Separator and lithium-sulfur battery comprising same

A lithium-sulfur battery and diaphragm technology, applied in the field of lithium-sulfur batteries, can solve the problems of lithium ion path extension, blockage, and inability to ensure battery performance, and achieve the effect of improving stability and high capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0102] Hereinafter, Examples, Comparative Examples, and Experimental Examples will be described to help understand the effects of the present invention. However, the following description is only an example of the contents and effects of the present invention, and the scope and effects of the present invention are not limited thereto.

Embodiment 1

[0105] (1) Preparation of diaphragm

[0106] A 16 μm polypropylene (50% porosity) membrane was prepared as a porous substrate.

[0107] An aqueous dispersion of graphene oxide (concentration of 0.01% by weight, thickness of 10 nm, length of 5 μm) and an aqueous dispersion of boron nitride (concentration of 0.1 mg / mL, thickness of 0.2 μm to 0.5 μm, length of 1 μm to 3 μm) and ultrasonic waves were applied thereto for 8 hours to prepare a coating solution (weight ratio: graphene oxide: boron nitride = 1:9).

[0108] The coating solution was poured on the porous substrate, followed by filtration under reduced pressure to form a coating on both sides of the porous substrate, which was dried at 70° C. for 24 hours to prepare a separator. At this point, the coating was measured to have a thickness of about 1.5±0.5 μm.

[0109] (2) Lithium-sulfur battery

[0110] Conductive carbon having electrical conductivity and sulfur were mixed at a weight ratio (% by weight) of conductiv...

