Ion sputtering film-plating machine

An ion sputtering and coating machine technology, applied in the field of ion sputtering coating machine, can solve the problems of poor coating surface quality, difficult control of film thickness uniformity, small effective coating area, etc., so as to achieve film thickness uniformity control and increase Effective coating area, improving the effect of coating surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

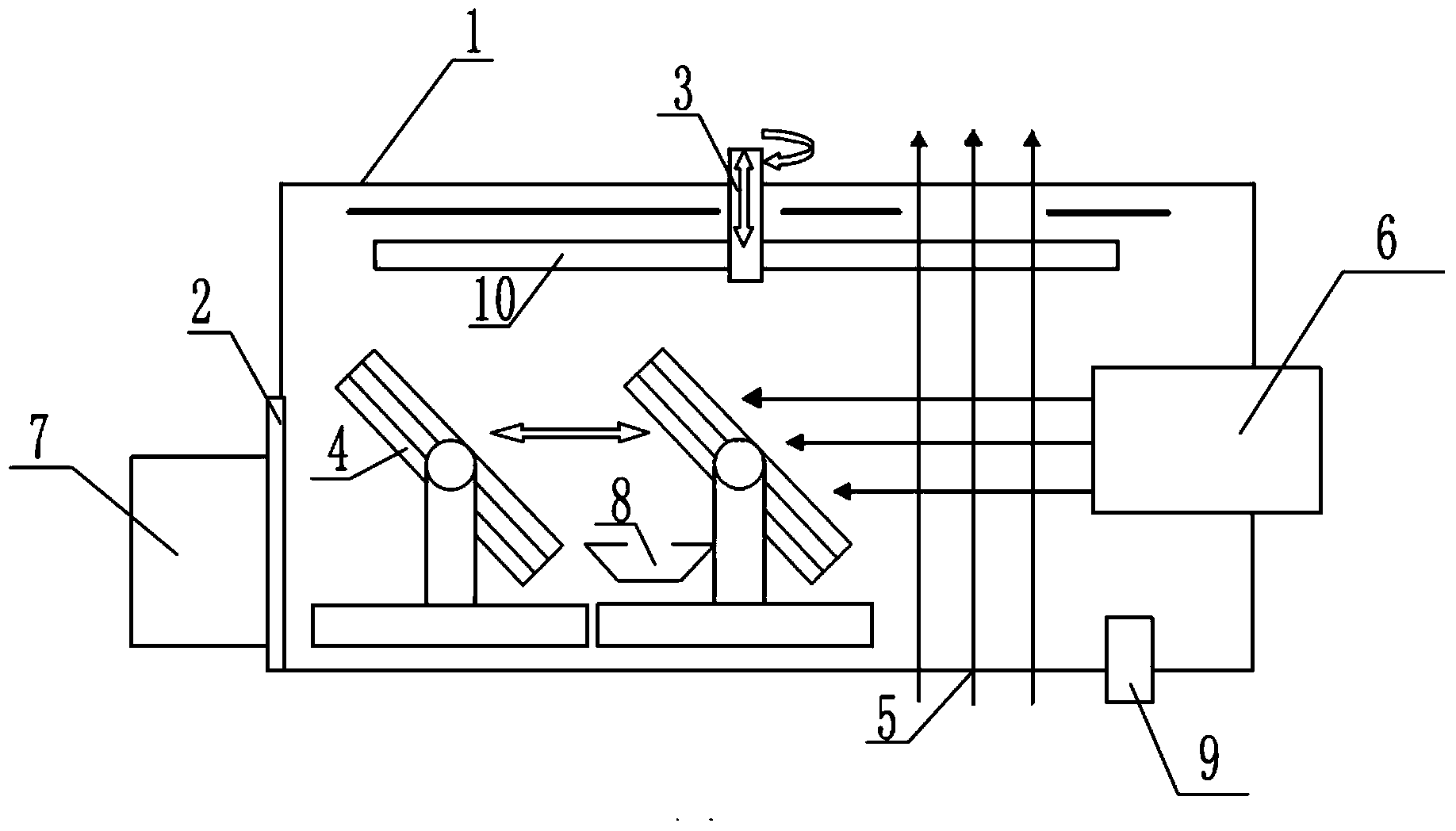

[0026] Such as figure 1 , figure 2 , Figure 5 and Figure 6 As shown, the ion sputtering coating machine in the present embodiment comprises a vacuum chamber 1, a large valve 2, an ion source 6, an observation window 5 of a multi-beam optical film thickness meter, a high vacuum pump 7, a heater 8 and ion neutralization device 9, wherein: it also includes a moving coating target 4 and a rotating substrate support 3, the moving coating target 4 is located at the bottom of the vacuum chamber 1 and is positioned under the coating fixture 10 in the rotating substrate support 3, and the moving coating target 4 can be positioned at the bottom of the vacuum chamber 1 The vacuum chamber 1 moves linearly, and the rotating substrate support 3 is set above the vacuum chamber 1 and can move up and down. On the rotation radius, the monitoring points 23 arranged on different rotation radii of the rotating substrate holder 3 can be observed in real time. The large valve 2 and the ion so...

