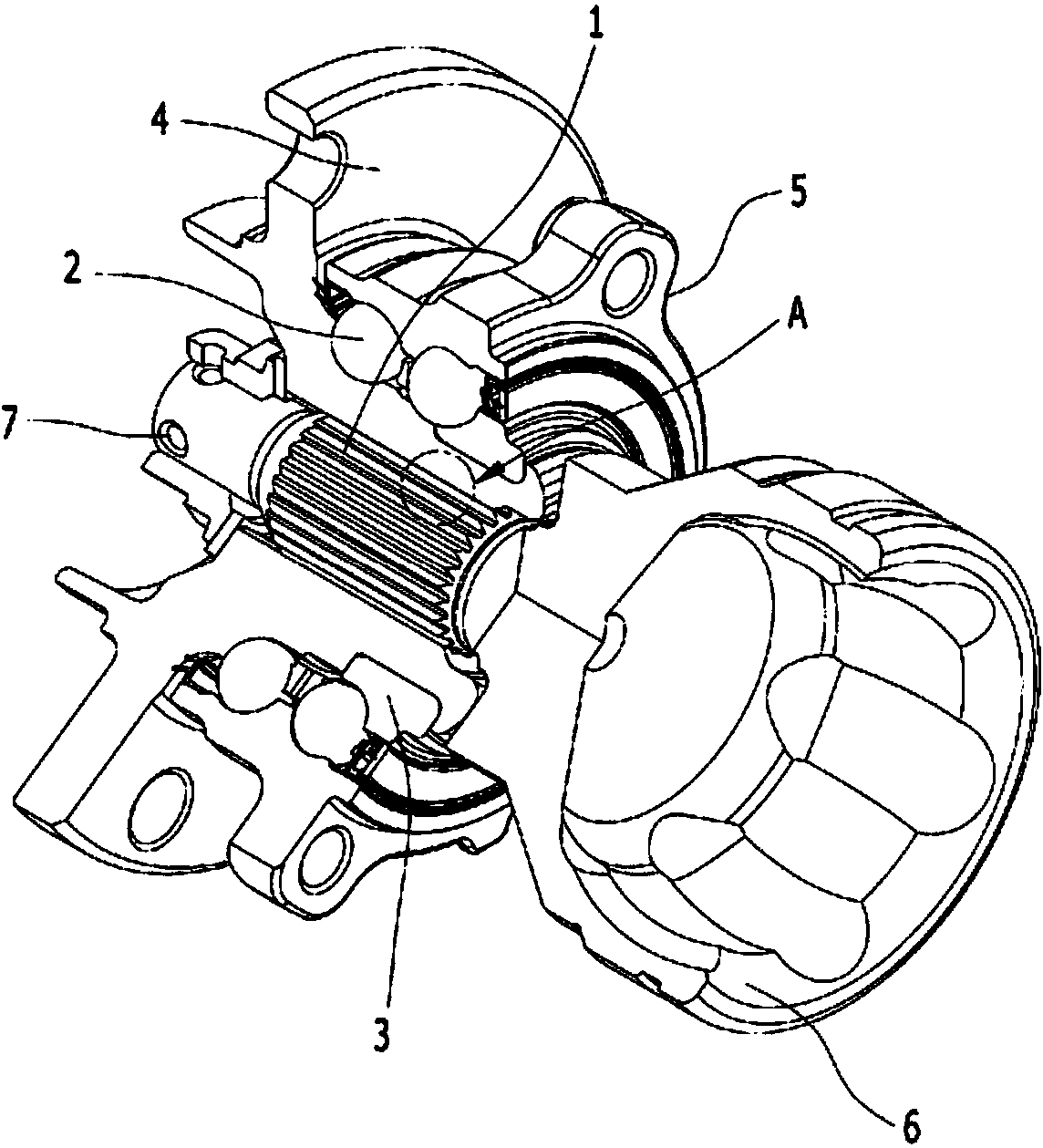

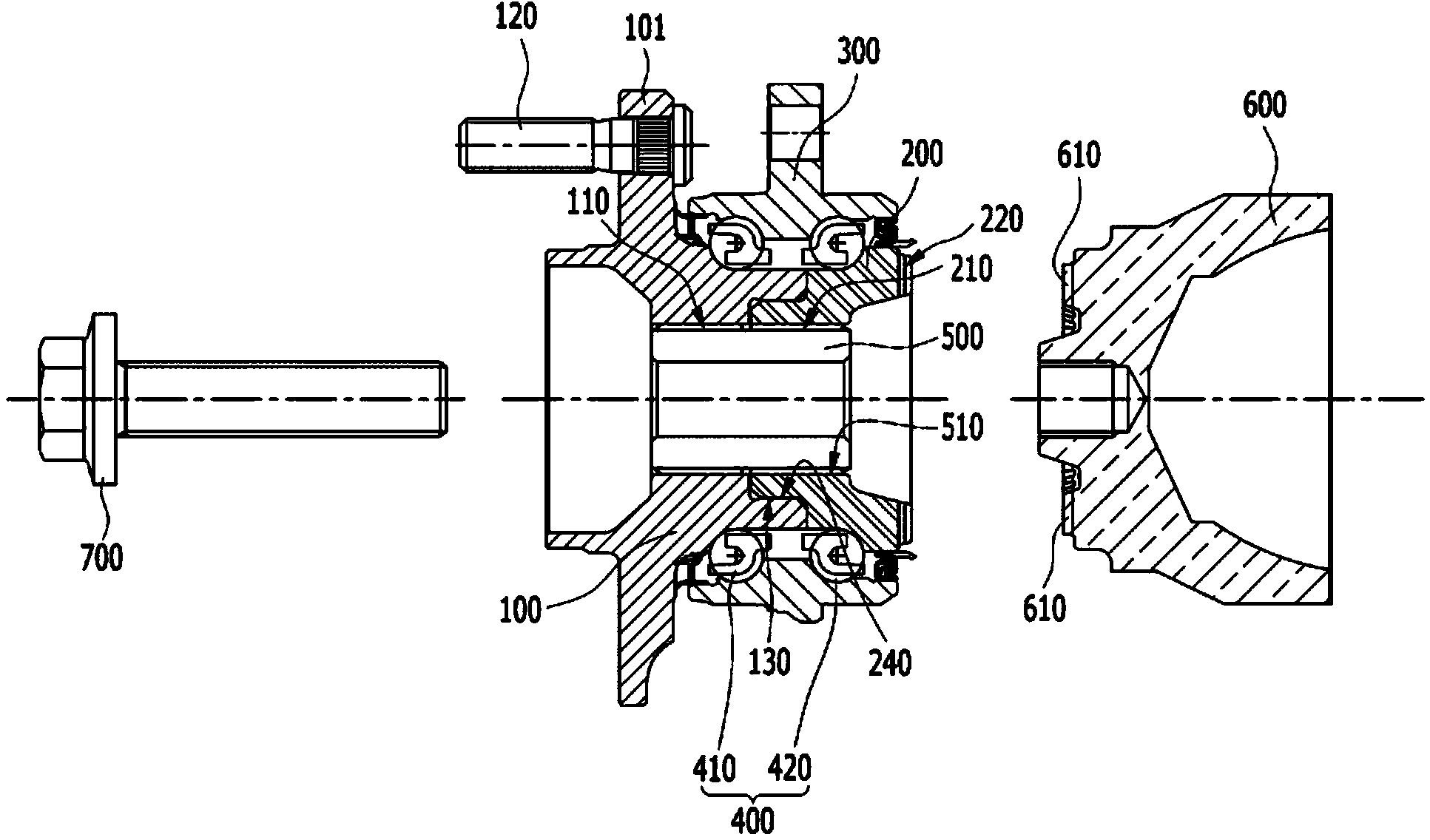

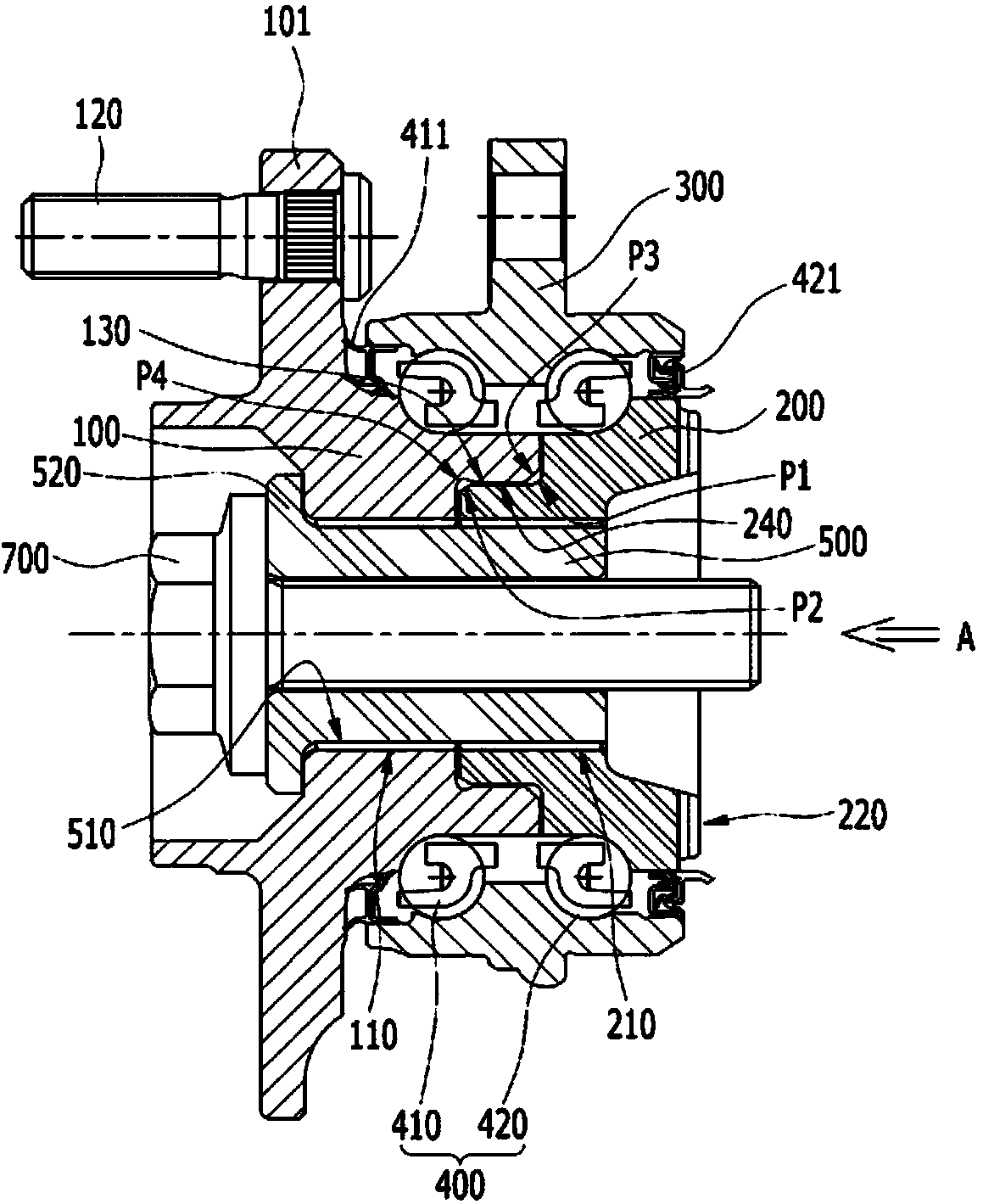

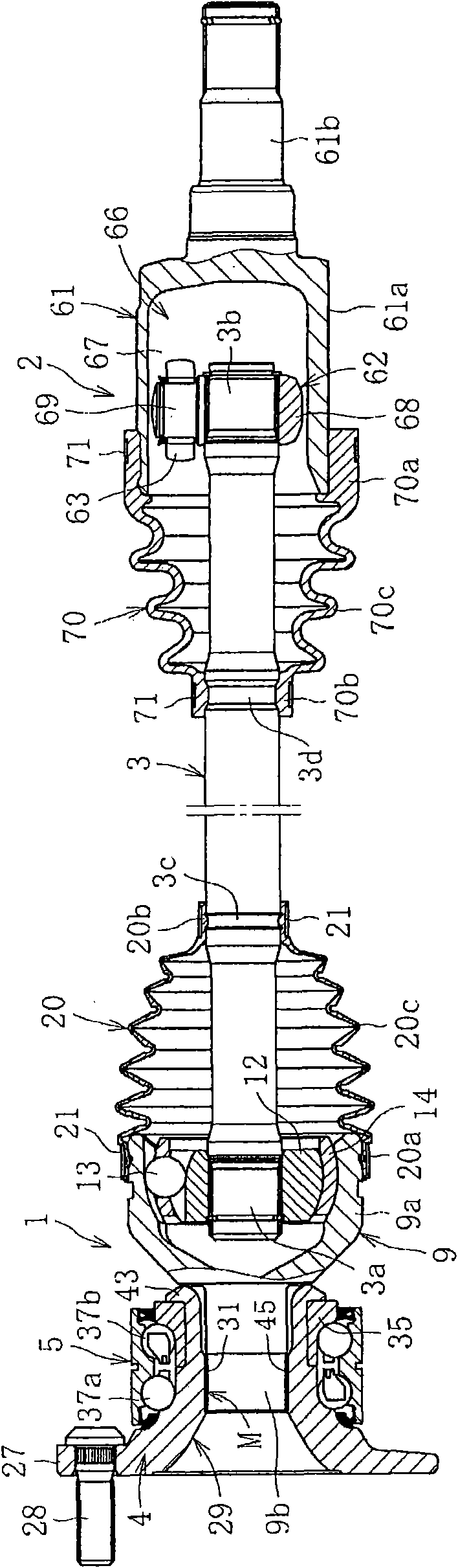

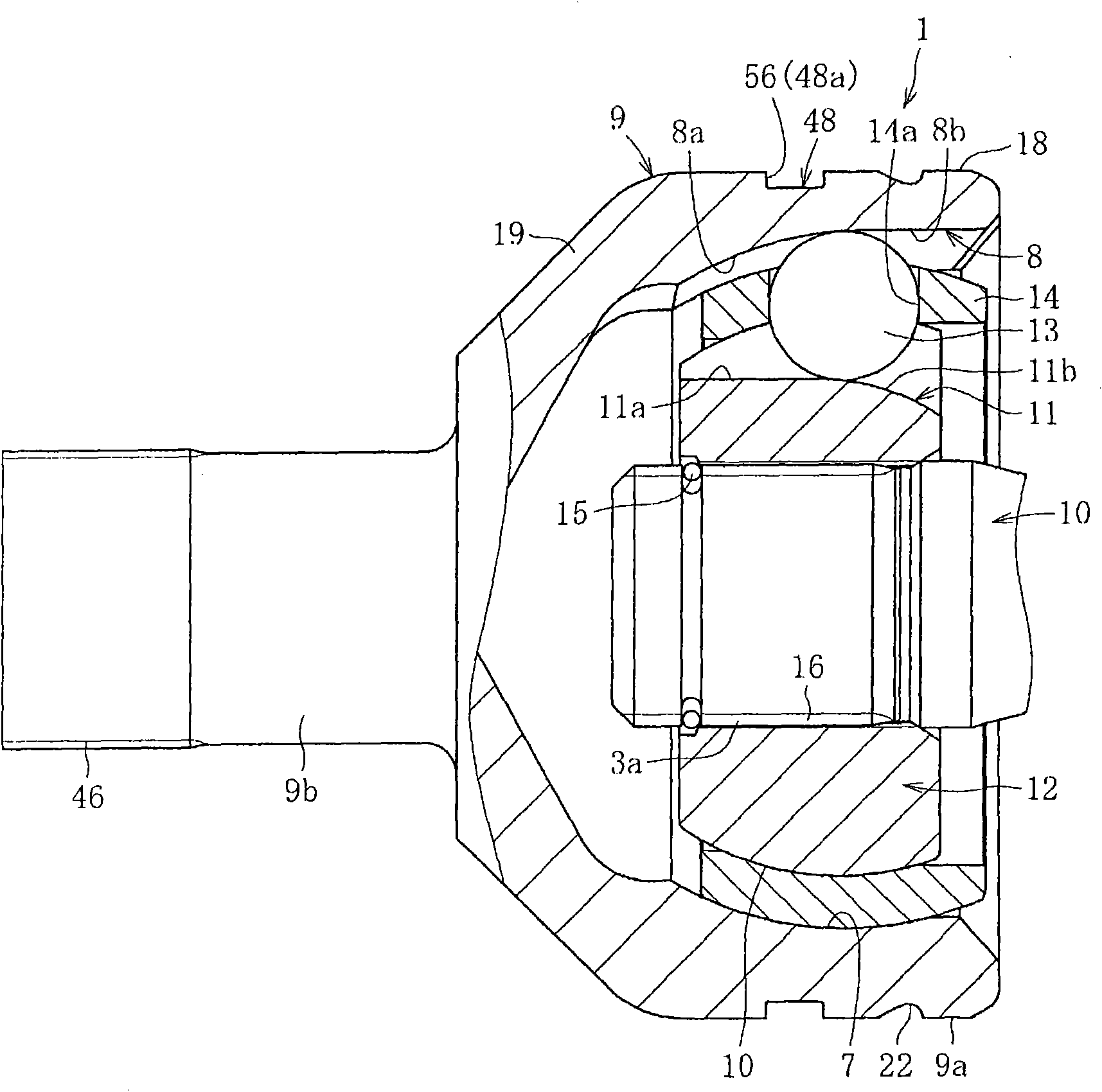

Structure and method for coupling wheel bearings

InactiveCN104245355AStable deliveryIncreased durabilityRolling contact bearingsBearing assemblyEngineeringConstant-velocity joint

The present invention relates to a structure and method for coupling a wheel bearing. The structure comprises: a wheel hub on which a vehicle wheel is mounted; a hollow inner wheel press-fitted into one side of the wheel hub; a ring-shaped outer wheel arranged outside the wheel hub and the inner wheel; and a rolling element interposed between the wheel hub or the inner wheel and the outer wheel. The wheel hub and the inner wheel are coupled together by a spline, and the inner wheel and a joint member are coupled together by a facial spline. According to the present invention, the driving force of a constant velocity joint can be stably transferred to the wheel hub, and noise can be reduced.

