Car rear windshield heating wire silver paste and preparation method thereof

A rear windshield and heating wire technology, applied in ohmic resistance heating, heating element materials, transparent/reflective heating devices, etc., can solve problems such as aging, achieve strong adhesion, low void rate, and good defogging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

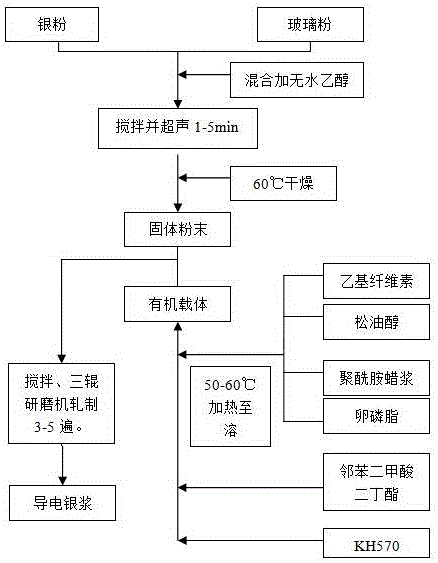

Method used

Image

Examples

Embodiment 1

[0023] The automobile rear windshield heating wire silver paste described in this embodiment is prepared from the following raw materials, and each raw material and mass percentage are:

[0024] 70% silver powder, of which the mass ratio of flake silver powder to spherical silver powder is 7:3; Na-Ca lead-free glass powder 5%; ethyl cellulose 1%; organic additive 4%; terpineol 20%.

[0025] Among them, the organic additives are plasticizers, anti-settling agents, coupling agents, and surfactants, the plasticizer is dibutyl phthalate, the anti-settling agent is polyamide wax slurry, and the coupling agent is KH-570. The surfactant is lecithin, and the mass ratio of plasticizer, anti-settling agent, coupling agent and surfactant is 2:1:2:1.

[0026] The preparation method of the automobile rear windshield heating wire silver paste described in the present embodiment specifically comprises the following steps:

[0027] (1) Heat ethyl cellulose, organic additives and organic solv...

Embodiment 2

[0031] The automobile rear windshield heating wire silver paste described in this embodiment is prepared from the following raw materials, and each raw material and mass percentage are:

[0032] Silver powder 80%, of which, the mass ratio of flake silver powder and spherical silver powder is 1:1; Na-Ca series lead-free glass powder 2%; ethyl cellulose 0.5%; organic additive 1.5%; terpineol 16%.

[0033] Among them, the organic additives are plasticizers, anti-settling agents, coupling agents, and surfactants, the plasticizer is dibutyl phthalate, the anti-settling agent is polyamide wax slurry, and the coupling agent is KH-570. The surfactant is lecithin, and the mass ratio of plasticizer, anti-settling agent, coupling agent and surfactant is 2:1:2:1.

[0034] The preparation method of the automobile rear windshield heating wire silver paste described in the present embodiment specifically comprises the following steps:

[0035] (1) Heat ethyl cellulose, organic additives, an...

Embodiment 3

[0039] The automobile rear windshield heating wire silver paste described in this embodiment is prepared from the following raw materials, and each raw material and mass percentage are:

[0040] Silver powder 60%, wherein the mass ratio of flake silver powder and spherical silver powder is 7:3; Na-Ca series lead-free glass powder 10%; ethyl cellulose 2%; organic additive 3%; terpineol 25%.

[0041] Among them, the organic additives are plasticizers, anti-settling agents, coupling agents, and surfactants, the plasticizer is dibutyl phthalate, the anti-settling agent is polyamide wax paste, and the coupling agent is KH-570. The surfactant is lecithin, and the mass ratio of plasticizer, anti-settling agent, coupling agent and surfactant is 2:1:2:1.

[0042] The preparation method of the automobile rear windshield heating wire silver paste described in the present embodiment specifically comprises the following steps:

[0043] (1) Heat ethyl cellulose, organic additives and organ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com