Embodiment 2

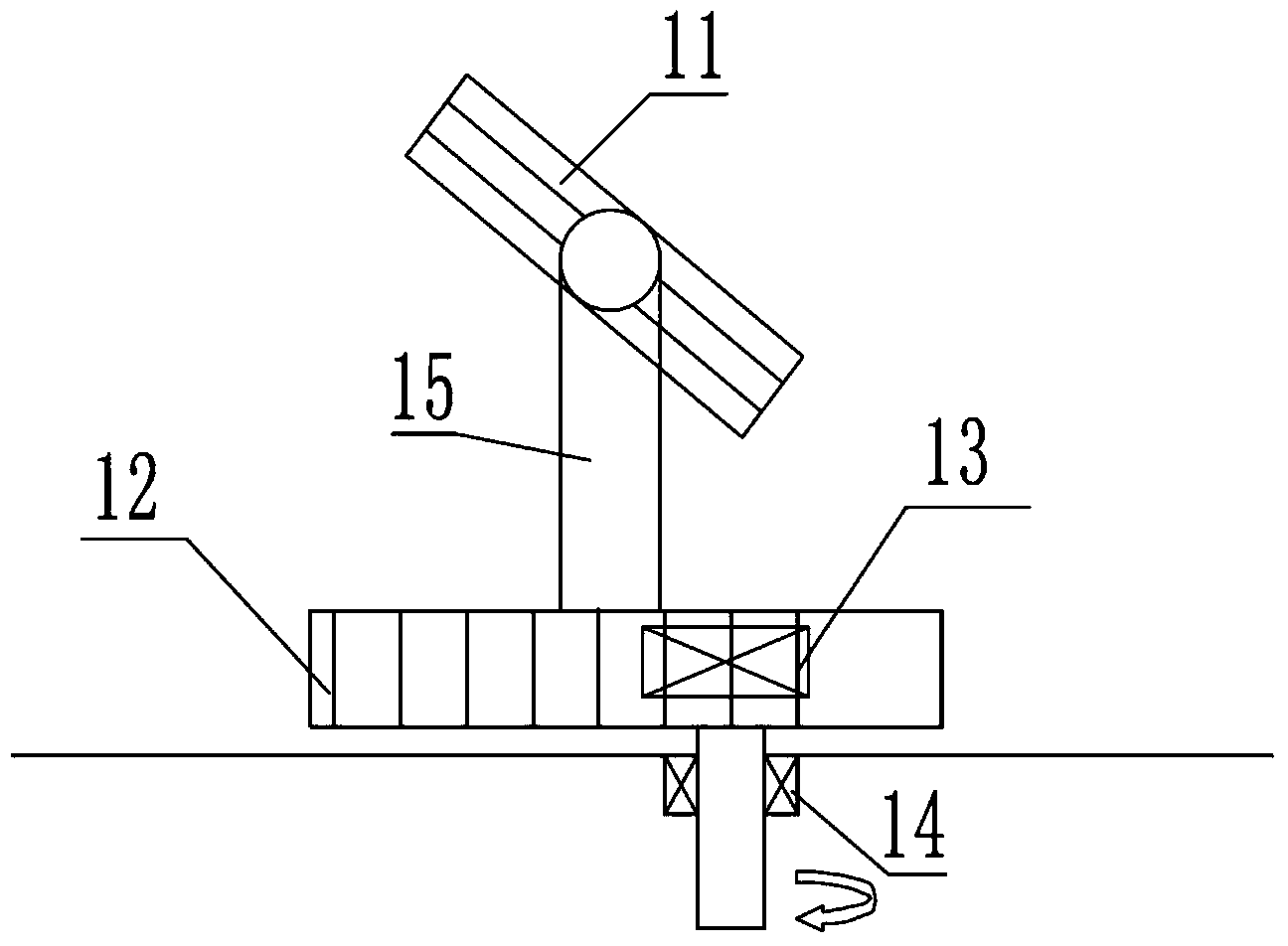

[0028] Such as figure 1 , image 3 , Figure 5 and Figure 6 As shown, in the ion sputtering coating machine in this embodiment, the linear motion mechanism is composed of a screw 16, a nut 18, a bearing 17 and a magnetic fluid rotary seal 14, and the nut 18 is arranged at the bottom of the target support 15 Leading screw 16 is located in screw nut 18 and is installed on the bottom surface of vacuum chamber 1 through bearing 17. One end of leading screw 16 is connected with magnetic fluid rotary seal 14, and magnetic fluid rotary seal 14 is located on vacuum chamber 1.