Owner:ILJIN GLOBAL

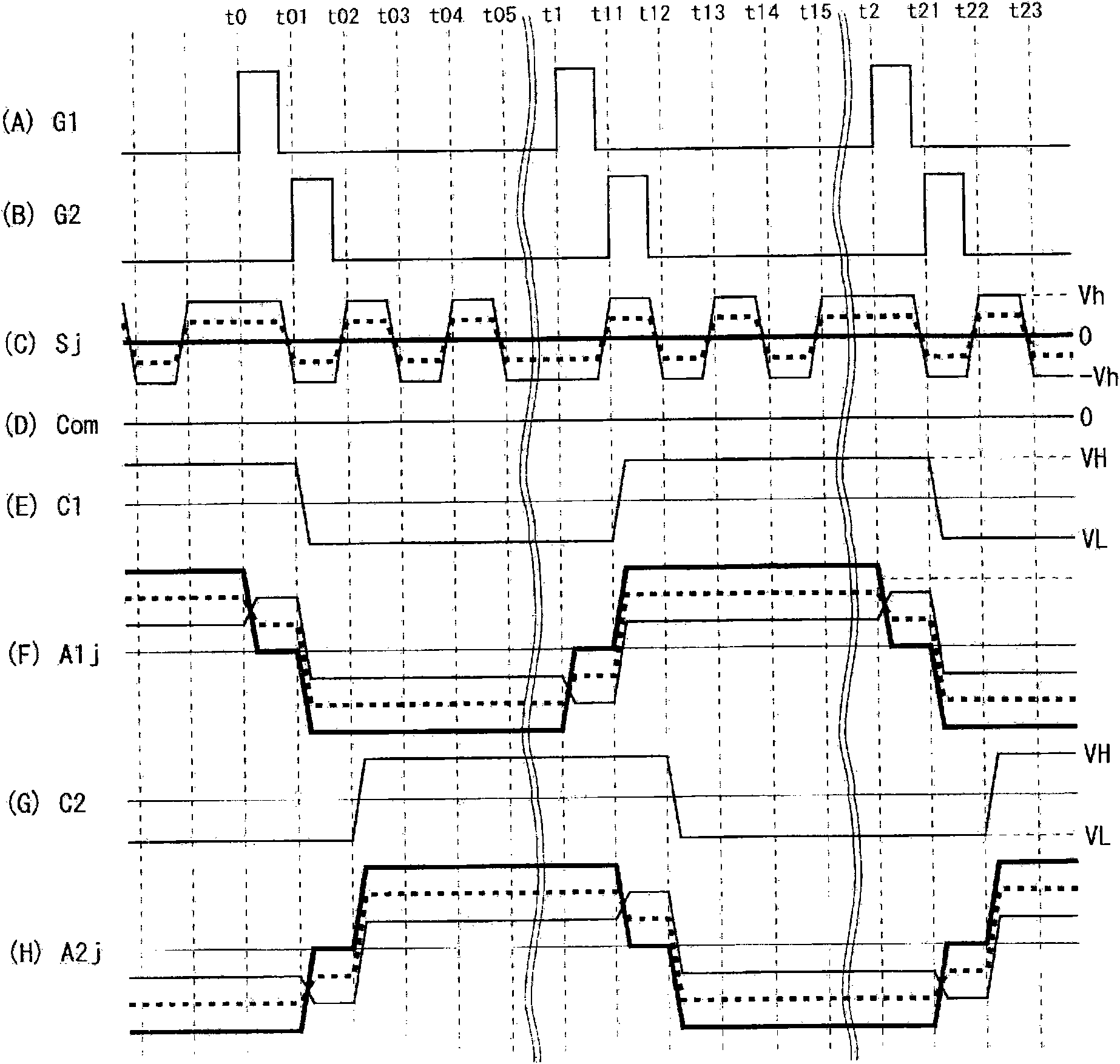

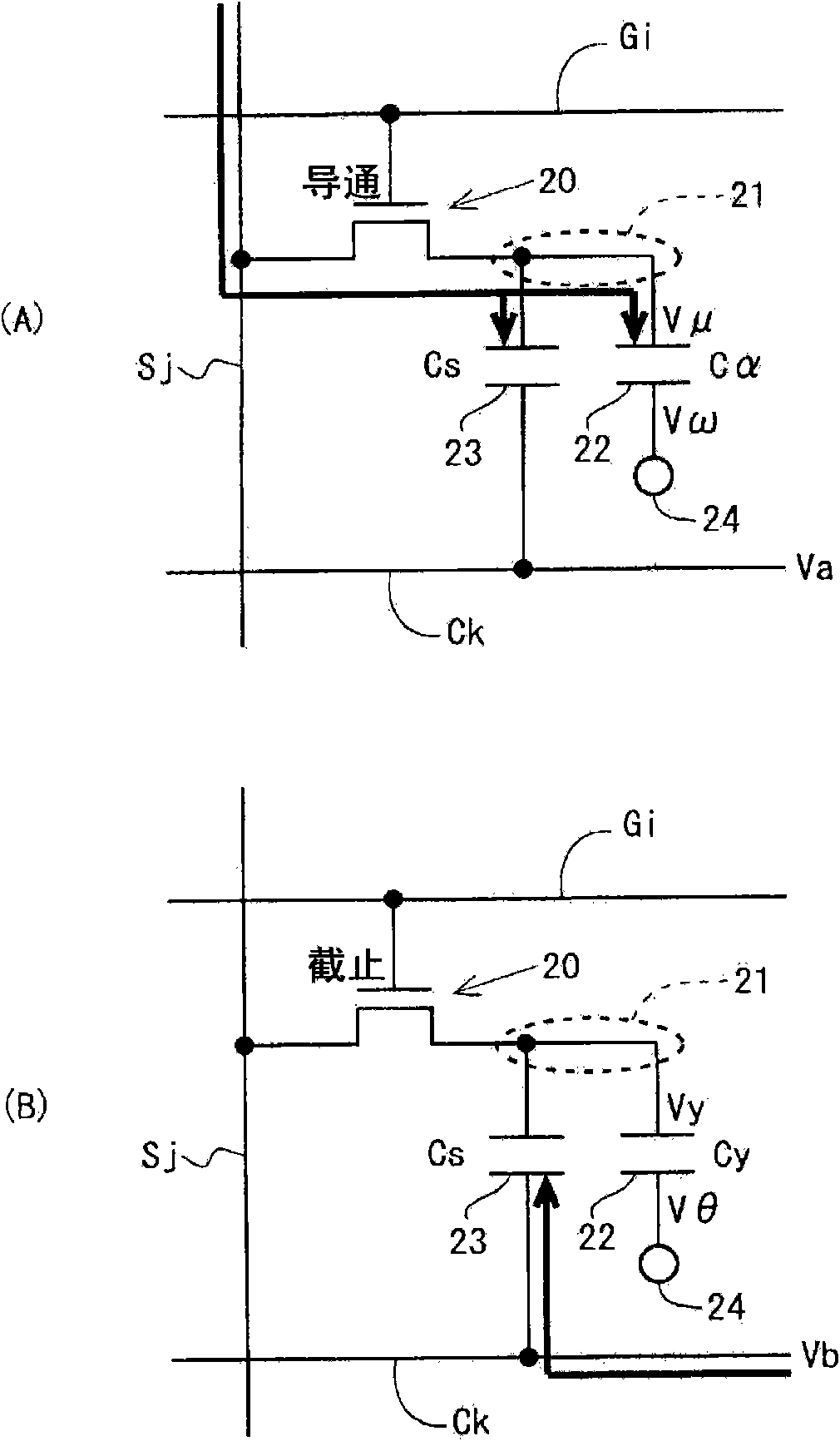

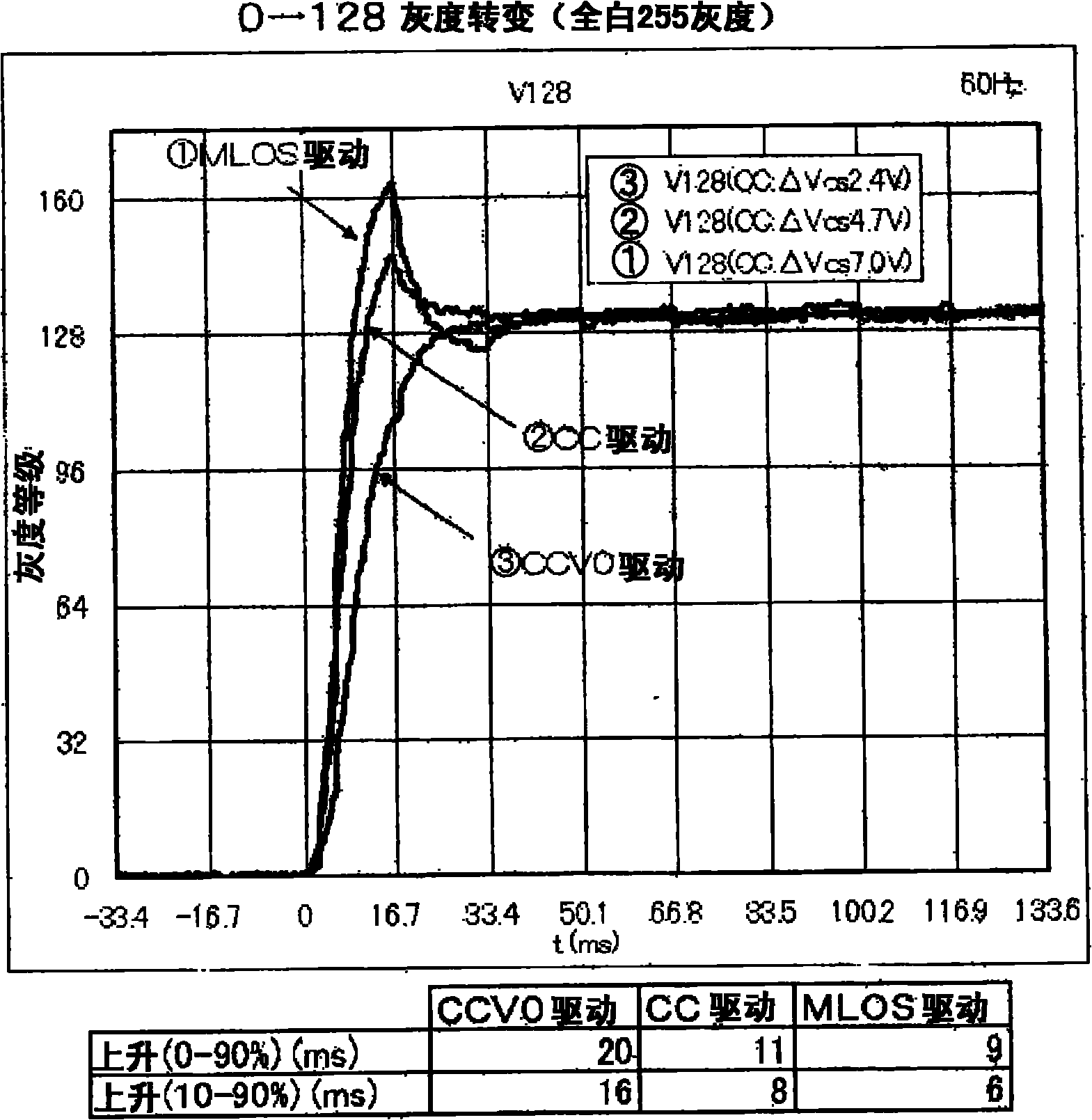

Display device and drive method for the same

InactiveCN101952876AReduce the amplitudeApply stabilityStatic indicating devicesCapacitanceDisplay device

Owner:SHARP KK

Tension and compression ring shear circumferential seepage tester and system thereof

PendingCN107167381AStable and firmSmooth load applicationMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesTorque sensorServo

The invention provides a tension and compression ring shear circumferential seepage tester and a system thereof, and relates to the technical field of mechanical test devices. The tension and compression ring shear circumferential seepage tester is connected with an upper shearing box through an axial piston rod, a torque force transmission shaft is connected with a lower shearing box, the axial piston rod is provided with an axial force sensor, the torque force transmission shaft is provided with a torque sensor, the upper shearing box is fixedly connected with a force transmission plate, and the force transmission plate can transmit counter force of applied torque to keep the stability of the upper shearing box. A circumferential seepage structure arranged in the invention can execute circumferential seepage test. The tension and compression ring shear circumferential seepage tester realizes independent and coupled application of the axial load and the torque, and guarantees the stability of a test device and the load applying stability in the test loading process. The tension and compression ring shear circumferential seepage system comprises a servo pump and the tension and compression ring shear circumferential seepage tester. The system has the advantages of accuracy in control, small error and good stability.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

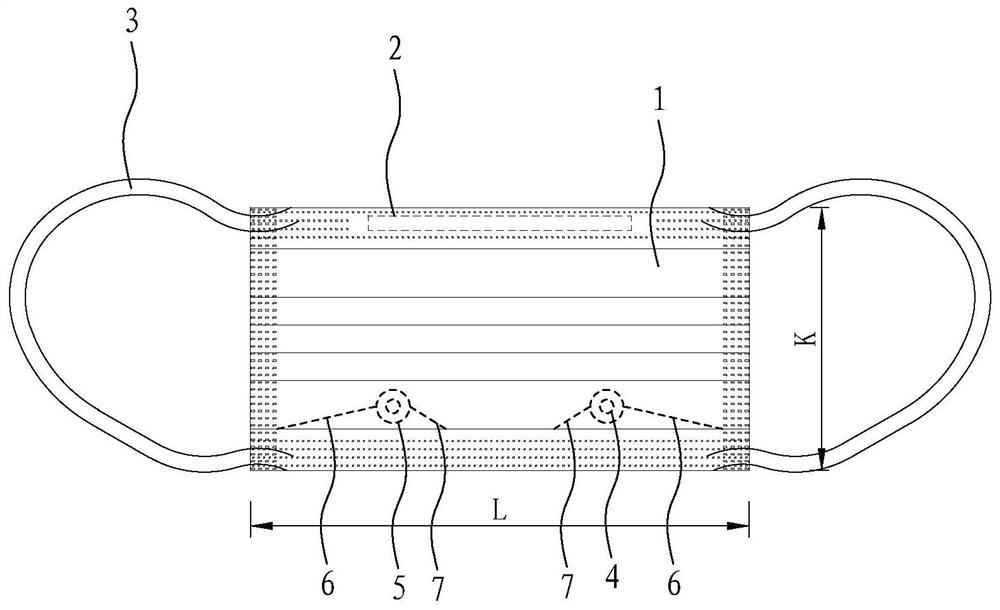

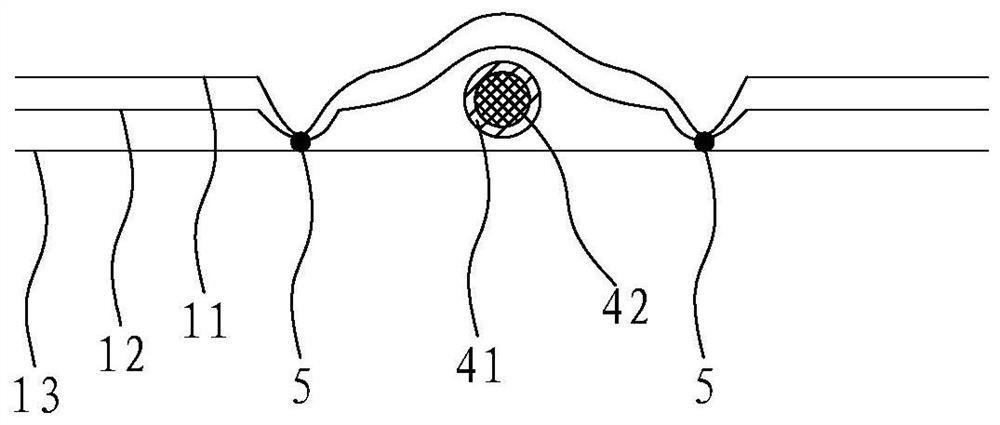

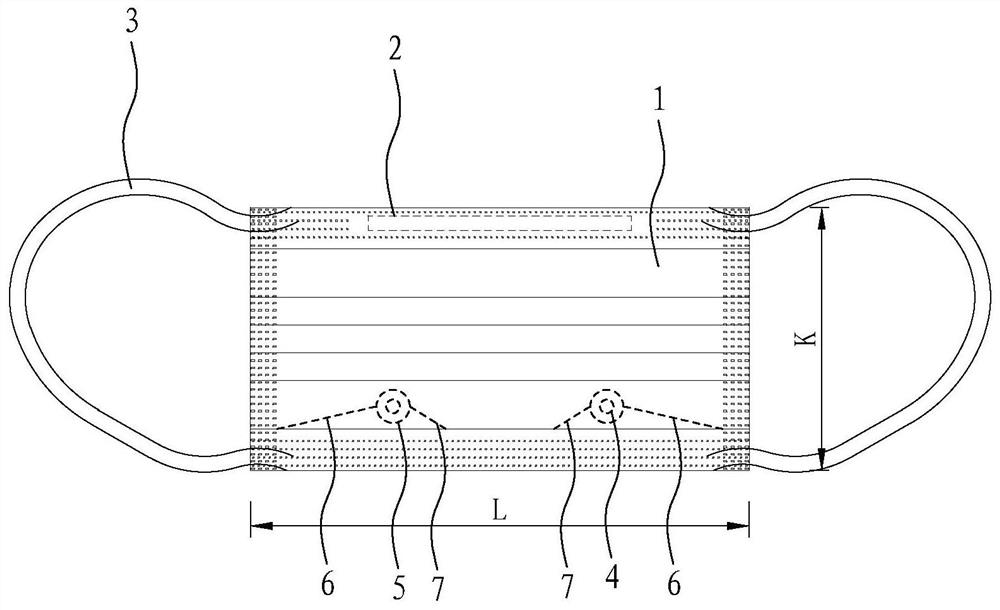

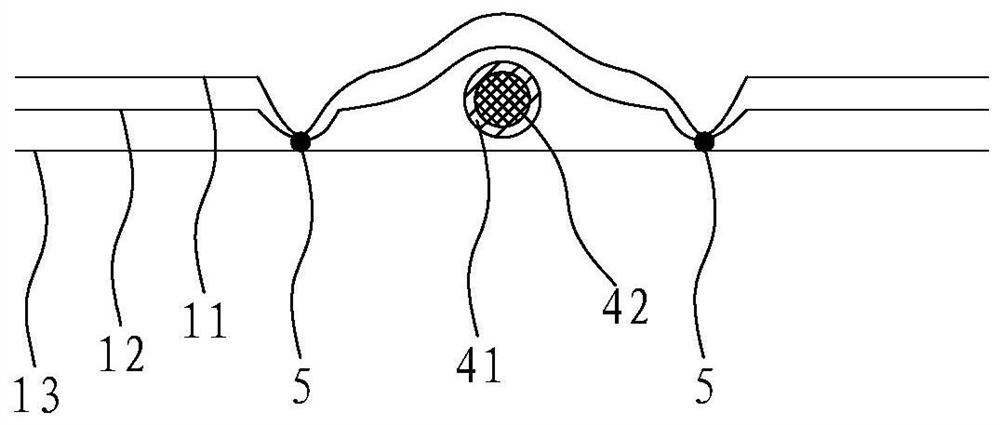

Forming process of ice-cold type mask with blasting beads

ActiveCN112208127AGood stabilityImprove stabilityDomestic articlesProtective garmentWoven fabricManufacturing engineering

The invention relates to the field of disposable hygienic products, in particular to a forming process of an ice-cold type mask with blasting beads. The forming process solves the technical problem that an ice-cold type mask with the blasting beads in the prior art is low in production efficiency. The forming process comprises the following steps that firstly, a nose bridge strip is cut off afterbeing unwound, and the cut-off nose bridge strip is input and adheres to a strip-shaped non-woven fabric at intervals; secondly, an outer-layer non-woven fabric, a melt-blown non-woven fabric and an inner-layer non-woven fabric are unwound, blasting bead particles adhere to the inner-layer non-woven fabric at intervals, the strip-shaped non-woven fabric is clamped between the melt-blown non-wovenfabric and the inner-layer non-woven fabric, and therefore a mask base material is formed; thirdly, the middle of the mask base material is folded and then flattened; fourthly, the mask base materialis subjected to hot pressing, and a peripheral indentation on the peripheral side of the mask, a limiting indentation surrounding the nose bridge strip and a positioning indentation surrounding the blasting bead particles are formed; fifthly, an ear strip material is unwound, cut, adsorbed and conveyed and finally compounded on the mask base material; and sixthly, slitting and outputting are conducted.

