Magnetic conversion separation device

A separation device and magnetic technology, applied in the direction of magnetic separation, solid separation, measuring devices, etc., can solve the problems of high complexity and difficult operation of the position of magnets and test tubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The technical means and effects used by the present invention to achieve the purpose will be described below with reference to the accompanying drawings, and the embodiments listed in the following drawings are only for auxiliary illustrations to facilitate understanding, but the technical means of this case are not limited to the above-mentioned List the schema.

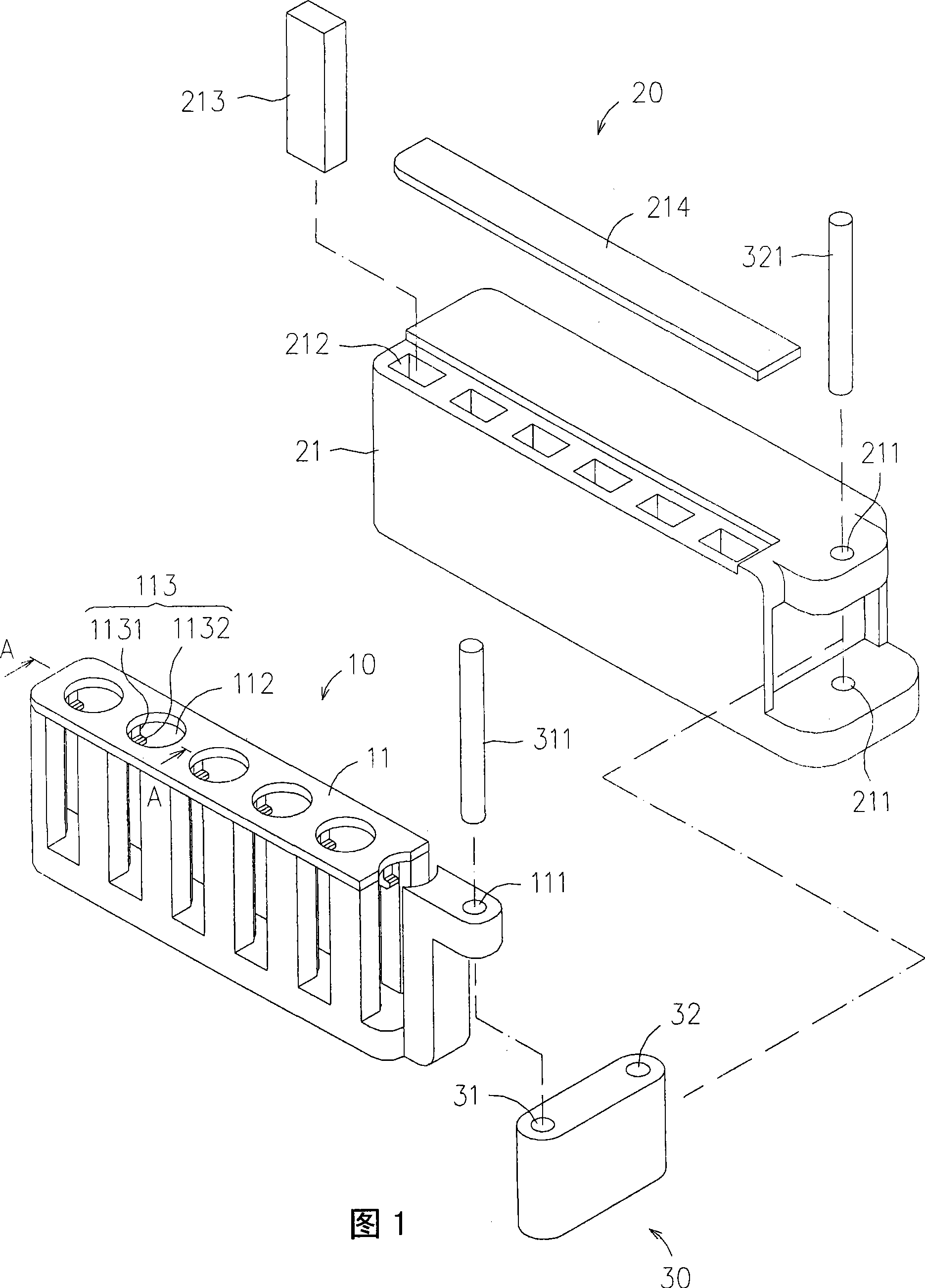

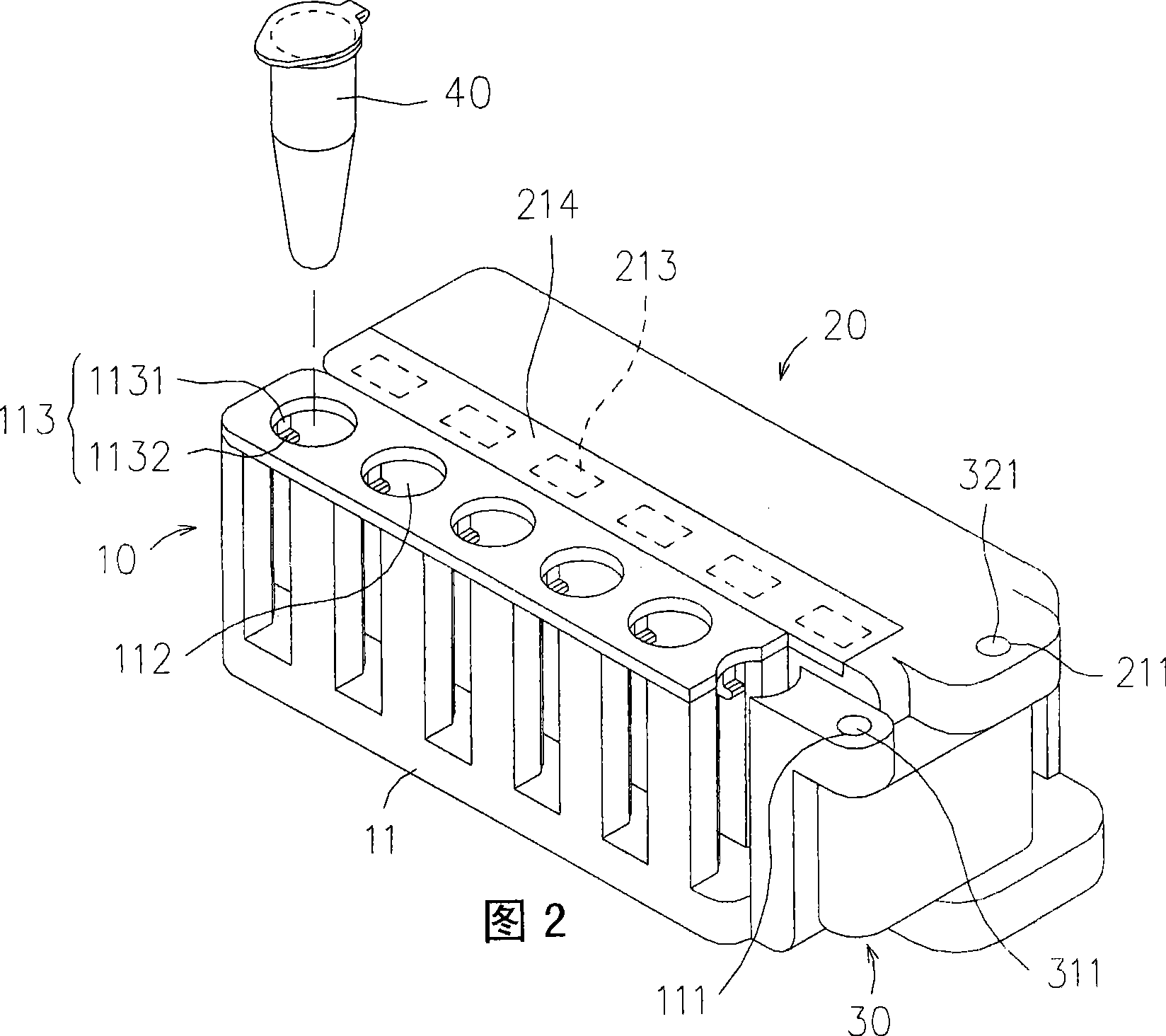

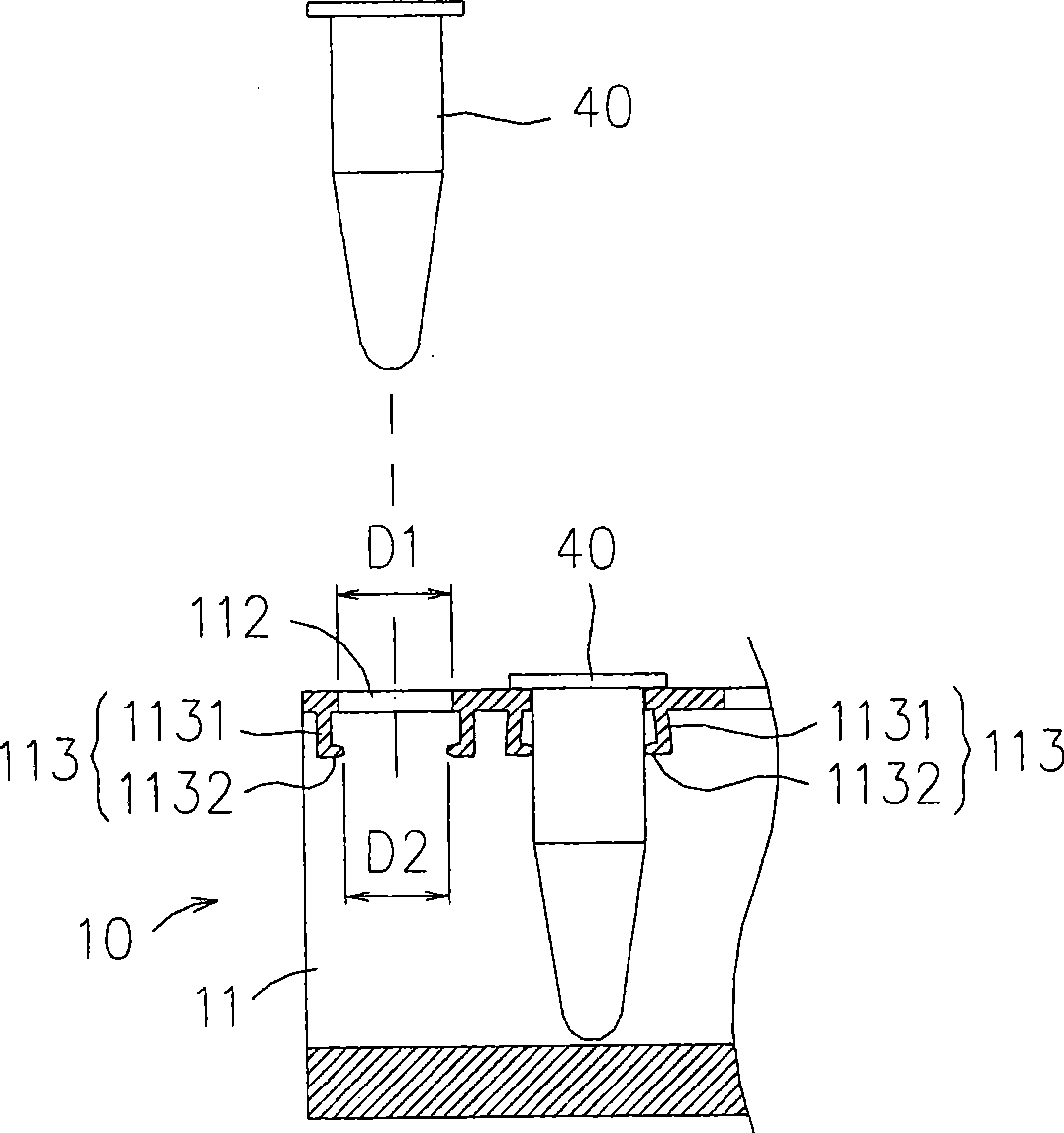

[0067] Please refer to Figure 1 to image 3 As shown, the first embodiment of the magnetic conversion separation device provided by the present invention is mainly composed of a test tube holder 10 and a magnetic member 20, and a connecting member 30 is arranged between the test tube holder 10 and the magnetic member 20. The test tube holder 10, the magnetic part 20 and the connecting part 30 are pivotally connected to each other.

[0068] The test tube holder 10 includes a body 11, one end of the body 11 has a pivot hole 111, and a plurality of slots 112 are arranged on the body 11, and the slots 112 are rad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com