Forming process of ice-cold type mask with blasting beads

A technology of blasting bead ice-cooling and molding technology, which is applied in clothing, other household appliances, household appliances, etc., can solve the problems of low production efficiency of popping bead ice-cooling masks, improve application efficiency, realize layout, and strengthen precise positioning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

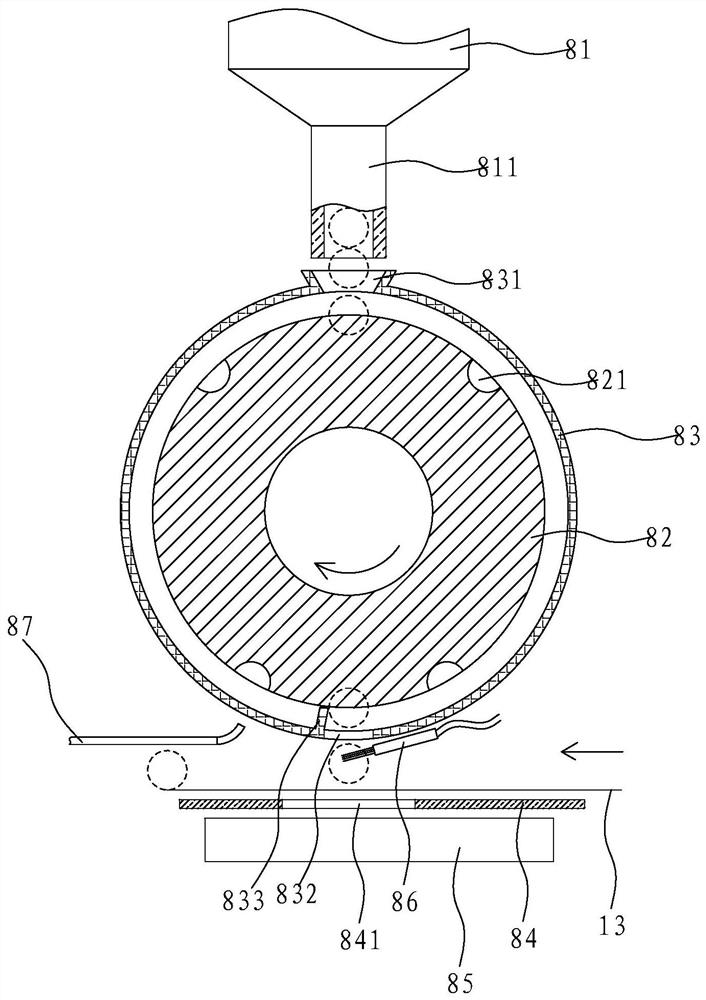

[0027] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

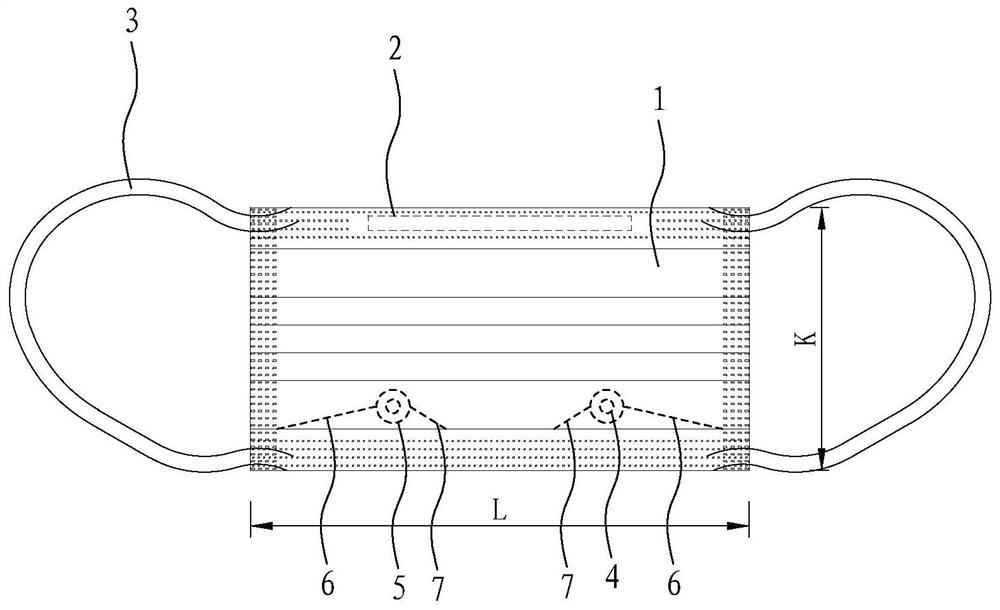

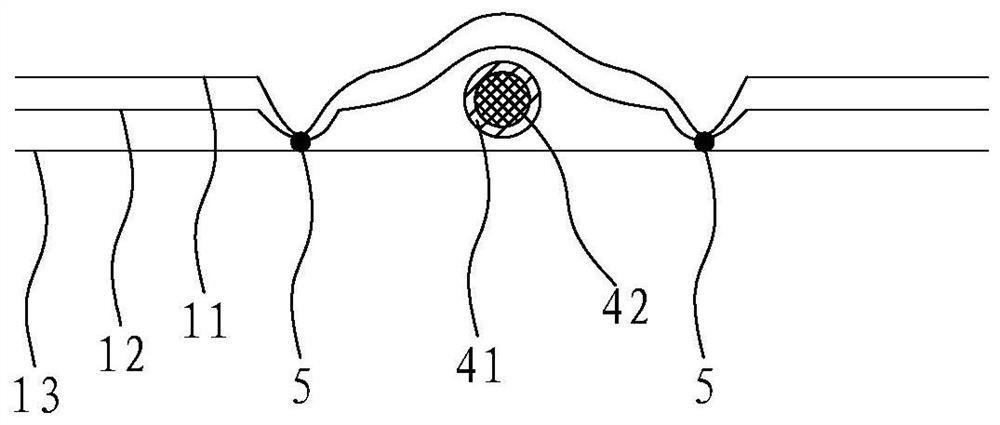

[0028] refer to figure 1 , figure 2 , the present embodiment provides a kind of quick-fried beads ice-cold mask, comprising a mask body 1, a nose bridge strip 2 arranged in the mask body 1, ear straps 3 arranged on both lateral sides of the mask body 1, and the mask body 1 consists of an outer layer Non-woven fabric 11, melt-blown non-woven fabric 12, and inner layer non-woven fabric 13 are stacked to form, and the mouth mask body 1 is sandwiched between the melt-blown non-woven fabric 12 and the inner layer non-woven fabric 13 to be provided with two The explosive bead particle 4 , the explosive bead particle 4 includes a fragile shell 41 and an oil body 42 wrapped in the shell 41 . The popping beads 4 are located in the left area and the right area of the mask body 1. Define the length of the lateral direction of mask body 1 as L, define the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com