Owner:泉州市嘉佰利卫生材料有限公司

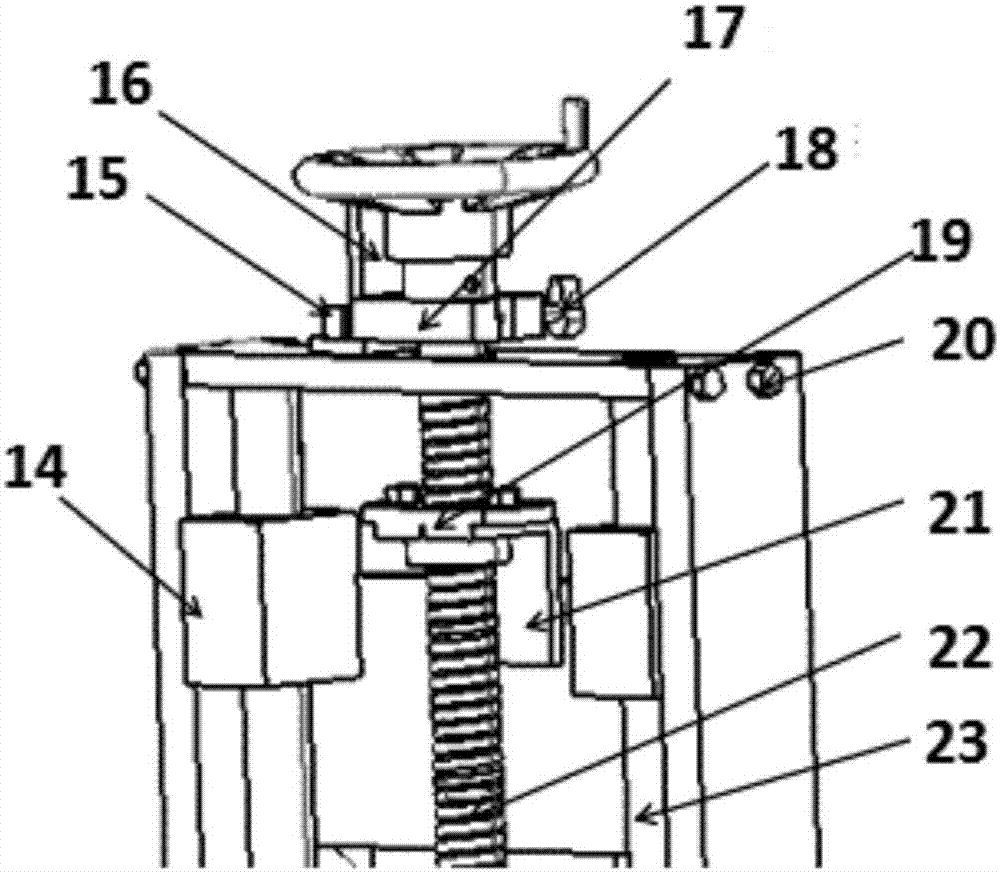

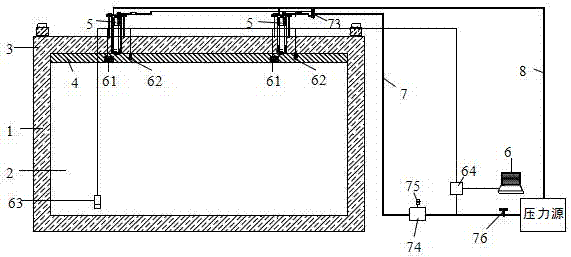

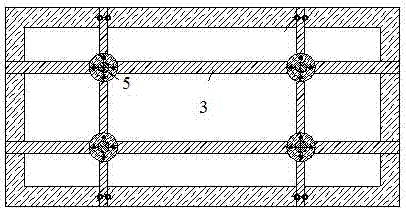

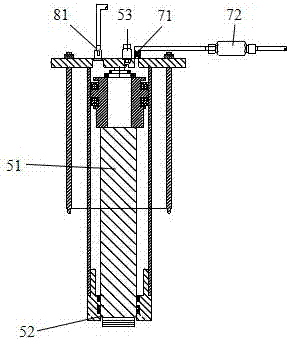

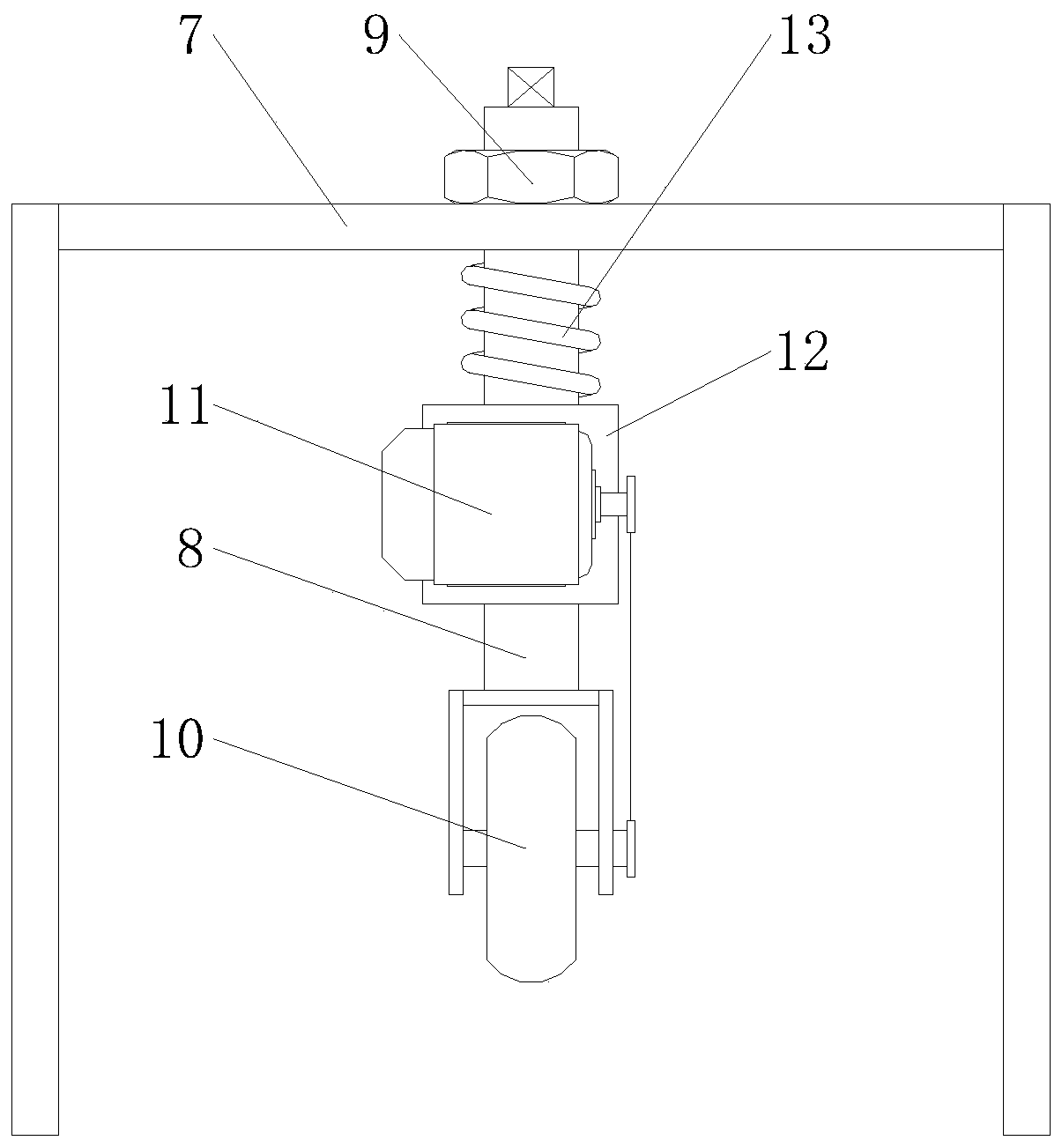

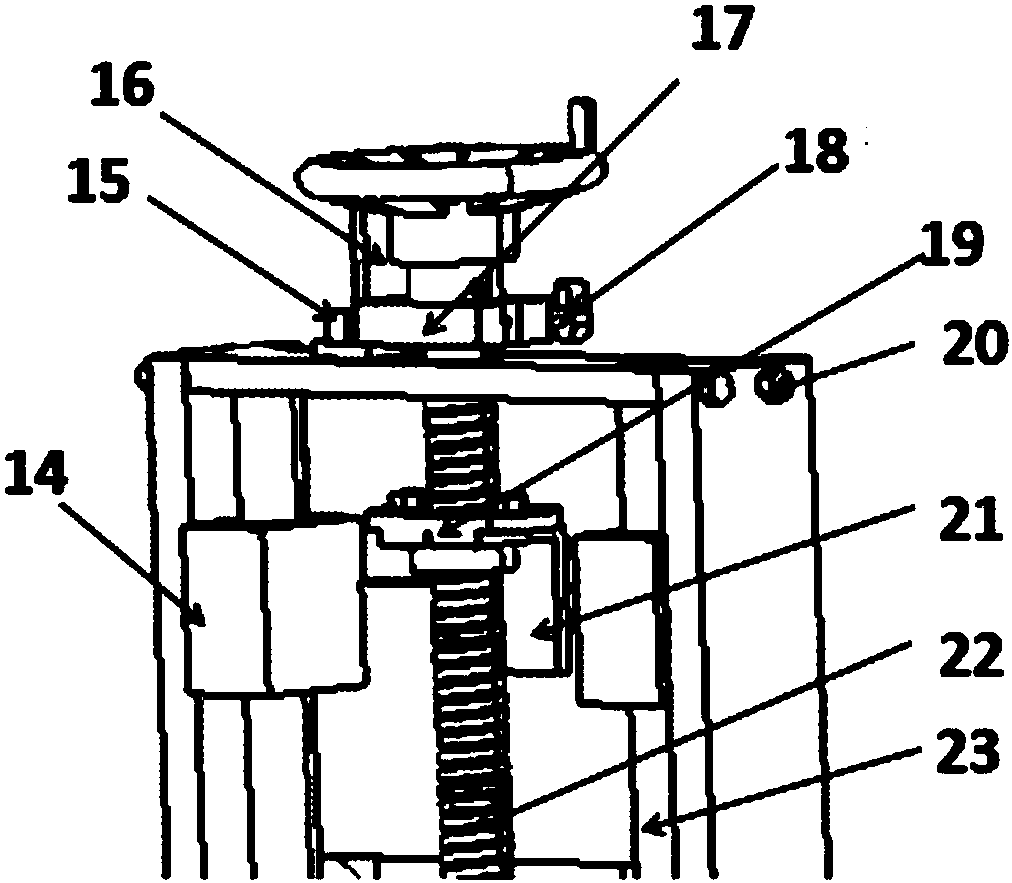

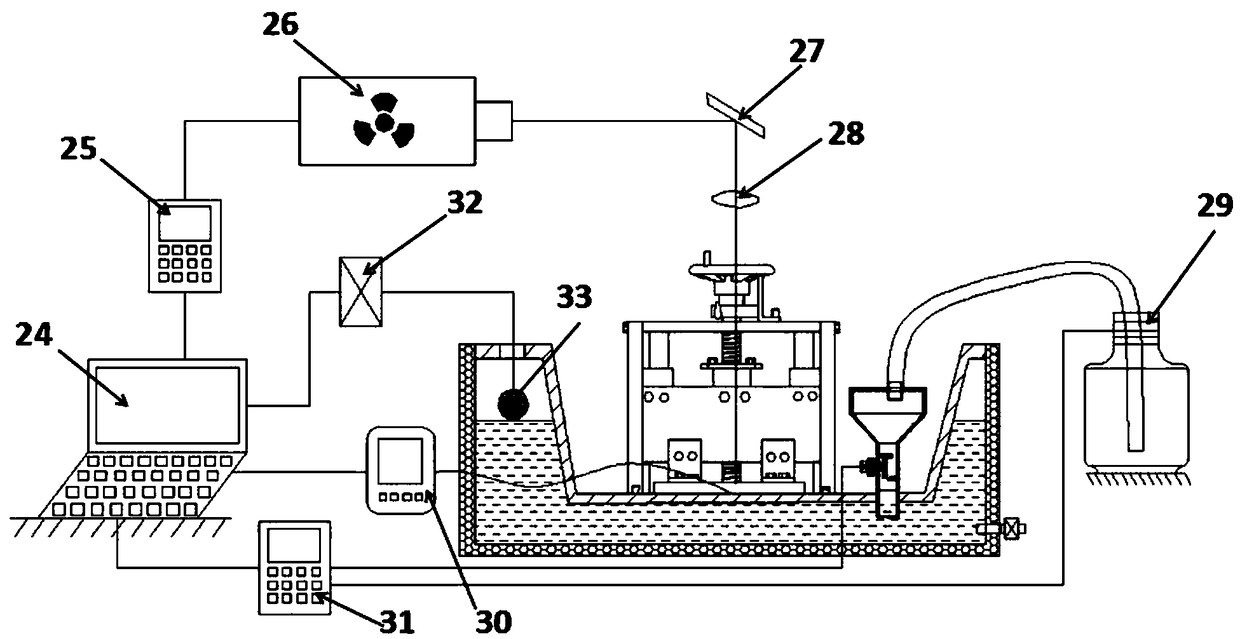

Temperature-controllable deep cooling laser shock peening system

ActiveCN107267743AQuick and easy clamping and positioningHigh repeat positioning accuracyPeeningScrew press

The invention provides a temperature-controllable deep cooling laser shock peening system which comprises a clamp base, a liquid nitrogen automatic supplementary device, a liquid level monitor device, first supporting plates, a cover plate, a screw pressing device and a circumferential locating device. An automatic flow adjusting funnel, an electric liquid nitrogen pump, a liquid level monitor and a computer system are connected, it is guaranteed that the liquid nitrogen liquid level height is kept constant, and then the workpiece temperature is controllable; a screw pressing mechanism is used for tightening and locating a workpiece and a restraint layer; and the circumferential locating device achieves circumferential restraining on a screw through a clamping block and a check block. The clamping and locating process is fast and simple, the repeated locating precision is high, and locating is reliable; and the deep cooling laser shock peening experimental effects of being controllable in temperature and better in restraint effect are achieved.

