A kind of molding process of ice-cold mask with explosive beads

A technology for the cooling type of explosive beads and the molding process, which is applied in protective clothing, household appliances, clothing, etc., can solve the problems of low production efficiency of the cold-exploding beads, and achieves high application efficiency, rapid adhesion, and adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

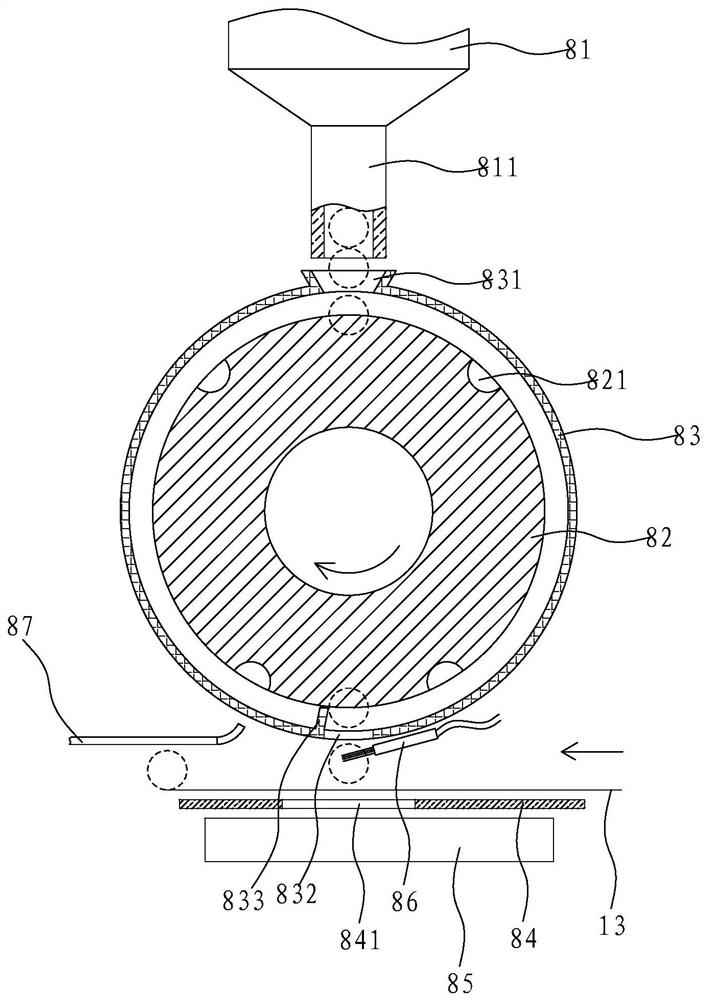

[0027] The present invention will now be further described with reference to the accompanying drawings and specific embodiments.

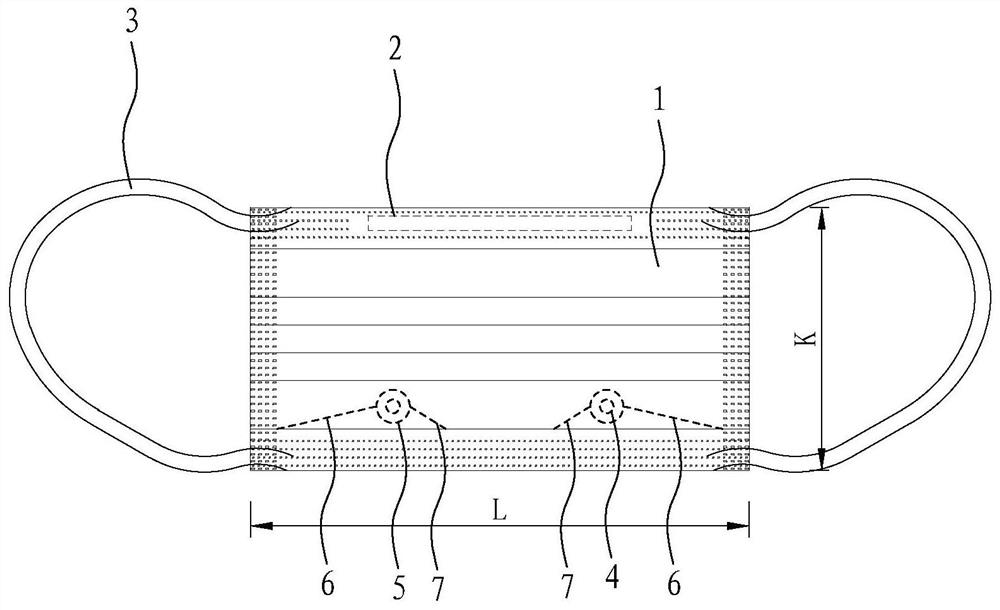

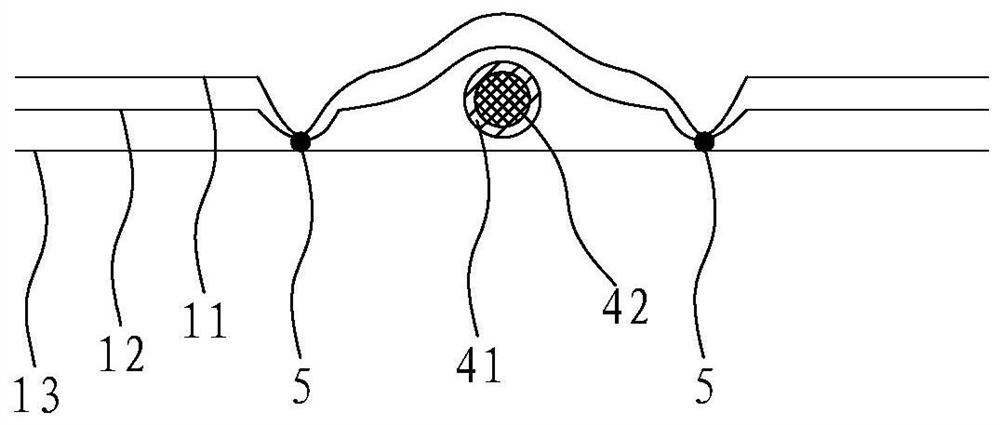

[0028] refer to figure 1 , figure 2 The present embodiment provides an ice-cold type mask with explosive beads, comprising a mask body 1, a nose bridge 2 arranged in the mask body 1, and ear straps 3 arranged on both lateral sides of the mask body 1. The mask body 1 consists of an outer layer. The non-woven fabric 11, the melt-blown non-woven fabric 12, and the inner-layer non-woven fabric 13 are stacked and formed. The mask body 1 is sandwiched between the melt-blown non-woven fabric 12 and the inner-layer non-woven fabric 13. The explosive bead particles 4 include a fragile shell 41 and an oil body 42 that coats the shell 41 . The explosive beads 4 are located in the left and right regions of the mask body 1 . The length of the lateral direction of the mask body 1 is defined as L, and the length of the longitudinal direction of the mask body ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com