Structure and method for coupling wheel bearings

A technology for wheel bearings and wheels, which is applied in the direction of rolling contact bearings, bearings, axles, etc., can solve the problems of unstable power transmission, reduced durability, and noise generation, and achieve improved maintainability, increased durability, and reduced weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] Hereinafter, exemplary embodiments of the present invention will be described in detail with reference to the accompanying drawings.

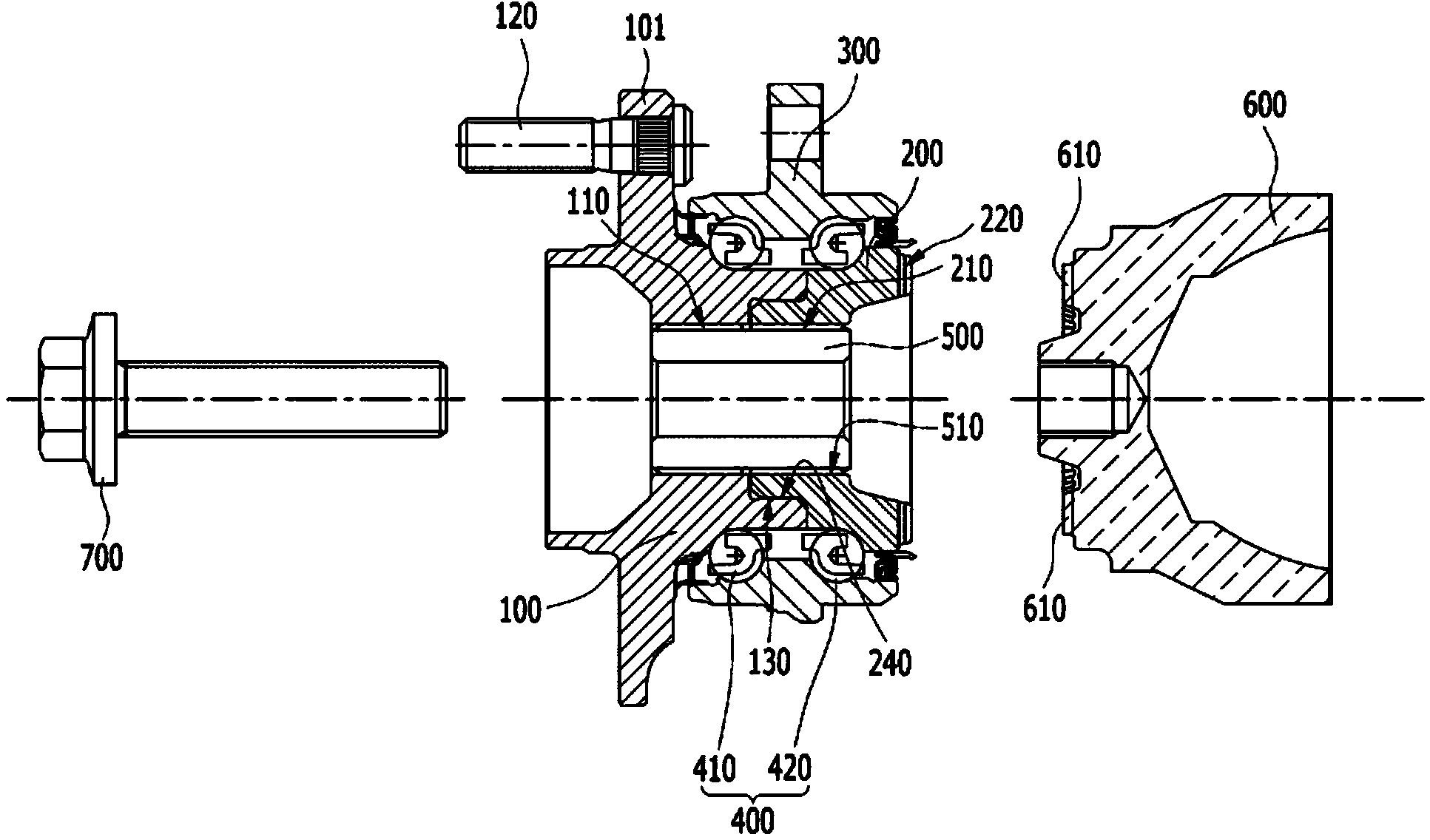

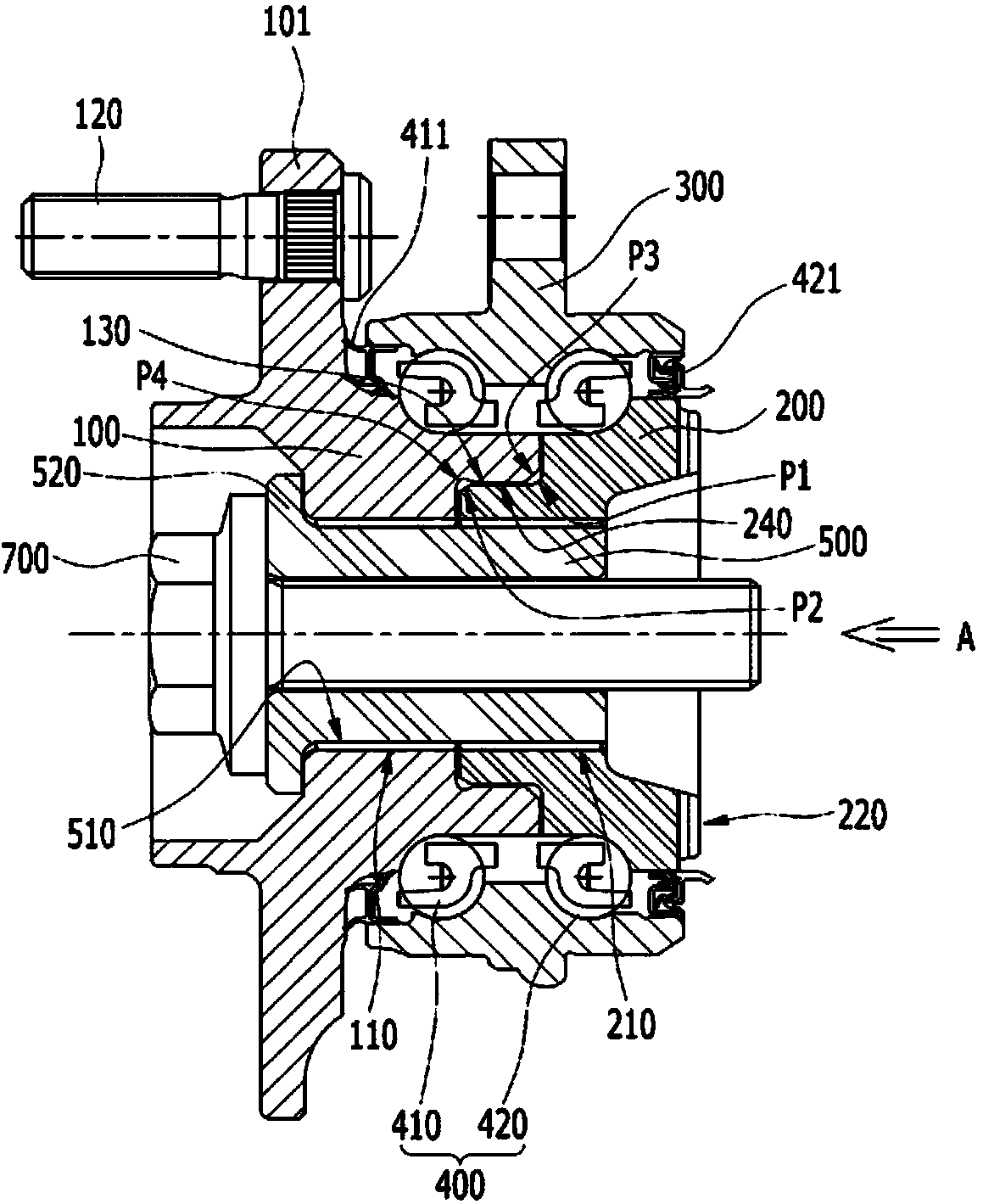

[0065] Figure 2 to Figure 6 A structure for coupling a wheel bearing according to a first exemplary embodiment of the present invention is shown.