Owner:JIANGSU UNIV

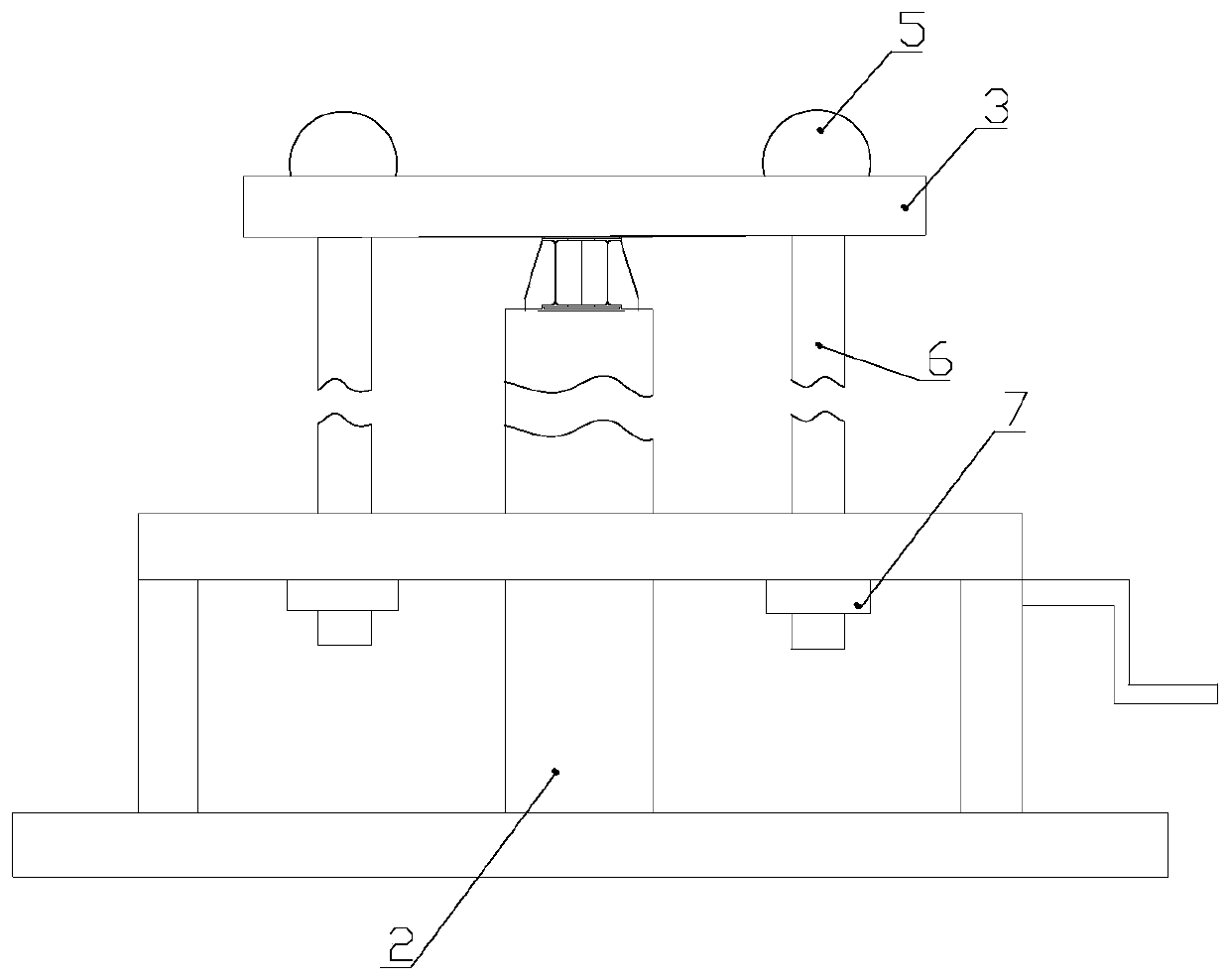

Clutch shifting fork punching equipment

ActiveCN108526269AApply stabilityPrevent movementShaping toolsMetal-working feeding devicesPunchingEngineering

The invention relates to clutch shifting fork punching equipment which comprises a punching base; fixed blocks are arranged on the punching base; two punching cushion plates are rotationally connectedto the fixed blocks respectively and can abut against each other; a cylinder body and a piston rod are arranged above the punching cushion plates; a lower pressure module is fixedly connected to thebottom end of the piston rod; a supporting table is arranged below the punching base and is provided with a first groove; the first groove is internally provided with a supporting column; the top endof the supporting column penetrates through the punching base and abuts against the punching cushion plates; the supporting column is transversely provided with a fixed plate in a sleeving manner; a supporting spring sleeves the external of the supporting column below the fixed plate; the other end of the supporting spring is fixedly connected to the bottom of the first groove; U-shaped blocks arefixedly connected to the two sides of the fixed plate respectively; lugs are arranged at the two ends of the supporting table respectively; a clamping jaw is rotationally connected to each lug; a rolling wheel is rotationally connected to one end of each clamping jaw and abuts against each U-shaped block; the other end of each clamping jaw is provided with an abutting block which is bended downward. The device can perform clamping work in the punching process.

Owner:重庆驰明汽车配件有限公司

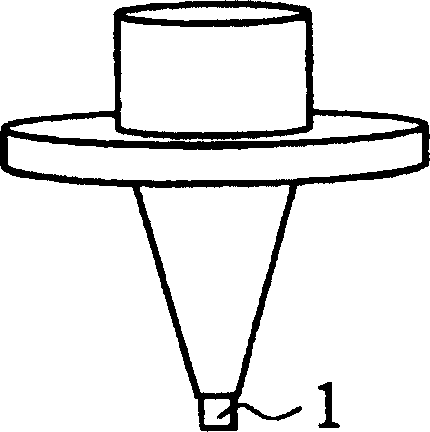

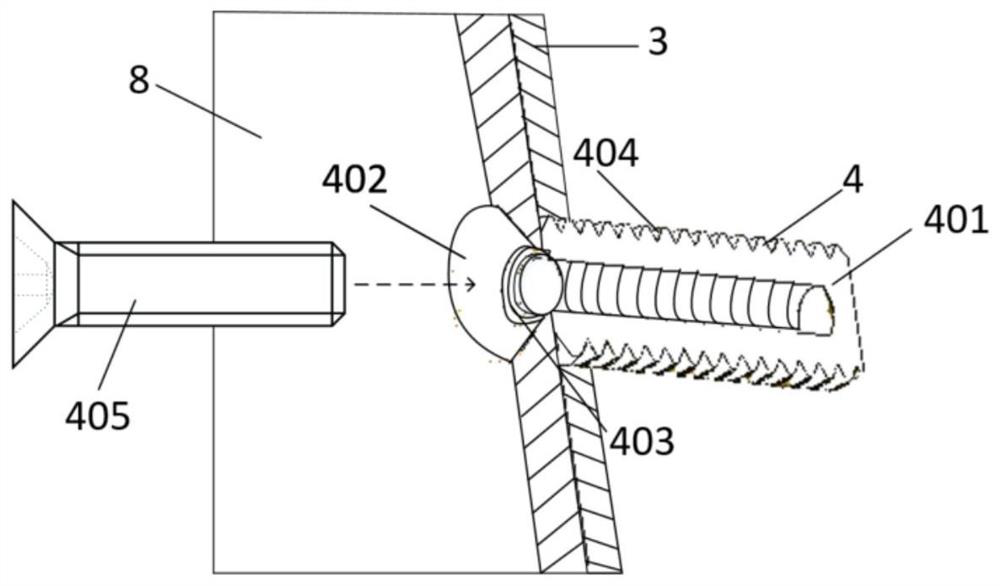

Micro adhesive nozzle and adhesive applying apparatus

InactiveCN1701859AApply stabilityChange in reductionPrinted circuit assemblingLiquid surface applicatorsAdhesiveEngineering

A micro adhesive nozzle for applying adhesive on a printed circuit board is disclosed. The nozzle includes a nozzle tip portion with a protruding portion arranged at a periphery of the nozzle tip portion, an adhesive discharge opening portion formed within the periphery of the nozzle tip portion, and a gap provided between the discharge opening portion and the protruding portion.

Owner:RICOH KK

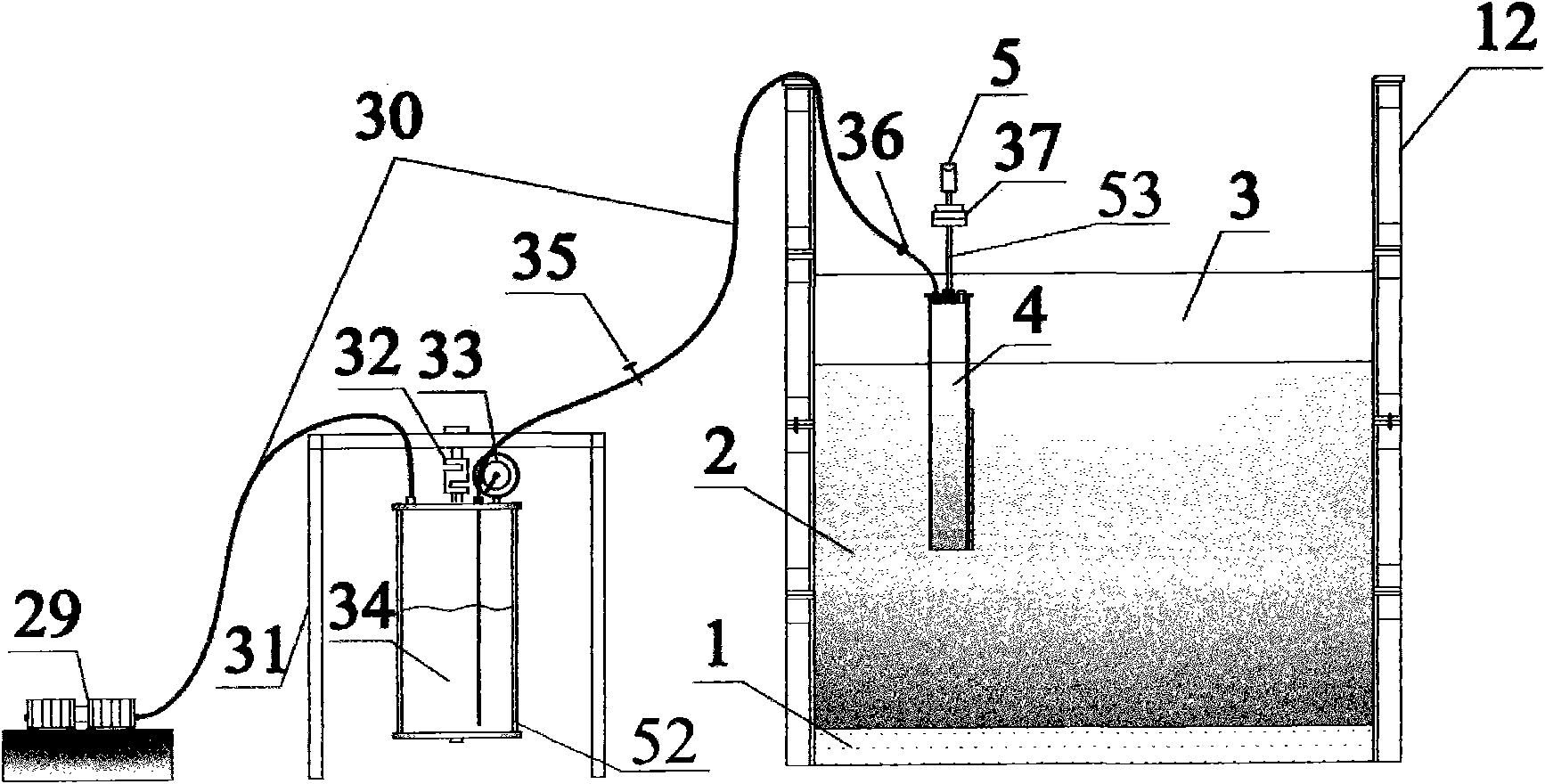

Hydraulic consolidation apparatus and hydraulic consolidation method for geotechnical centrifugal model test

ActiveCN106950348AHigh degree of automationIncrease stiffnessEarth material testingSpecific testHypergravity

The present invention relates to a hydraulic consolidation apparatus and a hydraulic consolidation method for a geotechnical centrifugal model test. The hydraulic consolidation apparatus comprises a consolidation container, a reaction frame, a pressure loading device and a test device, wherein the consolidation container is a centrifuge model box, the pressure loading device comprises a loading plate, a hydraulic cylinder, an oil inlet pipeline and an oil return pipeline, the oil inlet pipeline is provided with a diversion valve and a pressure stabilization control device, and the test device comprises a pressure sensor, a pore pressure sensor, a displacement sensor and a computer. With the hydraulic consolidation apparatus and the hydraulic consolidation method of the present invention, the consolidation load can be provided for the model foundation in the constant stress field, the designed consolidation load can be provided for the model foundation in the hypergravity field, the loading pressure is accurate and uniform, the automation degree is high, the advantages of safety, quietness and convenience are provided, and the pressure range can be adjusted according to the specific test requirements.

