A device for water level control and waste heat removal of passive spent fuel storage pool

A technology of waste heat discharge and water level control, applied in power plant safety devices, nuclear power generation, nuclear power plant auxiliary equipment, etc., can solve the problems of radioactive diffusion and accident deterioration, and achieve the effect of reducing radioactive water spillover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

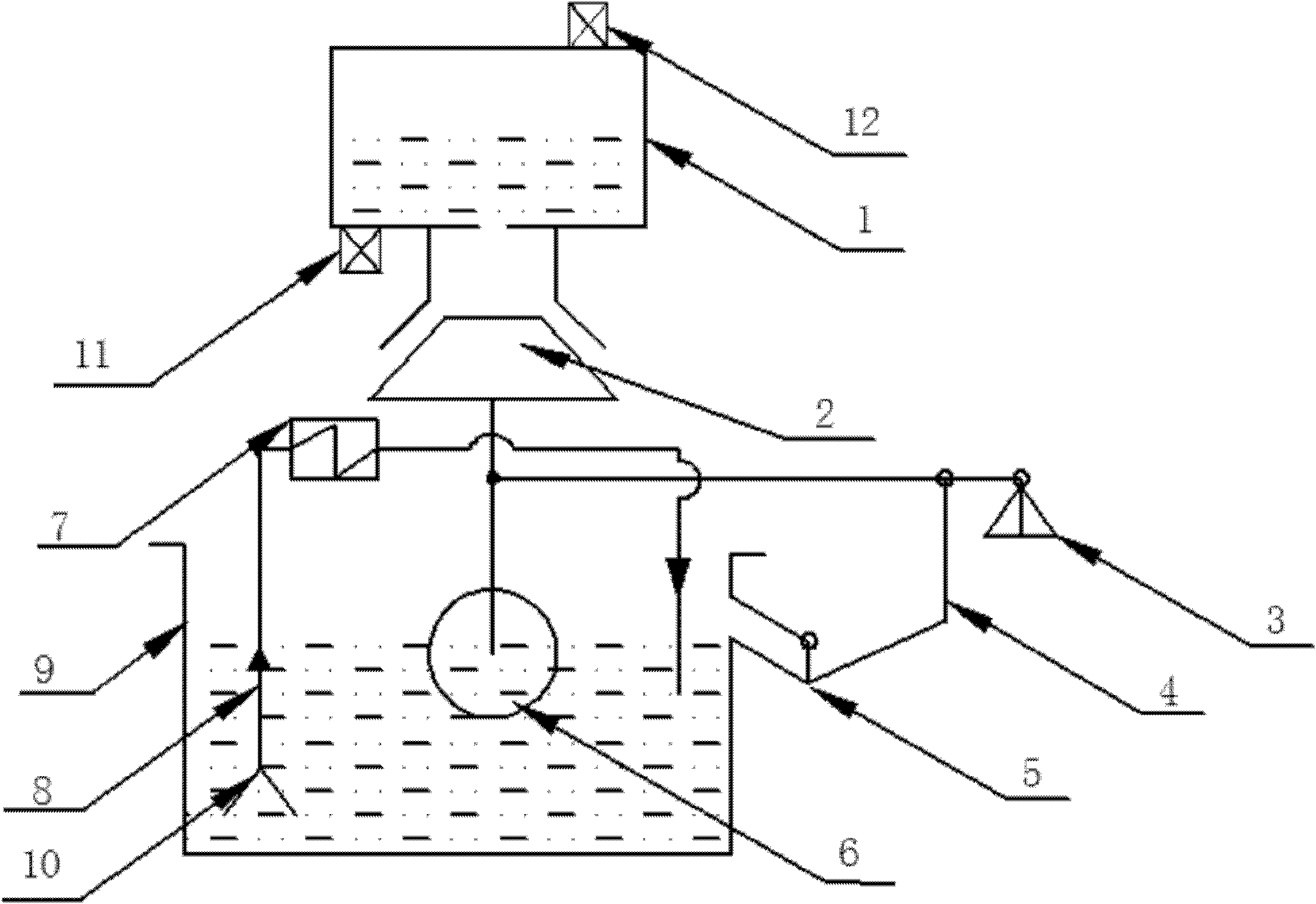

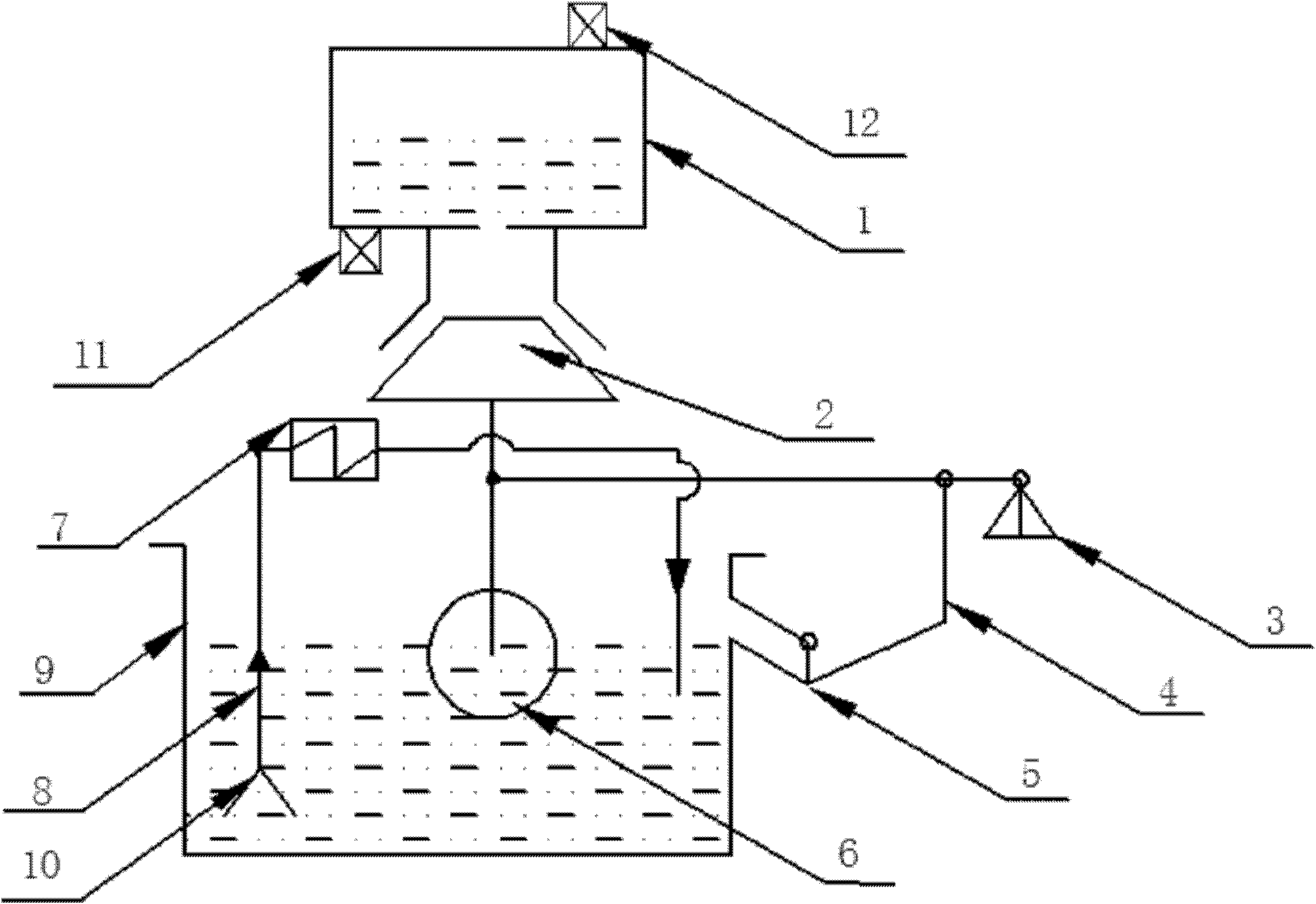

[0010] The present invention will be further described below through the accompanying drawings and specific embodiments.

[0011] A passive spent fuel storage pool water level control and waste heat discharge device, including two rows A and B, each row has a pump, a heat exchanger, an ion exchanger and a filter, and the two rows share the inlet and outlet headers , also includes a float filling and draining circuit and a natural circulation cooling circuit.

[0012] The schematic diagram of the float filling and draining circuit and the natural circulation cooling circuit in this embodiment is as follows figure 1 As shown, the float filling and draining circuit is composed of a boron-containing water pool 1, a rubber valve 2, a hinge 3, a lever 4, a one-way valve 5, a float 6, a spent fuel storage pool 9, a water filling valve 11, and an exhaust valve 12; The pool 1 is placed above the spent fuel storage pool 9, the float 6 is placed in the spent fuel storage pool 9, the rub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com