Surface mounting device and method for silver solder paste connection

A surface mount and silver soldering technology, which is applied to the assembly of printed circuits with electrical components, electrical components, and printed circuit manufacturing, can solve the problems of not being able to significantly reduce the void rate of the solder paste layer, and achieve compact structure, overall appearance and firmness, well-structured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

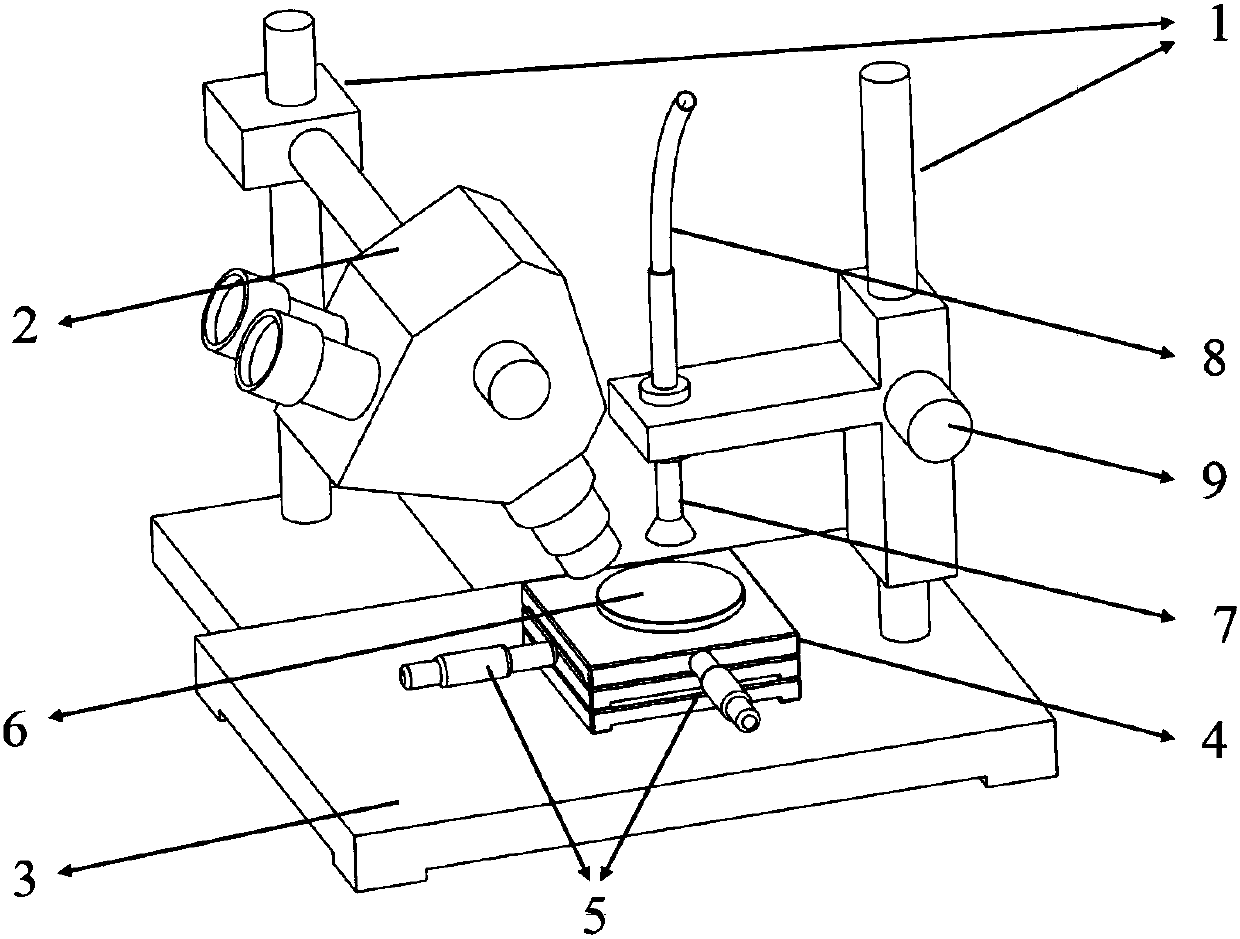

[0032] 1. Sample preparation: Print the silver solder paste evenly on the surface of the substrate by screen printing to ensure a smooth surface.

[0033] 2. Lofting: Place the substrate coated with solder paste and the chip to be mounted on the sample stage (6) respectively, and use the optical microscope (2) to ensure that the sample is within a reasonable field of view.

[0034]3. Picking: adjust the high-precision differential head (5) and combine the visual centering system (2) to make the chip move to the bottom of the vacuum nozzle (7), and adjust the displacement adjustment knob (9) to make the vacuum nozzle (7) Drop and contact the chip, turn on the vacuum pump, pick up the chip, and pick up the chip by adjusting the displacement adjustment knob (9).

[0035] 3. Positioning: adjust the high-precision differential head (5) and combine with the visual centering system (2), so that the solder paste printing position of the substrate is translated to the directly below th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com