Owner:NANJING HYDRAULIC RES INST

Separator for lithium-sulfur battery and lithium-sulfur battery including same

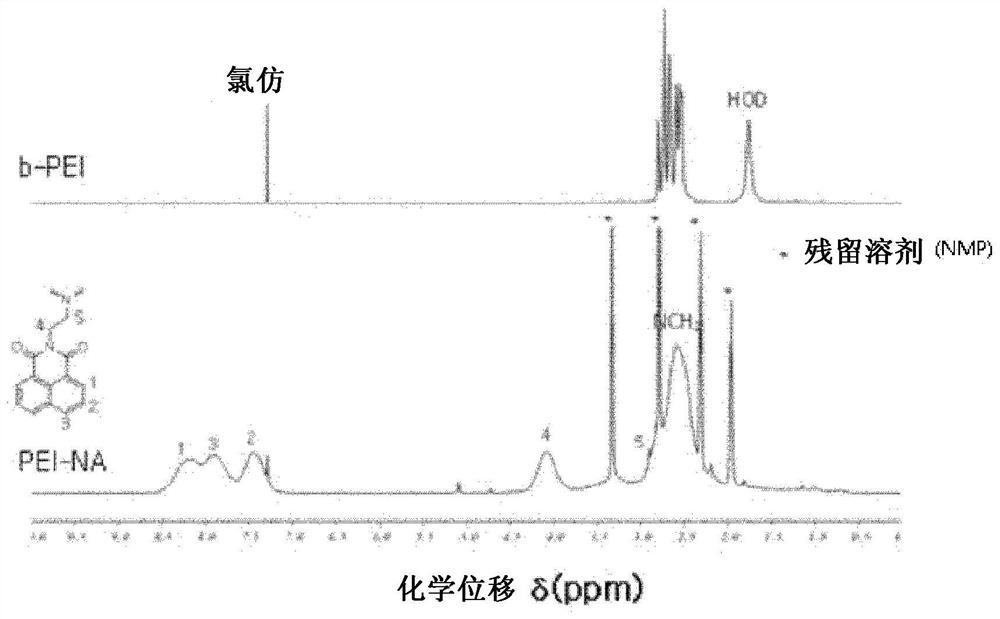

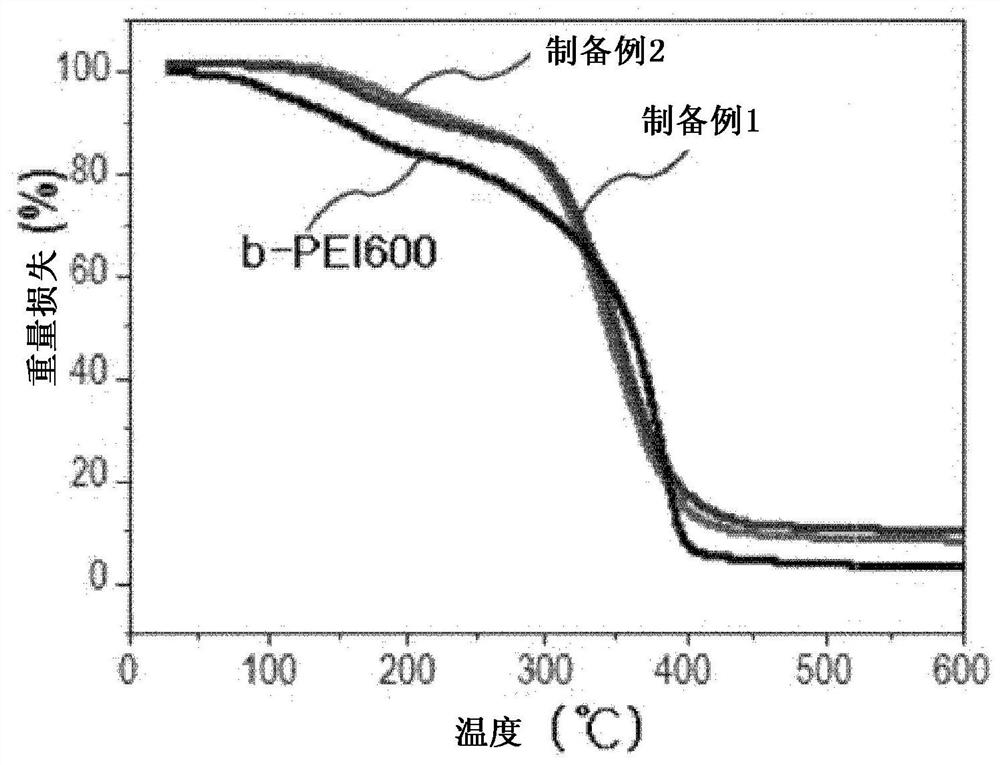

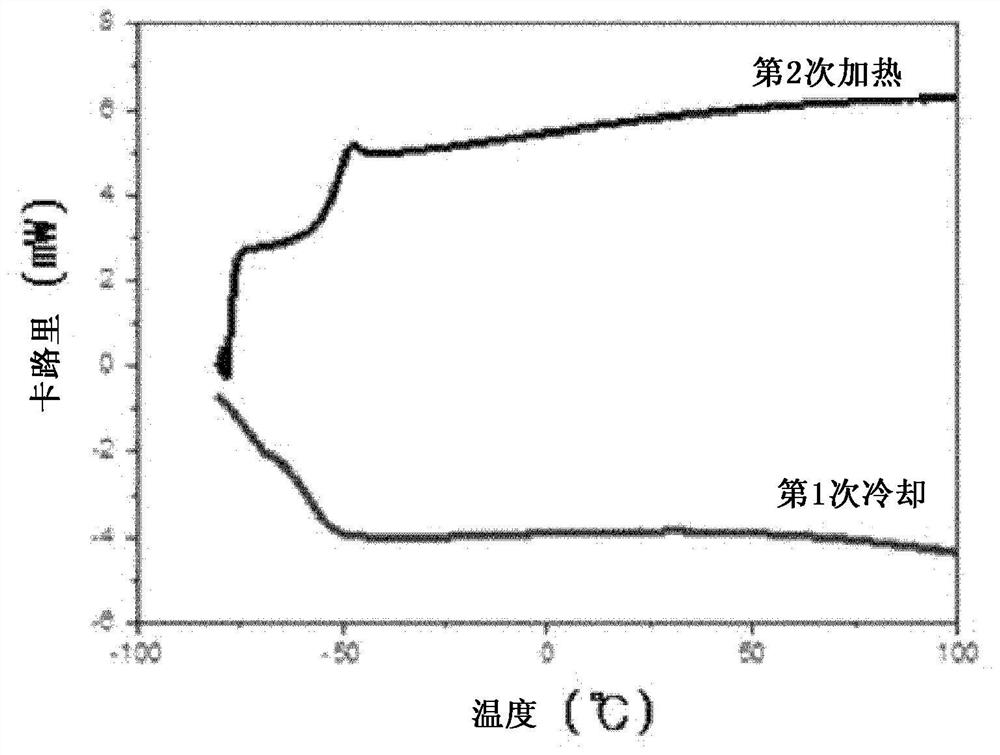

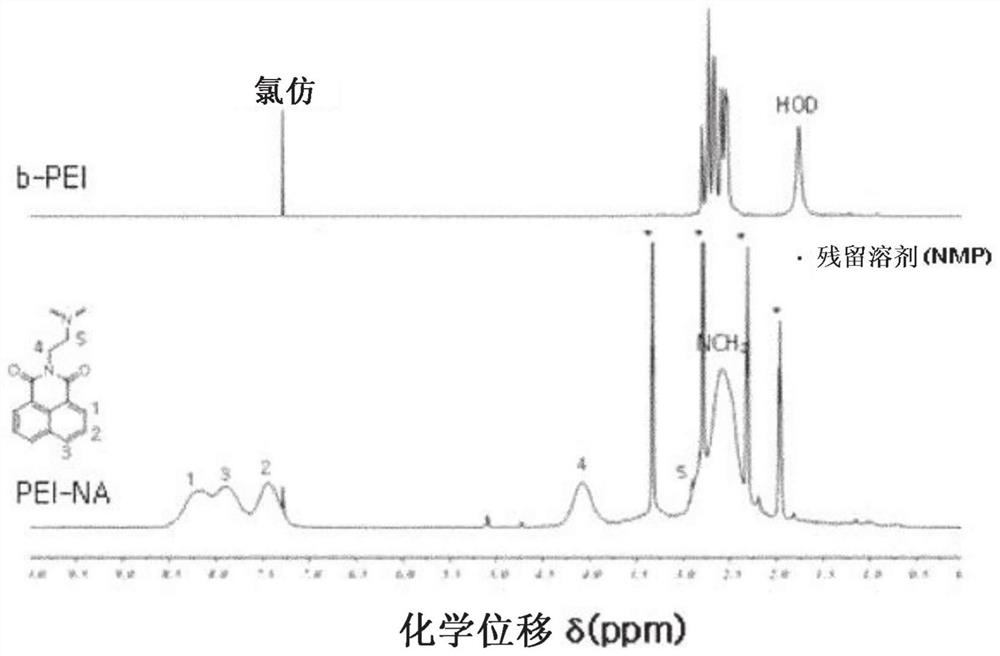

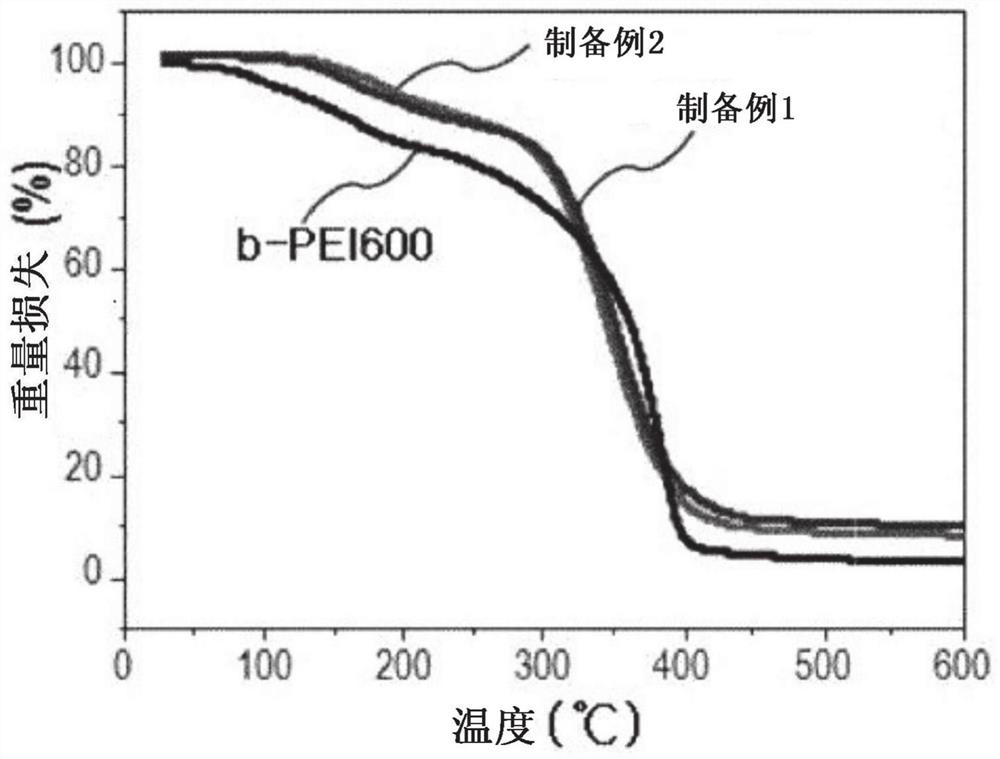

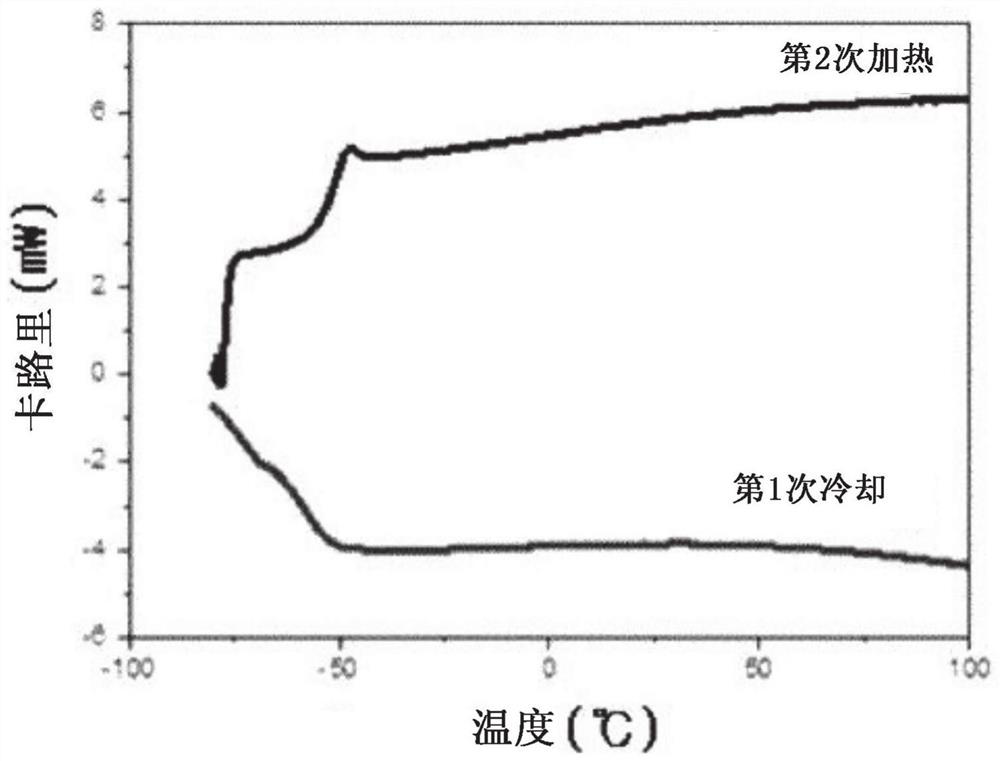

PendingCN111615763ASolving Lithium Polysulfide ProblemsApply stabilityCell seperators/membranes/diaphragms/spacersCell electrodesPorous substrateLithium–sulfur battery

The present invention relates to a separator for a lithium-sulfur battery and a lithium-sulfur battery including same and, more specifically, to a separator for a lithium-sulfur battery, the separatorincluding: a porous substrate; and a coating layer formed on at least one surface of the porous substrate, wherein the coating layer includes: a polymer having, on the backbone thereof, functional groups including unshared electron pairs, and, on the side chains thereof, aromatic hydrocarbon groups; and a graphitic carbon-based compound.

Owner:LG ENERGY SOLUTION LTD

Guide device of compression type garbage transfer station

InactiveCN110978595AStable forceApply stabilityRefuse transferringLoading/unloadingStructural engineeringMechanical engineering

The invention discloses a guide device of a compression type garbage transfer station. The device comprises a pressure head, a garbage compression box and a first telescopic cylinder, wherein the pressure head is positioned above the garbage compression box; and the top of the garbage compression box is provided with an opening allowing the pressing head to be pressed in. Supporting columns are arranged at the four corners of the garbage compression box correspondingly. A first rail is arranged on the inner side of each supporting column; a pressure head guide sliding block connected with thepressure head is slidably connected into the first rail; a first height detection sensor is arranged at the upper end of the inner side of each first rail; the lower end of the first telescopic cylinder is connected with the upper end of the pressure head; electric telescopic push rods parallel to the axis of the first telescopic cylinder are arranged at four corners of the lower end surface of the oil cylinder structure; and telescopic ends of the electric telescopic push rods point to the pressure head. Guiding is smooth, it is ensured that the acting force of the pressure head is stably applied to garbage blocks, the compression stability is improved, the compaction density of the garbage blocks is improved, and the garbage transportation cost is reduced.

Owner:LIXIN JIANGHUAI YANGTIAN AUTOMOBILE

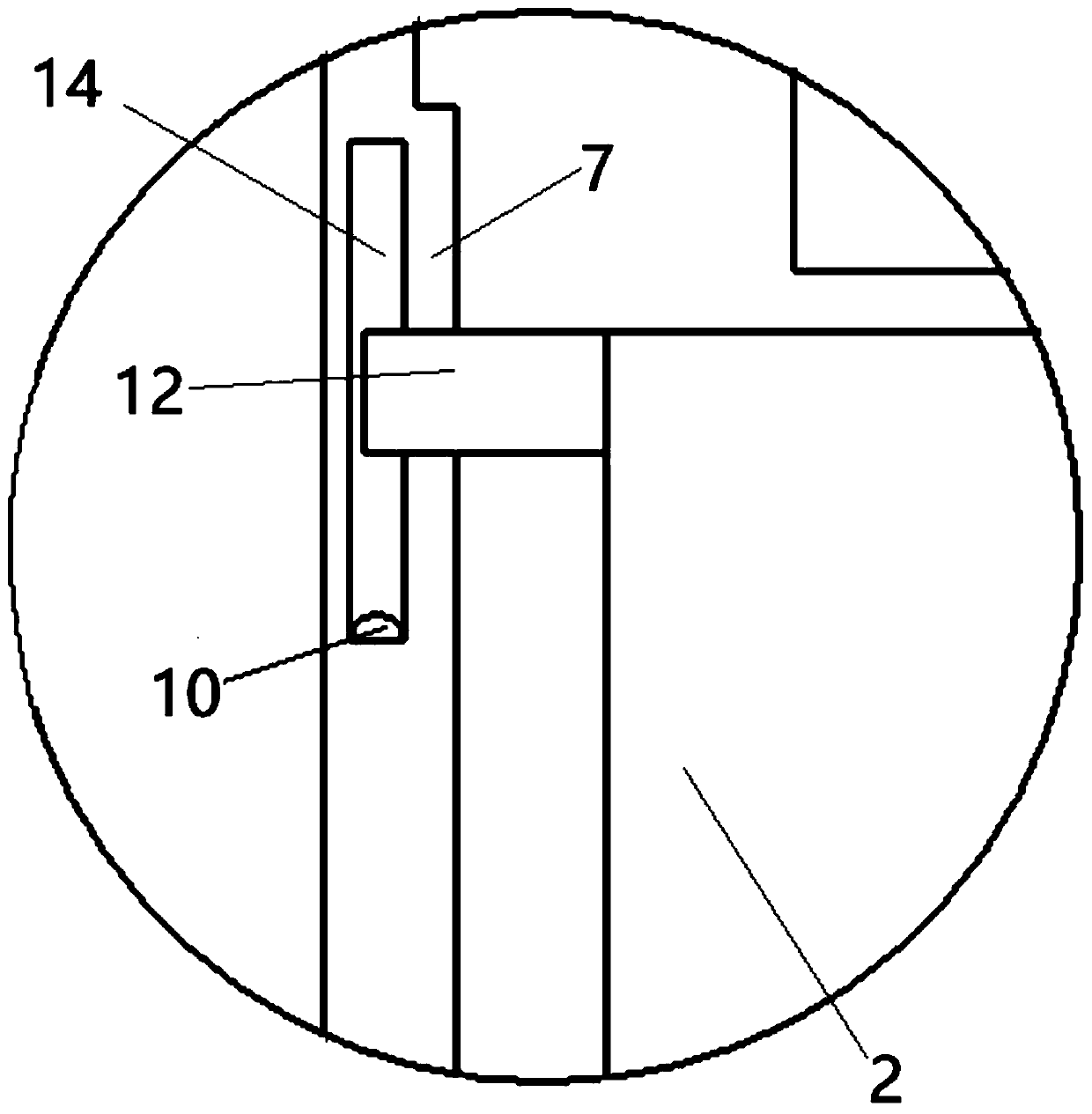

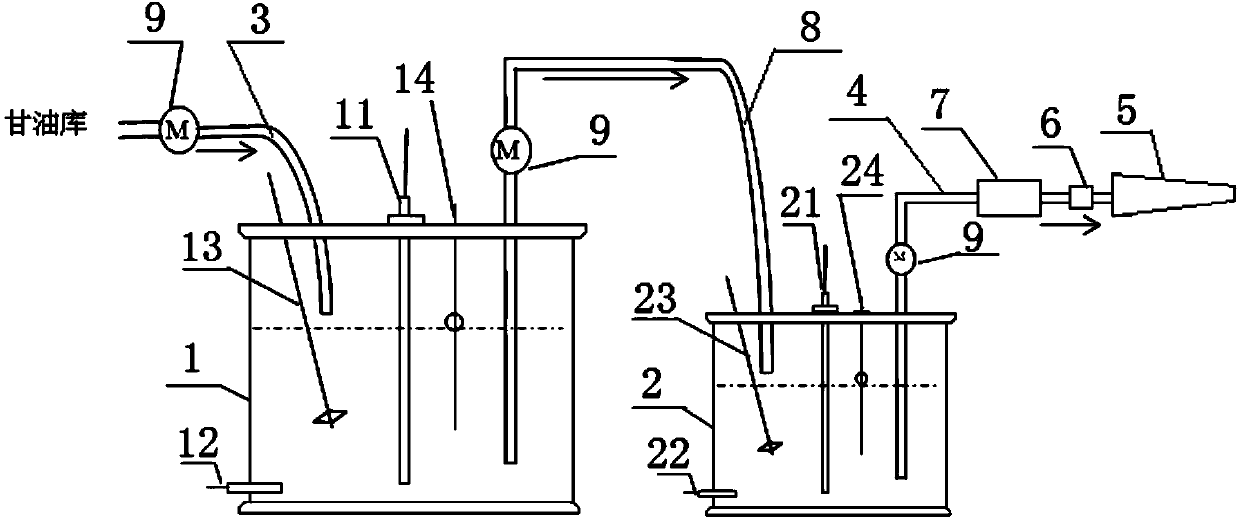

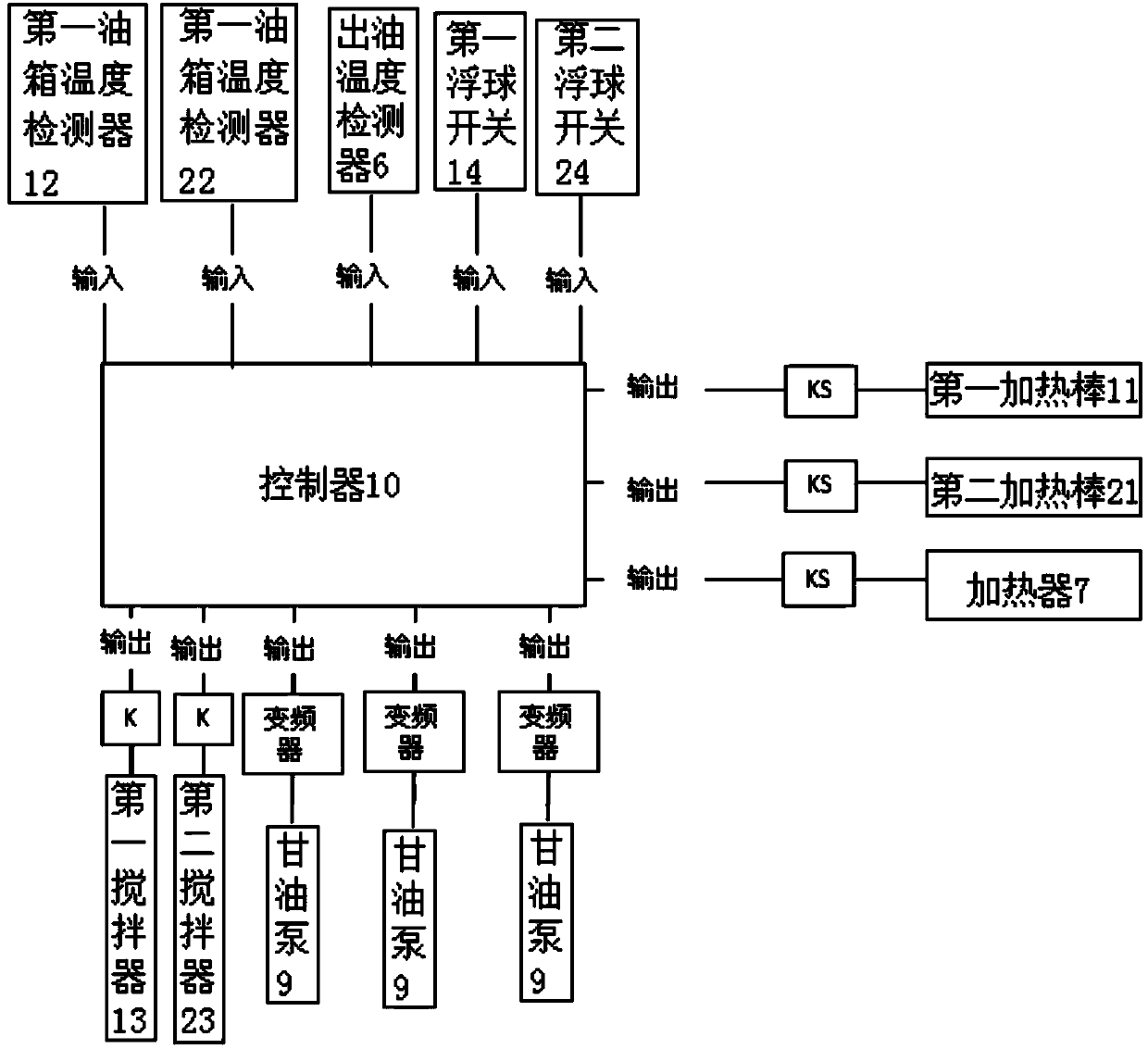

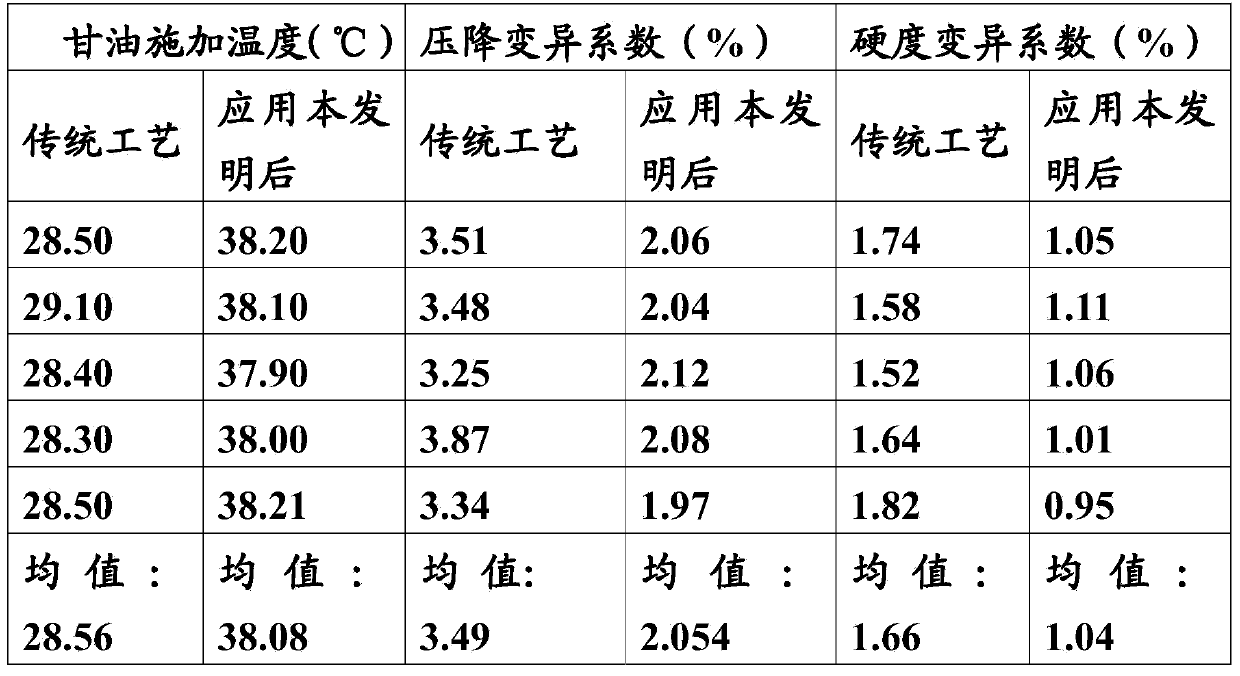

Heating device and heating method for glycerol in forming production of filter rod