[0029] The ion sputter coating machine in this embodiment is different from the linear motion mechanism in the ion sputter coating machine in embodiment 1 except that the linear motion mechanism is the same as that of the ion sputter coating machine in embodiment 1. .

Embodiment 3

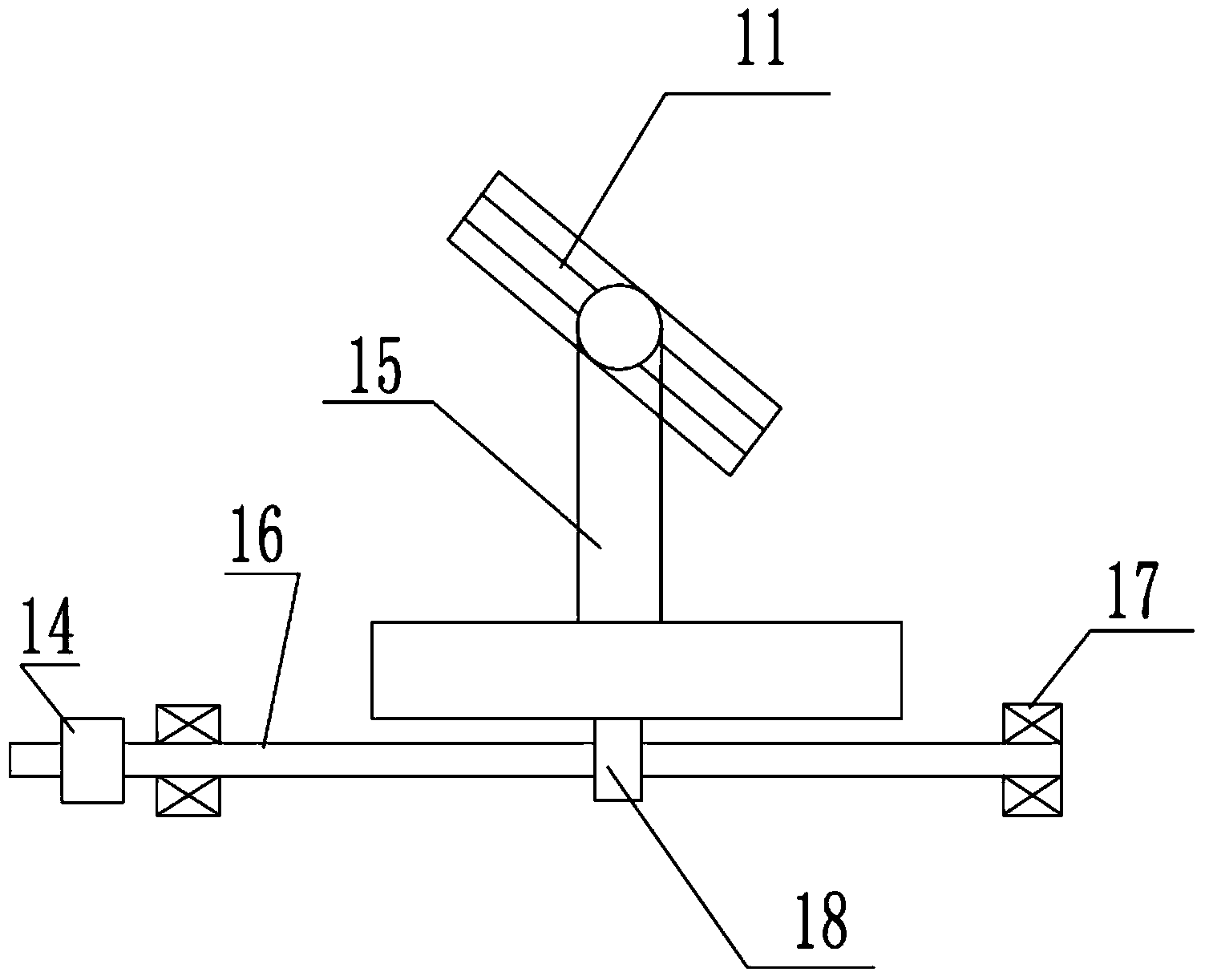

[0031] Such as figure 1 , Figure 4 , Figure 5 and Figure 6 As shown, in the ion sputtering coating machine in this embodiment, the linear motion mechanism is a linear motor 19, the primary of the linear motor 19 is arranged at the bottom of the target support 15, and the secondary of the linear motor 19 is arranged in the vacuum chamber 1 on the bottom surface.

[0032] The ion sputter coating machine in this embodiment is different from the linear motion mechanism in the ion sputter coating machine in embodiment 1 except that the linear motion mechanism is the same as that of the ion sputter coating machine in embodiment 1. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com