Injection molding based CSP packaging structure and manufacturing process

A technology of packaging structure and injection molded parts, which is applied in the direction of electrical components, semiconductor devices, circuits, etc., can solve problems such as the difficulty in ensuring the quality of chip-level packaging LEDs, the difficulty in controlling the shape and amount of fluorescent glue, and the difficulty in controlling the uniformity of the thickness of fluorescent glue. , to achieve the effect of improving light extraction efficiency and good reflection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

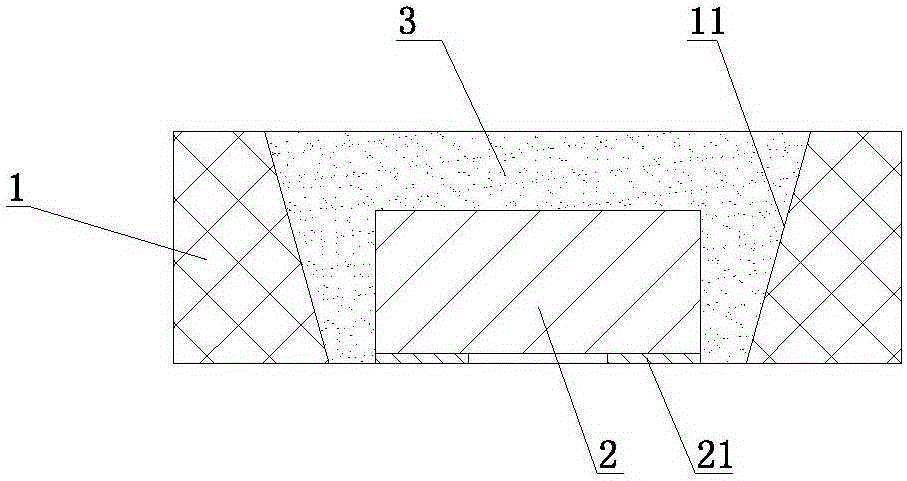

[0046] Such as figure 1 As shown, a CSP packaging structure based on injection molded parts includes an injection molded part body 1 through injection molding. One-sided light emission, the injection molded part body 1 is provided with a through hole 11, the through hole 11 is in the shape of a truncated cone with a large top and a small bottom, so that the through hole 11 can make it easier for the fluorescent glue 3 to flow downward so that the fluorescent glue can be filled to the full. The purpose of the hole; in addition, the through hole 11 of this structure helps to reflect the light of the LED chip 2, thereby achieving the purpose of improving light efficiency; a layer of reflective layer is coated on the inner wall of the through hole 11, so that the reflection of light Better performance, improve light efficiency. The through hole 11 is provided with an LED chip 2, and the LED chip 2 is provided with an electrode 21. The lower surface of the electrode 21 is flush wi...

Embodiment 2

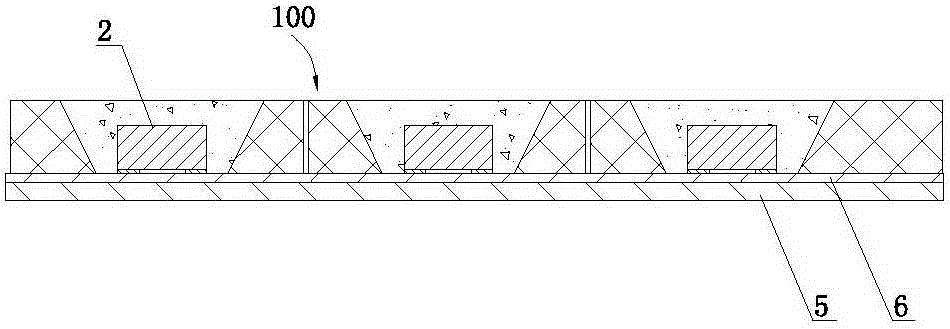

[0049] Such as figure 2 As shown, a CSP packaging structure based on injection molded parts includes an injection molded part body 1 through injection molding. One-sided light emission, the injection molded part body 1 is provided with a through hole 11, the through hole 11 is in the shape of a truncated cone with a large top and a small bottom, so that the through hole 11 can make it easier for the fluorescent glue 3 to flow downward so that the fluorescent glue can be filled to the full. The purpose of the hole; in addition, the through hole 11 of this structure helps to reflect the light of the LED chip 2, thereby achieving the purpose of improving light efficiency; a layer of reflective layer is coated on the inner wall of the through hole 11, so that the reflection of light Better performance, improve light efficiency. The through hole 11 is provided with an LED chip 2, and the LED chip 2 is provided with an electrode 21. The lower surface of the electrode 21 protrudes ...

Embodiment 3

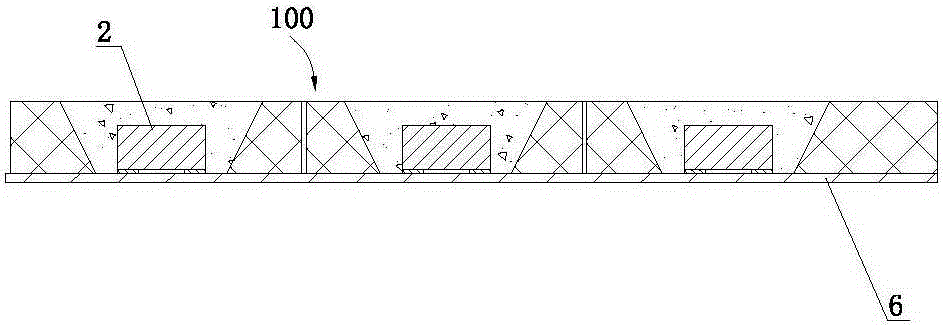

[0053] Such as image 3 As shown, the LED device based on injection molding includes a CSP packaging structure based on injection molding and a substrate 4 .

[0054] Such as figure 1 As shown, the CSP packaging structure based on injection molded parts includes the injection molded part body 1 through injection molding. To emit light, the main body 1 of the injection molded part is provided with a through hole 11. The through hole 11 is a truncated cone with a large upper part and a smaller lower part. In this way, the through hole 11 allows the fluorescent glue 3 to flow downward more easily so that the fluorescent glue can fill the through hole. Purpose; In addition, the through hole 11 of this structure helps to reflect the light of the LED chip 2, thereby achieving the purpose of improving light efficiency; a layer of reflective layer is coated on the inner wall of the through hole 11, so that the reflection performance of light is better Well, improve the light extract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com