InactiveCN103806241AStable temperature controlTemperature controlTextile treatment machine arrangementsTextile treatment by spraying/projectingBiochemical engineeringGlycerol

The invention relates to a heating device and method for glycerol in the forming production of a filter rod. The heating device comprises one or more glycerol heating tanks; all the glycerol heating tanks are sequentially communicated through an intermediate oil path; an oil outlet pipeline is arranged on the last glycerol heating tank; an atomizing spray nozzle is arranged at the tail end of the oil outlet pipeline; an oil outlet temperature detector and a heater are arranged in positions, close to the atomizing spray nozzle, on the oil outlet pipeline. According to the heating device and method, disclosed by the invention, the glycerol can be heated in a graded manner and the temperature of the glycerol can be stably controlled; thus the effects that atomized particles of the glycerol are uniform and the glycerol is uniformly applied are achieved; further, the hardness and pressure drop index of the filter rod are kept stable and the quality of the filter rod is greatly improved.

Owner:CHINA TOBACCO FUJIAN IND

Separator for lithium-sulfur battery and lithium-sulfur battery comprising same

PendingCN111615764ASolving Lithium Polysulfide ProblemsApply stabilityCell seperators/membranes/diaphragms/spacersCell electrodesPorous substrateLithium–sulfur battery

The present invention relates to a separator for a lithium-sulfur battery and a lithium-sulfur battery comprising same and, more specifically, to a separator for a lithium-sulfur battery, comprising:a porous substrate; and a coating layer formed on at least one surface of the porous substrate, wherein the coating layer includes a functional group containing a non-covalent electron pair in a mainchain and includes a polymer containing a side chain having an aromatic hydrocarbon group.

Owner:LG ENERGY SOLUTION LTD

Main tower lower cross beam support pre-pressing device and pre-pressing method thereof

ActiveCN111576223AGuaranteed force balanceBroaden applicationBridge erection/assemblyTowerIndustrial engineering

The invention provides a main tower lower cross beam support pre-pressing device and a pre-pressing method thereof, and belongs to the technical field of civil engineering construction devices. The device specifically comprises a stand column, a cross beam, a tensioning mechanism, a transmission mechanism, a rotary driving mechanism and a bottom supporting frame. The stand column is arranged belowthe cross beam to support the cross beam; the tensioning mechanism is arranged below the cross beam; a mounting hole is arranged in the cross beam; the tensioning mechanism penetrates through the mounting hole and extends to an upper part of the cross beam; a top size of the tensioning mechanism is greater than an aperture of the mounting hole; and the tensioning mechanism is further connected with the transmission mechanism, the transmission mechanism is connected to the bottom supporting frame, the stand column penetrates through the bottom supporting frame, the rotary driving mechanism isconnected to the transmission mechanism, a vertically-downward pulling force is applied to the cross beam through the transmission mechanism and the tensioning mechanism, and a vertically-downward pre-pressing force is applied to the stand column through the cross beam. According to the main tower lower cross beam support pre-pressing device, stress balance of the two sides of the stand column canbe guaranteed, pressure borne by the stand column is ensured to be vertically downward, and a pre-pressing force applying process is simple.

Owner:陕西中立检测鉴定有限公司

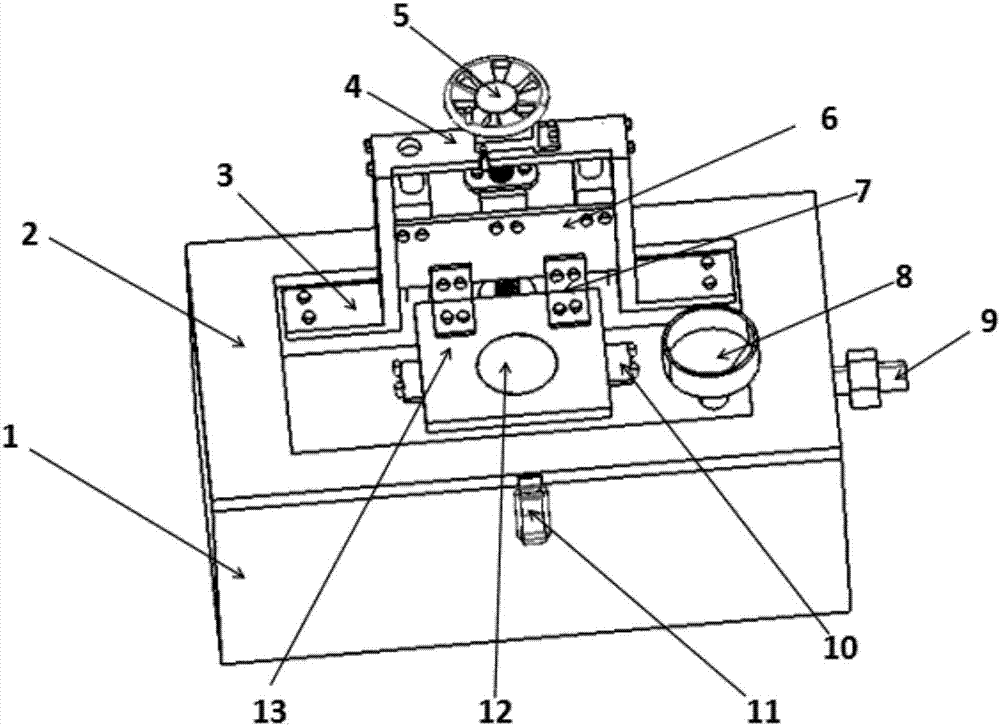

A radial loading experimental device for tire dynamic testing

ActiveCN104614189BGuaranteed normal rotationGuaranteed accuracyVehicle tyre testingForce sensorRotating drum

The invention discloses a radial loading experimental device for a tire dynamic test. The radial loading experimental device for the tire dynamic test comprises a base frame and a radial loading mechanism which is fixedly arranged at the upper end of the base frame, wherein a tire to be tested is connected with the radial loading mechanism. The radial loading experimental device is characterized in that a tire turning mechanism is arranged on the radial loading mechanism, and an inclinable rotating drum device is arranged at the lower end of the base frame. When the test is conducted, the outer circumferential surface of the tire abuts against the inclinable rotating drum device. The radial loading experimental device has the advantages that the whole radial loading experimental device can test the radial mechanical feature and the rigidity feature of the tire in an upright posture, a deflection posture, a sideward inclination posture and a deflection and sideward inclination combination posture, the radial loading mechanism changes the radial displacement of the tire through cooperation between a lead screw and a transmission nut, and measures the value of the radial load in real time through a first force sensor, the radial load can be applied to the tire accurately and stably, and accuracy of the experimental result is guaranteed; in addition, the whole radial loading experimental device is simple and compact in structure and low in cost, and convenient to assemble and disassemble.

Owner:NINGBO UNIV

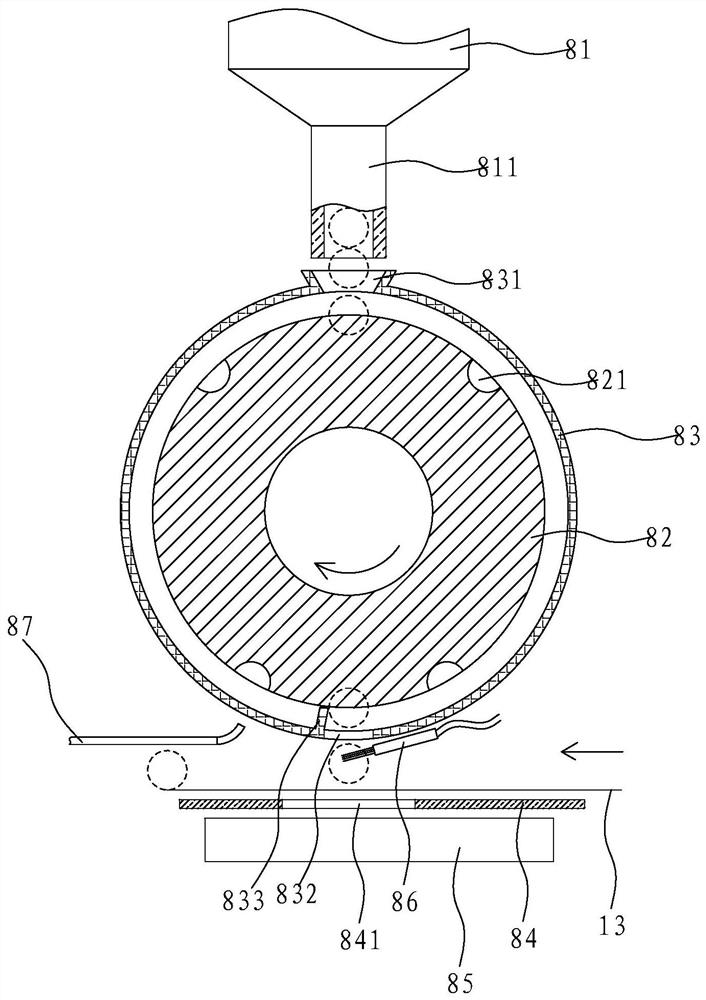

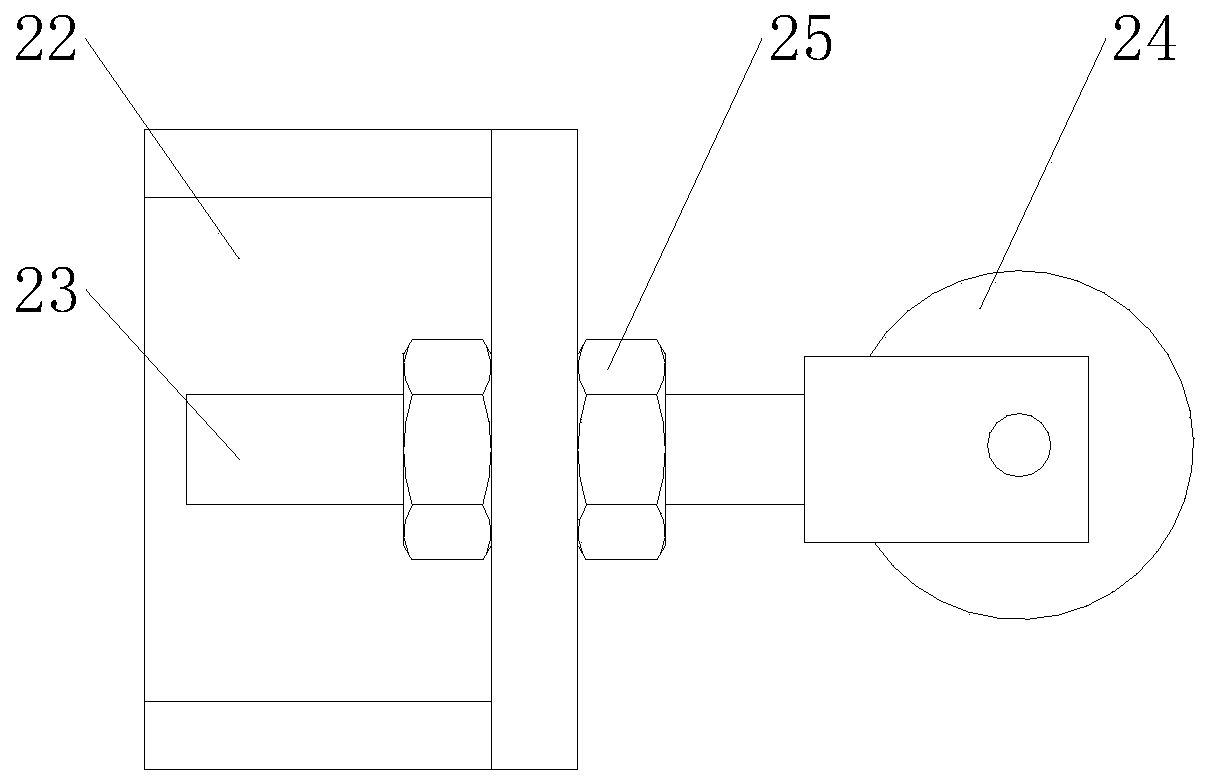

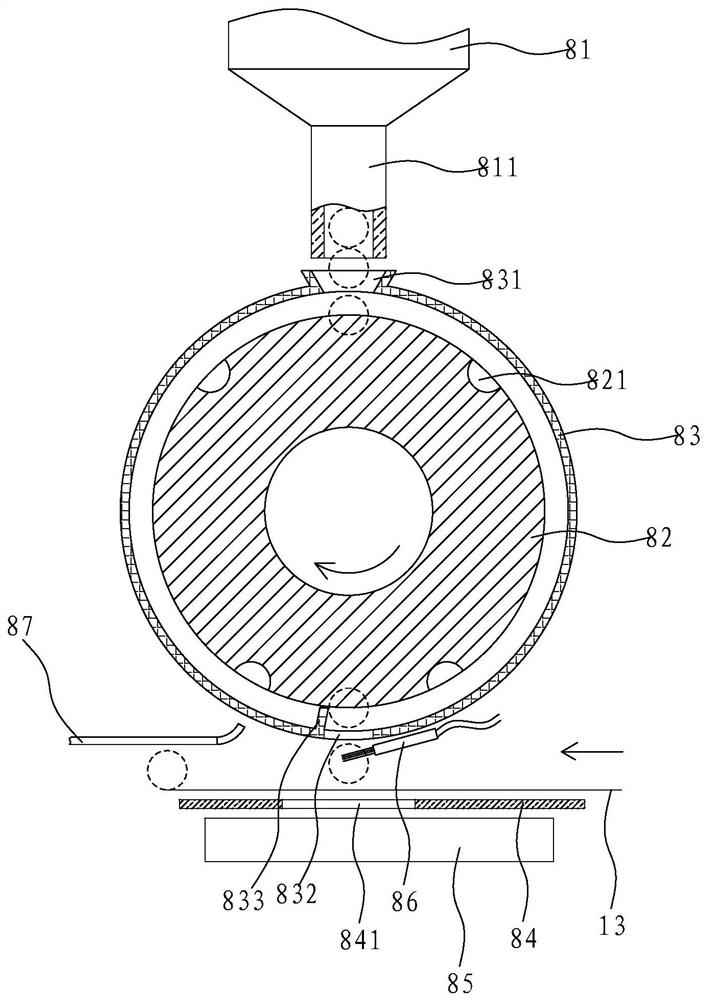

A kind of special-shaped surface coating device for wood strips

ActiveCN108889538BStable deliveryStable paint jobLiquid surface applicatorsCoatingsElectric machinerySprocket

The invention discloses a wood molding painting device for different surfaces. The device includes a conveying roller way, and a first conveying group, a painting group for different surfaces and a second conveying group are arranged on the outer side of the conveying roller way in the transmission direction; the first conveying group and the second conveying group are identical in structure and include multiple pressing wheel groups and limiting wheel groups both of which are arranged side by side, wherein the pressing wheel groups and the limiting wheel groups are alternately arranged with each other, and each pressing wheel group includes a pressing bracket positioned above the conveying roller way; a lifting screw rod is connected to the middle of each pressing bracket through a circular hole, a locking nut positioned on the top of the corresponding pressing bracket is arranged on each lifting screw rod, a rotatable pressing wheel is arranged at the lower end of each lifting screwrod, the outer side of each pressing wheel is in an arc shape, a push motor is connected to one side of each pressing wheel through a chain of a chain wheel, the push motors are connected with the lifting screw rods through mounting racks, and pressure springs positioned on the outer sides of the lifting screw rods are arranged between the mounting racks and the pressing brackets. The device has the advantages of being high in coating efficiency, great in coating effect and high in applicability.

Owner:湖州亨力木业有限公司

Cathode of lithium secondary battery comprising iron oxide, and lithium secondary battery comprising same

ActiveCN111542948AImprove responseInhibit side effectsPositive electrodesFerric oxidesBattery cellCharge and discharge

Owner:LG ENERGY SOLUTION LTD

A kind of molding process of ice-cold mask with explosive beads

ActiveCN112208127BRealize online fast compositeApply stabilityDomestic articlesProtective garmentNonwoven fabricMechanical engineering

The invention relates to the field of disposable sanitary products, in particular to a molding process of an ice-cooled explosive bead mask, which solves the technical problem of low production efficiency of the existing ice-cooled explosive bead mask. Including the following steps: the first step, the nose bridge strip is cut off after unwinding, and after cutting, it is input and adhered to a strip of non-woven fabric at intervals; The non-woven fabrics are respectively unrolled, and explosive beads are adhered to the inner non-woven fabric at intervals, and the strip-shaped non-woven fabric is clamped between the melt-blown non-woven fabric and the inner non-woven fabric to form the mask base material; The third step is to fold the middle of the mask base material and then flatten it; the fourth step is to hot-press the mask base material to form a peripheral indentation on the peripheral side of the mask, a restricted indentation surrounding the bridge of the nose, and an indentation surrounding the explosive beads. Positioning the indentation; the fifth step, the earband material is unrolled, cut, adsorbed and transported, and finally compounded on the mask substrate; the sixth step, slitting and output.

