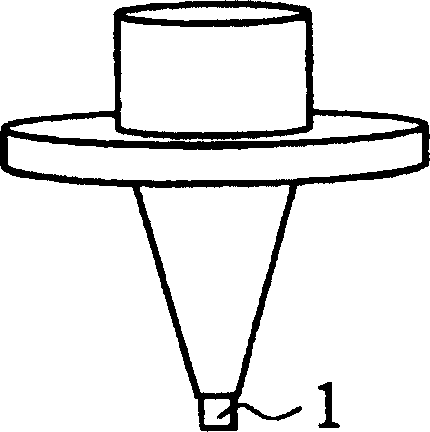

Micro adhesive nozzle and adhesive applying apparatus

A technology for adhesives and nozzles, applied in the field of adhesive nozzles, which can solve the problem of touching the top of the nozzle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

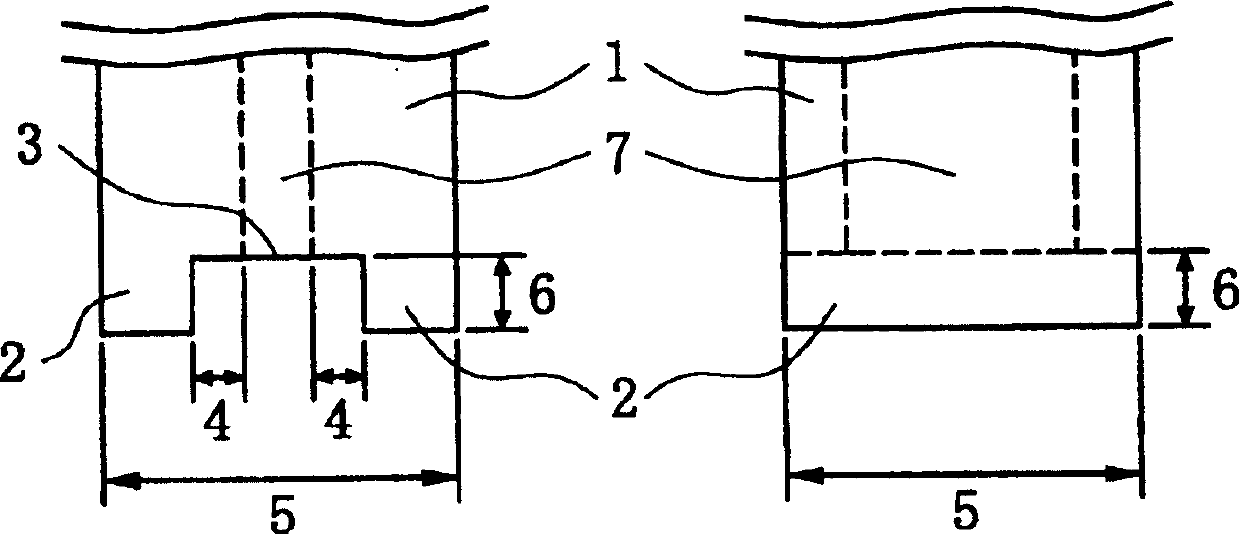

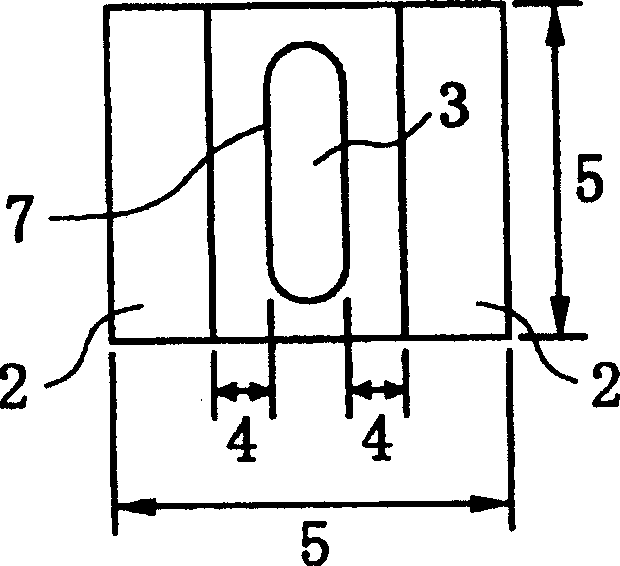

[0030] Hereinafter, preferred embodiments of the present invention will be described with reference to the accompanying drawings.

[0031] FIG. 9 shows the structure of an adhesive applying device including a miniature adhesive nozzle according to an embodiment of the present invention.

[0032] The adhesive applying device in FIG. 9 includes a printed circuit board 21 , a head unit 28 , a table unit 35 , and guides 37 and 38 . The head unit 28 can be guided by the guide 37 to move in the X direction (represented by the double-headed arrow X-X in FIG. Y-Y means) move. The head unit 28 comprises an adhesive application head 45 and a damping unit 47 , wherein the adhesive application head 45 is realized by the adhesive nozzle 26 with the nozzle top 29 . The printed circuit board 21 is supported by the table unit 35 via support pins 36 . By moving the head unit 28 in the X direction and the table unit 35 in the Y direction, the adhesive nozzle 26 can be positioned at a desired...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com