Device and method for manufacturing enhanced type welding columns

A preparation device and enhanced technology, applied in welding equipment, welding media, manufacturing tools, etc., can solve the problem of lack of enhanced welding column technical capabilities, and achieve the effects of good consistency, easy device operation and less damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with embodiment the present invention is described in further detail:

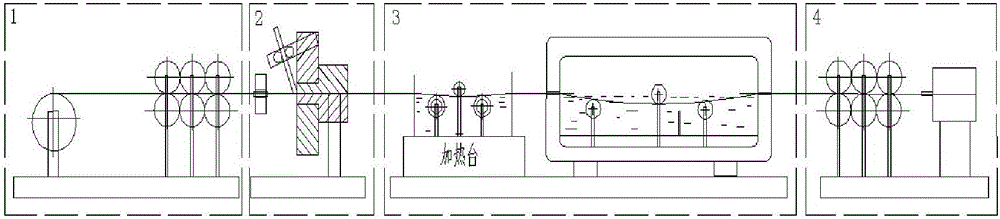

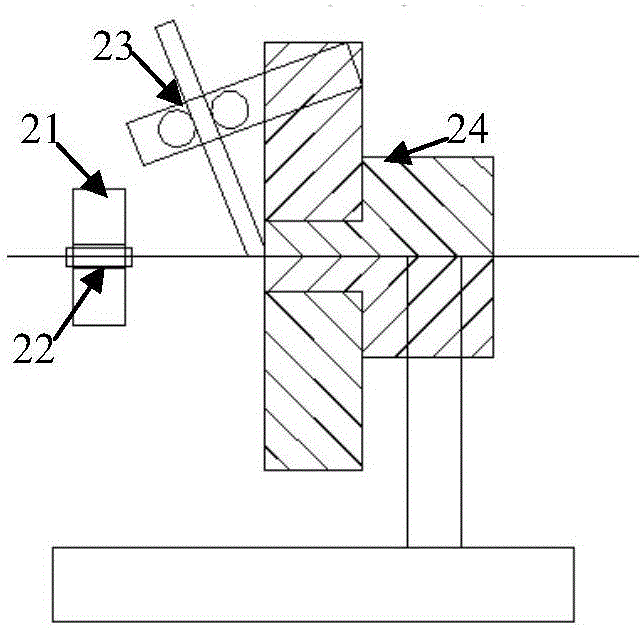

[0038] The present invention proposes an enhanced welding column preparation device, such as figure 1 As shown, it includes a welding wire supply mechanism 1 , a copper strip winding mechanism 2 , a copper strip dipping mechanism 3 and a welding wire leveling and cutting mechanism 4 .

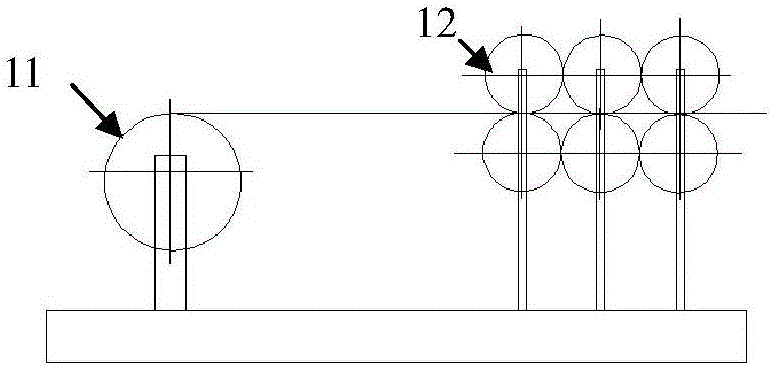

[0039] Welding wire feeding mechanism 1 is used to deliver straight welding wire to copper tape winding mechanism 2, such as figure 2 As shown, it includes a welding wire conveying structure 11 and a first welding wire leveling structure 12. The welding wire conveying structure 11 includes a rotating screw and a bracket for fixing the rotating screw. The coiled welding wire is placed on the rotating screw to adjust the welding wire feeding mechanism 1. to the proper height, ensuring that the wire moves horizontally throughout the unit. The first welding wire leveling structure 12 includes mult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com