Owner:泉州市嘉佰利卫生材料有限公司

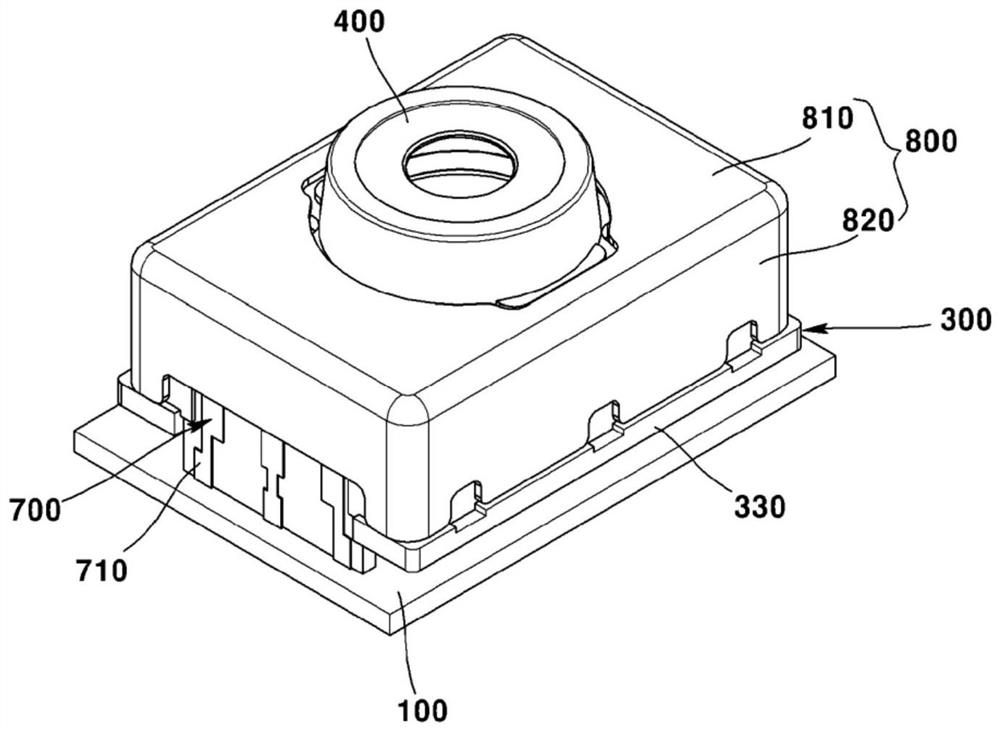

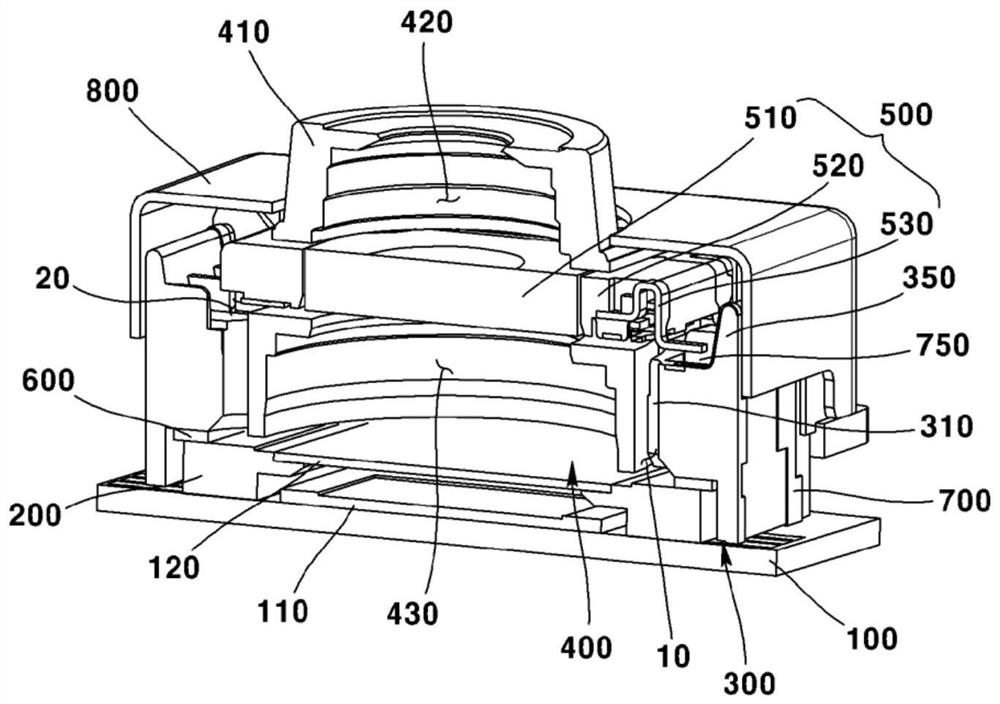

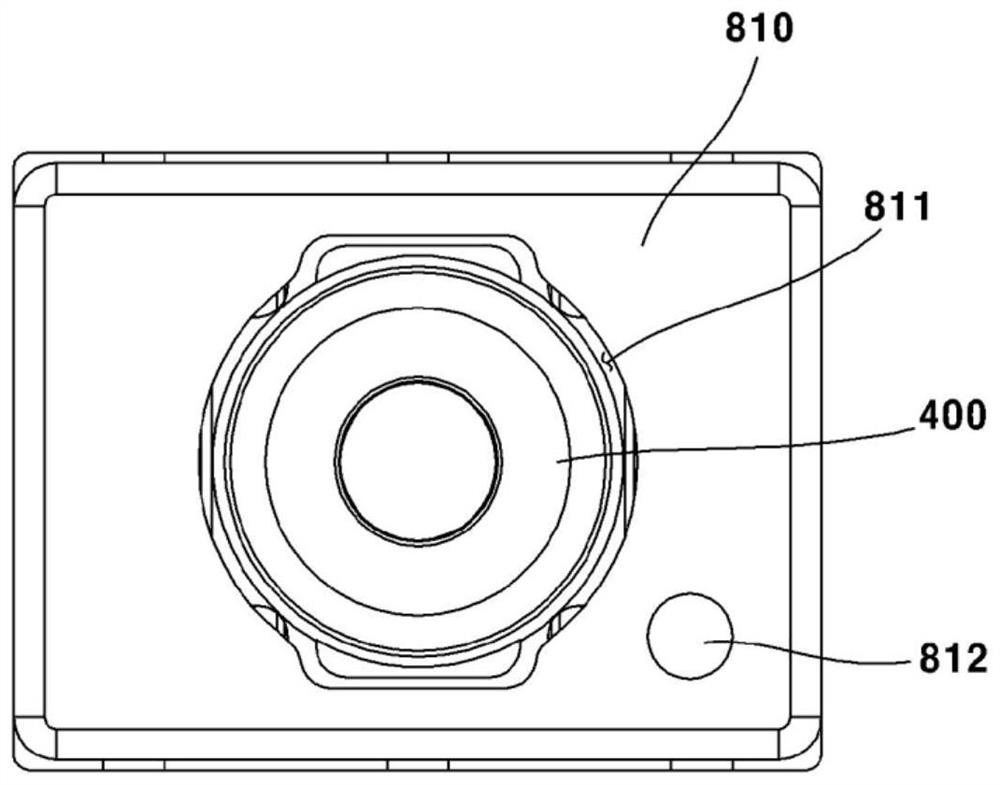

Camera device

ActiveCN113260919AEnsure combined reliabilityMake sure to escapeMountingsCamera body detailsMechanical engineeringLiquid lens

The present embodiment relates to a camera device comprising: a substrate; an image sensor disposed on the substrate; a base disposed on the substrate; a lens holder disposed on the base; a lens module disposed in the lens holder; a liquid lens module coupled to the lens module; and an adhesive for coupling the lens holder to the base, wherein the lens holder comprises a groove formed between the base and the liquid lens module.

