Soldering flux which generates few concaves after welding and is used for pre-formed soldering lug

A preformed solder and flux technology, applied in welding media, welding equipment, welding/cutting media/materials, etc., can solve problems such as poor tinning and virtual welding, and achieve less residue, good wettability, and low The effect of voiding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the soldering flux of the present invention is as follows: according to the above proportions, each component is added in sequence and stirred.

[0033] The flux of the present invention can be applied on the solder preform to help and promote the soldering of the solder preform, and / or reduce the void rate after the solder preform is soldered. In specific applications, the flux should be coated on the preform On the surface of the solder preform, the mass of the solder flux accounts for 1.0%-4.0% of the total mass of the solder preform.

Embodiment 1

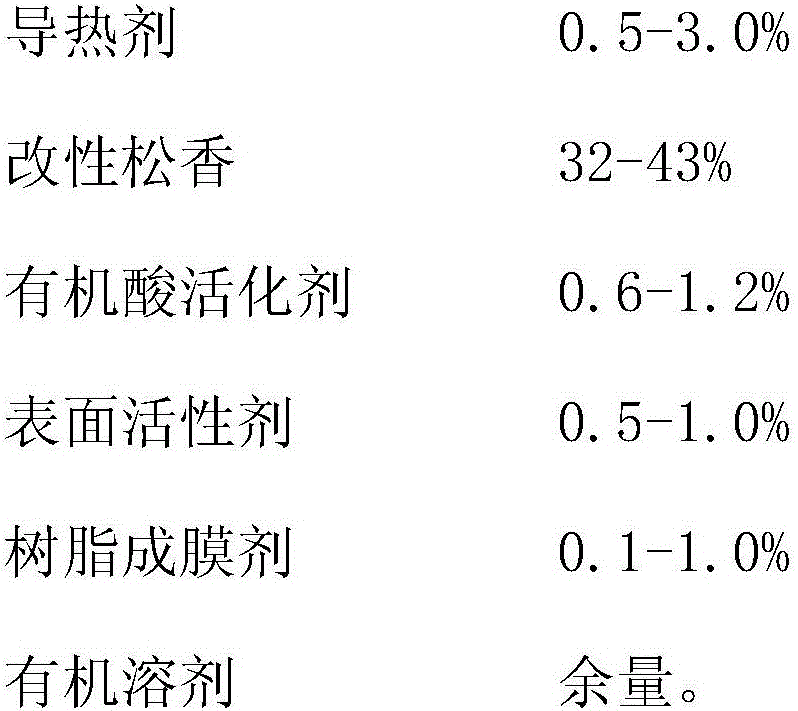

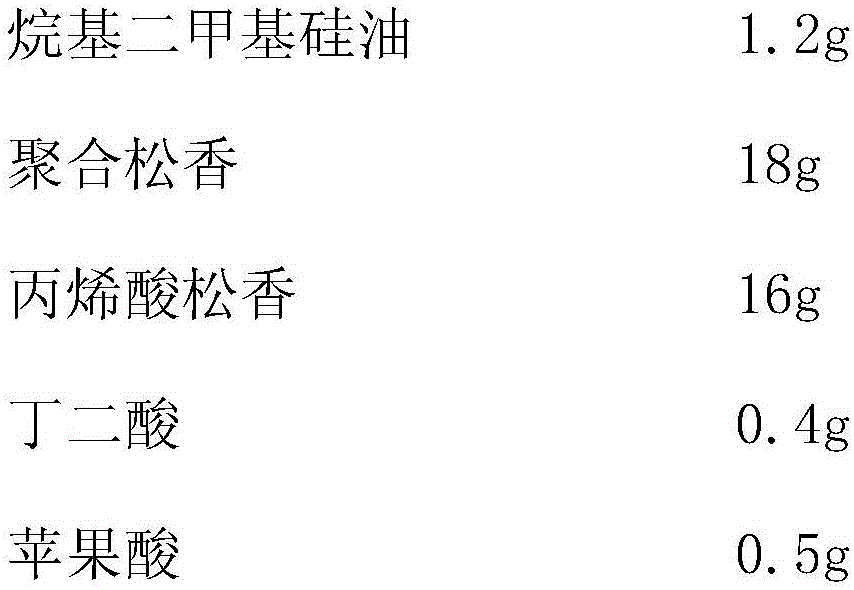

[0036] A kind of soldering flux is provided in this embodiment, is prepared from the raw material of following weight:

[0037]

[0038]

[0039] The preparation method of the above-mentioned flux is as follows:

[0040] The flux of this embodiment was prepared by adding each component in sequence according to the above weight and stirring.

[0041] Void rate test:

[0042] Spray the flux of this example evenly on the solder preform to form a layer of uniform liquid film, and then use heating and baking equipment to quickly volatilize the organic solvent in the liquid flux at a temperature of 90°C. A layer of evenly distributed solid flux is left on the surface, wherein the mass percentage of the flux accounts for 2.5% of the total mass of the solder preform. Sandwich the sprayed solder preform between two copper plates, lay it flat, and pass it through an infrared reflow oven (model: Genesis608, Made in Suneast Co., Ltd.) together, and set the maximum reflow heating t...

Embodiment 2

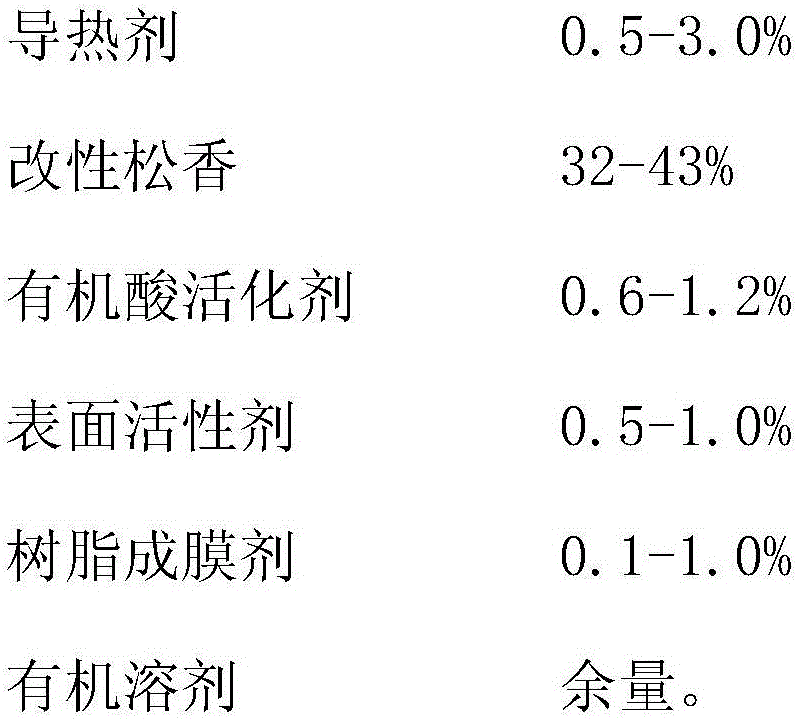

[0044] A kind of soldering flux is provided in this embodiment, is prepared from the raw material of following weight:

[0045]

[0046]

[0047] The preparation method and void rate test of the flux in this embodiment are the same as those in Example 1, and the test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com