experiment example 1

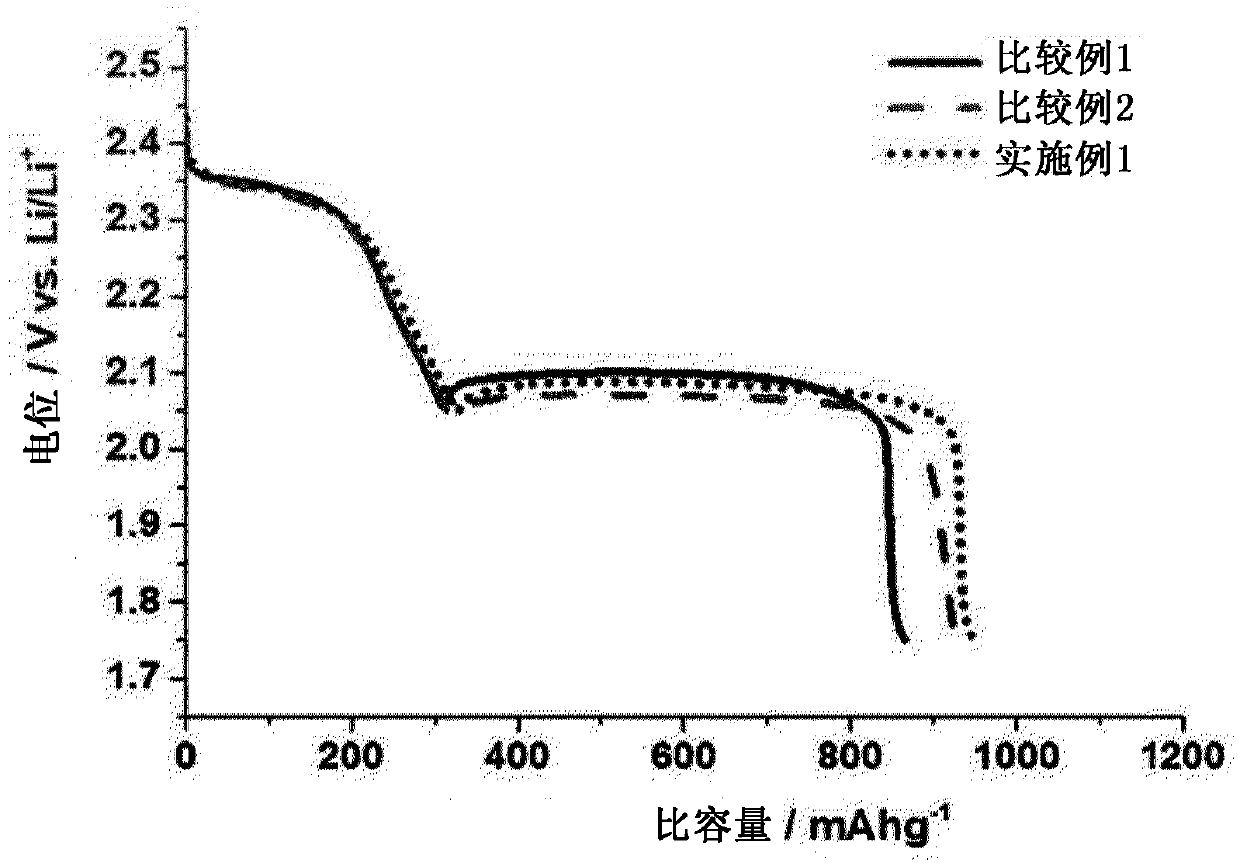

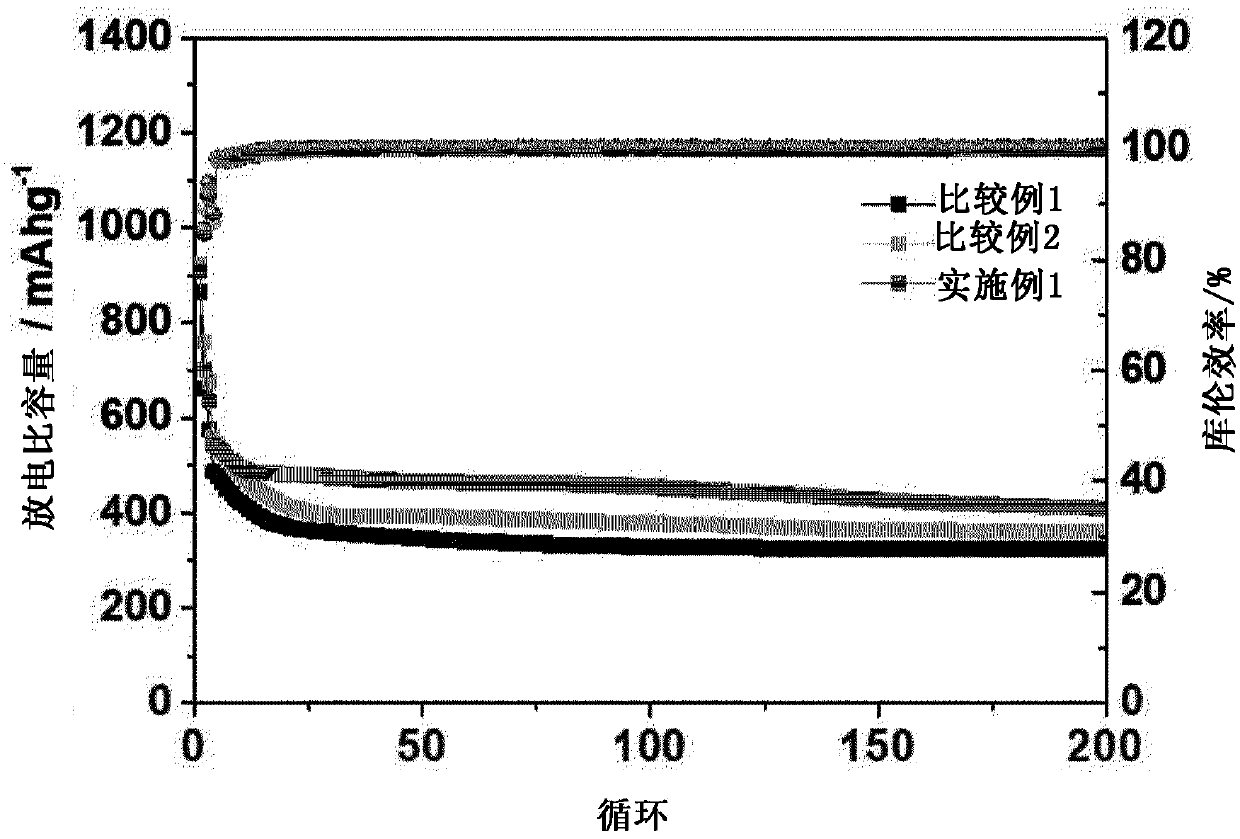

[0117] The lithium-sulfur batteries manufactured in the above examples and comparative examples were driven under the charge / discharge conditions of 0.3C / 0.5C, the initial charge / discharge capacity was measured, and the capacity change was confirmed by performing 200 cycles.

[0118] figure 2 is a graph showing the initial discharge capacity of the lithium-sulfur batteries manufactured in Example 1 and Comparative Examples 1 and 2. refer to figure 2 , it can be seen that compared with Comparative Example 1 without coating and Comparative Example 2 with a single graphene oxide layer, the battery of Example 1 with the coating according to the present invention has a high initial discharge capacity.

[0119] image 3 It is a graph showing the lifetime characteristics of the lithium-sulfur batteries manufactured in Example 1 and Comparative Examples 1 and 2. refer to image 3 , it can be seen that the battery of Example 1 shows a high capacity retention rate and capacity imp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com