Owner:LG INNOTEK CO LTD

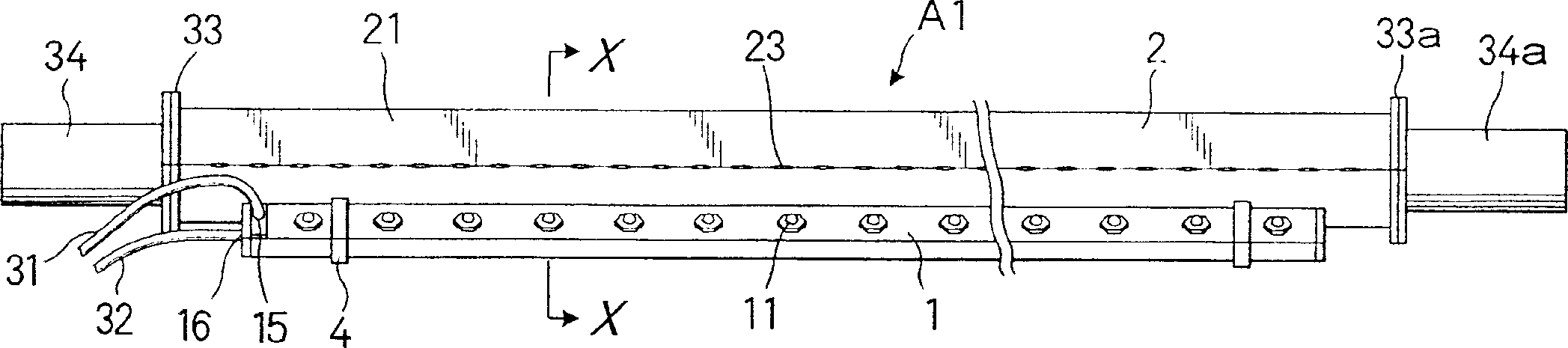

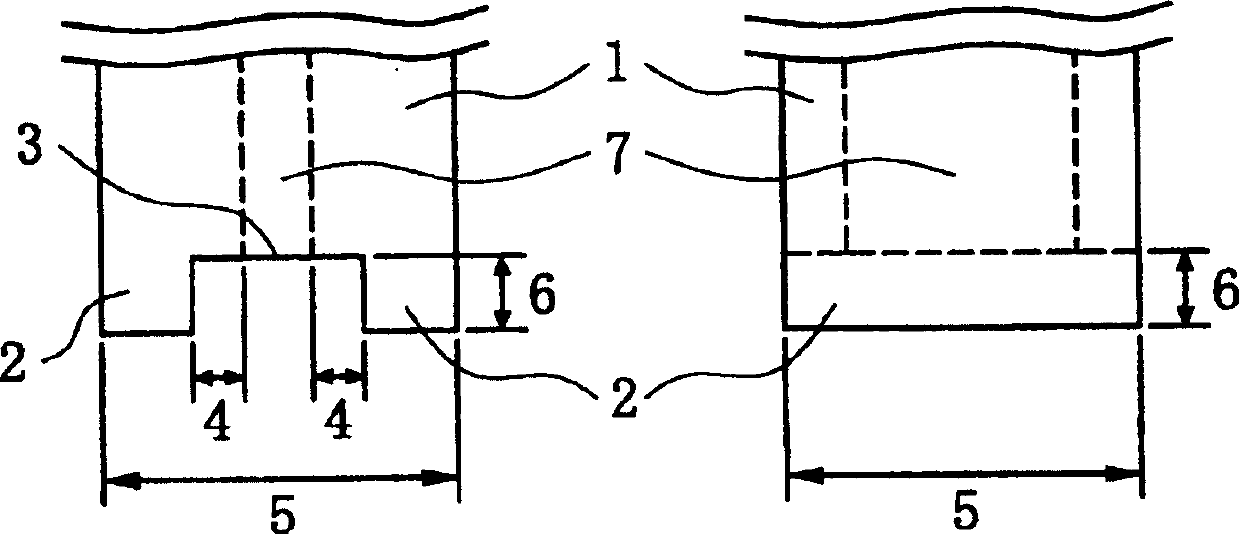

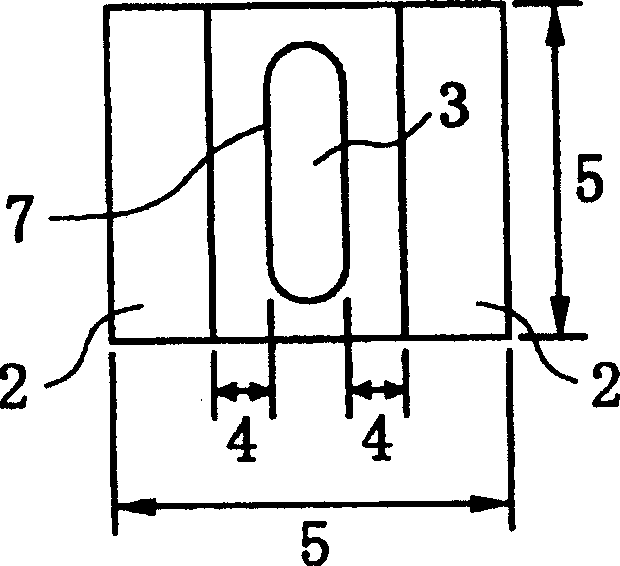

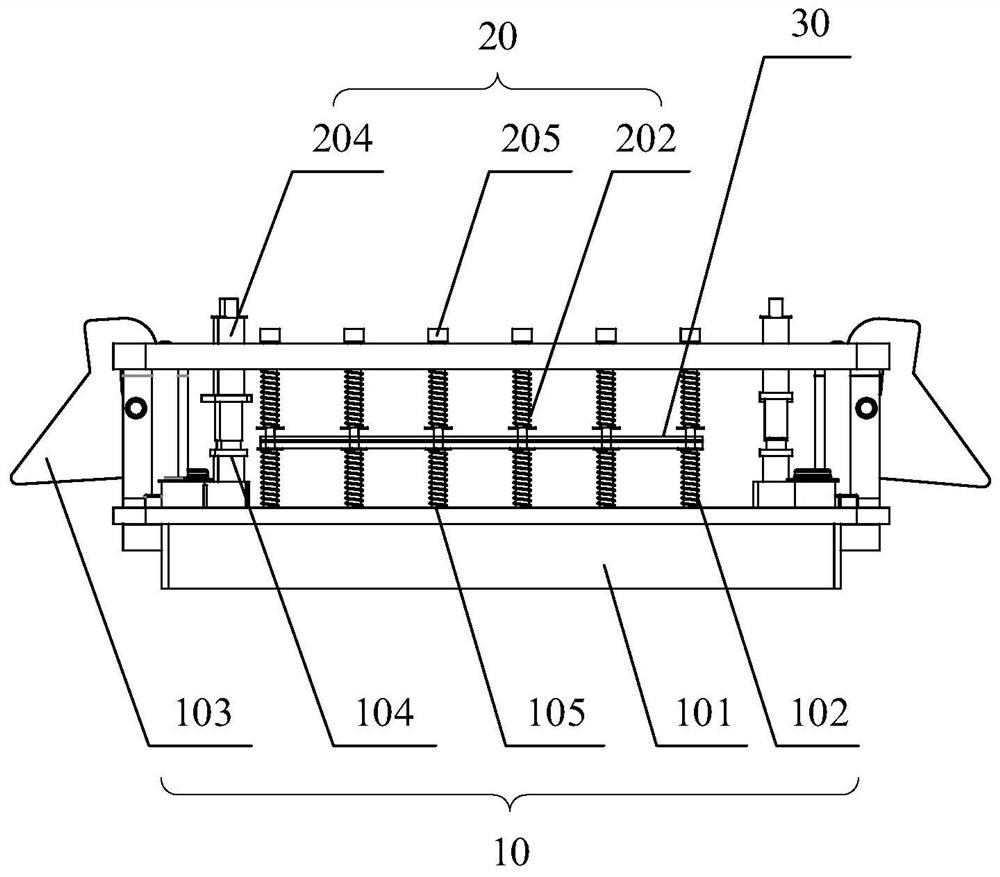

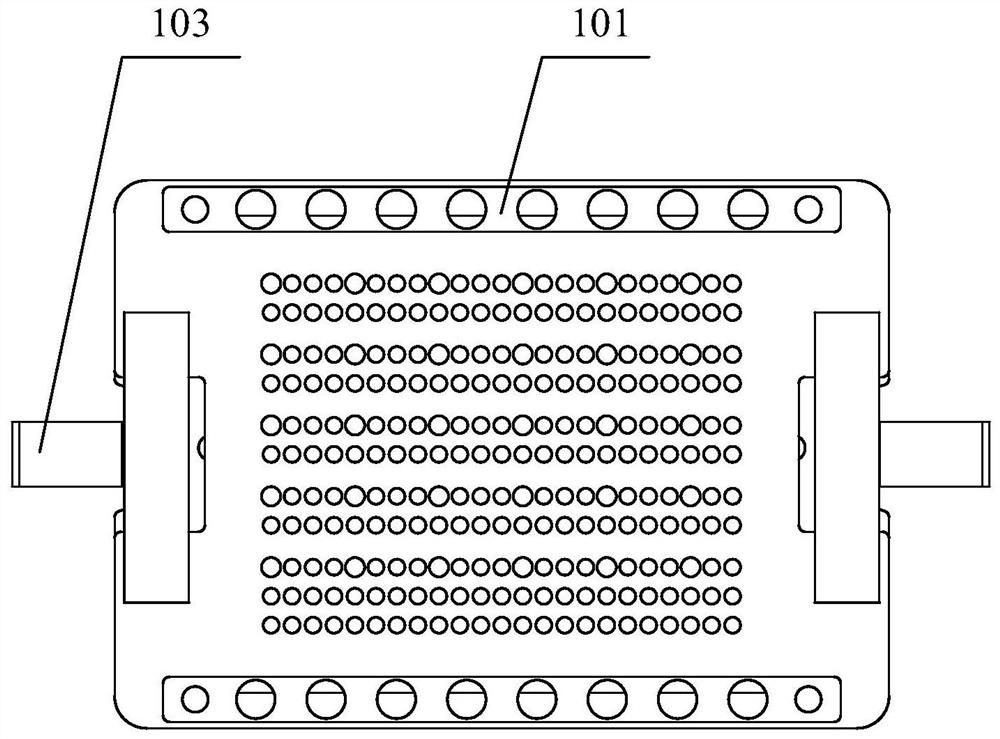

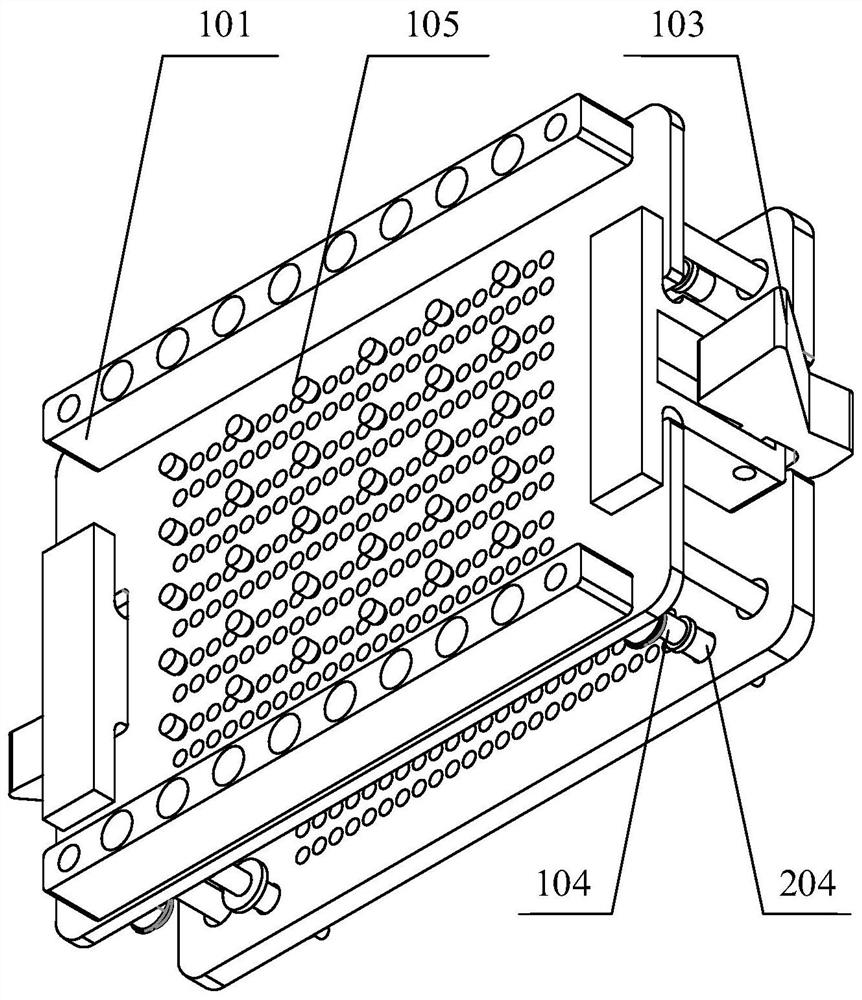

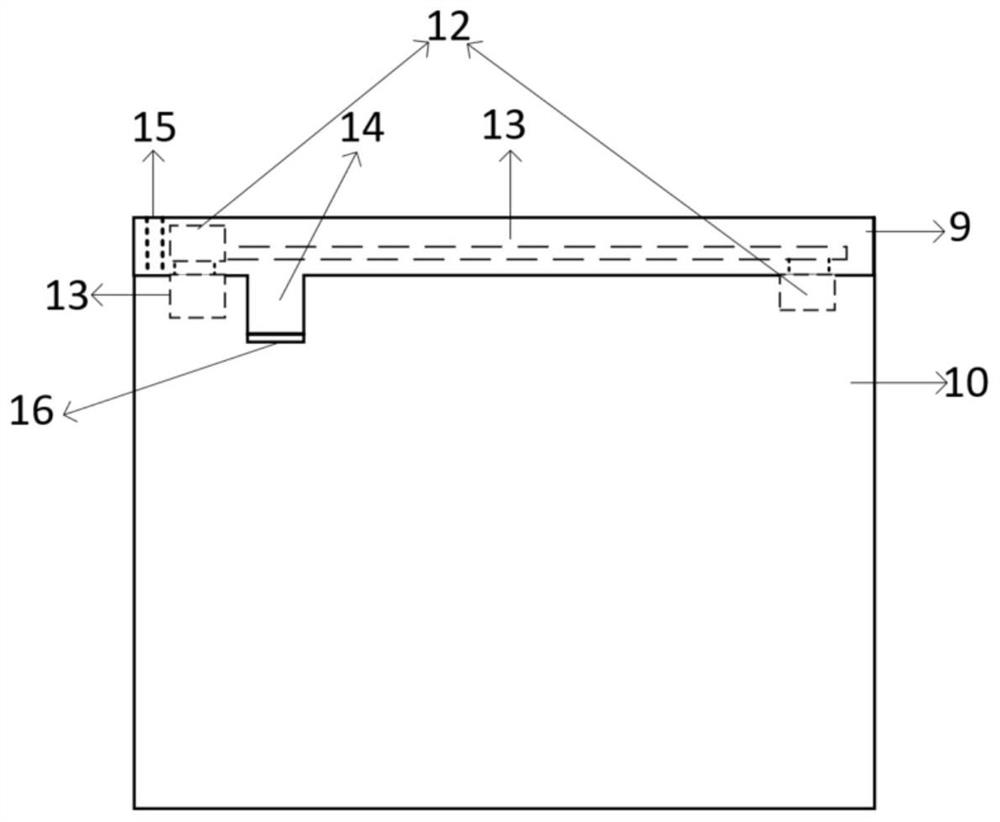

Press-fit jig and press-fit method for printed circuit board

PendingCN114080120AGood force consistencyPress evenlyMultilayer circuit manufacturePrinted circuit boardBackplane

The invention discloses a press-fit jig and a press-fit method for a printed circuit board. According to the embodiment of the invention, the press-fit jig for a printed circuit board comprises a bottom plate which is used for placing a printed circuit board; and a cover plate which is matched with the bottom plate and is used for covering the printed circuit board. The bottom plate is provided with a first press-fit column located on the bottom plate, and a first spring located on the first press-fit column. The cover plate is provided with a second press-fit column located on the cover plate, and a second spring located on the second press-fit column. The first spring and / or the second spring are / is deformed by locking the bottom plate and the cover plate. The deformed first spring and / or the deformed second spring provide press-fit force for the printed circuit board so as to press the printed circuit board. According to the press-fit jig and the press-fit method for the printed circuit board, spring press fit is adopted, the stress consistency is better, press fit is uniform, the air tightness after press fit is good, the precision is high, and the product yield is high.

Owner:东莞市瑞勤电子有限公司

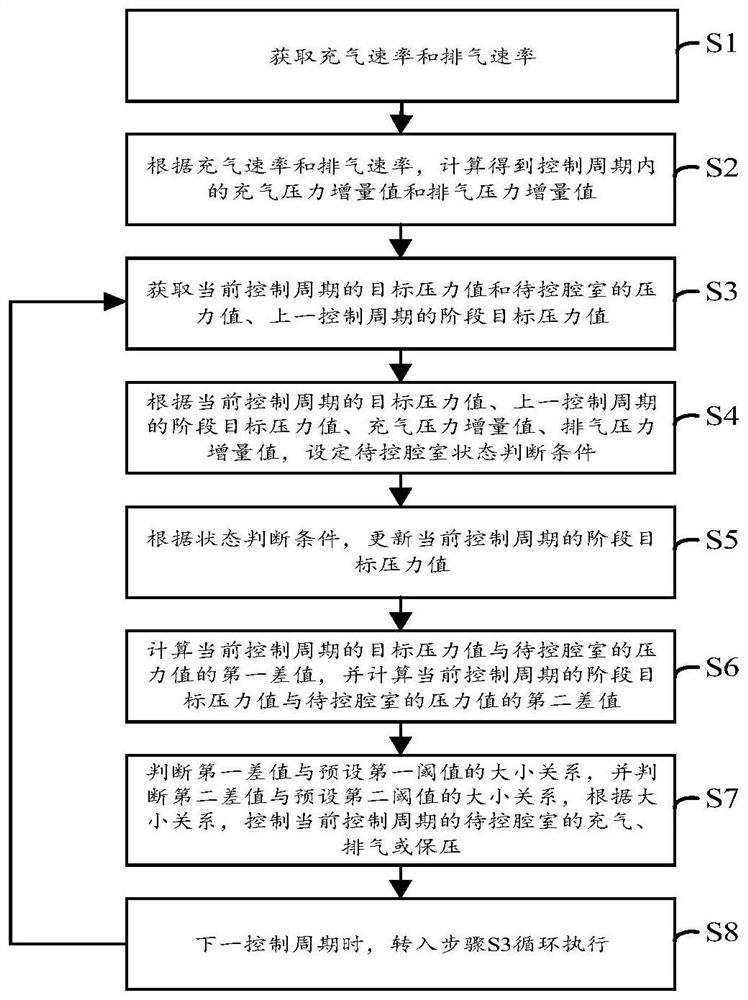

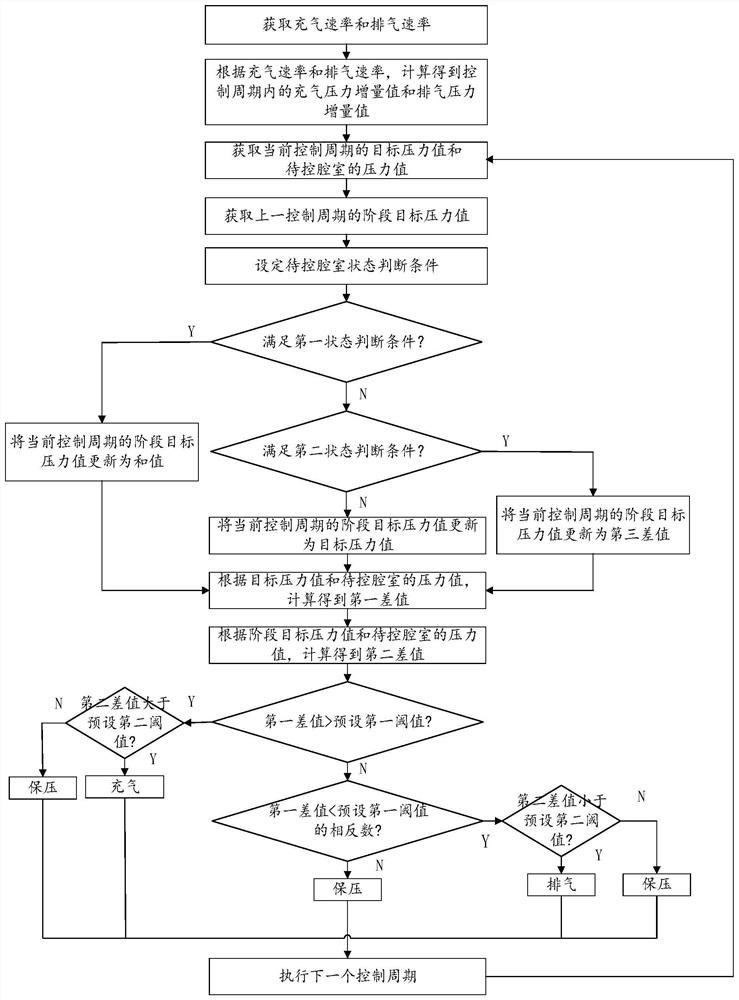

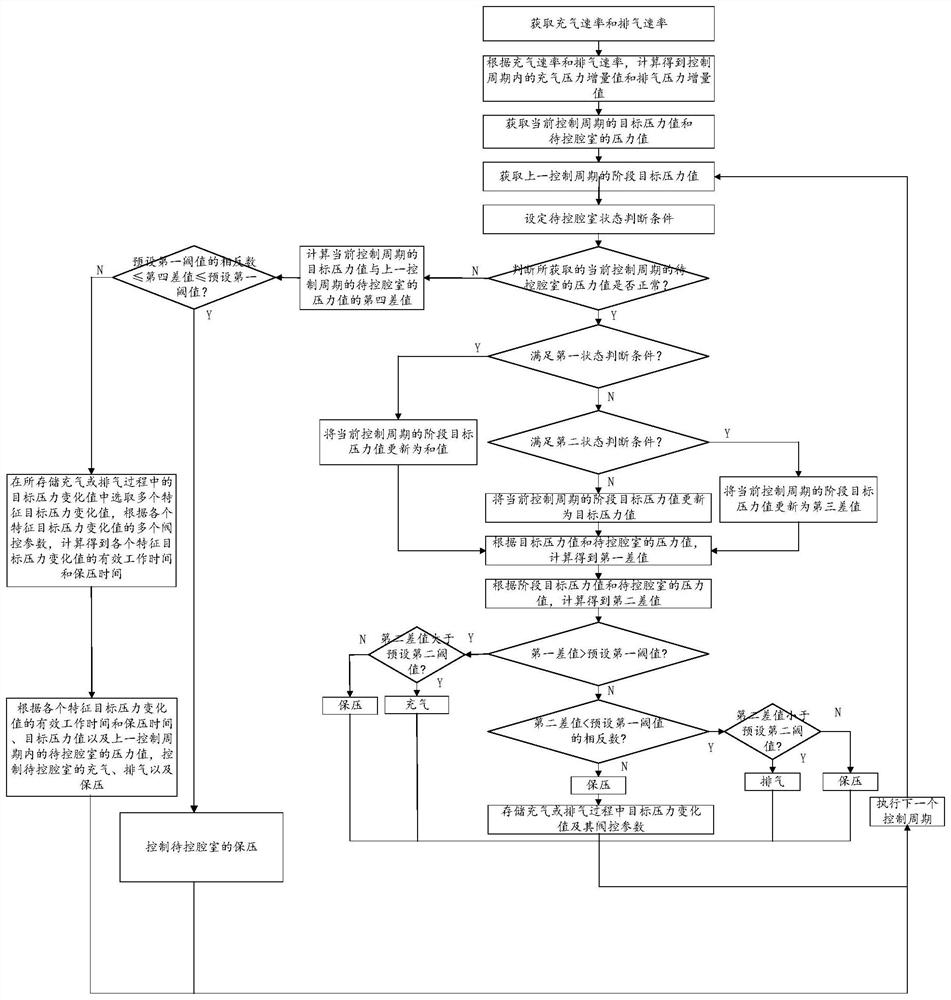

Pressure control method and control system for a locomotive

ActiveCN111332265BControl pressurePrecise pressure controlAerodynamic brakesRail brake actuationControl systemMechanics

The invention discloses a pressure control method of a locomotive. The method comprises the steps of obtaining an inflation rate and an exhaust rate, calculating to obtain an inflation pressure increment value and an exhaust pressure increment value in a control period; according to the target pressure value, the stage target pressure value of the previous control period, and the inflation and exhaust pressure increment value, updating a stage target pressure value of the current control period; according to the target pressure value of the current control period and the pressure value of thecavity to be controlled, and calculating a first difference value, calculating a second difference value according to the stage target pressure value of the current control period and the pressure value of the to-be-controlled chamber, and controlling inflation, exhaust or pressure maintaining of the to-be-controlled chamber of the current control period according to the size relationship betweenthe first difference value and a preset first threshold value and the size relationship between the second difference value and a preset second threshold value. According to the pressure control method provided by the invention, accurate control over the locomotive pressure is realized, stable application and release of braking force are ensured, and the comfort of passengers is improved.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST +1

A fresh-keeping device for fruits and vegetables based on nanosecond pulsed low-voltage electric field

ActiveCN108271856BReduce rotReduce breathing intensityFruits/vegetable preservation by irradiation/electric treatmentFood ingredient for microbe protectionLow voltageEngineering

The invention discloses a fresh-keeping device for fruits and vegetables based on a nanosecond pulse low-voltage electric field, which includes a treatment chamber and a nanosecond pulse electric field generating device. Among them, the processing chamber includes a box body with a closed cavity and an opening at the top, and an upper cover provided at the top opening of the box body containing a copper sheet protection passage. The box body and the upper cover are fitted by a positioning component, and the electromagnetic device and copper sheet The protection circuit and the working indicator light together form a safety protection device; the nanosecond pulse electric field generating device includes a parameter-adjustable nanosecond pulse power supply and a multi-channel double electrode sealed in an insulating partition and connected to an electrode outlet post. The electric field generating device forms a nanosecond pulse electric field in the box, and the fruits and vegetables are placed in it for electric field treatment, which can not only achieve the effect of inactivating enzymes by changing the inherent electric field of fruits and vegetables, inhibit the respiration of fruits and vegetables, but also have a good cold sterilization effect. The operation method of the invention is convenient and pollution-free, and is suitable for fresh-keeping of various perishable fruits and vegetables, and has high application value.

Owner:XI AN JIAOTONG UNIV

A temperature-controllable cryogenic laser shock peening system

ActiveCN107267743BApply stabilityImprove quality and efficiencyTemperature controlComputerized system

The invention provides a temperature-controllable deep cooling laser shock peening system which comprises a clamp base, a liquid nitrogen automatic supplementary device, a liquid level monitor device, first supporting plates, a cover plate, a screw pressing device and a circumferential locating device. An automatic flow adjusting funnel, an electric liquid nitrogen pump, a liquid level monitor and a computer system are connected, it is guaranteed that the liquid nitrogen liquid level height is kept constant, and then the workpiece temperature is controllable; a screw pressing mechanism is used for tightening and locating a workpiece and a restraint layer; and the circumferential locating device achieves circumferential restraining on a screw through a clamping block and a check block. The clamping and locating process is fast and simple, the repeated locating precision is high, and locating is reliable; and the deep cooling laser shock peening experimental effects of being controllable in temperature and better in restraint effect are achieved.

Owner:JIANGSU UNIV

A thin-walled structure vibration test device and test method taking into account differential pressure conditions

ActiveCN112373738BRealize vibration testRealize the loadCosmonautic condition simulationsVibration testingAirbagPressure difference

The invention relates to a thin-walled structure vibration test device and a test method taking into account pressure difference conditions, and belongs to the technical field of spacecraft structural product vibration test. The thin-walled structure is a part of the spacecraft cabin, and the thin-walled structure is a circular plate, and the thickness of the circular plate is not more than 15mm, preferably 15mm. The device can realize the vibration test of the thin-walled structure and simultaneously realize the comprehensive loading of the thin-walled structure under pressure difference. It is always in a tight fit state, and the pressure differential conditions are applied evenly and stably; at the same time, the flexible structure of the airbag makes the device have a certain universal type, which is suitable for various spacecraft thin-walled structures with combined pressure differential and vibration conditions vibration test; the test method is simple, reliable and versatile.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com