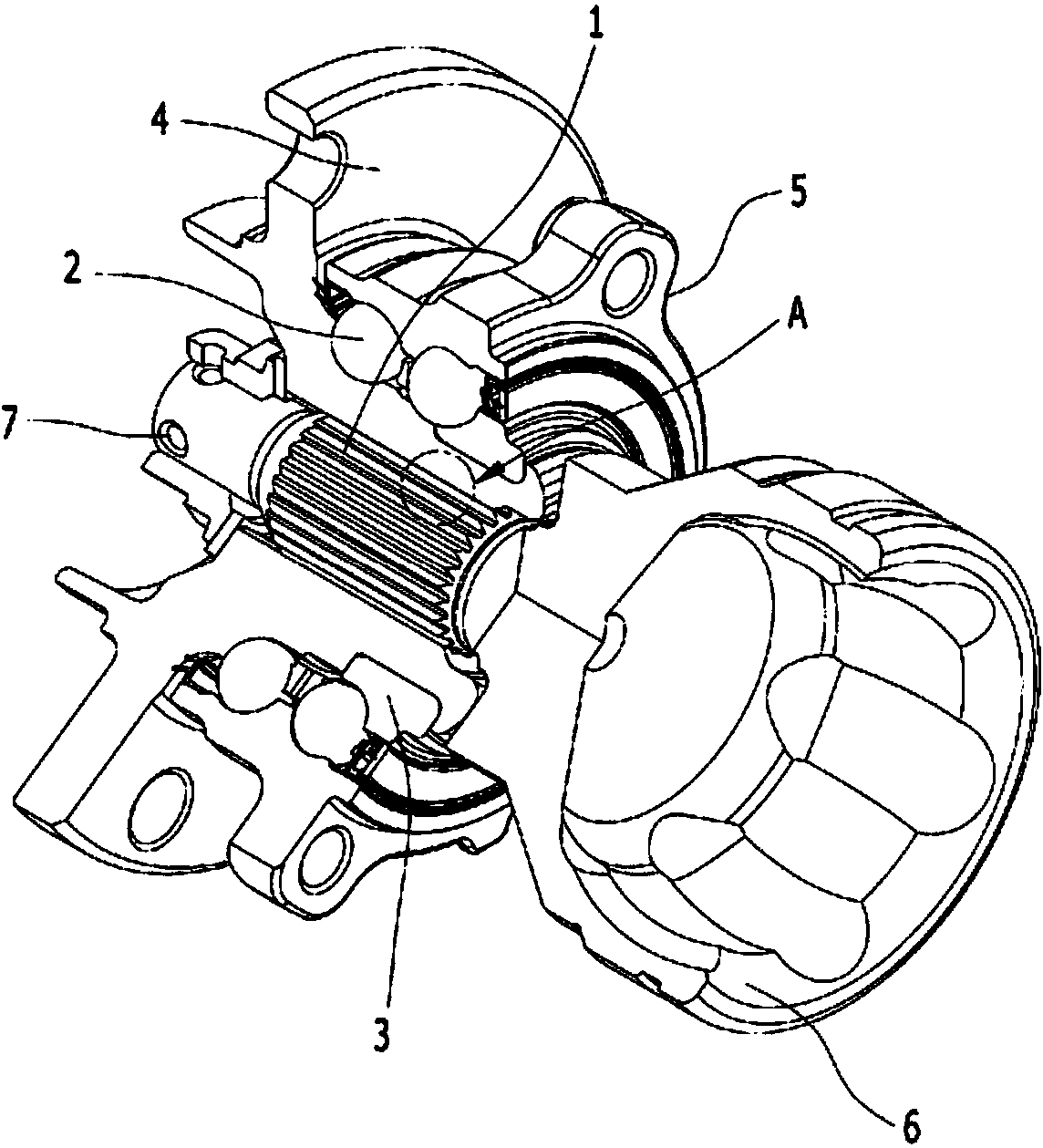

[0066] Such as Figure 2 to Figure 6 As shown in , the structure for coupling wheel bearings according to the first exemplary embodiment of the present invention includes a hub 100 , an inner ring 200 , an outer ring 300 , rolling elements 400 , hollow pins 500 , joint members 600 and bolts 700 .

[0067] The hub 100 transmits driving torque of a joint member 600 such as a constant velocity joint (CVJ) to a vehicle wheel. The hub 100 is provided with a flange 101 and hub bolts 120 for mounting a vehicle wheel. Such as figure 2 As shown in , the flange 101 protrudes radially outward from the hub 100 and generally has a disc shape. A plurality of bolt holes are formed in the flange 101, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com