TR module pressing and carrying device and installation method thereof

An installation method and component technology, applied in the microwave field, can solve problems such as low product yield, inaccurate alignment, and excessive oxidation dross, and achieve the effects of reducing welding void rate, improving alignment accuracy, and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

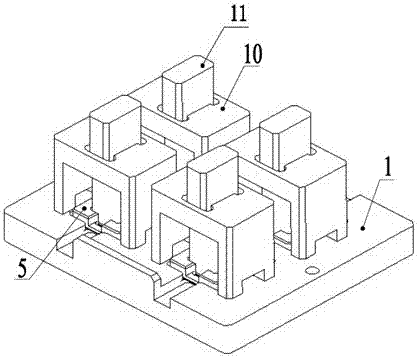

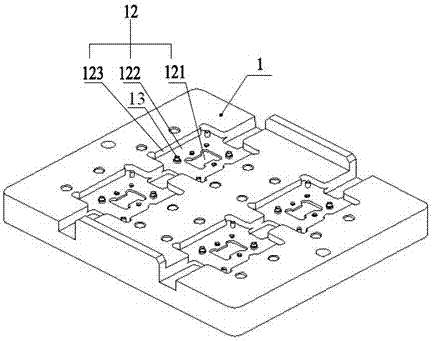

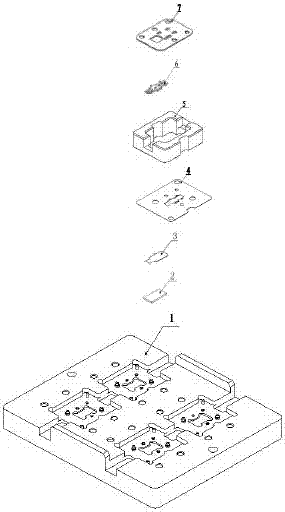

[0067] as attached figure 1 To attach Figure 17 In this embodiment shown, a TR component ballasting device and installation method include a base 1, a heat bearing plate 2, a forming solder piece 3, a positioning steel piece 4, an anti-loose pressing block 5, a TR component 6, a chip pressing piece 7, and a chip Counterweight pressing block 8, displacement counterweight 9, radio frequency microstrip counterweight guide plate 10, radio frequency microstrip counterweight 11, eutectic groove 12, substrate 121, positioning surface 122, limit step 123, screw 13 , high-density multi-chip and heat sink carrier plate vacuum eutectic welding tooling, use the tooling to ensure that 3 devices with different thicknesses (chips, row capacitors and microstrips, the structural size is less than 2mm, and the thickness is above 0.1) on the TR module 6, Positioning the device through tooling and separately pressurizing devices of different heights can be eutectic on a small heat sink carrier ...

Embodiment 2

[0077] as attached figure 1 To attach Figure 17, which shows a TR component ballasting device and installation method in this embodiment. The base 1 with several eutectics 12 is molded at one time, and each eutectic groove 12 includes a substrate 121, a positioning surface 122 and a limiting step 123, Therefore, multiple TR components 6 can be vacuum eutectically welded at the same time, greatly improving production efficiency and saving production costs. By positioning the positioning steel sheet 4 and the screw 13 of the chip pressing sheet 7 and setting the anti-loosening pressure block 5 on the positioning steel sheet 4, In order to ensure that the positioning steel sheet 4 is not deformed and shake up and down to improve the alignment accuracy of the TR assembly 6 in the positioning steel sheet 4 during eutectic welding, the chip counterweight pressing block 8 is placed on the chip pressing sheet 7 to realize chip processing. Pressurize, through the through hole of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com